OPERATION AND MAINTENANCE MANUAL 01-2016

3

1 TECHNICAL DESCRIPTION

1.1 PRODUCT NAME AND FEATURES

The subject of this O&MM is:

Underground full flow hydrant with single closure TYPE 8851

- With additional protection against flow in the form of ball valve;

located below poppet TYPE 8852

- With automatic water drainage activated by medium flow stoppage;

- With poppet (closure) embedded in 100% pure elastomer;

- Internal parts may be replaced without cutting off flow (TYPE 8852).

1.2 PURPOSE

Underground fire hydrants with single closure and additional flow protection are intended for fire

protection systems, for chemically neutral pure water, free of solid impurities and for industrial systems. For

use on underground installations on pipelines laid horizontally below the freezing zone.

1.3 TECHNICAL SPECIFICATION

Underground fire hydrants with single closure and additional flow protection are intended for transport

of potable water and industrial water at temperatures from +1°C to +50°C.

- Available diameters (dimensions) DN80 -DN 100[mm]

- Maximum medium flow rate: - liquid up to 4 [m/s]

- driving torque at opening start and closing end are listed below:

DN [mm]

80 100

Mmax [Nm]

80 80

- equipment control: closing direction in the standard version of hydrant:

clockwise closing sense of rotation.

The closing sense of rotation can be opposite on special order.

-connection flanges are manufactured in accordance with PN-EN 1092-2:1999

with the dimensions adequate to the relevant nominal pressure of 1.6 MPa.

-Hydrant's efficiency with nominal pressure 0.2 MPa is:

10 dm

3

/s – above ground DN80

15 dm

3

/s – above ground DN100

In accordance with PN-B-02863: 1997 "Fire water supply"

-Key for controlling valves and taps PN-63/M-74085

-Manufactured in accordance with PN-EN 14339:2009

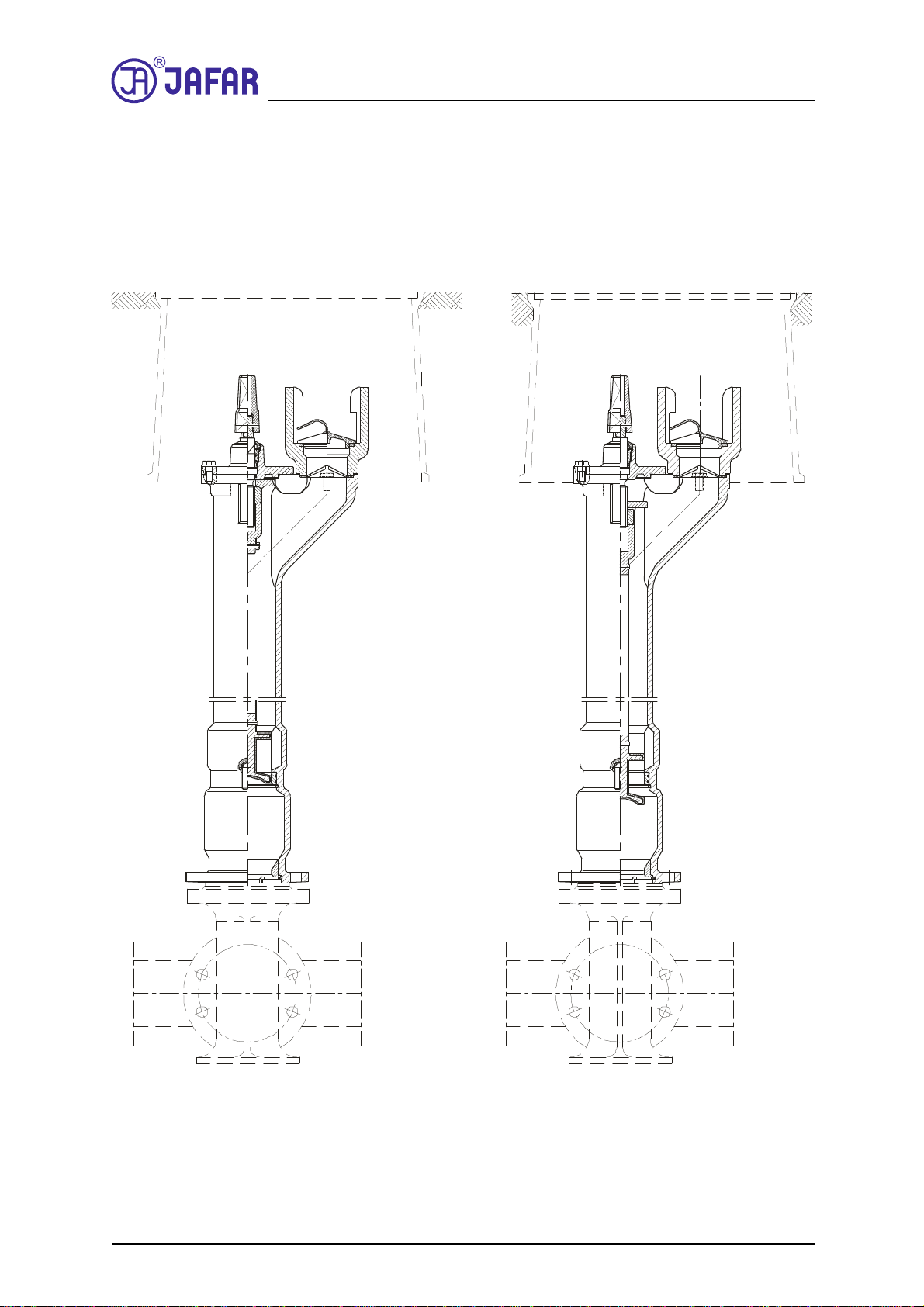

2 STRUCTURE

2.1 HYDRANT DESIGN DESCRIPTION

The underground hydrant is a column with internal structure to enable drawing water from main

pipeline. In the lower part of the hydrant there is a cast-iron valve chamber with a poppet acting as closing

element and a drainage device. The chamber housing is connected to the ball's (ball return valve) valve chamber

finished with a connection flange for installing the hydrant on the pipeline. The top body also has a driving

element on the end of bolt used for transferring rotational movement to the hydrant's poppet via distance pipe.

The hydrant's main body has a toothed socket for connecting a hydrant stand which is used for attaching fire

hoses.

The rotating stem is seated in a stopper with rubber sealing rings. Rotate the hydrant clockwise to close the

flow. Poppet moves during rotation of the stem and flow opens. The poppet's movement closes the water draining