2

Varyscan®4 1200 HMI

Illustration of VS 4 1200HMI..........................................................................................................................3

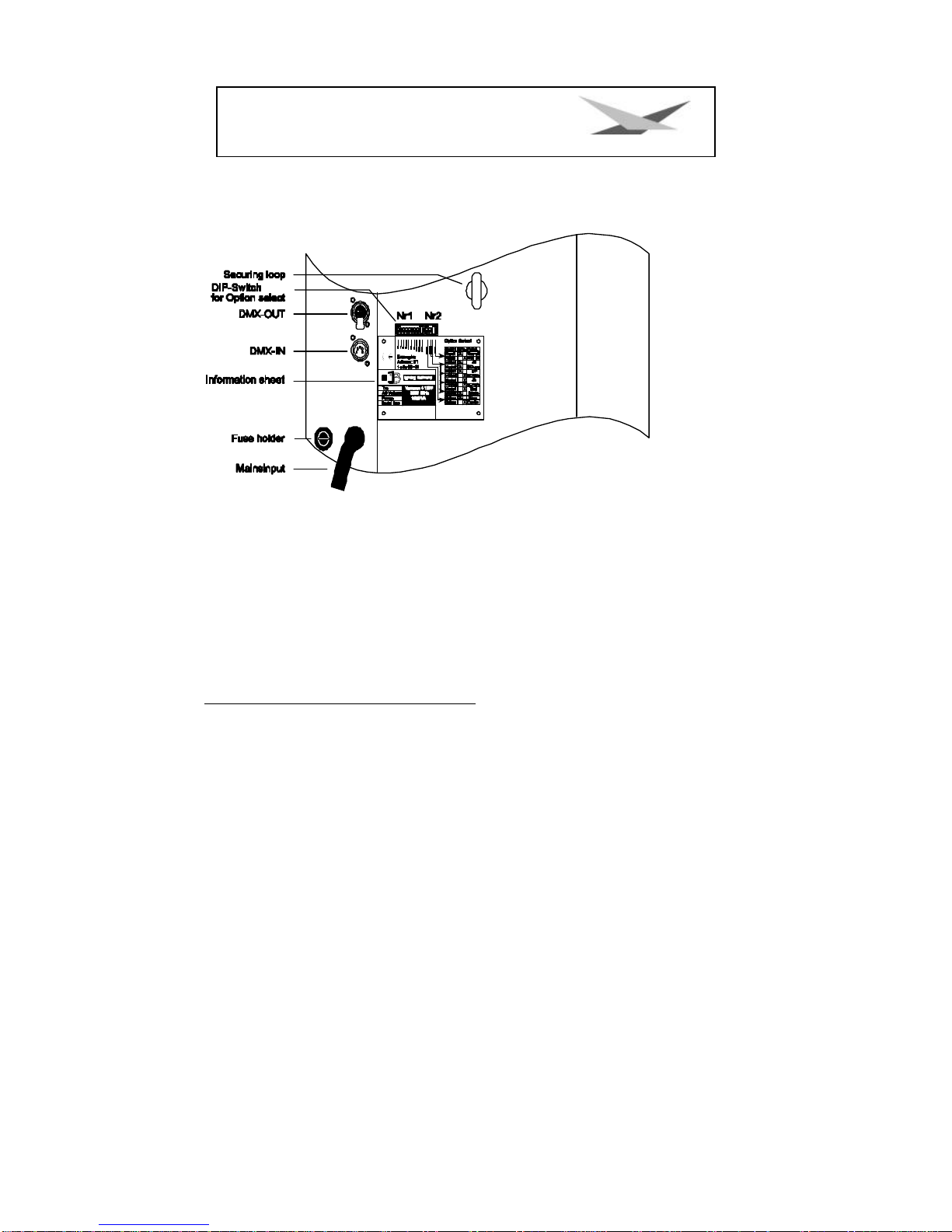

Back view and position of operating sections...................................................................................4

Unpacking of the Varyscan®Equipment.....................................................................................................4

Put in/ Exchange of the Bulb.........................................................................................................................5

Starting the Equipment..................................................................................................................................5

1. Hang up of Varyscan®........................................................................................................................5

2. Adjustment of Varyscan®...................................................................................................................5

3. Cabling of Varyscan®..........................................................................................................................5

