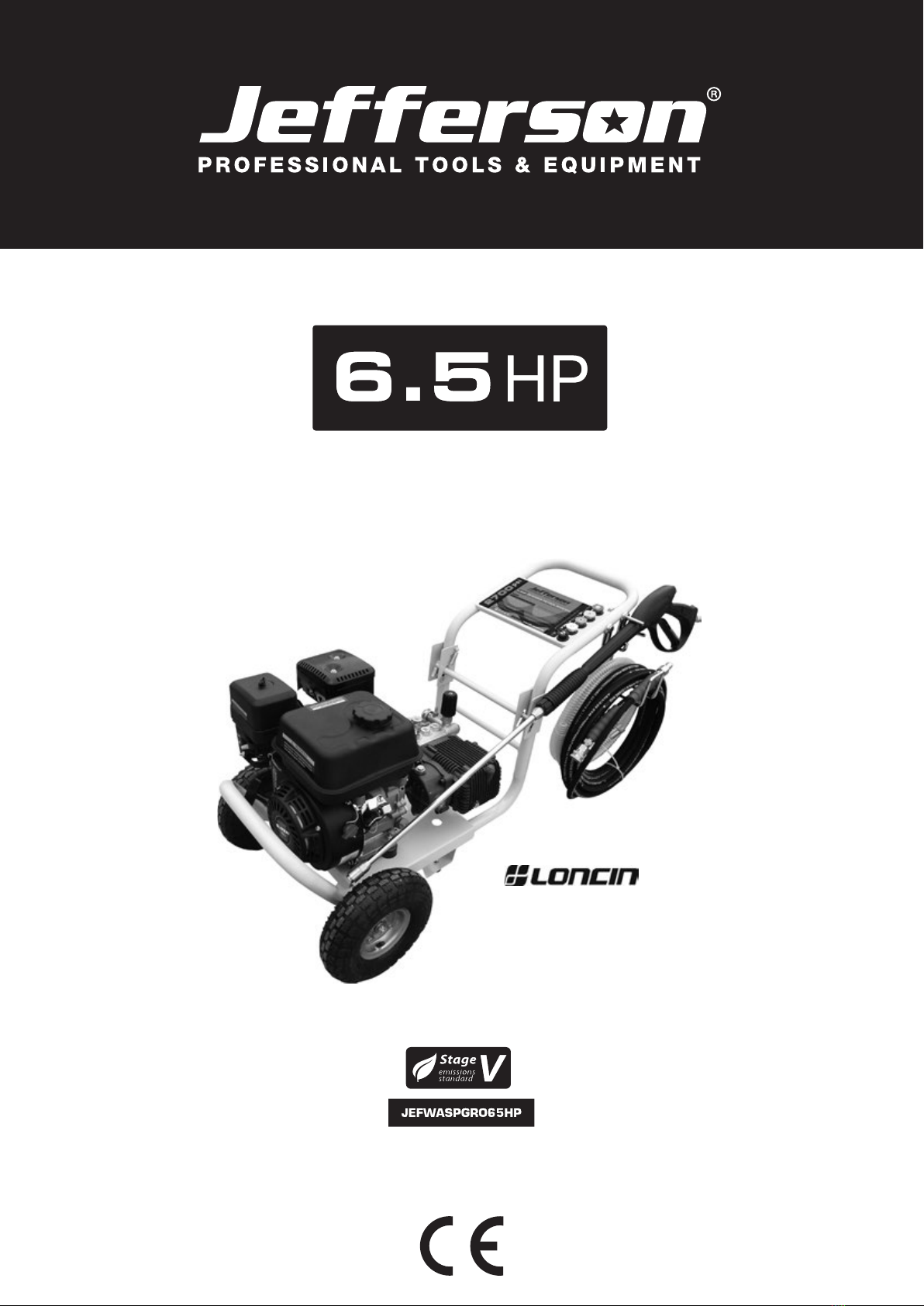

Jefferson Professional Tools & Equipment 6.5HP User manual

User Manual

v.2.1

12.6 L/min Flow Rate • 2700psi / 185 Bar Rated Pressure

GEARBOX PETROL WASHER

Powered By:

3

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

CONTENTS

Contents / About This Document 3

Specications 4

Equipment Identication 4

Safety Guidelines 5

Unpacking & Assembly 7

Equipment Setup 9

Safe Working Environment 10

Startup Procedure 10

Stopping The Pressure Washer 12

Spray Nozzles 12

Adjusting Spray Pressure 13

Using Chemicals & Detergents 13

Maintenance 14

Storage 17

Troubleshooting 18

Pressure Washer Main Assembly - Parts List & Diagram 20

Pump - Parts List & Diagram 21

Gear Box - Parts List & Diagram 22

Engine - Cylinder Head - Parts List & Diagram 23

Engine - Crank Case - Parts List & Diagram 23

Engine - Crank Case Cover - Parts List & Diagram 23

Engine - Crankshaft / Piston - Parts List & Diagram 24

Engine - Gas Distribution Adjustment - Parts List & Diagram 24

Engine - Crank Case Cover - Parts List & Diagram 24

Engine - Diversion Assembly - Parts List & Diagram 25

Engine - Carburetor - Parts List & Diagram 25

Engine - Flywheel/Coil Assembly - Parts List & Diagram 25

Engine - Crank Case Cover - Parts List & Diagram 25

Engine - Air Filter - Parts List & Diagram 26

Engine - Mufer - Parts List & Diagram 26

Engine - Fuel Tank - Parts List & Diagram 26

Pressure Washing Tips & Techniques 27

Limited Warranty Statement 28

EC Declaration Of Conformity 30

ABOUT THIS DOCUMENT

This manual has been compiled by Jefferson Tools and is an integrated part of the product with which it's enclosed and should be kept with it for

future reference. Please read all of the information supplied in this User Manual before operating this product. This manual describes the purpose

for which the product has been designed and contains all the necessary information to ensure its correct and safe use. We recommend that you

read the information supplied before carrying out any maintenance or repair. By following all the general safety instructions contained in this

manual you will help to ensure operator safety and extend the potential life span of the equipment.

