The JAE series was designed and developed as a result of a joint venture between IMPBA Hall

of Fame member Rod Geraghty, David Hall, Ron Zaker Jr. & Martin Truex Jr.

The main difference between this hull and all the others is the use of sharp edges on the bottom

of the sponsons and tub, as opposed to curved surfaces. This helps break any surface tension

of the water and makes for a faster boat.

This design approach has been built, developed and tested a great deal.

The 12G4 Hybrid kit is a light version of our popular JAE 12G2 kit. About 25% lighter…

This reduction in weight is substantially faster, and is still robust enough for everyday heat

racing. The JAE 12G holds several world speed records.

The Hybrid refers to a mix of all of the JAE 12G versions. Light, but not too light. Strong, but not

too heavy. Easier to build too.

In addition to a marine engine, you can use any air cooled 12, 15, 18, 20 (small block) car or

truggy engine, with excellent results.

The kit is not hard to assemble, as all of the hard stuff has been done for you.

That is no excuse to do a poor job with assembly. The better you build this boat, the better it will

run. Often the difference between an excellent building job and a poor one is a simple sanding

block.

A note about overhangs:

This boat is designed to shear water and prevent any capillary action of water. To do this the

tub, ski and sponsons have sharp edges and rear overhangs. These shear the water off and

must be left in place and not rounded in any way.

Take the time to read this entire manual, so that you are familiar with all the buildings steps and

their proper order. Take your time; make sure you understand everything before you do it and

you will be rewarded with an impressive running hull…

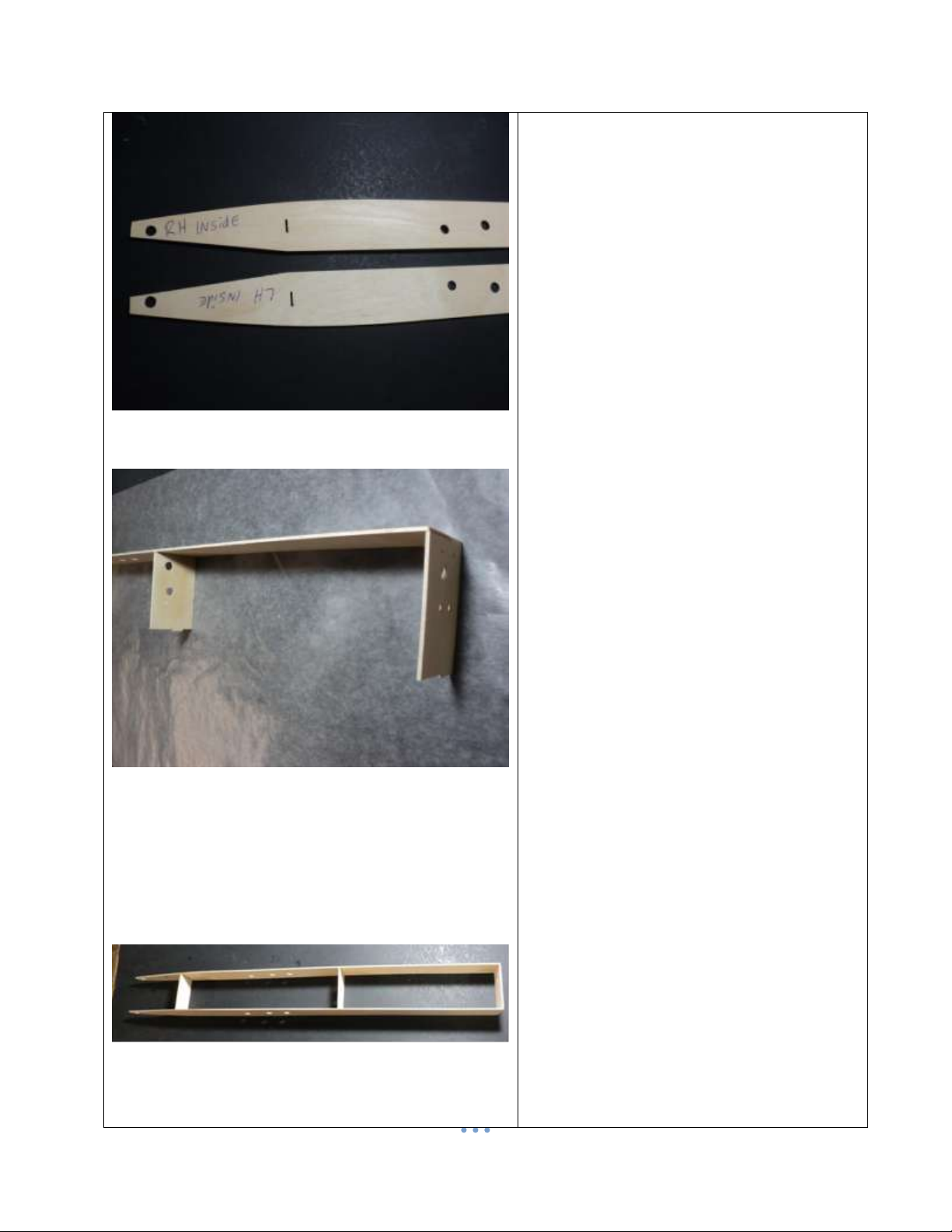

Note that the pictures in this manual may be of a different boat to better illustrate a point.

This boat is built exactly like the 12G2, so we used some of the same pictures.

This kit is not a toy. Although R/C boating is a fun and rewarding hobby, it can be dangerous

if not done with common sense and safety in mind. Just about anyone should be able to

build this kit, but it should not be operated by children without close adult supervision.

The manufacturer assumes no liability for damages or other loss in theuse of this product, as

we have no control over the construction or end use of this product.