J&E Hall V3 FUSION User manual

COMMERCIAL CONDENSING UNITS

TECHNICAL MANUAL

V3 FUSION & FUSION SCROLL

Commercial Condensing Units

Medium & Low Temperature Applications

ISSUE: 01.06.2023

V3

Issue: 01.06.2023 Page II

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

This guideline is intended for users to ensure safe installation, operation, and maintenance of J & E Hall Fusion & Fusion scroll

condensing units. This guideline is not intended to replace the system expertise available from the system manufacturers.

This equipment is a relatively complicated apparatus. During installation, operation, maintenance or service, individuals may be

exposed to certain components or conditions including, but not limited to refrigerants, materials under pressure, rotating

components, and both high and low voltage. Each of these items has the potential, if misused or handled improperly, to cause

bodily injury or death. It is the obligation and responsibility of operating/service personnel to identify and recognize these

inherent hazards, protect themselves, and proceed safely in completing their tasks. Failure to comply with any of these

requirements could result in serious damage to the equipment and the property in which it is situated, as well as severe personal

injury or death to themselves and people at the site.

This document is intended for use by owner-authorized operating/service personnel. It is expected that these individuals possess

independent training that will enable them to perform their assigned tasks properly and safely. It is essential that, prior to

performing any task on this equipment, this individual shall have read and understood this document and any referenced mate-

rials. This individual shall also be familiar with and comply with all applicable governmental standards and regulations

pertaining to the task in question.

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to specific situations:

WARNING

Warning! Risk of serious injury or

death to person!

CAUTION

Caution! Danger which can lead to

serious damages!

NOTICE

Notice! Risk of damage to equipment!

NOTICE

Disposal requirement:

Your refrigeration product is marked with this symbol. This means that electrical and electronic products shall

not be mixed with unsorted household waste. Do not try to dismantle the system yourself: the dismantling of

the refrigeration system, treatment of the refrigerant, of oil and of other parts must be done by a qualified

installer in accordance with relevant local and national legislation. Refrigeration equipment must be treated

at a specialized treatment facility for re-use, recycling and recovery.

By ensuring this product is disposed of correctly, you will help to prevent potential negative consequences for

the environment and human health. Please contact J & E Hall for more information.

Batteries must be removed from the controller if applicable and disposed of separately in accordance with

relevant local and national legislation.

Issue: 01.06.2023 Page 1

Contents

NOMENCLATURE.............................................................1

PRODUCT FEATURES .......................................................1

SPECIFICATIONS ..............................................................1

Table 1: Technical Data.............................................2

PERFORMANCE DATA ..........................................................3

APPLICATION GUIDELINES...............................................3

Table 2: Operating Limit ...........................................3

HEALTH AND SAFETY.......................................................3

GENERAL INFORMATION.......................................................3

INSTALLATION.................................................................4

UNIT LOCATION..................................................................4

Figure 1: Positioning of condensing unit ...................4

Figure 2: Air circulation for condenser ......................4

INSTALLATION CLEARANCES...................................................4

Figure 3: Installation Clearance ................................4

FIELD PIPING......................................................................4

Figure 4: Piping layout for outdoor above indoor .....5

Figure 5: Piping layout for outdoor below indoor .....5

PRESSURE TESTING .............................................................6

Table 3: Maximum working pressure........................6

EVACUATION AND CHARGING................................................6

ELECTRICAL........................................................................6

REVERSE ROTATION PROTECTION AND VOLTAGE UNBALANCE .....7

COMMISSIONING............................................................7

SCROLL COMPRESSOR OPERATION .........................................7

DUAL PRESSURE SWITCH......................................................7

Figure 6: Saginomiya DNS-D306 ...............................7

Figure 7: Adjustment on Danfoss KP17WB ...............8

Figure 8: KP17WB: high pressure reset option.........8

Table 4: Dual Pressure Switch Manufacturer Setting8

PRESSURE SWITCH SETTINGS .................................................8

Table 5: Compressor operating pressures in barg.....8

CRANKCASE HEATERS ..........................................................9

FAN SPEED CONTROLLER XGE-4C .........................................9

Figure 9: Full voltage adjustment on XGE-4C............9

Table 6: FSC settings to obtain ecodesign data.........9

FAN CONTROL SWITCH SYS-C130 .........................................9

Table 7: Fan control switch factory setting ...............9

DISCHARGE THERMOSTAT ....................................................9

VOLTAGE MONITORING DEVICE MG73BF............................10

Table 8: LED indication on front plate of MG73BF..10

VAPOR INJECTION CONTROLLER EXD-HP1............................10

Table 9: Digital input status of EXD-HP1.................10

Figure 10: Display/ keypad unit (LEDs and button

functions) ................................................................11

Table 10: Display parameters .................................11

Table 11: Parameter list for manual mode operation

................................................................................11

Table 12: EXD-HP1 error/ alarm handling...............11

OUTLINE DRAWING.......................................................12

Figure 11: Outline Drawing Series 1........................12

Figure 12: Outline Drawing Series 2........................12

Figure 13: Outline Drawing Series 3........................12

Figure 14: Outline Drawing Series 4........................12

Figure 15: Outline Drawing Series 6........................12

WIRING DIAGRAMS.......................................................13

Figure 16: JEHR-0050-B1-M-1 .................................13

Figure 17: JEHR-0067/0100/0113-B1-M-1..............13

Figure 18: JEHR-0115/0135-B1-L-1 .........................14

Figure 19: JEHR-0140/0170-B2-M-1 .......................14

Figure 20: JEHR-0140/0170-B2-M-3 .......................15

Figure 21: JEHR-0180/0210-B2-L-1 .........................15

Figure 22: JEHR-0180/0210-B2-L-3 .........................16

Figure 23: JEHS-0200/0250/0300/0350-B2-M-1.....16

Figure 24: JEHS-0200/0250/0300/0350-B2-M-3,

JEHS-0300-B2-L-3 ....................................................17

Figure 25: JEHS-0350/0400-B3-M-1........................17

Figure 26: JEHS-0350/0400/0500/0600/0680-B3-M-

3, JEHS-0400/0500/0600-B3-L-3 .............................18

Figure 27: JEHS-0800/1000-B4-M-3........................18

Figure 28: JEHS-1300-B4-M-3, JEHS-1500-B6-M-3..19

Figure 29: JEHS-0750-B4-L-3 ...................................19

Figure 30: JEHS-0951-B4-L-3 EVI .............................20

Figure 31: JEHS-1150-B4-L-3 EVI .............................20

Figure 32: JEHS-1400-B4-L-3 EVI .............................21

SERVICE & MAINTENANCE ............................................22

Table 13: Torque Tightening ...................................23

F-GAS REQUIREMENT....................................................24

Table 14: Tonnes CO

Equivalent ............................24

Table 15: Leak Inspection Frequency ......................24

Table 16: Trouble Shooting .....................................24

Figure 33: Declaration of conformity ......................27

Figure 34: Declaration of incorporation..................29

Figure 35: EU Declaration of conformity.................30

Figure 36: EU Declaration of incorpolation.............32

Issue: 01.06.2023 Page 1

Nomenclature

Product Features

J & E Hall V3 Fusion and Fusion Scroll condensing unit adopt fix speed compressor in a flexible plug and play package, for

medium and low temperature refrigeration application.

Standard features for all medium and low temperature model:

•Tecumseh reciprocating compressors

•Copeland scroll compressors

•Microchannel condenser coil in -B1 and -B2 units

•Liquid receiver with fusible plug

•Fitted liquid line drier & sight glass

•Dual LP/HP Pressure control

•Flexible pressure hoses

•External service valves

•IP rated enclosure

•Combined mains isolator with short circuit / overload protection

•Fuse protection to fan and control circuit

•Fan speed control (except -B1-M-1 units)

•Crankcase heater on compressor (except -B1-M-1 units)

•Alarm output available from high pressure switch

•Acoustic insulation to compressor compartment

Specifications

Indicator:

•Oil Type A: Uniqema Emkarate RL32CF

•Oil Type B: Polyolester Oil - (Copeland Ultra 22 CC, Copeland Ultra 32 CC, Copeland Ultra 32-3MAF, Mobil EAL Arctic

22CC, Uniqema Emkarate RL32CF)

•COP/SEPR according to Ecodesign conditions.

•n/c: not compatible with this refrigerant

•n/a: compatible with this refrigerant but no data available at Ecodesign condition or does not meet Ecodesign requirement

•a NC: Nominal Current rated at condition (-10°C Te / +32°C Ta) for MT and (-35°C Te / +32°C Ta) for LT with R448A

refrigerant.