All photographs and drawings in this manual are supplied by Jefferson Tools to help illustrate the operation of the product. Whilst every effort

has been made to ensure accuracy of information contained in this manual our policy of continuous improvement determines the right to make

modifications without prior warning. The information contained in this Instruction Manual is designed to assist you in the safe operation and

maintenance of the pressure washer. Some illustrations in this Instruction Manual may show details or attachments that differ from those on

your own model. Contact your nearest Jefferson Dealer if you are unsure about any information included in this manual or require any additional

information about the safe use, operation maintenance, or repair of this equipment.

4

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

SPECIFICATIONS

Flow Rate: 12.6 L/Min

Rated Pressure: 2700psi / 185bar

Engine: Loncin 6.5HP Stage V / OHV Petrol 196cc

Starting System: Recoil Start

Guaranteed Sound Power Level: * 101 dB Lwa

Fuel Tank: 3.6L

Lubrication Oil: Engine: SAE 10W30 (600ml)

Gearbox: SAE 10W30 (160ml)

Pump: SAE 10W30 (440ml)

Hose: 10M Steel Braided

Lance: 20" Stainless Steel

Nozzles: 0°, 15°, 25°, 40°, 65°

* Sound Power Level:

The figures quoted in this table are emission (sound power) levels and are not necessarily safe working levels. Whilst there is a correlation between the emission and exposure

levels, this can not be used reliably to determine whether or not further precautions are required.

Factors that influence the actual level of exposure to the work-force include the characteristics of the work room, the other sources of noise, the number of machines and

other adjacent processes, and the length of time for which an operator is exposed to the noise. Also the permissible exposure level can vary between regions. This information,

however, will allow the user of the machine to make a better evaluation of the hazard and risk.