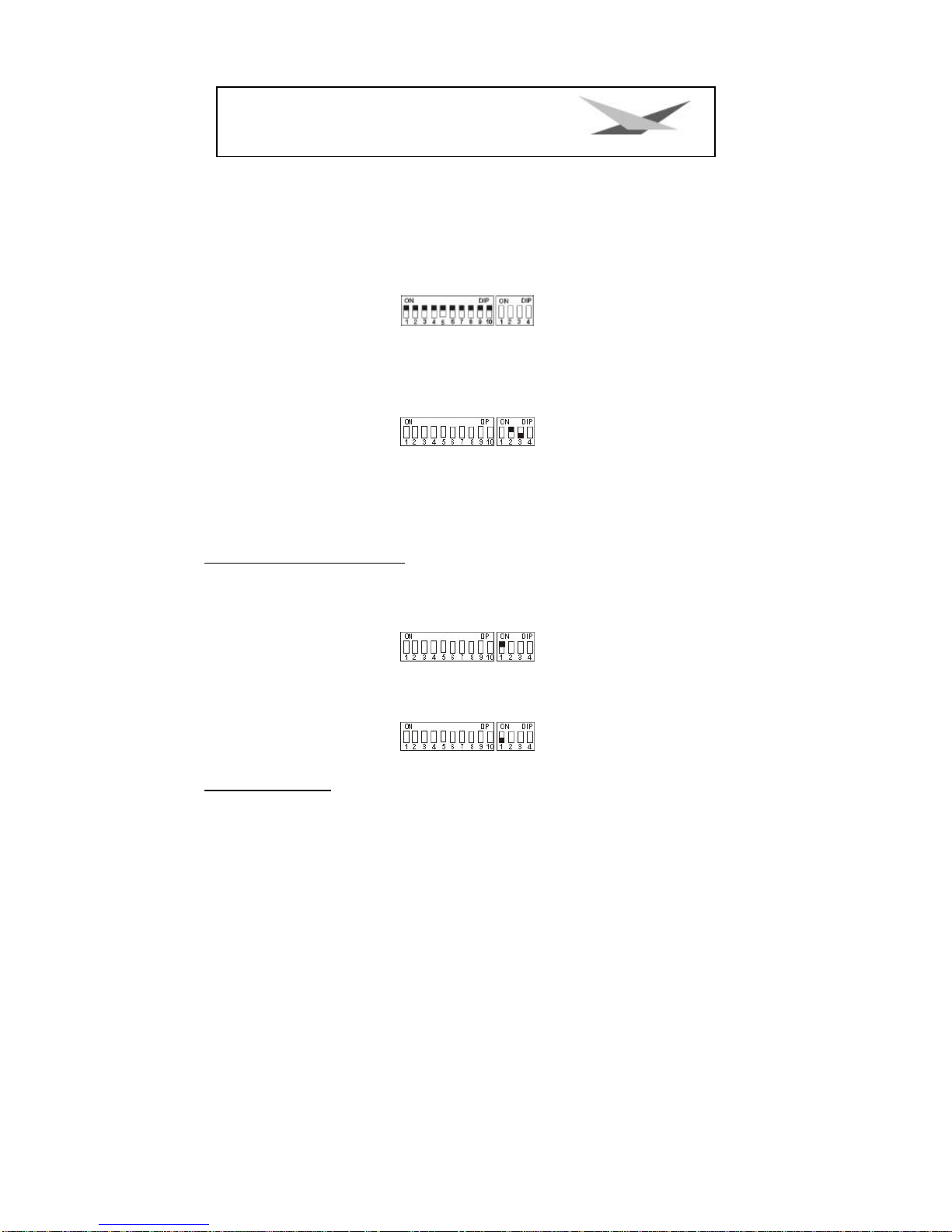

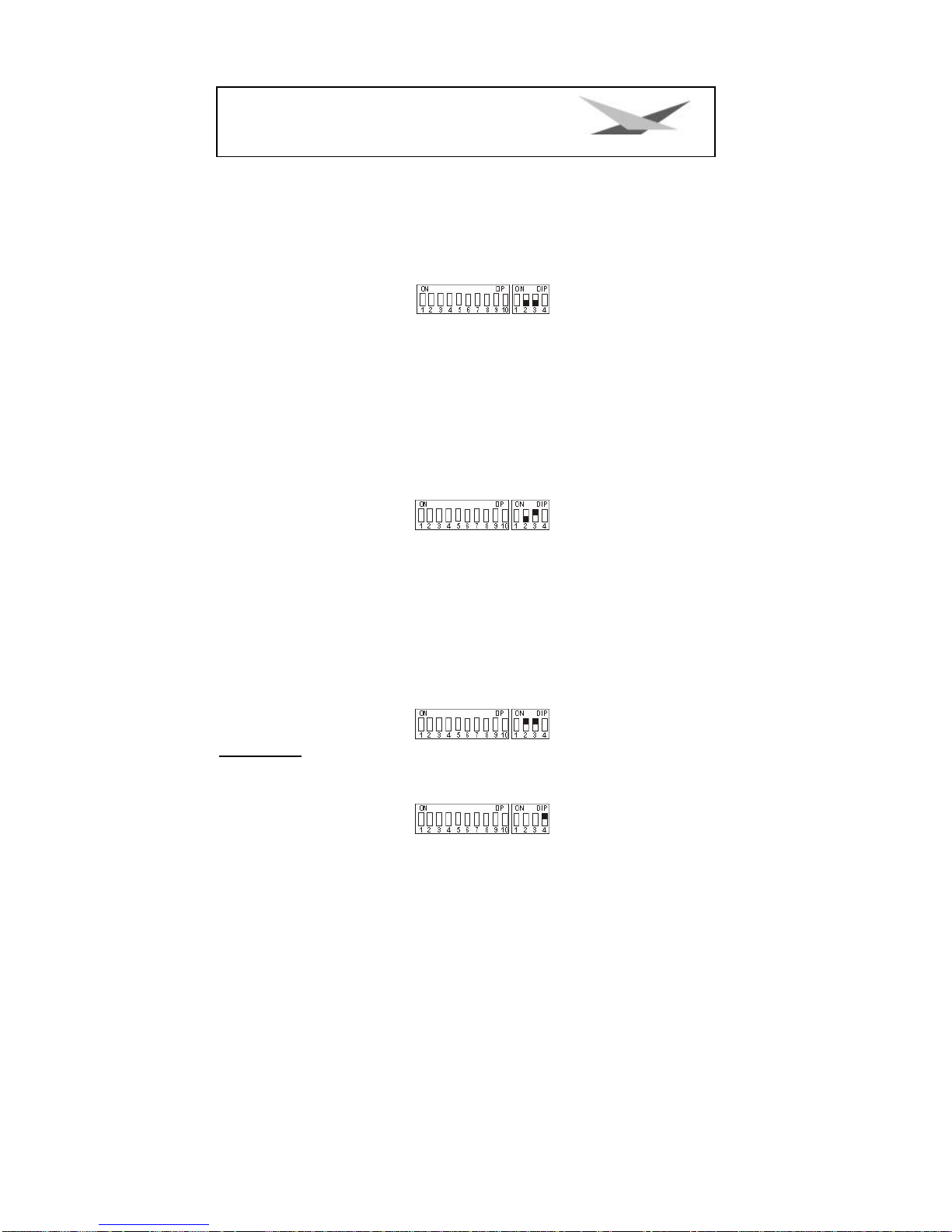

4. Adjustment at DIP-switches .............................................................................................................5

Initialisation Mode...................................................................................................................................6

Test Mode.................................................................................................................................................6

Adjustments at DIP-Switch No.2..........................................................................................................6

1. JB lighting 8 channel drive mode....................................................................................................6

2. 6 channel drive mode (Clay Paky -Goldenscan 3 compatible).................................................7

3. JB-lighting 6 channel drive mode....................................................................................................7

Definition of DIP-switch positions for defined DMX-addresses.............................................................9