•b MCC: Maximum Continuous Current

•cLRC: Locked Rotor Current

•d SPL @10m: Sound Pressure Level measured 10m from unit, in an anechoic room rated at (-10°C Te / +32°C Ta) for MT

and (-25°C Te / +32°C Ta) for LT. Alternative conditions may produce different results

•FLC: Full load current of fan

0140-

JEHR -

Approximate Horsepower

0140: 1.4hp

Product Type

JEHR: J & E Hall International Reciprocating

JEHS: J & E Hall International Scroll

B 2 - M - 3

Unit Generation

B: Second Generation

Unit Series

2: Series 2

Application

M: Medium Temperature

L: Low Temperature

Power Supply

1: 230V/1Ph/50Hz

3: 400V/3Ph/50Hz

Issue: 01.06.2023 Page 2

Table 1: Technical Data

Swept

Volume

Oil

Charge

NC a MCCbLRCc

Total

FLC

Liquid

Gas

Unit

(W x Dx H)

Mounting

(W x D)

(m³/h) (Litres) (Litres) (A) (A) (A) (A) (Litres) (Litres) (m³/h) (inch) (inch) (mm) (mm) (kgs) dB(A)

JEHR-0050-B1-M-1 n/c 1.59 1.77 1.66 1.66 1.67 AE4460Z-FZ1C 1.80 0.28 - 3.4 5.9 19.4 1 0.2 0.44 2.4 1250 1/4 3/8 49 28

JEHR-0067-B1-M-1 n/c 1.62 1.76 1.64 1.64 1.67 CAJ9480Z 2.64 0.48 - 3.1 6.7 24.1 1 0.2 0.44 2.4 1250 3/8 1/2 56 28

JEHR-0100-B1-M-1 n/c 1.66 1.77 1.64 1.64 1.68 CAJ9510Z 3.18 0.48 - 3.9 8.4 29.5 1 0.2 0.44 2.4 1250 3/8 1/2 57 28

JEHR-0113-B1-M-1 n/c 1.78 1.85 1.71 1.71 1.73 CAJ9513Z 4.21 0.48 - 4.9 11.3 33.5 1 0.2 0.44 2.4 1250 3/8 1/2 58 28

JEHR-0140-B2-M-1 n/c 1.74 1.93 2.09 2.09 1.92 CAJ4517Z 4.52 0.48 - 5.3 12.7 38.5 1 0.6 0.51 4.5 2700 3/8 1/2 67 32

JEHR-0140-B2-M-3 n/c 1.66 1.85 2 2 1.83 TAJ4517Z 4.52 0.48 - 2.3 4.0 18.0 1 0.6 0.51 4.5 2700 3/8 1/2 67 32

JEHR-0170-B2-M-1 n/c n/c n/c 1.73 1.73 1.65 CAJ4519Z 6.00 0.48 - 6.4 15.2 45.0 1 0.6 0.51 4.5 2700 3/8 5/8 68 33

JEHR-0170-B2-M-3 n/c n/c n/c 1.76 1.76 1.73 TAJ4519Z 6.00 0.48 - 3.1 4.8 22.0 1 0.6 0.51 4.5 2700 3/8 5/8 68 33

JEHS-0200-B2-M-1 1.92 2.18 1.92 2.02 2.02 n/c ZB15KQE-PFJ 5.90 1.30 - 7.3 18.5 58.0 1 0.6 0.51 4.5 2700 3/8 3/4 70 33

JEHS-0200-B2-M-3 2.19 2.12 1.88 2.02 2.02 n/c ZB15KQE-TFD 5.90 1.30 - 2.9 7.0 26.0 1 0.6 0.51 4.5 2700 3/8 3/4 70 33

JEHS-0250-B2-M-1 n/a 2.06 1.83 1.93 1.93 n/c ZB19KQE-PFJ 6.80 1.30 - 9.3 20.5 61.0 1 0.6 0.51 4.5 2700 3/8 3/4 72 34

JEHS-0250-B2-M-3 n/a 1.99 1.83 1.93 1.93 n/c ZB19KQE-TFD 6.80 1.30 - 4.2 7.0 32.0 1 0.6 0.51 4.5 2700 3/8 3/4 72 34

JEHS-0300-B2-M-1 n/a n/a 1.74 1.85 1.85 n/c ZB21KQE-PFJ 8.60 1.45 - 12.2 21.5 82.0 1 0.6 0.51 4.5 2700 3/8 3/4 74 36

JEHS-0300-B2-M-3 n/a 1.92 1.69 1.85 1.85 n/c ZB21KQE-TFD 8.60 1.45 - 4.4 10.3 40.0 1 0.6 0.51 4.5 2700 3/8 3/4 74 36

JEHS-0350-B2-M-1 1.86 n/a n/a (2.72) (2.72) n/c ZB26KQE-PFJ 9.90 1.50 - 14.8 25.0 97.0 1 0.6 0.51 4.5 2700 3/8 3/4 74 39

JEHS-0350-B2-M-3 2.08 n/a n/a (2.72) (2.72) n/c ZB26KQE-TFD 9.90 1.50 - 5.8 9.0 46.0 1 0.6 0.51 4.5 2700 3/8 3/4 74 39

JEHS-0350-B3-M-1 2.13 (3.43) (3.16) (3.02) (3.02) n/c ZB26KQE-PFJ 9.90 1.50 - 13.9 25.0 97.0 1 0.9 4.42 7.6 4250 1/2 3/4 112 37

JEHS-0350-B3-M-3 2.36 (3.48) (3.22) (3.02) (3.02) n/c ZB26KQE-TFD 9.90 1.50 - 5.9 9.0 46.0 1 0.9 4.42 7.6 4250 1/2 3/4 112 37

JEHS-0400-B3-M-1 n/a (3.61) (3.54) (3.13) (3.13) n/c ZB29KQE-PFJ 11.40 1.36 - 16.1 28.0 114.0 1 0.9 4.42 7.6 4250 1/2 7/8 119 37

JEHS-0400-B3-M-3 2.36 (3.79) (3.49) (3.13) (3.13) n/c ZB29KQE-TFD 11.40 1.36 - 7.3 11.0 50.0 1 0.9 4.42 7.6 4250 1/2 7/8 119 37

JEHS-0500-B3-M-3 n/a (3.21) (3.07) (2.97) (2.97) n/c ZB38KQE-TFD 14.40 2.07 - 8.2 13.5 65.5 1 0.9 4.42 7.6 4250 1/2 7/8 123 38

JEHS-0600-B3-M-3 n/a (3.19) (3.12) (3.22) (3.22) n/c ZB45KQE-TFD 17.10 1.89 - 8.7 14.2 74.0 1 0.9 6.89 7.6 4100 1/2 1 1/8 125 40

JEHS-0680-B3-M-3 n/a (2.96) n/a (2.96) (2.96) n/c ZB48KQE-TFD 18.80 1.80 - 11.4 19.1 101.0 1 0.9 6.89 7.6 4100 1/2 1 1/8 126 40

JEHS-0800-B4-M-3 (3.10) (3.12) (2.95) (2.88) (2.88) n/c ZB57KCE-TFD 21.40 1.89 - 9.6 21.3 102.0 2 1.8 8.73 13.6 8500 3/4 1 1/8 204 43

JEHS-1000-B4-M-3 (3.37) n/a n/a (2.83) (2.83) n/c ZB76KQE-TFD 29.10 3.20 - 14.4 28.0 118.0 2 1.8 8.73 13.6 8500 3/4 1 3/8 226 43

JEHS-1300-B4-M-3 (3.09) n/a n/a (2.97) (2.97) n/c ZB95K5E-TFD 36.40 3.37 0.6 20.2 34.0 140.0 2 1.8 12.84 13.6 8200 3/4 1 3/8 238 46

JEHS-1500-B6-M-3 6 (2.96) n/a n/a (2.94) (2.94) n/c ZB114K5E-TFD 43.40 3.37 0.6 24.0 38.0 174.0 2 3.4 19.00 18.0 11340 3/4 1 3/8 1735 x 854 x 1727 1240 x 808 332 48

JEHR-0115-B1-L-1 n/c n/c n/c n/a n/a 1.05 CAJ2446Z 4.55 0.48 - 2.8 8.2 30.0 1 0.2 0.44 2.4 1250 3/8 1/2 59 27

JEHR-0135-B1-L-1 n/c n/c n/c n/a n/a 0.98 CAJ2464Z 6.00 0.48 - 4.6 10.0 40.0 1 0.2 0.44 2.4 1250 3/8 1/2 61 27

JEHR-0180-B2-L-1 n/c n/c n/c 0.96 0.96 1.03 FH2480Z-XC3A 9.45 1.14 0.5 6.1 12.0 65.0 1 0.6 0.51 4.5 2700 3/8 5/8 81 35

JEHR-0180-B2-L-3 n/c n/c n/c 1.00 1.00 1.07 FH2480Z-XG1A 9.45 1.14 0.5 2.5 6.4 31.0 1 0.6 0.51 4.5 2700 3/8 5/8 80 35