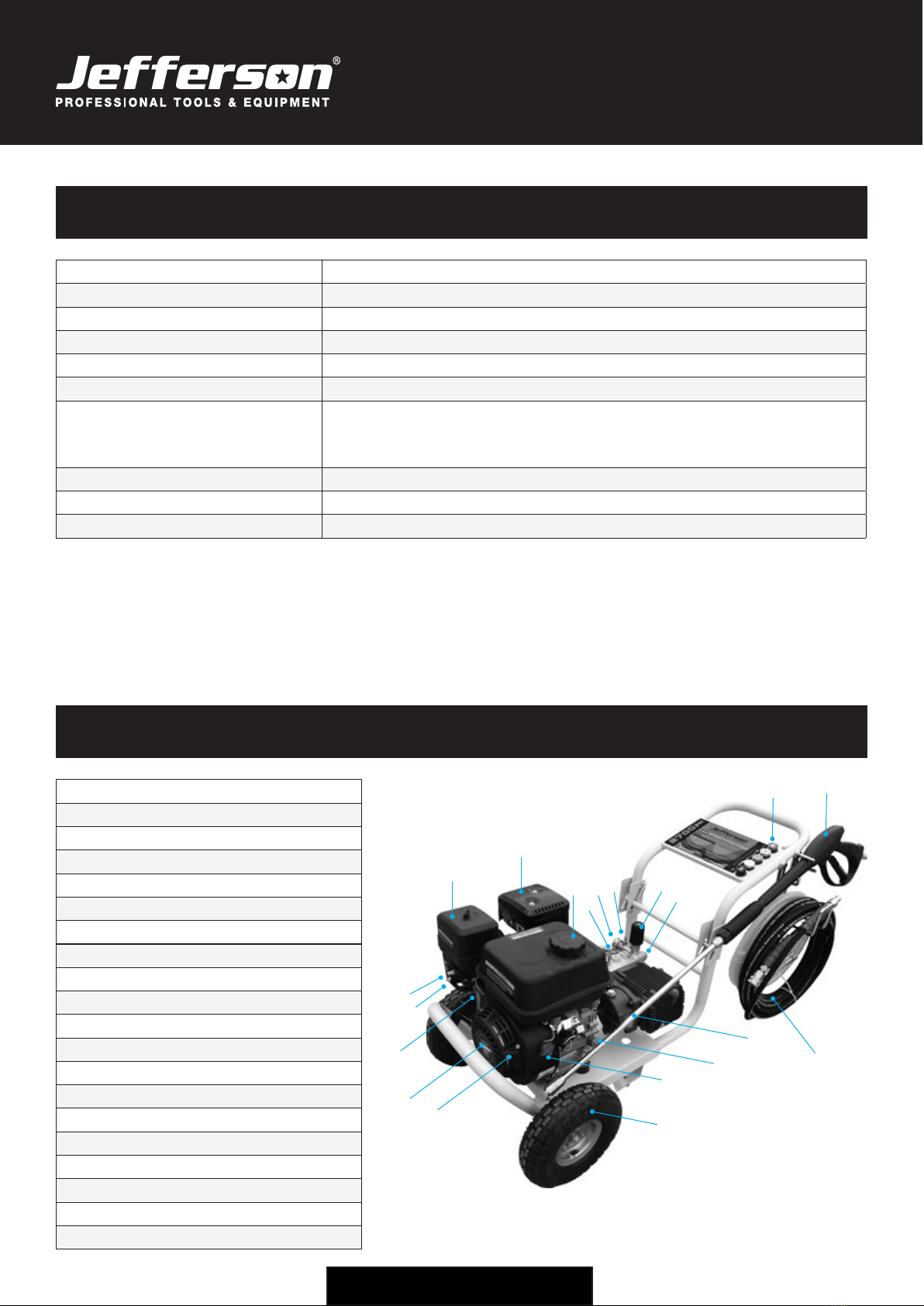

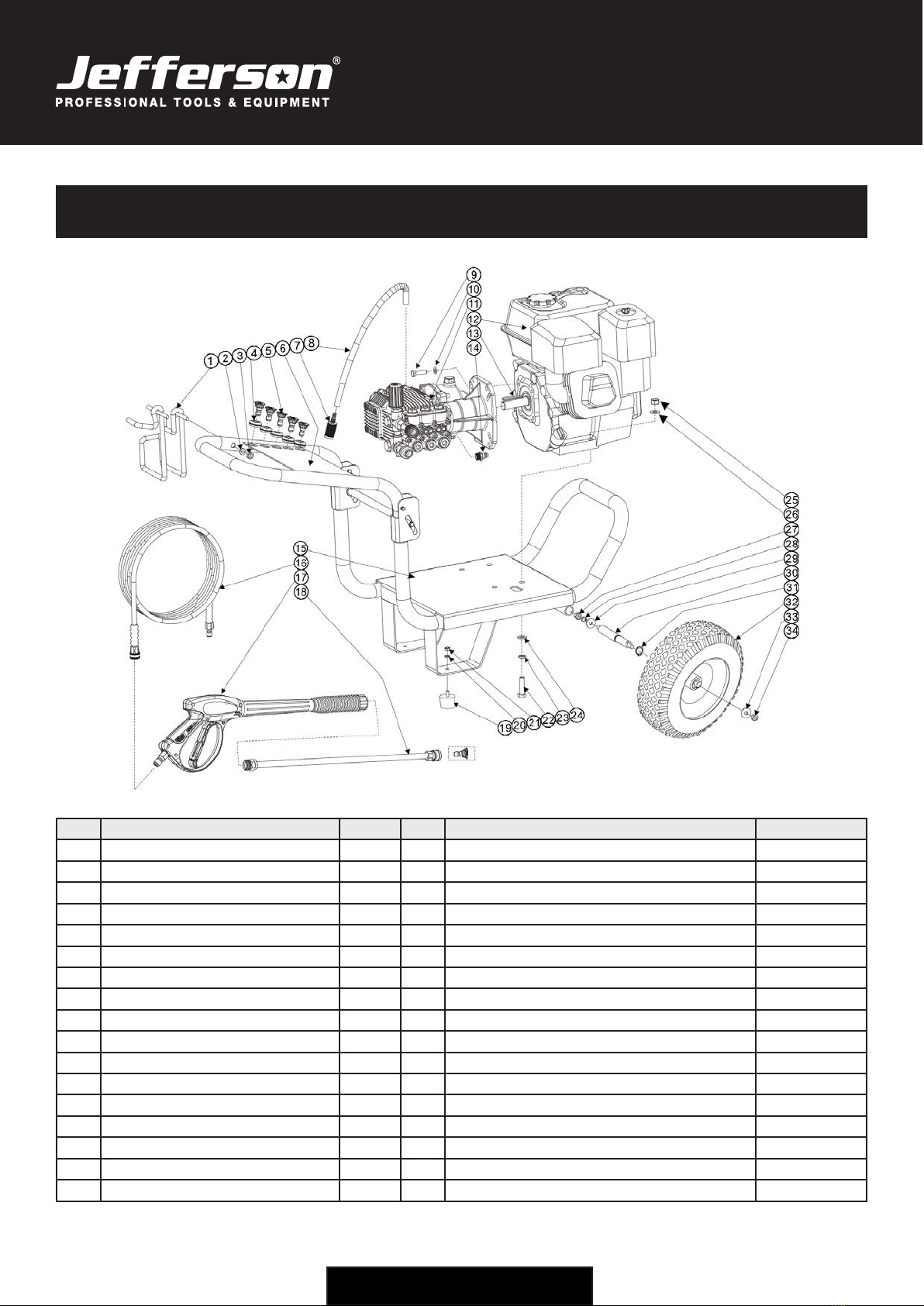

EQUIPMENT IDENTIFICATION

1. Recoil Starter

2. 6.5HP Loncin Engine

3. Throttle Lever

4. Fuel Valve Lever

5. Choke Lever

6. Air Filter

7. Mufer

8. Fuel Cap / Fuel Tank

9. Brass Pump

10. Water Outlet

11. Detergent Injector

12. Pressure Adjustment

13. Water Inlet & Filter Screen

14. Cleaning Nozzles

15. Spray Gun

16. High Pressure Hose

17. Lance

18. Engine Oil Reservoir Cap

19. Ignition Switch

20. Wheels

1

2

3

4

5

6

7

8

9

10 11 1213

14 15

16

17

18

19

20

5

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

SAFETY GUIDELINES

Please read and ensure that you understand all of the operating instructions, safety

precautions and warnings in this Instruction Manual before operating or maintaining this

equipment. An accident can often be avoided by recognizing a potentially hazardous

situation before it occurs, and by observing the appropriate safety procedures. Hazards

that must be avoided to prevent bodily injury or machine damage are identied by warnings

on the equipment and in this Instruction Manual. Never use this equipment or modify it in

any way that has not been specically recommended by the manufacturer.

Risk of Explosion or Fire

Important: Petrol and its vapours are extremely flammable and explosive. Fire or explosion can cause severe burns

and injuries. Please follow the following guidelines:

• Always shut off the engine and allow it to cool before adding fuel to the tank.

• Always use care when lling the tank to avoid spilling fuel. Move the pressure washer away from the fuelling area

before starting the engine.

• Always operate and fuel the equipment in well-ventilated areas free from obstructions. Ensure that the work area

is equipped with re extinguishers suitable for petrol res

• Never operate the pressure washer in an area containing dry brush or weeds

• Always keep the pressure washer a minimum of four feet away from surfaces that could be damaged by mufer

exhaust heat (for example houses, cars, plants etc.)

• Always store fuel in an OSHA approved container in a secure location away from the work area

• Never spray ammable liquids.

Dangerous Fumes - Breathing Hazard

Important: Running the petrol engine gives off carbon monoxide which is an odourless, poisonous gas. Breathing

carbon monoxide can cause nausea, fainting or death. Some chemicals or detergents may be harmful if inhaled or

ingested, seek medical advice immediately in the event of breathing any toxic fumes

• Always operate this equipment in a

well-ventilated work environment (avoid

enclosed areas such as garages and

basements etc.)

• Prevent exhaust fumes from entering

into conned areas (for example: through

windows doors, ventilation etc.)

• Do not operate near children or animals

• Only use uids and detergents

recommended by your supplier that are

suitable for high pressure washers

• Always follow the manufacturers

recommendations, wear a respirator or

mask whenever there is a chance that toxic

vapours can be inhaled

• Never use chlorine bleach or any other

corrosive compound with this equipment

6

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

SAFETY GUIDELINES

This equipment should only be operated by qualified and

responsible individuals who have read and understood

the information and guidelines described in this

document. In particular, the following safety instructions

should be followed to reduce the risk of injury to the

operator and members of the public.

1. Ensure that all the necessary safety precautions are

observed for the handling of fuel.

