300459-10-2016

9/16

Verfügbare Modelle

COD. TWW Durchfluss

[l/min] (*)

Leistung

[kW] (*) Mischventil Zirkulation Plattenanzahl Wärmetauscher Umwälzpumpe Primärseite Umwälzpumpe VFS-Sensor

[l/min]

SAP-35E 35 85 - - 20 Yonos Para PWM 25/7 - 2-40

SAP-45E 45 110 - - 30 Yonos Para PWM 25/7 - 5-100

SAP-60E 60 147 - - 50 Yonos Para PWM 25/7 - 5-100

SAP-80E 80 195 - - 50 Stratos Para 25/1-8 - 5-100

SAP-100E 100 244 - - 50 Stratos Para 25/1-12 - 5-100

SAP-35RE 35 85 - 20 Yonos Para PWM 25/7 ZRS 12/2 2-40

SAP-45RE 45 110 - 30 Yonos Para PWM 25/7 ZRS 12/2 5-100

SAP-60RE 60 147 - 50 Yonos Para PWM 25/7 ZRS 12/2 5-100

SAP-80RE 80 195 - 50 Stratos Para 25/1-8 ZRS 12/6 5-100

SAP-100RE 100 244 - 50 Stratos Para 25/1-12 ZRS 12/6 5-100

COD. TWW Durchfluss

[l/min] (*)

Leistung

[kW] (*) Mischventil Zirkulation Plattenanzahl Wärmetauscher Umwälzpumpe Primärseite Umwälzpumpe VFS-Sensor

[l/min]

SAP-30ME 30 73

- 20 Yonos Para PWM 25/7 - 2-40

SAP-40ME 40 98

- 30 Yonos Para PWM 25/7 - 2-40

SAP-50ME 50 122

- 50 Yonos Para PWM 25/7 - 5-100

SAP-70ME 70 171

- 50 Stratos Para 25/1-8 - 5-100

SAP-90ME 90 220

- 50 Stratos Para 25/1-12 - 5-100

SAP-30MRE 30 73 20 Yonos Para PWM 25/7 ZRS 12/2 2-40

SAP-40MRE 40 98 30 Yonos Para PWM 25/7 ZRS 12/2 2-40

SAP-50MRE 50 122 50 Yonos Para PWM 25/7 ZRS 12/2 5-100

SAP-70MRE 70 171 50 Stratos Para 25/1-8 ZRS 12/6 5-100

SAP-90MRE 90 220 50 Stratos Para 25/1-12 ZRS 12/6 5-100

(*) Werte gelten für folgende Bedingungen: Kesseltemperatur 60 °C; Trinkwasser 10/45 °C.

Alle Umwälzpumpen der SAP-Module mit „E“ im Produktcode erfüllen die Anforderungen der ErP-Richtlinie für das Jahr 2020. Die Option mit primärseitiger Standard-

Umwälzpumpe steht nur außerhalb Europas zur Verfügung. In diesem Fall werden Yonos Para 25/7, Stratos Para 25/1-8 und Stratos Para 25/1-12 jeweils durch RS 25/6, Top

S 25/8 und Top S 25/10 oder gleichwertige Umwälzpumpen ersetzt). Die hydraulischen Eigenschaften der verschiedenen Modelle sind in Fig. 3 (Primärseite) und Fig. 4

(Sekundärseite) dargestellt. Die Kennlinien der elektronischen und normalen Umwälzpumpen sind in Fig. 5 dargestellt.

Installationsanleitung

Vorbereitung der Anlage

Für Details zu Abmessungen, Anschlussgewinde und Achsabstände wird auf die Zeichnungen der Fig. 1 verwiesen. Sicherstellen, dass die Zuleitungen zum SAP-Modul mit

dessen Eigenschaften kompatibel sind. Das SAP-Modul muss mit 230 VAC 50 Hz versorgt werden und ist mit einem Schuko-Stecker für den direkten Netzanschluss

ausgestattet.

⚠Achtung. Das SAP-Modul muss so nah wie möglich am Speicherbehälter installiert werden. Die in diesem Anleitungsblatt angegebenen Leistungsdaten wurden

unter Verwendung einer 2 m Verbindungsleitung DN25 zwischen Primärseite des SAP-Moduls und Pufferbehälter ermittelt. Jede Vergrößerung der Länge oder

Verkleinerung des Durchmessers der Primärleitung verursacht eine Leistungsminderung des SAP-Moduls gegenüber den nachfolgenden Daten.

Wandmontage

Alle SAP-Modelle können Dank der vier Aussparungen im Rahmen problemlos an der Wand montiert werden (siehe Details A und B in Fig. 1). In diesem Fall wird die

Installation mit Dübelschrauben empfohlen (nicht mitgeliefert). Vor der Installation des SAP-Moduls die Montageposition an der Wand festlegen und die Bohrpositionen

gemäß Fig. 1 markieren. Die Löcher bohren und die Dübel einsetzen. Das SAP-Modul ansetzen und sicher mit Unterlegscheiben und Schrauben fixieren.