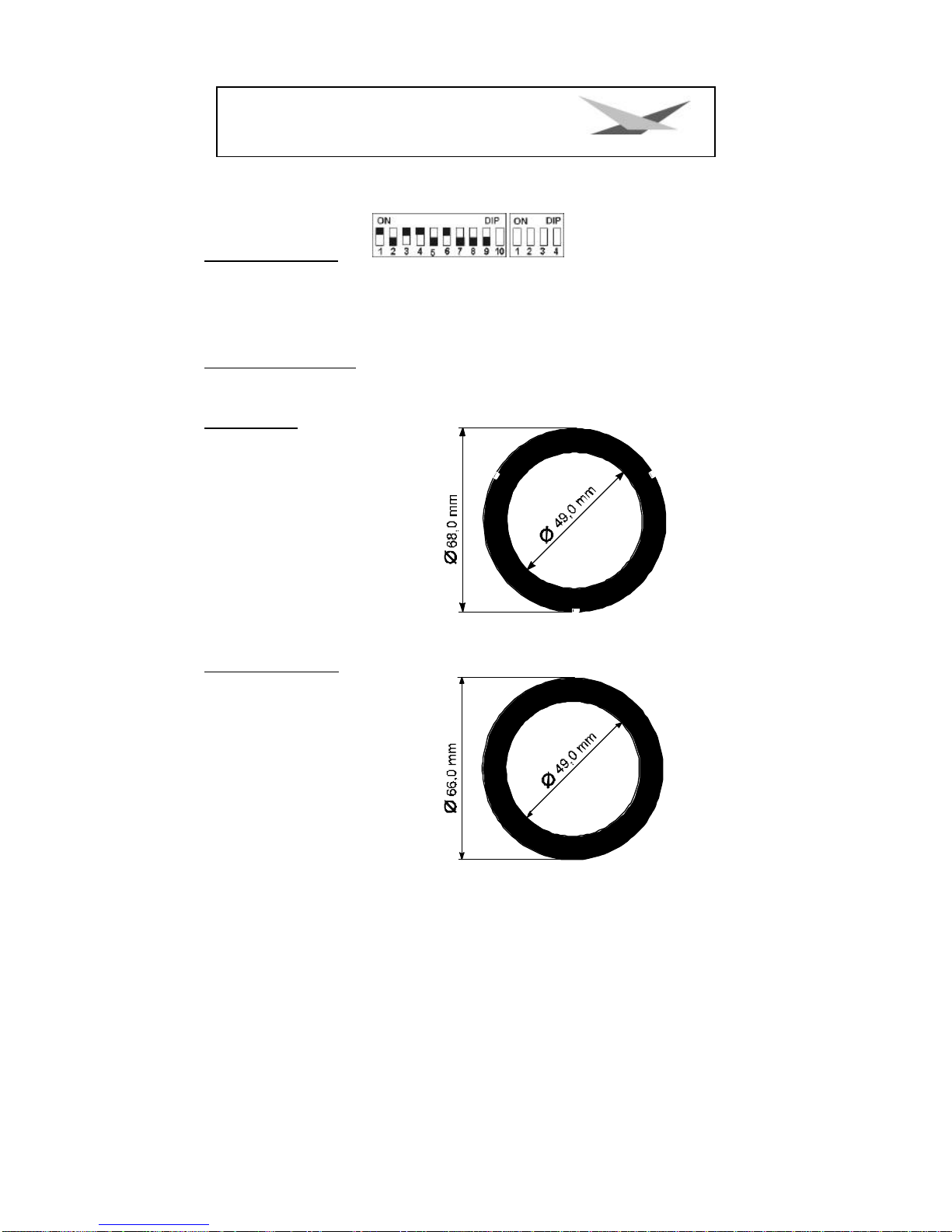

Changing of gobos......................................................................................................................................10

GOBO measurements................................................................................................................................10

B Service instructions..................................................................................................................................11

Adjustment of the mirror stop............................................................................................................11

Adjustment of the motor brake..........................................................................................................11

Regular Maintenance Performances...............................................................................................12

1. Cleaning of all optical parts...........................................................................................................12

2. Cleaning of ventilation............................................................................................................................12

3. Oiling of rotating gobos ..................................................................................................................13

General Information about DMX512 record............................................................................................13

Occupation of channels for Varyscan®4 1200 HMI ...............................................................................13

Occupation DMX-In / DMX-Out...................................................................................................................18

Technical data ..............................................................................................................................................18

Change of Eprom/ Software Update ........................................................................................................19

Plan of current circuits for Varyscan®4 1200HMI...................................................................................20

Occupation of connectors and Jumper....................................................................................................21

List of parts or electronic board of Varyscan®4 1200 HMI ...................................................................21

Plan of electronic parts for electronic board of Varyscan®4 1200 HMI..............................................25