2. Familiarise yourself with this equipment and its

operation before use - read this user manual

carefully before use. Save for future reference.

3. This appliance is for outdoor use only. Ensure that all

bystanders are kept at a safe distance and that animals

and children are kept from the work area. Ensure that the

exhaust emissions are kept away from air intakes.

4. Never use this equipment if any part or accessory is

damaged or malfunctioning.

5. This appliance has been designed for use with

detergents specified by the manufacturer. Please

consult the manufacturer or supplier for advise before

using other detergents or chemicals in order to prevent

damage to the equipment and the environment.

6. Do not direct the nozzle towards mechanical parts

containing lubricant grease. High pressure jet can be

harmful and dangerous always ensure a safe working

distance when spraying objects and assess and fix the

appropriate nozzle for the job at hand.

Never point the high pressure hose directly

at people animals, live electrical parts or the

appliance itself.

7. Do not step or stand on the high pressure hose

and ensure that the hose is clean, free from debris,

obstructions and kinks before use. Always unwind the

hose fully before use.

8. Check and ensure that the nozzle has been fitted

correctly before use as the high pressure can result in the

nozzle being "fired" from the lance with

considerable force if not fitted correctly.

9. Beware of kick-back force and the sudden torque on

the spray gun assembly when operating the trigger.

10. Ensure that you have evaluated the pressure

required for the job at hand and selected the appropriate

nozzle before use. High pressure jets can remove paint

and other specialised surface treatments (including alloy

wheel lacquer). High pressure jets may also breakdown

and remove the grouting between paving slabs and can

even damage tarmac.

11. Always shut the equipment off completely when not

in use and if left unattended.

12. Keep the hose clear from the engine exhaust as this

can be extremely hot before and after use and can burn

and damage the hose.

13. Never refuel the engine when it is running, and allow

the engine to cool sufficiently before refuelling. Dry up

any fuel spillage before restarting the equipment. Only

use fresh clean high-quality fuel. Always restart the

equipment away from the refuelling area. Fill tank to

within 10mm of neck to allow space for fuel expansion.

14. Do not operate this equipment in an explosive

atmosphere, near combustible materials.

15. Only operate outdoors in well-ventilated areas.

16. Never run the engine without oil - always check for

oil and refill where necessary before use.

17. Only Jefferson approved engineers should carry

out repairs and maintenance on this equipment. Only

use Jefferson-approved replacement parts to repair

this equipment. Never modify the equipment in anyway.

Ensure that the equipment is kept in good working order

and cleaned and serviced regularly. Regularly check

external nuts and fixings to ensure that they have not

loosened from vibration during use.

18. After use: remove the spark plug ignition lead from

the back of the spark plug and position the lead to

prevent avoid accidental reconnection. Store in a clean

dry environment. Store all fuel in a suitable container

designed for petrochemical applications - away from

heat and out of direct sunlight.

7

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

UNPACKING & ASSEMBLY

This equipment requires assembly and some initial servicing (adding oil and fuel)

after unpacking.

1. Unpack the pressure washer:

Set the carton on a rigid at surface and remove all loose packaging, Leave the

pressure washer in the carton.

Warning: This equipment is heavy. Do not attempt to lift and remove

the petrol washer from the carton without assistance.

Using a safety knife or box cutter, open the carton completely by cutting down to

the four corners allowing the sides to fall at. Leave the equipment on the carton

to provide a clean working surface to t the wheel and rubber leg bumpers.