JEHR-0210-B2-L-1 n/c n/c n/c 0.99 0.99 0.99 FH2511Z-XC3A 11.83 1.14 0.5 6.7 24.0 71.0 1 0.6 0.51 4.5 2700 3/8 5/8 83 38

JEHR-0210-B2-L-3 n/c n/c n/c 1.00 1.00 1.05 FH2511Z-XG1A 11.83 1.14 0.5 3.4 8.3 60.0 1 0.6 0.51 4.5 2700 3/8 5/8 81 38

JEHS-0300-B2-L-3 n/c n/a n/a 0.97 0.97 n/c ZF09KQE-TFD 8.00 1.50 0.5 3.8 6.5 40.0 1 0.6 0.51 4.5 2700 3/8 3/4 78 33

JEHS-0400-B3-L-3 n/c (1.67) (1.65) (1.67) (1.67) n/c ZF13KQE-TFD 11.80 1.90 0.6 4.9 10.0 51.5 1 0.9 4.42 7.6 4250 1/2 7/8 132 37

JEHS-0500-B3-L-3 n/c (1.67) (1.64) n/a n/a n/c ZF15KQE-TFD 14.50 1.90 0.6 6.7 12.0 64.0 1 0.9 4.42 7.6 4250 1/2 7/8 132 39

JEHS-0600-B3-L-3 n/c (1.64) n/a (1.64) (1.64) n/c ZF18KQE-TFD 17.10 1.90 0.6 7.6 12.5 74.0 1 0.9 4.42 7.6 4250 1/2 7/8 133 41

JEHS-0750-B4-L-3 n/c n/a n/a (1.64) (1.64) n/c ZF25K5E-TFD 21.40 1.90 0.6 6.9 16.6 102.0 2 1.2 4.14 13.6 5750 1/2 1 1/8 203 41

JEHS-0951-B4-L-3 EVI n/c (1.65) (1.74) (1.68) (1.68) n/c ZFI26KQE-TFD 17.10 1.90 0.6 7.3 13.0 74.0 2 1.2 8.73 13.6 5870 1/2 7/8 200 37

JEHS-1150-B4-L-3 EVI n/c (1.68) (1.78) (1.71) (1.71) n/c ZFI36KQE-TFD 21.40 1.90 0.6 8.9 16.6 102.0 2 1.8 8.73 13.6 8500 1/2 1 1/8 211 42

JEHS-1400-B4-L-3 EVI n/c (1.89) n/a (1.67) (1.67) n/c ZF34K5E-TFD 29.10 3.37 0.6 13.7 25.0 100.0 2 1.8 12.84 13.6 8200 1/2 1 3/8 235 44

Unit Model

545 x 400

876 x 430 x 606

940 x 560

1348 x 612 x 1727

B

Low Temperature

4

B

1348 x 612 x 1727

940 x 560

3

1353 x 575 x 872

945 x 500

1

876 x 430 x 606

545 x 400

Airflow

Fan

Compressor

1101 x 444 x 662

703 x 408

Series

COP/ (SEPR)

Compressor

Medium Temperature

4

3

1

R449A

R134a

R407A

R407F

R448A

2

App.

SPL @

10md

Type

R452A

Connections

Oil

Type

Oil Sep.

Charge

1101 x 444 x 662

Unit Dry

Weight

Dimensions

No.

Electrical Data

Coil

Volume

Liquid

Receiver

Volume

A

2

703 x 408

A

1353 x 575 x 872

945 x 500

Issue: 01.06.2023 Page 3

Performance Data

Scan below QR code to access

https://commercial.jehall.co.uk/ to view

performance data, eco design sheet, technical

manual.

Application Guidelines

It should ensure that the refrigeration system

which adopts this condensing unit, wherever

possible to integrate pump down features.

This is to avoid liquid compression which

could damage the compressor.

Ensure that new compressors are not

subjected to liquid abuse. Turn the crankcase

heater on 12 hours before starting the

compressor to avoid oil dilution and bearing

malfunction.

Table 2: Operating Limit

Operating Limits

Recommendation

Maximum discharge

gas temperature

Fusion: 1200C

Fusion scroll: 1300C

Low pressure side

Minimum 0.5barg; Maximum

19barg

High pressure side

Maximum 28barg

Evaporator outlet

superheat

Above 6K (to avoid liquid flood

back)

Suction gas

superheat at

compressor inlet

Not more than 20K

Voltage supply

1phase: Min: 207V, Max: 253V

3phase: Min: 360V, Max: 440V

Phase asymmetry

+/- 2%

Frequency

50Hz +/- 1%

Outdoor ambient

Min: -200C, Max: 430C (except -B1-

M-3, where head pressure control is

recommended to be integrated for

ambient below 100C to avoid

erratic expansion valve operation)

Maximum pipe run

Fusion: 25m

Fusion scroll: 50m

Suction line shall be insulated to avoid:

•High superheat during high ambient condition can

create high discharge temperature.

•Too low superheat during low ambient condition that

can condense refrigerant inside suction line.

Health and Safety

Only qualified personnel, who are familiar

with refrigeration systems and components

including all controls, should perform the

installation and start-up of the system. To

avoid potential injury, use care when working around

coil surfaces or sharp edges of metal cabinets. All piping

and electrical wiring should be installed in accordance

with all applicable standards and local by-laws.

General information

Before Installation

•Ensure the units received are the correct models for the

intended application.

•Ensure the refrigerant, voltage and maximum working

pressure are all suitable for the proposed application.

•Check there is no damage to the units. Any damage

should be reported to the supplier immediately.

•Check that the proposed equipment locations are

suitable and provide adequate support for the weight

of the units.

Offloading and Lifting

•Whenever a condensing unit is lifted, it should be from

the base and, where possible, all packing and

protection is kept in position.

•If lifting equipment is required, ensure that it is suitable,

certificated, and that the operators are qualified to

use it.

•When using a fork-lift or pallet truck to lift the unit, the

two support points should be sufficiently apart to give

stability when lifting and suitably placed to distribute

the load on the forks.

•If slings are used, care should be taken to ensure that

the slings do not crush the casework or coil.

•When lifting by crane, use spreader bars to prevent

compressing the top of the equipment.

•Do not drop the unit. Should this inadvertently happen,

it should be immediately unpacked and inspected for

damage.

•Use the appropriate spreader bars/lifting sling with

the holes and lugs provided.

During Installation and subsequent maintenance

•Installation and maintenance are to be performed only

by qualified personnel who are familiar with local

codes and regulations and experienced with this type

of equipment.

•Safe working methods are identified, and operators

should/must have suitable Personal Protective

Equipment (PPE).

•Ensure the working area has adequate ventilation

during brazing procedures.

•The units contain moving machinery and electrical

power hazards, which may cause severe injury or

death. Disconnect and shut off power before

installation or service of the equipment.

•Refrigerant release into the atmosphere is illegal.

Proper evacuation, recovery, handling, and leak testing

procedures must be observed all the time.

•Units must be grounded to the screw terminal labelled

•No maintenance work should be attempted prior to

disconnecting the electrical supply.

•The electrical covers and fan guards must remain fitted

all the time.

•Use of the units outside of the design conditions and the

application for which the units were intended may be

Issue: 01.06.2023 Page 4

unsafe and be detrimental to the units, regardless of

short or long-term operation.

•The units are not designed to withstand loads or stress

from other equipment or personnel. Such extraneous

loads or stress may cause failure/leak/injury.

•The units are not designed to operate with any

restrictions such as heavy snowfall around them.

Additional measures (such as shielding of the units) shall

be implemented as required.

•The installer must fix the unit securely on installation

using the M8 bolt holes in the unit feet to prevent

instability from accidental contact or from exposure to

the elements (e.g.: wind).

•When the compressor operates under stabilized

conditions, the oil level must be visible in the sight glass.

Foam filling the oil sight glass indicates presence of

large concentration of liquid to the compressor.

•No additional oil is required for installation with good

oil returns, line runs up to 20m. Additional oil might be

required if lines exceeded 20m, with minimum oil level

must not lower than ¼ of sight glass (not applicable to

compressor without sight glass). Top-up the oil while

compressor is idle, via suction schrader connector with a

suitable pump.

•Ensure correct rotation of scroll compressor. If there is

no compression, shut off the incoming power supply

and swap connection of any two of the three incoming

phases at the condensing unit’s motor rated circuit

breaker.

Installation

Unit location

•To achieve maximum cooling capacity, the installation

location for the condensing unit should be carefully

selected.

•Install the condensing unit in such a way so that hot air

ejected by the condensing unit cannot be drawn in

again (short circuit of hot discharge air). Allow

sufficient space for maintenance around the unit.

Figure 1: Positioning of condensing unit

•Ensure that there is no obstruction to air flow into or out

of the unit. Remove obstacles which block air intake or

discharge.

Figure 2: Air circulation for condenser

•The location must be well ventilated, so the unit can

draw in and distribute plenty of air thus lowering the

condensing temperature.