Anschluss der Rohrleitungen

Die Rohre auf die erforderliche Länge abschneiden. Einen sauberen und rechtwinkligen Schnitt ausführen, darauf achten, dass das Rohr nicht abgeflacht wird und alle Grate

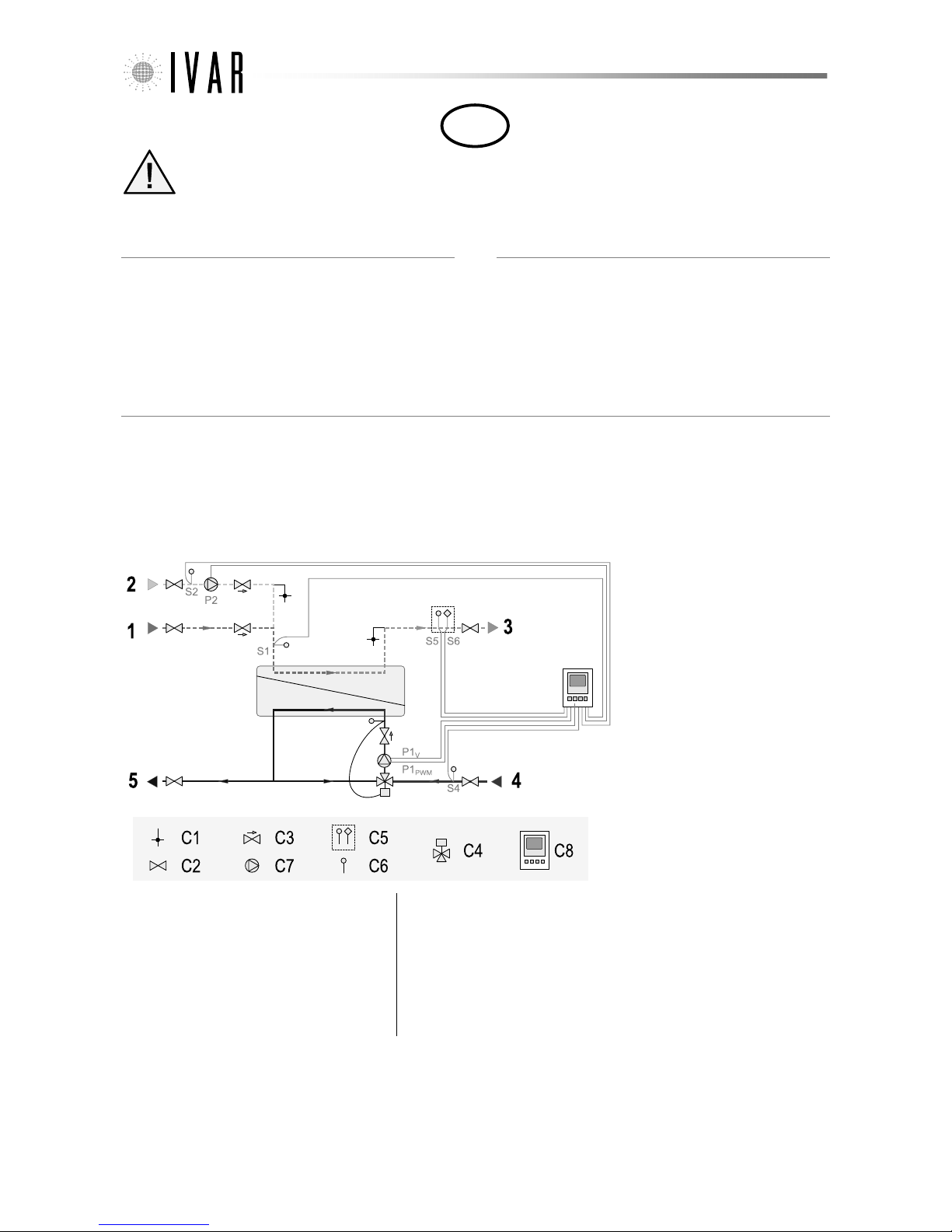

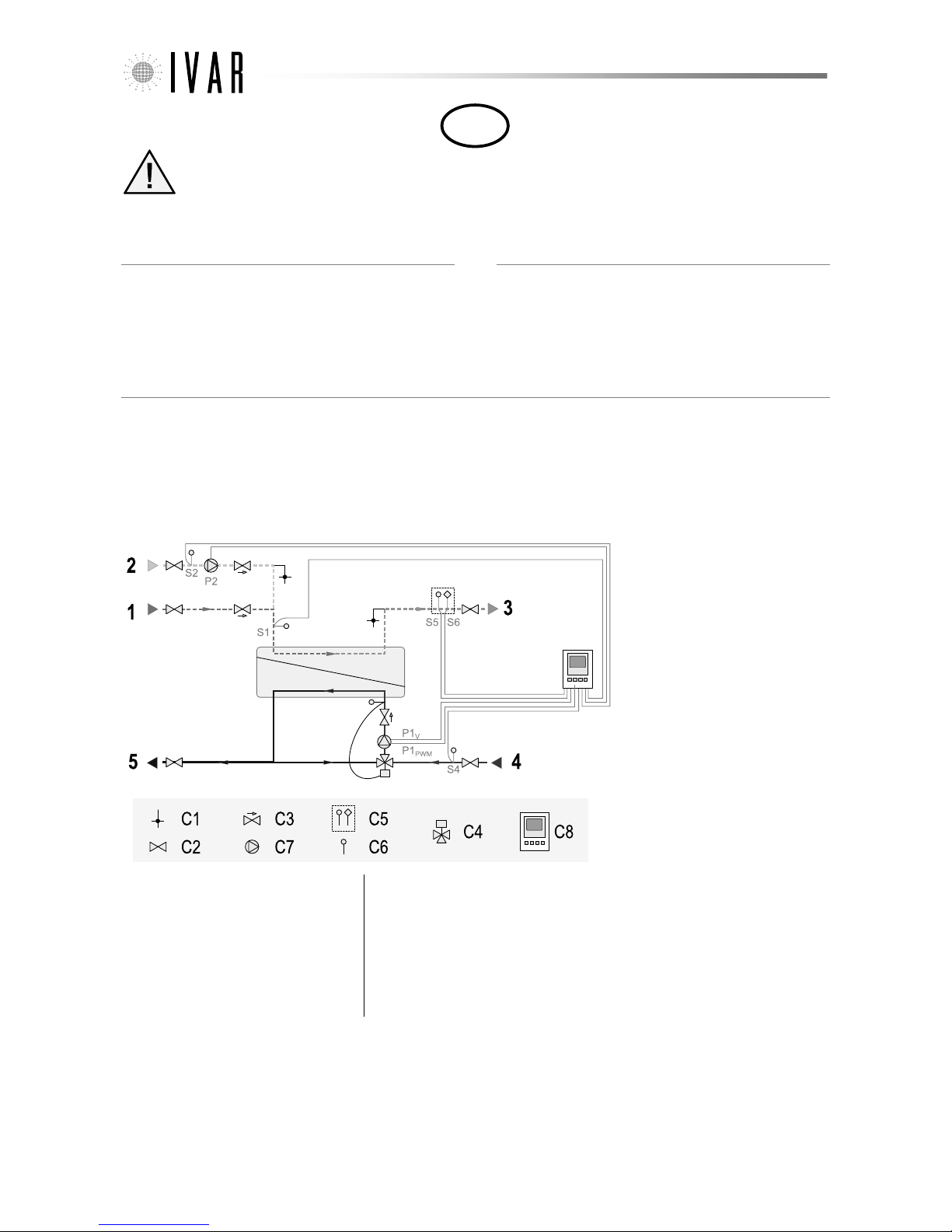

oder Unregelmäßigkeiten entfernen. Siehe Fig. 2a und Fig. 2b für die korrekte Ausführung der Anschlüsse. Die verwendeten Symbole haben folgende Bedeutung:

Vorlauf von

Speicherbehälter

(Primär)

Rücklauf zu

Speicherbehälter

(Primär)

Eintritt

Kaltwasser

(Trinkwasser)

Austritt

Warmwasser

(Trinkwasser)

Eintritt

Zirkulation

(Trinkwasser)

Die Verbindung zwischen SAP-Modul und primärseitigen Vor- und Rücklauf können mittels Quetschverschraubungen 1'' AG x DN und 1 1/4'' x DN (z. B. Verschraubungen IVAR

Art. RP 761 für Mehrschichtverbundrohr und RP 731 für PE-Rohr) ausgeführt werden, oder mit Pressfittings 1'' AG x DN und 1 1/4'' x DN (z. B. Fittings IVAR Art. MP 5608 für

Mehrschichtverbundrohr) für die Anschlüsse der Primär- und Sekundärkreise. Die Verbindung an die Zirkulationsleitung kann mittels Quetschverschraubungen 3/4'' AG x DN