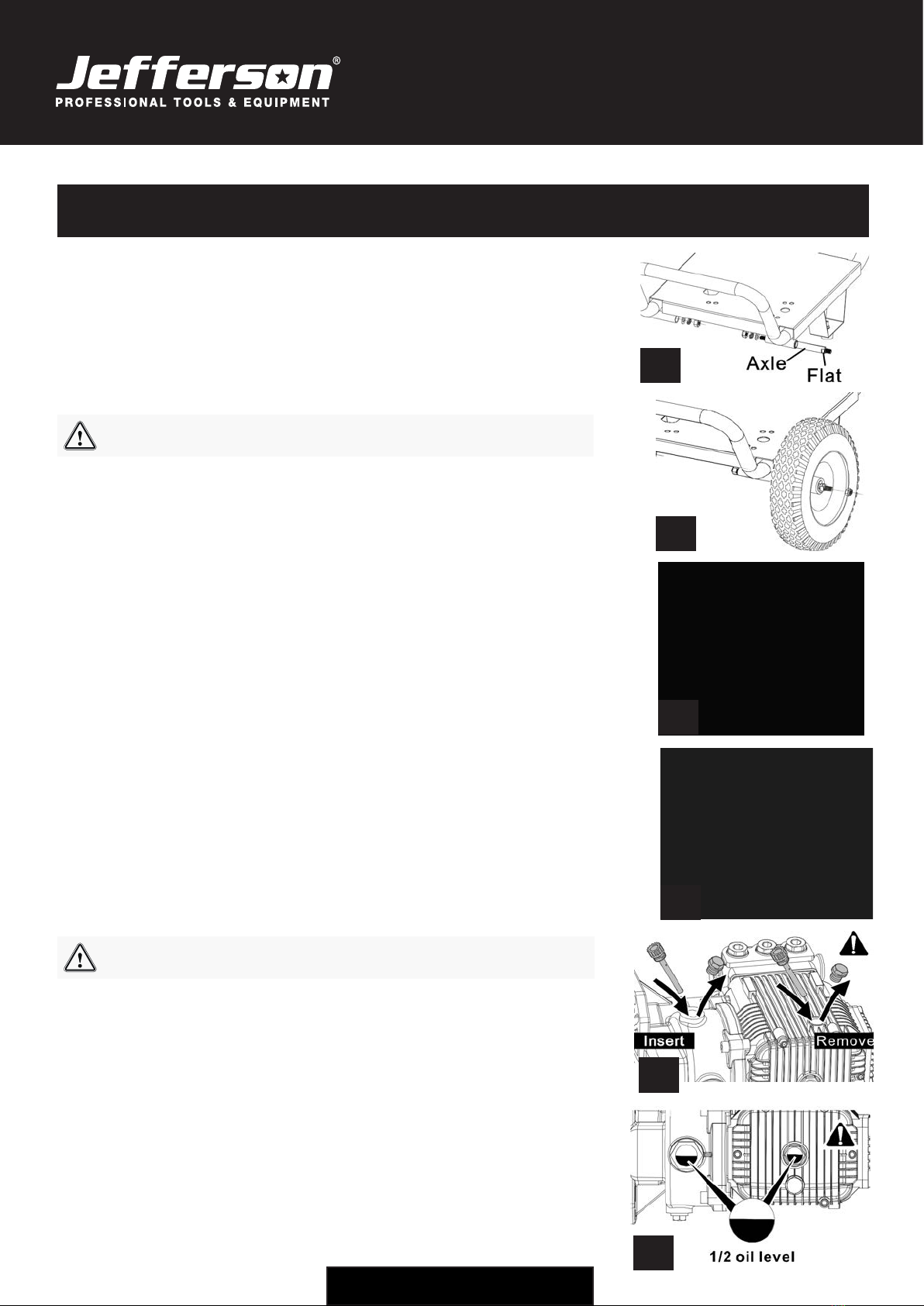

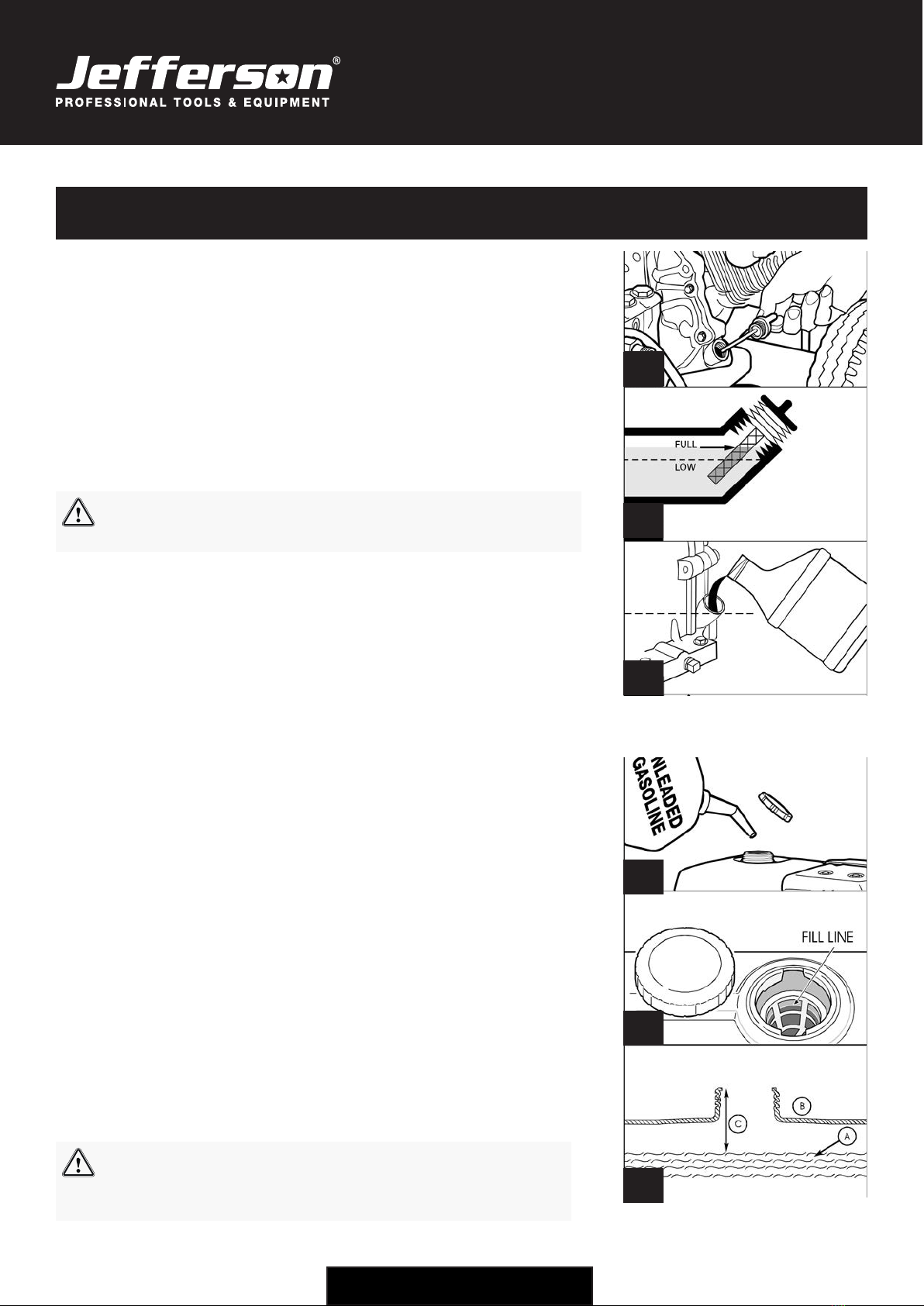

2. Wheel assembly:

Fit the axles into the axle ports as shown in Fig 1. Secure with the nut spring

washer and washer. Fit the wheels to the axles and secure with the nut and

washer Fig 2. (Note: Do not overtighten the nuts to allow the wheels to turn freely.)

3. Assemble the rubber feet:

Fit the rubber feet to the legs as shown in Fig 3.

4. Assemble the gun/hose hook:

Fit the hook into the position shown in Fig 4.

5. Prepare the pressure pump and gearbox:

The pressure pump and gearbox are packed with a shipping plug inserted into

the opening for the pump breather plug. It is important that the shipping plug is

removed and replaced with the dipstick / oil plug to prevent damage to the pump.

Warning: Failure to remove the shipping plugs could void the

warranty for this equipment.

Using a 17mm open-end spanner carefully remove the shipping plugs from the

pressure pump and gearbox. Discard the shipping plug. (See Fig 5.) Remove the

breather plug from the parts bag and insert it into the oil/dipstick socket. Tighten

securely by hand to prevent any damage to the threads.

6. Check/fill Oil:

Use the sight glass on the end of the pump and gearbox to ensure oil level is at

1/2 the level of the sight glass. (See Fig. 6). Use SAE 10W30 oil for gearbox and

pump (capacities are shown in the specication table on Page 4.

