Cover............................................................................................ 1

Table of Contents.....................................................................2

About User Manual......................................................2

Revision History.....................................................2

1.Safety Notices..................................................................... 3

2.Product Introduction........................................................ 4

2.1 Product Specifications....................................................5

2.2 Battery Specifications.....................................................5

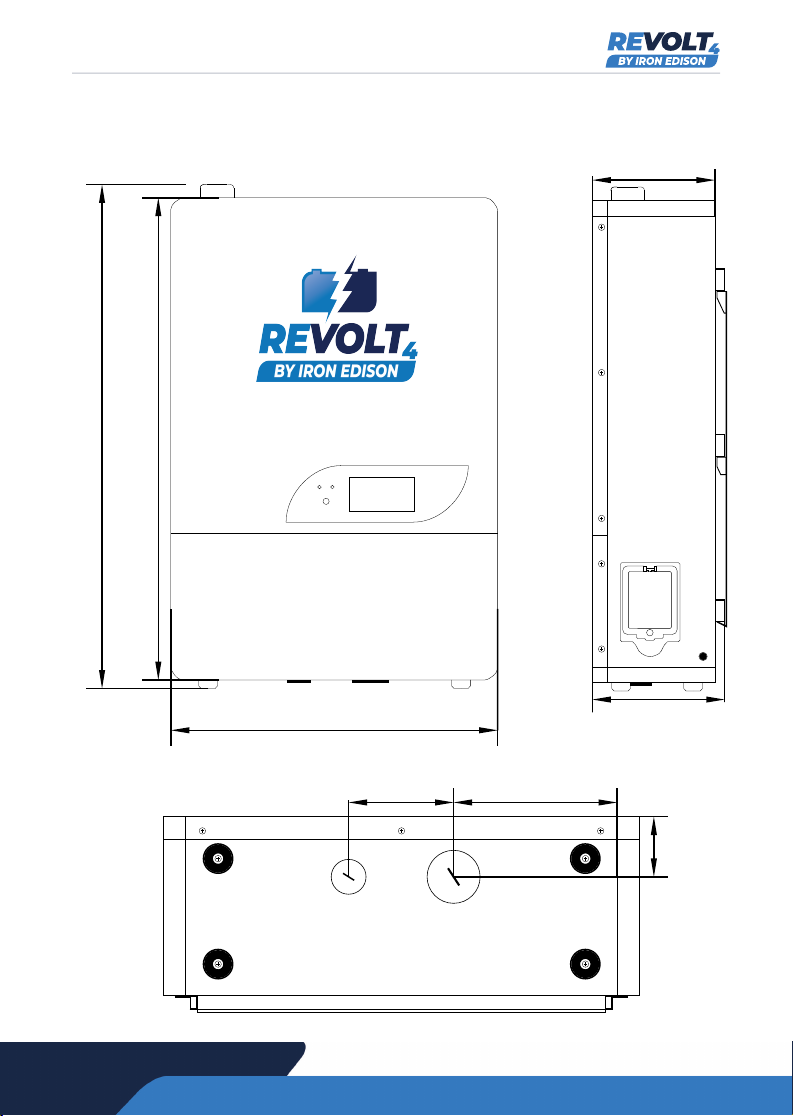

2.3 Structure Size.................................................................6

3.Storage and Transport.................................................... 7

3.1 Storage...........................................................................7

3.2 Transport........................................................................7

4.Installation Preparation.................................................. 7

4.1 Check the packing list.....................................................7

4.2 Product Picture...............................................................8

5.Battery Installation............................................................8

5.1 Installation Location....................................................... 9

5.1.1 Environment Requirement............................................9

5.1.3 Wall Mount Bracket Installation...................................10

5.1.4 Battery Pack Installation............................................. 11

5.2 Cable Connection...........................................................12

5.2.1 Connection Order.........................................................12

5.2.2 Disconnection Order....................................................13

5.2.3 Set the Address of the Dip Switches............................ 14

5.2.4 Wiring Diagram............................................................15

6.Commissioning...................................................................16

6.1 Operation........................................................................17

6.2 Battery Information Display.............................................20

7.Troubleshooting..................................................................22

About User Manual

This manual describes the installation, operation and maintenance of the

ReVolt battery system. This document will be updated periodically for

product revisions. Unless otherwise agreed, this document is to be used

only as a guide. All statements, information and recommendations in

this document do not constitute any express or implied warranty.

Revision History

12/08/2022 v.1.5

Table of Contents

2

b