•To optimize the unit running conditions, the condenser

coil must be cleaned at regular intervals.

•The unit must be level in all directions.

•It is recommended to install the unit on rubber grommet

or vibration dampers.

•Wall mounting on brackets is only suitable for models -

B1/-B2/-B3.

Special attention should be given if unit

installed near to the sea as this can reduce

unit lifespan due to corrosion of metal

parts.

Installation clearances

•The installation location should allow sufficient space

for air flow and maintenance around the unit.

Figure 3: Installation Clearance

Field Piping

Pipe sizing should only be determined by

qualified personnel. Correct line sizing will

minimize the pressure drop and maintain

sufficient gas velocity for proper oil return.

All applicable standards must be observed in the

installation of refrigerant piping.

To ensure satisfactory operation and performance, the

following points should be noted:

•Pipework routes must be as simple and as short as

possible.

•Avoid low points on pipework where oil can

accumulate.

•Suction gas velocity must be sufficient to ensure good

oil return.

•Use only clean, dehydrated refrigeration grade

copper tube with long radius bends.

•Avoid flare type connections and take great care when

brazing. Use brazing filler alloys containing phosphorus

such as BCuP-7 without flux for joining copper tubes.

•Dissimilar metals such as copper and brass shall be

joined using an appropriate flux with high silver

content filler material such as BAg-34. Apply flux

sparingly to the clean tube only and in a manner to

avoid leaving any excess inside of completed joints.

✓

✓

X

X

Issue: 01.06.2023 Page 5

•Run braze without over filling to ensure there is no

leakage into the tube.

•To prevent oxidation, blow oxygen free nitrogen

through pipework when brazing.

•To prevent condensation on pipe surface, install

insulation on all suction lines and on all pipes

penetrating walls or passing through hot areas.

•Adequately support all pipe work at a maximum of 2-

meter intervals.

•The maximum rise between the two units should be no

more than 6 meters, to ensure compressor ability to

handle pressure drop.

•In vertical pipework, the use of U-trap and double

suction risers is often required. These suction risers must

always be fitted with a U-trap at the bottom and a P-

trap at the top and never be higher than 4m unless a

second U-trap system is fitted.

•Additional oil may be required if piping length

exceeds 20m or multiple oil traps are fitted. Check the

oil level closely during commissioning and add oil as

necessary. Add oil in small amounts. Do not overfill the

compressor!

•Suction pipework should slope gently back towards the

unit to assist oil return to the compressor. A fall of

approximately 2cm per meter of pipework is

acceptable.

•Liquid lines should be sized to ensure a full supply of

liquid refrigerant to the expansion device. Attention

should be paid to the sizing of liquid lines on large

risers (maximum rise 6m).

•On systems with a large refrigerant charge and

without pump down cycle, or on any system where

liquid flood back is likely to occur, a suction

accumulator (not supplied) is strongly required. It offers

protection against liquid refrigerant flow back during

operation and against off-cycle migration by adding

internal free volume to the suction side of the system.

•Tests must be conducted to ensure the amount of off-

cycle migration to the compressor does not exceed the

compressor’s charge limit.

•Wherever possible the system should be installed to

utilize a pump down configuration.

•Pump down control can be used on all thermostatic

expansion valve systems with the addition of a liquid

line solenoid valve. By closing a liquid line solenoid

valve, the refrigerant can be pumped into the

condenser and receiver, and the compressor operation

controlled by means of a low-pressure control. The

refrigerant can thus be isolated during periods when

the compressor is not in operation, and migration of

refrigerant to the compressor crankcase is prevented.

•In case of fire incidence, pressure increases due to

increasing in temperature at receiver. Hence it is very

important to install the Pressure Relief Valve.

•No valves and detachable joints shall be in areas

accessible to the public except when they comply with

EN 16084.

•Field piping for outdoor unit located below indoor unit:

Inverted P-trap is necessary when pump down is not

used (Figure 5). To prevent refrigerant from draining

into the compressor during off-cycle.

One of the main factors affecting

equipment reliability and compressor

service life is refrigeration circuit

contamination.

During installation, circuit contamination could cause by:

•Brazing & Welding Oxides

•Filings & Particles from de-burring pipework

•Brazing Flux

•Moisture & Air

Figure 4: Piping layout for outdoor above indoor

Figure 5: Piping layout for outdoor below indoor

INDOOR

UNIT

OUTDOOR

UNIT

MAX. 4m MAX. 4m

8 TO 12 m/s

U-TRAP AS SHORT AS POSSIBLE

2cm/m SLOPE,

4m/s OR MORE

SUCTION LINE

LIQUID LINE

2cm/m SLOPE, 4m/s OR MORE

MAX. TOTAL HEIGHT <10M

BULB LOCATION

U-TRAP AS

SHORT AS

POSSIBLE

INVERTED P-TRAP

OUTDOOR

UNIT

INDOOR

UNIT

INVERTED P-TRAP

SUCTION LINE

LIQUID LINE

MAX. RISE 6M

2cm/m SLOPE, 4m/s OR MORE

BULB LOCATION

Issue: 01.06.2023 Page 6

Installation

Pressure Testing

Never use oxygen, dry air, or acetylene for

pressure testing of the system as these may

form an inflammable mixture.

•The condensing units are pressure tested in the factory

prior to dispatch. All units come with a holding charge

of oxygen free nitrogen ~2barg. Remove the holding

charge indication tag which is tied to service valve

before installation.

•Once the pipework installation is complete, it should be

pressure tested for leak prior to evacuation.

•A pressure leak test should be carried out using

oxygen free nitrogen (OFN). A calibrated nitrogen

pressure regulator must always be used. Before

starting any pressure testing, ensure the area

surrounding the system is safe, inform relevant

personnel and fit warning signs indicating high pressure

testing. Also, use correct PPE as required.

•Always pressurize the system slowly, preferably in

stages up to the maximum required pressure. Never

exceed maximum working pressures shown in below

table. Failure to obey the limit will cause premature

failure on the pressure safety device.

Table 3: Maximum working pressure

High Side, barg (psig)

Low Side, barg (psig)

28 (405)

19 (275)

•Listen for any possible leaks and check all joints with

bubble spray. If any leaks are discovered, release

pressure slowly from both suction and liquid line of

system until empty, repair leak and then repeat

pressure testing procedure. Never attempt to repair a

leak on a pressurized system.

•A strength test should also be incorporated (to the

installed pipework only) according to applicable

standards.

•Once testing has been completed satisfactorily, release

the pressure from the system gradually and safely to

external atmosphere.

Evacuation and Charging

Moisture prevents proper functioning of the

compressor and the refrigeration system.

Ensure that a good quality vacuum pump is

used to pull a minimum vacuum of 250

microns (0.25 torr) measured at refrigeration system, and

not at the vacuum pump gauge.

Once pressure testing has been completed, the system

needs to be evacuated to remove any moisture from the

piping. This can be done as follows:

•Ensure any nitrogen charge is safely released from the

system.

•Connect a gauge manifold to the connections on the

service valves on the condensing unit.

•Connect a vacuum pump and vacuum gauge to the

system.

•Ensure all gauge manifold and service valves in open

position.

•Evacuate the system until vacuum is below 250 microns

(0.25 torr).

Note: A triple evacuation procedure is recommended for

all new systems or where moisture is suspected.

•Once the system is isolated and the vacuum pump is

switched off, any rise in pressure indicates that either

there may be a leak in the system or moisture is still

present. In this case, recheck the system for leaks,

repair as necessary, and then repeat the evacuation

procedure.

•Once evacuation is completed satisfactorily, the

vacuum pump and vacuum gauge can be removed. At

this point, the refrigerant charge can be added to the

system as required. Refrigerant blend must be charged

in liquid form to avoid change of chemical properties.

•Ensure an adequate liquid charge (4~5barg) has been

introduced to the high side of the system before

starting the compressor.

•The remaining charge is slowly throttled into suction

side until the installation has reached a level of stable

nominal condition during operation. Charging liquid

into the suction side of the system should ONLY be

done with a metering device. Ensure a minimum

operating pressure 0.5 barg is maintained when

adding refrigerant to the suction side, otherwise

overheating of the compressor may occur. Use

calibrated weighing scales to record the amount of

refrigerant added to the system.

•Stop the filling once obtain sufficient suction superheat

and liquid subcooling, remove the cylinder from circuit.

Refrigerant charge by judging the liquid

sight glass does not guarantee as 100%

correct way.

Electrical

The mains electrical supply to the condensing

unit must be via a suitable motor rated circuit

breaker or fuse. A mains isolator is fitted to

all condensing units. Therefore, an additional

isolator is not required unless site conditions

or regulations dictate differently.

J & E Hall Fusion & Fusion Scroll condensing units require

power supply single or three phase which include Neutral

and an Earth. These systems are not suitable for any other

supply voltages (other than specified in Table 2).

•Mains supply cable type and size must be selected to

suit the application and the electrical installation should

conform to the current local standards.