Note: Outdoor temperatures can determine the proper oil viscosity

1.

2.

3.

4.

5.

6.

8

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

UNPACKING & ASSEMBLY

1. Adding Engine Oil:

1. Place the assembled pressure washer on a at, level surface.

2. Clean the area around the oil ll and remove oil ll cap.

3. Using an oil funnel slowly pour the oil into the oil ll to the required

level. (See Fig 7.1 - 7.3).

Use SAE 10W30 grade oil to ll the engine oil resevoir (capacities are

shown in the specication table on Page 4.

Important: Never attempt to start the engine before oil has been

checked and added. Failure to do so can result in engine failure

and could void your warranty.

2. Adding Fuel:

Do not use any unapproved petrol types (for example E85 85% ethanol

15% petrol) - speak to your nearest Jefferson dealer for advice on the

best unleaded petrol to use if you are unsure.

Do not mix oil with petrol.

Do not modify the engine to run on alternative fuels.

Mix in a fuel stabilizer when adding fuel to the pressure washer to

protect the fuel system from forming deposits. If the engine does not run

properly please check that you are using the correct type of fuel. The

engine is certied to run on petrol. The emission control system for this

engine is EM (Engine Modications).

1. Turn the pressure washer Off and let it cool for at least two minutes

before removing the fuel cap. Loosen the fuel cap slowly to release the

pressure.

2. Always ll the fuel tank outdoors in good ventilation.

3. Do not overll the fuel tank (See Fig 8.2).

4. Wait for spilled fuel to evaporate before cranking the engine.

5. Keep fuel away from sparks, open ames, pilot lights, heat and other

ignition sources.

6. Clean the area around the fuel cap and slowly remove the cap to allow

any pressure to escape.

7. (See Fig 8.3) Slowly add the unleaded petrol (A) to the fuel tank

(B). Use extreme caution not to ll fuel above the bafe (C) to allow

appropriate space for fuel expansion.

8. Replace the fuel caps and allow any spilled fuel to evaporate before

starting the engine.

Important: Fuel and fuel vapour are extremely flammable and

potentially explosive. Take care to follow the following safety

precautions when refuelling. Failure to use fuel as recommended

in this manual can void your warranty.

4.

7.2

7.1

7.3

8.1

8.2

8.3

9

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

EQUIPMENT SETUP

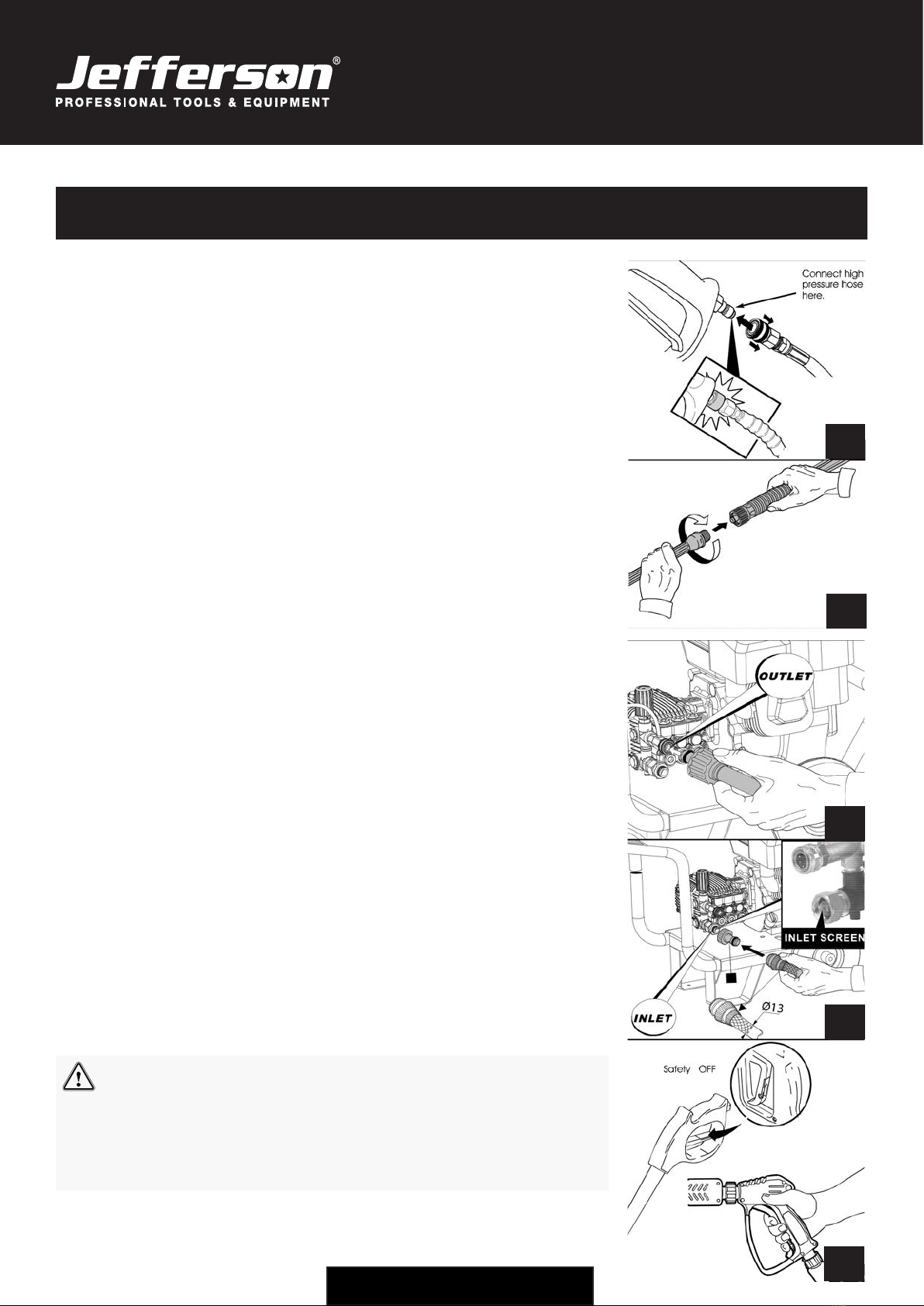

1. Attaching the Spray Gun to the High Pressure Hose:

• Pull the slip ring on the female quick-disconnect tting back on the high

pressure hose (See Fig 9).