(z. B. Verschraubungen IVAR Art. RP 761 für Mehrschichtverbundrohr und RP 731 für PE-Rohr) oder mit Pressfittings 3/4'' AG x DN (z. B. Fittings IVAR Art. MP 5608 für

Mehrschichtverbundrohr) ausgeführt werden. Es dürfen nur die spezifischen Fittings für den verwendeten Rohrtyp eingesetzt werden. Die Komponenten der Fittings in der

richtigen Reihenfolge montieren und das vom Hersteller angegebene Drehmoment für das verwendete Material und Rohrdurchmesser anwenden. Bei der Verwendung von

IVAR-Fittings wird daran erinnert, dass es verboten ist, die Gummiteile mit Ölen und Fetten auf Mineralölbasis zu schmieren, und empfohlen wird, nur Wasser zu verwenden.

Elektrischer Anschluss

⚠Achtung. Alle Arbeiten an elektrischen und elektronischen Komponenten der SAP-Module müssen von Fachpersonal entsprechend den geltenden gesetzlichen

Vorschriften durchgeführt werden.

Die SAP-Module werden vorverdrahtet geliefert. Die SAP-Module erfordern eine 230 VAC ±10 %, 50...60 Hz Versorgung, der Anschluss erfolgt über den vorgesehenen Schuko-

Stecker.