•Cables to the condensing unit should, wherever

possible, be routed through the cable glands supplied

on the rear of the units.

•Connect the mains supply to the units as per the wiring

diagrams.

•Ensure that the power supply corresponds to the unit

and that the power supply is stable.

•Connect power supply according to the present norm

and legal requirement. Ensure that the unit is properly

connected to the ground.

•3phase scroll compressor: live wires need correctly

terminated at motor rated circuit breaker for the

compressor to rotate in correct direction (compression).

Issue: 01.06.2023 Page 7

•The unit is equipped with a motor circuit breaker with

thermal overload and magnetic trip short circuit

protection for the unit. It was preset from factory and

never set value higher than set current on wiring

diagram.

Reverse Rotation Protection and Voltage

Unbalance

The condensing unit does not include phase protector

except for model JEHS-1400-B4-L-3 EVI; JEHS-1500-B6-

M-3 and JEHS-1300-B4-M-3 units. Thus, it is necessary to

ensure correct scroll compressor rotation and incoming line

voltage variance within +/-2% during commissioning.

3 phase scroll compressors require proper

phase sequence to secure right rotation and

therefore compression.

•Do not use a megohmmeter nor apply power to the

compressor while the system under vacuum as this

may cause internal damage to the compressor.

•Never start the compressor under vacuum (do not

operate the compressor with the low-pressure cut-

out bypassing), as this will cause the rotating part to

overheat very quickly causing premature failure.

•There must be no more than 10 compressor’s start

per hour. A higher number reduces the service life of

the compressor. There is no minimum off time for the

compressors. Adequate minimum run time is

required to ensure proper oil return.

Commissioning

To gain access to the electrical box, turn the motor rated

circuit breaker on the side/front of the unit to the OFF

position and loosen the screws on the left-hand side of the

door. The electrical box is located behind the door. Remove

the screws in the electrical box cover to access components.

Pre startup checks

Before starting the condensing unit, the following checks

should be carried out as a minimum:

•Check electrical supply is correct and all connections

are sound.

•All moving parts are free, and guards are fitted.

•Compressor oil level satisfactory.

•Initial settings for safety switches and fan speed

control.

•Overload set correctly on motor rated circuit breaker.

•All valves are in correct operating position.

•Initial refrigerant charge.

•Crankcase heater energized for a minimum of 12 hours

before compressor start-up.

•Gauge manifold connected to both low and high sides

of system.

Running the unit

•Run the unit and check compressor and condenser fan

operation.

•Check system pressures and temperatures, gas charge

and running currents of motors to ensure correct

operation.

•Check compressor suction superheat. This should be

between 10K and 20K for normal operating

conditions.

•Final adjustment of safety switch settings and fan

speed control.

•Allow the system to run for 3 –4 hours. Check

compressor oil level and top up with the correct oil

type as required. Recheck the compressor oil level

again after 24 hours operation.

•Carry out final leak test and ensure all panels/covers

are fitted and screws tightened.

•Log all information along with the system model and

serial numbers for future reference.

•Ensure that the customer / responsible person is

provided with basic operating instructions and where

electrical isolators are situated in case of emergency.

Scroll Compressor Operation

Scroll compressor motors are designed to run only in one

direction. This is not an issue with single phase compressors

as they will always run in the correct direction. The correct

rotation of a three-phase compressor motor depends on the

connection of the three incoming phases to the unit. Correct

rotation can be determined by a drop in suction pressure

and a rise in discharge pressure when the compressor is

energized. Running the compressor for a short period of

time in reverse direction will have no negative impact but

prolonged running in reverse direction may cause

premature failure. To reverse the rotation of a three-phase

scroll compressor, shut off the incoming power supply to the

unit, swap connection of any two of the three incoming phases

at the unit motor rated circuit breaker, reapply power to the

unit and following compressor restart, recheck operating

pressures.

Compressor rotalock connections

All rotalock connections on compressor models are sealed

with Loctite 554 thread sealant. The connections should be

leak tested at commissioning and during

service/maintenance visits. Refer Table 13 for more

information including recommended tightening torque.

Dual Pressure Switch

The dual pressure switch fitted to condensing units is auto

reset for low pressure side and manual reset for high

pressure (fixed differential) are NOT factory preset for

application.

Figure 6: Saginomiya DNS-D306

Issue: 01.06.2023 Page 8

Adjustment on DNS-D306

•High Pressure Cut Out: Turning the adjusting screw (8)

clockwise to increase the cut-out pressure setting and

vice versa. Lock the spindle with locking plate after

setting.

•Low Pressure Cut in: Turning the range adjusting screw

(2) clockwise to decrease the cut-in pressure setting

and vice versa.

•Low Pressure Differential: Turning the differential

adjusting screw (3) clockwise to increase the

differential pressure setting and vice versa. Lock the

spindle with locking plate after setting.

Figure 7: Adjustment on

Danfoss KP17WB

KP17WB has high pressure convertible reset feature. Insert

screwdriver into the slot on the lock disc and turn it to the

desired reset configuration as shown in Figure 8.

Do not turn the screw on the lock disc as it may damage the

convertible reset mechanism.

Figure 8:

KP17WB:

high pressure reset option

When high pressure trip is changed to auto reset on

KP17WB, the compressor is ready to turn ON when

discharge pressure drops below the setting value of (Cut

Out –Fixed Differential).

When HP switch cut out mode is changed

from Manual to Auto operation, the fitting of

an ART (anti-recycle timer) is recommended

to protect the compressor.

Table 4: Dual Pressure Switch Manufacturer Setting

Series

Model

High (barg)

Low (barg)

Cut

Out

Diff.

(Fixed)

Cut

In

Diff (adj)

1,2

DNS-D306

20

7

3

2

3,4,6

KP17WB

18

4

3

2

Pressure switch settings

Both the LP and HP switch settings must be adjusted to

suit application before starting the unit. Ensure that the

high-pressure setting does not exceed the value shown in

Table 5.

High pressure safety

•The high-pressure safety switch is required to stop the

compressor should the discharge pressure exceed the

compressor’s high side operating pressure.

•The high-pressure switch can be set to lower values

depending on the application and ambient conditions.

Low pressure protection

•The low-pressure protection cut out switch protects the

compressor against deep vacuum operation, a

potential cause of failure due to internal arcing and

operating outside the compressor limits.

•The low-pressure protection cut out should never be set

lower than the min. LP cut out value in Table 5. For

systems without pump-down integrated, the LP switch

signal contact shall be used to energize a low-pressure

safety alarm.

•If a thermostat is used for room temperature control,

and a pump down feature is not integrated, a low-

pressure control of the manual reset type should be

wired in series with the thermostat to serve as a

protection cut-off in the event of loss of refrigerant

charge or other abnormal conditions which resulting in

low suction pressures.

•When used for low temperature operational control,

the low-pressure control should be provided with a low

differential for accurate control. For accuracy,

refrigeration gauges must be used in setting cut-in and

cut-out points, since the indicator on the face of the

pressure switch is not sufficiently accurate for control

purposes.

•Compressor operating pressures should be kept within

the limits in Table 5.

Table 5: Compressor operating pressures in barg

Series

1,2

2,3,4,6

1,2

2,3,4

Application

M*

L*

Compressor

Family

AE/AJ

ZB

AJ/FH

ZF/ZFI

Refrigerant

R407A

R407A

R134a

R448A

R407A

R407F

R407F

R449A

R407F

R448A

R448A

R452A

R448A

R449A

R449A

R449A

R452A

R452A

Min. LP Cut

Out

1.5

2

0.6

0.1

0.3

Max. HP

Cut Out

27.7

18

27.7

LP Range

1.5~8.3

2.0~7.1

0.6~3.8

0.1~3.3

HP Range

13.2~27.7

6.6~15.8

13.2~27.7

*M: Medium Temperature; L: Low Temperature

Issue: 01.06.2023 Page 9

Crankcase Heaters

•Crankcase heater should remain energized during the

compressor off cycles. The initial start in the field is a

very critical period for any new compressor because

all load-bearing surfaces are new and require a short

break-in period to carry high loads under adverse

conditions. Thus, the crankcase heater must be turned

on a minimum of 12 hours before the first-time start, to

prevent oil dilution and bearing stress on initial start-

up.

•To energize the crankcase heater while keeping

compressor OFF, isolate the compressor from circuit by

removing jumper wire which in series with H/L pressure

switch, such as terminal 3-4 in Series 2, and then turn

the motor rated circuit breaker to ON position.

Fan Speed Controller XGE-4C

(Applicable to Series 2/3/4 and 6)

•The fan speed controller is factory set to 19barg

(maximum speed) and cut off when drop below

13barg, for operation with R4*** series refrigerant to

ensure compressor always operates within the unit

operating envelope.

•When operate with R134a, the fan speed controller

setting need to be set to 13bar.