• Insert the male quick-tting on the spray gun into the female socket on the

high pressure hose.

• Release the slip ring on the female disconnect and twist. Listen for a

"click" to ensure both of the quick ttings have been coupled correctly

• Pull the high pressure hose and spray gun in opposite directions to ensure

that they do not separate under pressure.

2. Connecting the Spray Lance to the Spray Gun:

• Thread the spray lance on to the spray gun until secure (See Fig 10)

3. Connect the Hose and Water Supply to the Pump

Attach the other end of the high pressure hose to the high pressure outlet on

the pump. Pull down on the collar of the quick release tting and slide onto the

pump and let go of the collar.

Pull on the hose to ensure of a tight connection. (See Fig 11.)

Before connecting the hose to the water supply ensure that the lter screen is

clean and remove any dirt or debris found.

Replace the lter if it is damaged. (See Fig 12). Connect to the supply.

Run water through the hose for 30 seconds to remove any dirt before

connecting.

Important: Do not syphon any standing water to use for the water supply. Use

only cold running water from mains supply (no more than 100°F)

Connect the hose (it should not exceed 50ft in length) to the water inlet on the

pressure washer. Tighten by hand until secure.

Turn on the water. Squeeze the trigger to purge the pump system of air an

impurities. (See Fig 13).

Warning: Do not attempt to crank or start the engine before it has

been properly serviced with the recommended oil. This can lead to

engine failure and void your warranty.

Note: There must be at least 10ft (3m) of unrestricted hose between

the washer inlet and any fittings such as a vacuum breaker or check

valve.

9.

10.

11.

12.

13.

10

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

SAFE WORKING ENVIRONMENT

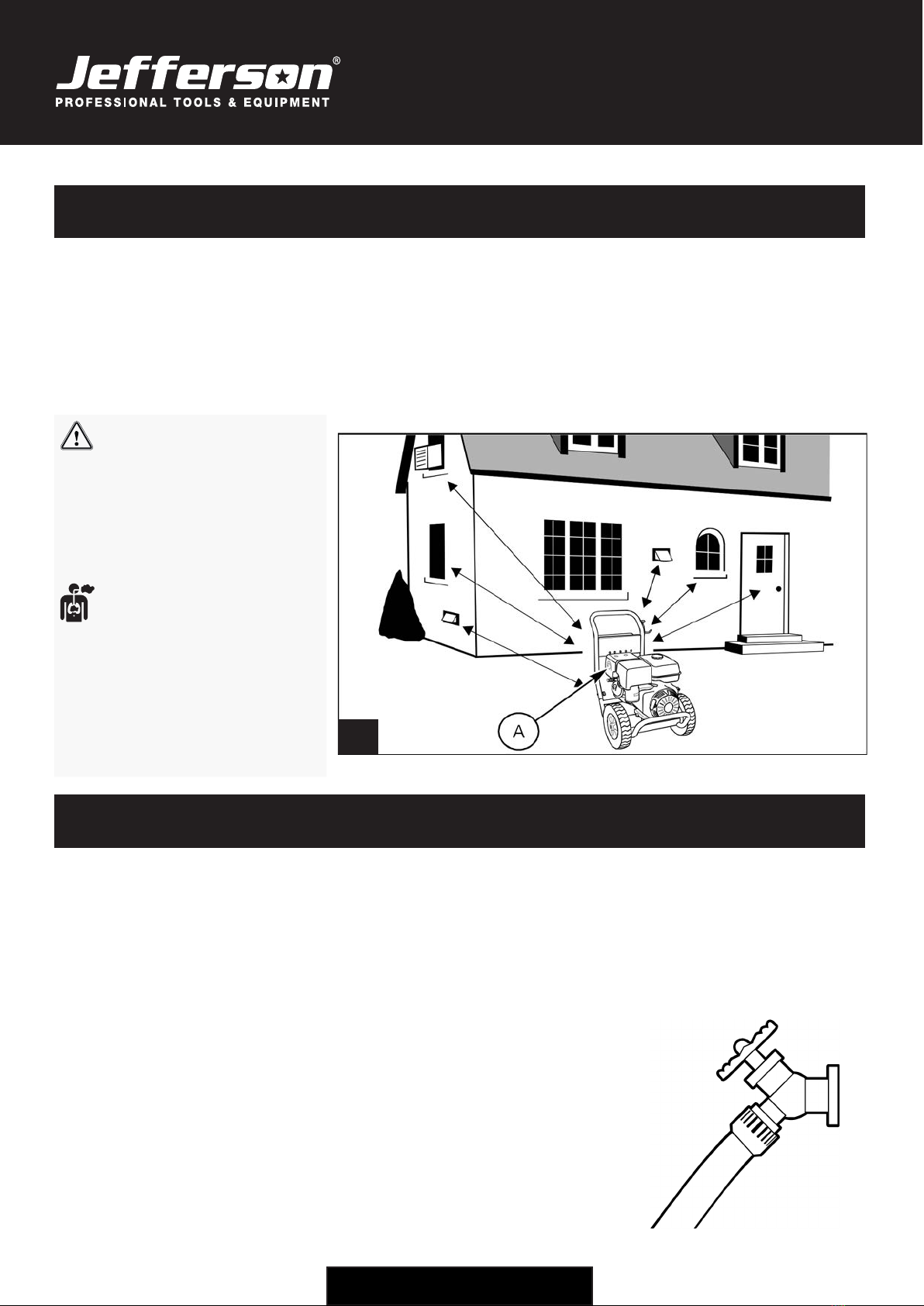

Set up the pressure washer in a well-ventilated area to prevent build up of carbon monoxide and other toxic fumes.

Do not use the pressure washer in an environment where exhaust gas can accumulate and enter or be drawn into an

occupied building or a conned area (for example via windows or other ventilation.)

Care should be taken to observe prevailing winds and air currents that could divert the fumes into occupied buildings

or conned areas. (See Fig 14).

Warning: Exhaust heat/gases

can ignite combustibles.

structures or damage

the fuel tank causing a fire

hazard. Ensure that you keep

at least 5ft (1.5m) of clearance

on all sides of the pressure

washer including overhead.)

