3

ENGLISH

1�5 UPDATE OF INSTRUCTION MANUAL

This instruction manual is consistent with the technical

knowledge available at the time of introduction of the

stove for marketing.

Stovessold withallindispensable technicaldocumentation

cannot be recognised by JØTUL as non-compliant with

requirements in relation to potential modifications or the

application of new technologies in equipment introduced

onto the market at a later time.

1�6 GENERAL INFORMATION

InformatIon

During exchange of information with the stove’s

manufacturer, providethe serialnumber andidentification

data in the appropriate data sheet.

LIabILIty

Delivery of this instruction manual releases JØTUL from

any civil or penal liability in the event of damage or injury

arising as a result of failure to adhere, even partially, to

the guidelines and instructions given in this document.

JØTUL also bears no liability in the case of inappropriate

or improper use of the equipment, in the case of

unauthorised modification and/or repair, as well as in

the case of use of spare parts that are no original or not

suitable for the stove model being the subject of this

instruction manual.

ExtraordInary maIntEnancE

Maintenance activities must be performed by qualified

personnel with knowledge on how to perform works on

the stove model to which this instruction manual pertains.

obLIgatIons rELatEd to InstaLLatIon works

JØTUL is not liable for any works related to stove

installation.

• Only the fitter is responsible for checking whether

there is an inlet for combustion air and for checking its

cross-section in accordance with applicable standards,

as well as for compliance of proposed solutions

concerning stove installation.

• The stove and its installation must also fulfil all safety

standards defined by detailed regulations binding in the

country where the stove is installed.

• The fitter must have the qualifications required by the

European Union directive on renewable energy sources.

UsE

Similarly to the requirements given in this instruction

manual, use of the equipment must be compliant with all

safety standards defined by detailed regulations applicable

in the country where the equipment is installed..

1�7 MAIN REFERENCE SAFETY

STANDARDS THAT MUST BE

ADHEREDTO

A) Directive 2006/95/EC: “Harmonisation of the laws

of Member States relating to electrical equipment

designed for use within certain voltage limits”.

B) Directive2004/108/EC: “Approximationofthe laws

of the Member States relating to electromagnetic

compatibility”.

C) Directive 89/391/EEC: “Introduction of measures to

encourage improvements in the safety and health of

workers at work”.

D) Directive 89/106/EEC: “on the approximation of

laws, regulations and administrative provisions of the

Member States relating to construction products”.

E) Directive 85/374/EEC: “on the approximation of

the laws, regulations and administrative provisions of

the Member States concerning liability for defective

products”.

F) Directive 1999/5/EC: “on radio equipment and

telecommunications terminal equipment and the

mutual recognition of their conformity”.

1 INTRODUCTION

Jøtul heating equipment (hereinafter referred to as pellet

stoves) are designed and installed in accordance with

the safety regulations defined in the relevant European

directives.

This instruction manual is intended for users, fitters and

maintenance technicians of stoves. In the case of doubts

concerning the content of this instruction manual and

to obtain explanations, contact the manufacturer or

authorised seller, specifying the number of the section to

which the question pertains.

Printing, translation and duplication of this document,

in part or entirety, requires written consent from the

JØTUL company.

Technical information, graphical representations and

detailed drawings given in this instruction manual may not

be made available to third parties.

If a fitter has not fully understood the contents of this

instruction manual, they should not service the stove. In

the case of doubts, ask a technician authorised by JØTUL

for assistance in every instance.

JØTUL reserves the right to introduce technical and/or

functional changes to the stove at any time without advance

notice.