Figure 9: Full voltage adjustment on XGE-4C

•The FSC is set according to Table 6 to gain higher

energy efficiency as published in the Ecodesign data

sheets.

Table 6: FSC settings to obtain ecodesign data

Model

FSC settings (barg, maximum speed)

R407A, R407F, R448A,

R449A, R452A

R134a

S2 except (JEHS-0350-

B2-M; JEHR-0180/210-

B2-L)

19

13

JEHS-0350-B2-M; JEHR-

0180/210-B2-L; S3

10

13

S4 except EVI; S6

10

10

S4 EVI

17

N/A

Fan control switch SYS-C130

(Applicable to Series 1- Low Temperature Model)

•The fan control switch is factory set as Table 7, which is

the same setting to obtain the Eco design data.

•Fan stopped when the pressure drop below fan cut out

pressure.

Table 7: Fan control switch factory setting

Model

Fan control Switch (barg)

Cut in

Differentiate

JEHR-0115/135-B1-L-1

16

7

Fan Cut Out = Cut In –Differentiate

Discharge Thermostat

(Applicable to JEHS-0750-B4-L-3, JEHS-1300-B4-M-3,

JEHS-1500-B6-M-3 and all EVI)

Only scroll models specified above are equipped with

discharge thermostat with specification (cut out = 125±4⁰C,

cut in = 95±5⁰C). The thermostat is connected in series to

dual pressure switches, to disconnect all three phases at

contactor in case of overtemperature.

For other 3phase models, it is recommended to install the

discharge thermostat with cut out temperature not more

than the maximum discharge gas temperature specified

in Table 2.

Overheating could be due to compressor working at high

compression ratio (low evaporating and high condensing

pressure); loss/ inadequate charge; or condenser fan not

working. Time must be allowed for the compressor to cool

down before the thermostat auto reset.

For scroll compressors with motor protection code “F”, an

internal line break motor protector is located at the center

of the Y of the motor windings (motor located in low

pressure dome), to disconnect all three phases in case

overcurrent or overtemperature condition. The protector is

the automatic reset device containing snap action bimetal

switch which reacts to a combination of motor current and

motor windings temperature. When the internal motor

protector has tripped, it will take 30 to 40 minutes to reset

and then the compressor will restart.

On a field application, when the internal motor protector

has tripped, the compressor will stop while each of 3

terminals is still energized, to which either the customer or

serviceman may regard the compressor as fail down.

Therefore, the above-mentioned situation should be taken

into consideration.

Units with microchannel condenser

•Care must be taken during charging a unit where a

microchannel condenser coil is fitted.

•The microchannel coils hold less refrigerant than

traditional fin/tube coils, it is easier to be overcharged,

especially if the system is commissioned during

wintertime which ambient temperature is colder.

•If too much refrigerant is added, this may cause

tripping of the high-pressure switch in warmer weather.

•Always check that the amount of condenser sub cooling

is not excessive which may indicate refrigerant

overcharge.

System operation

•Once the system is correctly charged with refrigerant

and the operating condition is stable, check that the

compressor suction superheat is between 10K~20K

and that the compressor discharge temperature is

between 50°C~ 90°C.

•A compressor suction superheat that is too low may

indicate liquid refrigerant return to the compressor,

1 Turn

~1.5bar

Full voltage adjusting

range

10~25barg

Full voltage set point

(factory setting)

19barg full

speed,

mode: cut

off at Pmin.

Effective proportional

band

6 barg

(fixed)

Issue: 01.06.2023 Page 10

whereas a suction superheat that is too high will not

provide enough cooling effect for the compressor and

will cause high discharge temperatures. In either case,

it is likely that compressor damage/failure will occur.

Precautions when operate with FH and AJ

Compressor

Follow instructions below when operating R448A/R449A in

low temperature condensing unit which integrated with

Tecumseh compressor FH/AJ.

Limit the suction superheat below 10K, to

ensure discharge temperature is maintained

below 120ºC with evaporating temperature

of -30ºC and below. Do not use capillary

tubes as throttling devices to prevent plugging issue.

Voltage Monitoring Device MG73BF

(Applicable to JEHS-1400-B4-L-3 EVI; JEHS-1300-B4-M-3

and JEHS-1500-B6-M-3 units only)

Only the above models are equipped with voltage

monitoring device to monitor the input power supply to

protect the 3-phase compressor from overheating as result

of working under phase lost, undervoltage or overvoltage.

Table 8: LED indication on front plate of MG73BF

LED

(ON/OFF)

Condition

ON

UV

OV

BLINK:

ASY, ON:

REV

Power ON

ON

OFF

OFF

OFF

Phase reverse

ON

OFF

OFF

ON

Asymmetry

ON

OFF

OFF

BLINK

Under voltage

ON

ON

OFF

OFF

Over voltage

ON

OFF

ON

OFF

Phase Fail

BLINK

OFF

OFF

OFF

Phase Fail when

input voltages lower

than UV set point

and below

asymmetry

BLINK

ON

OFF

BLINK

Neutral Fail

ON

BLINK

BLI

NK

BLINK

The off-delay timer will turn the system off after a set

amount of time for following situation:

•Supply phases exceed over

voltage or under voltage trip

level setting

•Any supply phase failure

•Line interruption

•Phase reverse occurrence

•Neutral failure

Vapor Injection Controller EXD-HP1

(Applicable to EVI units only)

The controller EXD-HP1 used in the EVI units operates as an

economizer control. The setting of the controller is factory

pre-set and is password protected. Users are not

recommended to change any settings in the controller.

Electronic expansion valves in the EVI unit

are in partially open condition. Do not

charge the system with refrigerant before

closure of valve.

Four main parameters Password (H5), type of function

(1uE), refrigerant type (1u0) and pressure sensor type (1uP)

can be set only when digital input DI1 is off

(open) while the power supply is ON (24Vac).

Digital input Di1

•The digital status is dependent on the operation of

system’s compressor or demand.

Table 9: Digital input status of EXD-HP1

Operating Condition

Di1 status

Compressor starts

Closed (Start)

Compressor stops

Open (Stop)

Electrical checked/modified before start-up

•To fully close the EEV, open circuit Di1-gnd of controller

through disconnecting the supply to compressor. For

1. Model JEHS-0951/1150-B4: remove the jumper

wire from terminal block labeled 8 and 9.

2. Model JEHS-1300-B5: remove twin jumper bars

from terminal blocks labelled 6 and 7.

•Switch ON the motor rated circuit to turn ON the power

supply 24V to the controller EXD-HP1. The valve will

be driven to a close position.

•After closure of the EEV valve, start charging the

system with refrigerant.

•Disconnect power supply through motor rated circuit

breaker, then reconnect back the original wiring from

factory.

•Do not apply voltage to the system before all cable

connections are completed.

•Use a class II category transformer for 24 Vac power

supply. Do not ground the 24 Vac lines.

•Higher voltage than specified will permanently

damage the controller.

•When connecting wires of EEV and pressure sensor

4~20mA to the controller EXD-HP1, follow the cable

color to connect to the respective abbreviation color

code printed on the EXD-HP1. Example for EXV: BR =

Brown; BL = Blue etc. Or refer to wiring diagram for

electrical connections.

Issue: 01.06.2023 Page 11

Figure 10: Display/ keypad unit (LEDs and button

functions)

•In the case of economizer control. The discharge

temperature is shown on the display.

•To display other MEASURED DATA on EXD-HP1, press

“SEL” button for 1 second until index number according to

below table appears. Release “SEL” button and the next

variable data will be displayed. Repeating the

procedure to view all variable data in sequence:

Table 10: Display parameters

Display Index

Variable Data

10

Default Superheat, K

11

Suction pressure, bar

12

Valve position, %

13

Suction gas temperature, °C

14

Saturation temperature, °C

15

Discharge temperature, °C

Note: After 30minutes, the display reverts to index 10.

Manual mode operation

•Manual mode is intended for temporary operation of

the valve at specific condition. Warning: All alarms are

disabled during manual operation. We do not

recommend unattended operation of the system during

manual control.

•Press and together for 5seconds to access to

manual mode operation.

•After achieving the required operation, set the

parameter 1Ho and 1HP at 0, so the controller

automatically operates the valve at its setpoints.

•List of parameters in scrolling sequence by pressing

button

Table 11: Parameter list for manual mode operation

Code

Parameter description

and choices

Min

Max

Factory

setting

1Ho

Manual mode

operation; circuit 1

0 = off 1 = on

0

1

0

1HP

Valve Opening (%)

0

100

0

Manual alarm reset clearing functional alarms (except

hardware error)

•Press and together for 5seconds. When the

clearing is done, “CL” message appears for 2 seconds.

Table 12: EXD-HP1 error/ alarm handling

Note: When multiple alarms occur, the highest priority alarm is displayed until being cleared. Then the next highest alarm is displayed

until all alarms are cleared. Then, the parameters will be shown again.

Issue: 01.06.2023 Page 12

Outline Drawing

Figure 11: Outline Drawing Series 1

Figure 12: Outline Drawing Series 2

Figure 13: Outline Drawing Series 3

Figure 14: Outline Drawing Series 4

Figure 15: Outline Drawing Series 6

Issue: 01.06.2023 Page 13

Wiring Diagrams

Figure 16: JEHR-0050-B1-M-1

Figure 17: JEHR-0067/0100/0113-B1-M-1

L N

I >I >

2

B1 1

BRN

I >

4 6

3 5

BLU

BLU

PE

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM

TERMINALS 2 & 3 TO CONNECT EXTERNAL THERMOSTAT FOR CONTROLLING

THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

B1: MOTOR CIRCUIT BREAKER

C1: START CAPACITOR

C2: FAN CAPACITOR

F1U: FUSE

K1R: START RELAY

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

Q1M: MOTOR OVERLOAD PROTECTOR

M1C

CR

S

M

1~

12N

C1

BLU

BLK

GRN/YLW

I>K1R

BLU

Q1M

220-240V 1~ 50Hz

BRN

MODEL B1 SETTING,(A)

JEHR-0050-B1-M-1 6.0

1

P>

LP

1

P<

4

HP

3S1PH

S1PL

2

N2 N1

ALM

BLK

F1U

3.15A

MAX 50VA

GRN/YLW

GRY

M1F

GRN/YLW

1~

M

C2

WHT

PPL

RED

BRN

3

BRN

BLU

BRN

BRN

NOTE 1

L N

I >I >

2

B1 1

BRN

I >

4 6

3 5

BLU

BLU

1

P>

LP

1

P<

4

HP

3S1PH

S1PL

RED

2

N2 N1

ALM

BLK

F1U

3.15A

BRN

MAX 50VA

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM

TERMINALS 2 & 3 TO CONNECT EXTERNAL THERMOSTAT FOR CONTROLLING THE

COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

B1: MOTOR CIRCUIT BREAKER

C1: START CAPACITOR

C2: RUN CAPACITOR

C3: FAN CAPACITOR

F1U: FUSE

K1R: START RELAY

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

Q1M: MOTOR OVERLOAD PROTECTOR

GRN/YLW

GRY

MODEL B1 SETTING,(A)

JEHR-0067-B1-M-1 6.5

JEHR-0100-B1-M-1 7.5

JEHR-0113-B1-M-1 9.5

PE

220-240V 1~ 50Hz

M1F

GRN/YLW

1~

M

C3

WHT

PPL

RED

BRN

3

BRN

BLU

BRN BRN

BRN

BLU

M1C

CR

M

1~

BLK

GRN/YLW

Q1M

S

K1R

2

51

C2

C1

4

BRN

BLU

BLK

BLU

BLU

BLK

NOTE 1

Issue: 01.06.2023 Page 14

Figure 18: JEHR-0115/0135-B1-L-1

Figure 19: JEHR-0140/0170-B2-M-1

GRN/YLW

A1

A2

K1M

L N

BLU

BLU

N2

I >I >

2

B1 1

BRN

BLK

642

I >

4 6

3 5

BRN

BLU

K1M 1

BRN

3 5

1

BLK

BLU

BRN

BRN

F1U

3.15A

BRN

ORG

BLU

N1

ORG

22

K1M

21

GRN/YLW

HP

P

31

5

BLU

E1HC

S1PH

S1P

PE

BLU

2

3

BRN

ALM GRY

220-240V 1~ 50Hz

MODEL B1 SETTING,(A)

JEHR-0115-B1-L-1 6.0

JEHR-0135-B1-L-1 7.5

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 2 & 3 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

B1: MOTOR CIRCUIT BREAKER

C1: START CAPACITOR

C2: RUN CAPACITOR

C3: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

K1R: START RELAY

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1P: FAN PRESSURE SWITCH

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

Q1M: MOTOR OVERLOAD PROTECTOR

S1PL LPP>

4

P< HP

1

3

NOTE 1

RED

BLU

M1C

CR

M

1~

BLK

GRN/YLW

Q1M

S

K1R

2

51

C2

C1

4

BRN

BLK

BLU

BLU

BLK

BRN

M1F

GRN/YLW

1~

M

C3

WHT

PPL

RED

M1F

E1HC

21

22

GRN/YLW

GRN/YLW

ORG

N1

GRN/YLW

1~

M

N3

BLK

C3

1

ORG

A2

N2

K1M

BLU

A1

1

LP

BLK

3

P>

A1P

2

ALM

F1U

3.15A BRN

BLU

S1PH

GRY

4

P< HP

1

3

K1M

14

BRN

BLK

2

BLK

(4)

BLK

RED

K1R

BLU

M1C

220-240V 1~ 50Hz

L N

A/S

2

C/CP/R

M

1~

K1M

BRN

BLU

I >I >

42

I >

B1 1 3

BLU

6

51

C2

C1

5

2 4

BRN

1 3

BLU

4

BLK

BRN

BLU

BLK

BLU

(1)

(2N)

BLK

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 1 & 2 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

( ): TERMINAL IN COMPRESSOR ELECTRICAL BOX

A1P: FAN SPEED CONTROLLER

B1: MOTOR CIRCUIT BREAKER

C1: START CAPACITOR

C2: RUN CAPACITOR

C3: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

K1R: START RELAY

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

Q1M: MOTOR OVERLOAD PROTECTOR

S1PL

13

PE

BLU

K1M

MAX 50 VA

(3L)

BRN

BRN

GRN/YLW

BLU

Q1M

NOTE 1

MODEL B1 SETTING,(A)

JEHR/JEHCCU0140B(C)M1 10.0

JEHR/JEHCCU0170B(C)M1 11.0

Issue: 01.06.2023 Page 15

Figure 20: JEHR-0140/0170-B2-M-3

Figure 21: JEHR-0180/0210-B2-L-1

M1F

E1HC

21

22

GRN/YLW

GRN/YLW

BLK

N2

GRN/YLW

1~

BRN

M

N3

BLU

BLK

C3

1

BLK

A2

BLU

N1

K1M

BLU

BLU

A1

3

BLK

5

A1P

2

ALM

F1U

3.15A BRN

BLU

S1PH

GRY

K1M

K1M

13

14

BRN

BRN

BLK

4

BLK

BRN

1

2

BRN(BLK)

RED

K1R

BLU

M1C

220-240V 1~ 50Hz

L N

S

2

CR

M

1~

BLU

K1

BRN

BLU

I >I >

42

I >

B1 1 3

BLU

BRN

6

51

C2

C1

5

2 4

BRN

1 3

BLU

S1PL

MAX 50 VA

GRN/YLW

BLK

(4)

BLU

BRN

MODEL B1 SETTING,(A)

JEHR/JEHCCU0180B(C)L1 11.0

JEHR/JEHCCU0210B(C)L1 12.0

LPP>

4

P< HP

1

3

NOTE 1

PE

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 3 & 4 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

( ): TERMINAL IN COMPRESSOR ELECTRICAL BOX

A1P: FAN SPEED CONTROLLER

B1: MOTOR CIRCUIT BREAKER

C1: START CAPACITOR

C2: RUN CAPACITOR

C3: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

K1R: START RELAY

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

380-415V 3N~ 50Hz

L2

L1

I >

B1

42 6

I >

1 3

I >

5

M

3~

M1C

K1M

BRN

2 4 6

1 3 5

M1F

E1HC

21

22

GRN/YLW

GRN/YLW

ORG

N2

GRN/YLW

1~

M

N3

1

ORG

A2

BLU

N1

K1M

BLU

BLU

A1

3

BLK

A1P

2

ALM

F1U

3.15A BRN

BLU

S1PH

GRY

K1M

N

L3

13

14

BRN

BLK

GRY

BRN

4

BLK

S1PL

MAX 50 VA

BLU

C/C

P/R

A/S

RD

BLK

BLU

3

K1M

14

13

BRN

GRN/YLW

BLK

BRN

1

2

BRN

BLU

C1

BLK

MODEL B1 SETTING,(A)

JEHR/JEHCCU0140B(C)M3 4.0

JEHR/JEHCCU0170B(C)M3 5.0

PE

LPP>

4

P< HP

1

3

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 3 & 4 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

( ): TERMINAL IN COMPRESSOR ELECTRICAL BOX

A1P: FAN SPEED CONTROLLER

B1: MOTOR CIRCUIT BREAKER

C1: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

NOTE 1

Issue: 01.06.2023 Page 16

Figure 22: JEHR-0180/0210-B2-L-3

Figure 23: JEHS-0200/0250/0300/0350-B2-M-1

380-415V 3N~ 50Hz

L2

L1

I >

B1

42 6

I >

1 3

I >

5

BLK

BRN

GRY

M

3~

M1C

K1M

BRN

2 4 6

1 3 5

M1F

E1HC

21

22

GRN/YLW

GRN/YLW

BLK

N2

GRN/YLW

1~

BRN

M

N3

BLU

BLK

C1

1

BLK

A2

BLU

N1

K1M

BLU

BLU

A1

3

BLK

5

A1P

2

ALM

F1U

3.15A BRN

BLU

S1PH

GRY

K1M

N

L3

13

14

K1M

13

14

BRN

BRN

BLK

GRY

BRN

BLK

4

BLK

BRN

1

2

S1PL

MAX 50 VA

GRN/YLW

MODEL B1 SETTING,(A)