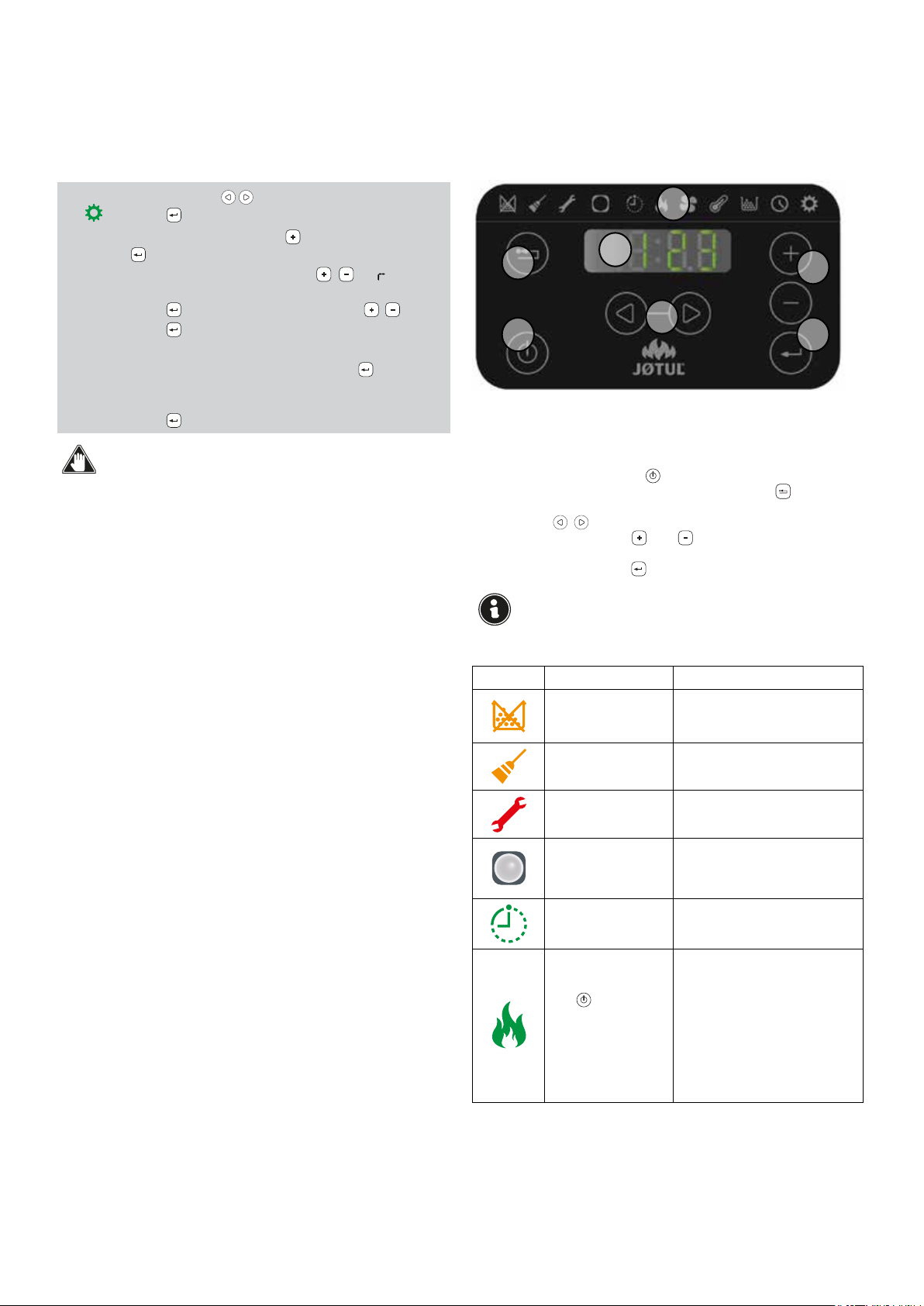

1�1 SYMBOLS

In this instruction manual, the most important guidelines,

instructions or recommendations are marked with one of

the following symbols:

Guidelines concerning proper use of the stove and

responsibilities of persons performing activities on the

stove�

Guidelines concerning safe use and operation�

1�2 USE

The JØTUL stove is intended for heating of the interior of

a house� It is technologically advanced and fired with wood

pellet in automatic work mode� Combustion is activated

only when the stove’s door is closed� It is strictly prohibited

to open the door while the stove is working�

The only method of use and configuration of the stove

permitted by the manufacturer is use in compliance with

the purpose and configurations given below� The heating

equipment may not be used in a manner that is non-

compliant with the given instructions�

1�3 PURPOSE AND CONTENT OF THE

INSTRUCTION MANUAL

The purpose of this instruction manual is to provide

the fitter with information and basic rules for proper

installation and maintenance. Precise adherence to the

instructions provided in this manual guarantees a high

level of safety and durability of the stove.

1�4 STORAGE OF THE INSTRUCTION

MANUAL

storagE and browsIng

The instruction manual must be stored with due diligence

and must be available for consultation by the user and by

specialists concerned with installation and maintenance.

The installation instruction manual is an integral part of

the stove.

dEstrUctIon or Loss

If necessary: request a new copy from your JØTUL

salesperson.

rEsaLE of stovE

In the case of resale of the stove, the user is obliged to

transfer the instruction manual to the new user.