JEHR/JEHCCU0180B(C)L3 4.0

JEHR/JEHCCU0210B(C)L3 5.5

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 3 & 4 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

A1P: FAN SPEED CONTROLLER

B1: MOTOR CIRCUIT BREAKER

C1: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

NOTE 1

LPP>

4

P< HP

1

3

PE

21

22

GRN/YLW

GRN/YLW

BLK

N2

GRN/YLW

1~

BRN

M

N3

BLU

BLK

C2

1

BLK

A2

BLU

N1

BLU

BLU

A1

3

BLK

5

2

ALM

3.15A BRN

BLU

GRY

K1M

13

14

BRN

BRN

BLK

4

BLK

BRN

1

2

220-240V 1~ 50Hz

L N

BRN

BLU

I >I >

42

I >

B1 1 3

BLU

6

5

2 4

BRN

1 3

BLU

GRN/YLW

1~

C1

BRN

R

BLU

BLK

CS

M

BRN

MAX 50 VA

E1HC

S1PH

S1PL

K1M

F1U

K1M

A1P

M1C M1F

K1M

GRN/YLW

MODEL B1 SETTING,(A)

JEHS/JEHSCU0200B2(C)M1 13.0

JEHS/JEHSCU0250B2(C)M1 13.0

JEHS/JEHSCU0300B2(C)M1 17.0

JEHS/JEHSCU0350B2(C)M1 21.0

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 3 & 4 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

A1P: FAN SPEED CONTROLLER

B1: MOTOR CIRCUIT BREAKER

C1: RUN CAPACITOR

C2: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

LPP>

4

P< HP

1

3

PE

NOTE 1

Issue: 01.06.2023 Page 17

Figure 24: JEHS-0200/0250/0300/0350-B2-M-3, JEHS-0300-B2-L-3

Figure 25: JEHS-0350/0400-B3-M-1

L2

L1

I >

B1

42 6

I >

1 3

I >

5

BLK

BRN

GRY

M

3~

M1C

K1M

BRN

2 4 6

1 3 5

M1F

E1HC

21

22

GRN/YLW

GRN/YLW

BLK

N2

GRN/YLW

1~

BRN

M

N3

BLU

BLK

C1

1

BLK

A2

BLU

N1

K1M

BLU

BLU

A1

3

BLK

5

A1P

2

ALM

F1U

3.15A BRN

BLU

GRY

K1M

N

L3

13

14

K1M

13

14

BRN

BRN

BLK

GRY

BRN

BLK

4

BLK

BRN

1

2

T1 T2 T3

GRN/YLW

S1PH

S1PL

MAX 50 VA

GRN/YLW

PE

NOTE 1

LPP>

4

P< HP

1

3

MODEL B1 SETTING,(A)

JEHS/JEHSCU0200B2(C)M3 5.5

JEHS/JEHSCU0250B2(C)M3 7.0

JEHS/JEHSCU0300B2(C)M3 7.5

JEHS/JEHSCU0350B2(C)M3 9.5

JEHS/JEHSCU0300B2(C)L3 6.5

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 3 & 4 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

A1P: FAN SPEED CONTROLLER

B1: MOTOR CIRCUIT BREAKER

C1: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

E1HC

22

21

BLK

N3

BLK

A2

BLU

N2

K1M

BLU

BLU

N1

A1

BLK

BLK BLK

ALM

F1U

3.15A BRN

BLU

GRY

K1M

MAX 50 VA

S1PH

GRN/YLW

5

1

BRN

L N

BRN

BLU

I >I >

42

I >

B1 1 3

BLU

6

5

2 4

1 3

BRN

BLU

K1M

C1

BRN

BLU

BLK BRN

1~

RC

S

M

M1C

GRN/YLW

4

3

K1M 14

13

BLU

BRN

GY

GY

Y/G

BL

BR

BK

M

~

C2

GRN/YLW

BRN

BRN

GRN/YLW

BLK

1

A1P

2

2

B

C

A

D

PE

S1PL

GRN/YLW

BRN

220-240V 1~ 50Hz

PE

P<

P>

NOTE 1:ONLY FOR NON PUMP DOWN SYSTEM, REMOVE LINK WIRE FROM TERMINALS 3 & 4 TO CONNECT

EXTERNAL THERMOSTAT FOR CONTROLLING THE COMPRESSOR ACTIVATION.

INDICATOR:

-- : FIELD WIRING

A1P: FAN SPEED CONTROLLER

B1: MOTOR CIRCUIT BREAKER

C1: RUN CAPACITOR

C2: FAN CAPACITOR

E1HC: CRANKCASE HEATER

F1U: FUSE

K1M: CONTACTOR

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

S1PL: LOW PRESSURE SWITCH

NOTE 1

MODEL B1 SETTING,(A)

JEHS-0350-B3-M-1 21.0

JEHS-0400-B3-M-1 24.5

This manual suits for next models

42

Table of contents

Popular Air Conditioner manuals by other brands

Perfectly Green

Perfectly Green Smart Frog owner's manual

Daikin

Daikin RXG25CVMB Technical data

Nordyne

Nordyne 16 SEER series User's manual & installation instructions

Airwell

Airwell AWSI-HMF009-N61 Service manual

Daikin

Daikin RXL18UMVJU installation manual

TemperZone

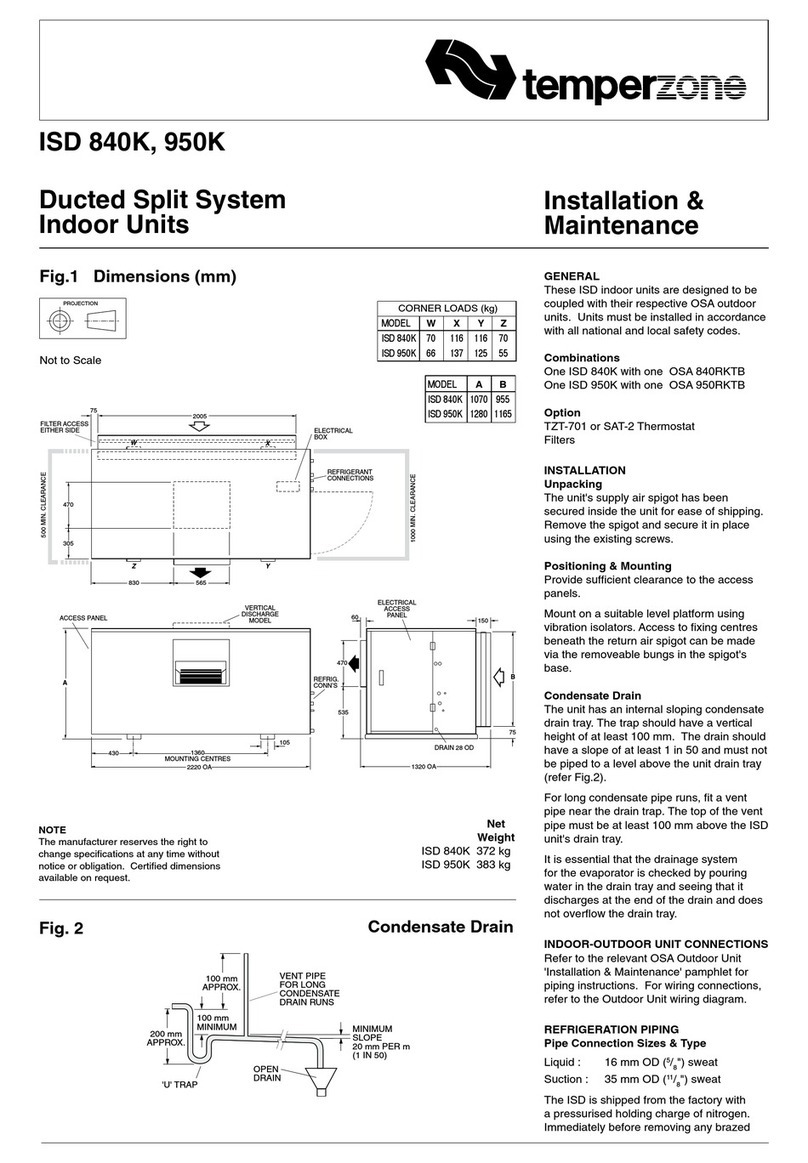

TemperZone ISD 840K Installation & maintenance