Warning: Running the petrol

engine gives off carbon

monoxide which is an

odourless, poisonous gas.

Breathing carbon monoxide

can cause nausea, fainting

or death. Seek medical advice

immediately in the event of

breathing any toxic fumes.

STARTUP PROCEDURE

To start your pressure washer for the rst time, follow these instructions step-by-step. This starting information also

applies if you have not used the washer on a regular basis.

1. Place the pressure washer near an outside water source capable of supplying water at a ow rate of at least 5

gallons per minute and no less than 20psi at the pressure washer end of the garden hose.

2. Check that the high pressure hose is securely connected to the spray gun and pump

3. Make sure the unit is sitting in a level position.

4. Uncoil the high pressure hose completely before using the pressure washer.

5. Connect the garden hose to the water inlet on the pressure washer pump.

14.

11

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

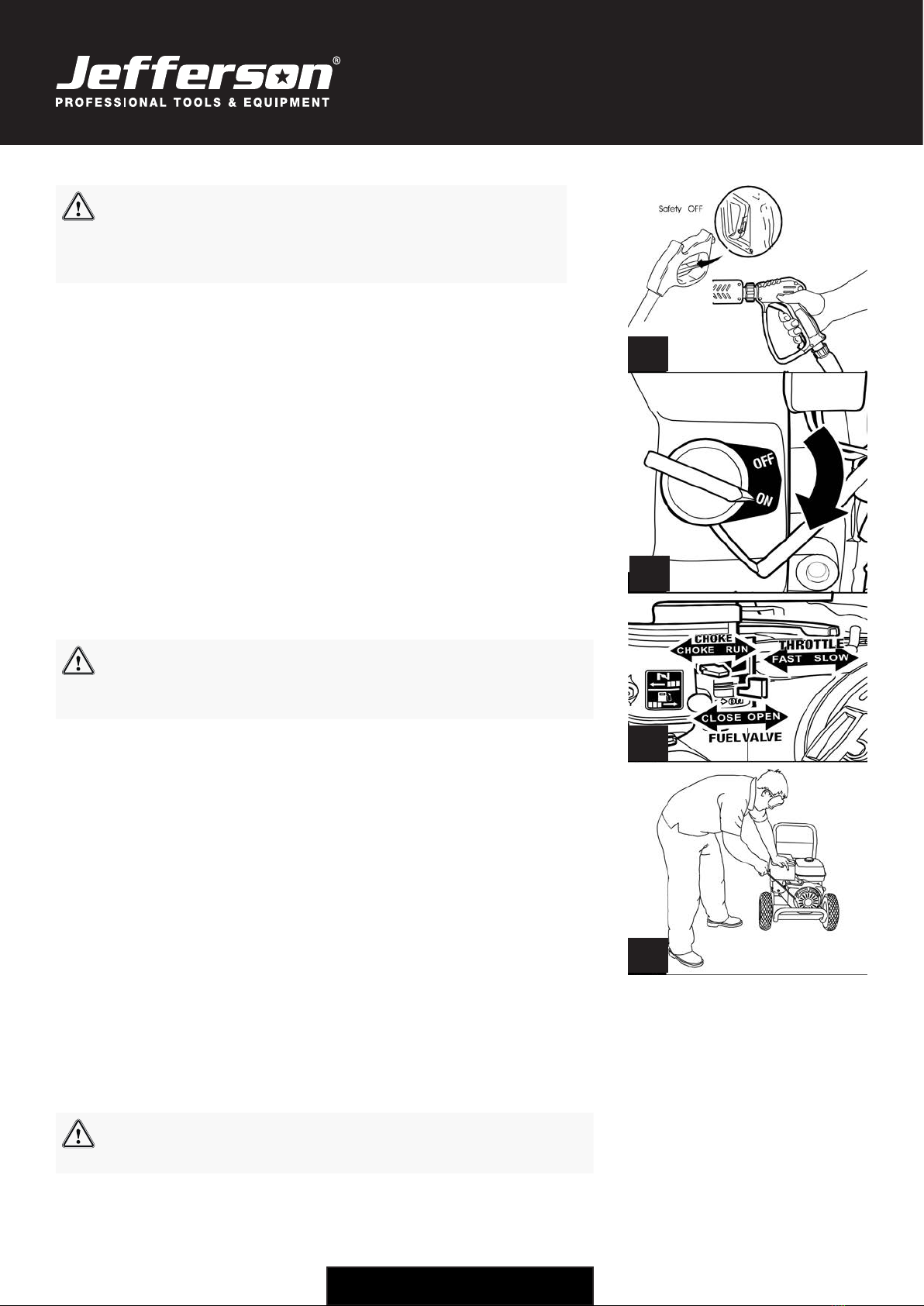

Warning: Do not run the pump without the water supply

connected and turned on.

Please Note: Any damage resulting from failure to follow this

instruction will void the warranty on this equipment.

6. Turn on the water, point the gun in a safe direction and squeeze the

trigger to purge the pump system of air and impurities (See Fig 15.).

7. Attach the lance to the spray gun and tighten by hand until secure.

8. Choose the nozzle you require for the job at hand, pull back the collar

on the quick tting, insert the nozzle and release the collar to connect.

Tug on the nozzle to make sure it is securely connected.

9. Turn the fuel shut off valve to the "On" position. (See Fig 16.)

10. Move the throttle control lever to the "High" position (indicated by

the rabbit icon on the engine). (See Fig 17.)

11. Move the choke lever to the "Choke" position (See Fig 17.)

Note: For warm engines ensure that the choke is in the "Run" position.

Warning: Before starting the pressure washer be sure you are

wearing the appropriate Personal Protection Equipment (PPE) for the

job at hand. Safety goggles should always be worn when using this

pressure washer.

12. When starting the engine, position yourself as shown in Fig 18. Grip

the starter handle and pull slowly until you feel some resistance. Then

pull rapidly to start the engine.

13. Return the starter grip handle slowly. Do not allow the starter cord to

"snap back" against the starter.

14. When the engine starts, slowly move the choke lever to the "Run"

position as the engine warms up. If the engine falters during this step,

move it back to the "Choke" position, then back to the "Run" position.

15. If the engine fails to start, point the spray gun in a safe direction and

squeeze the trigger to release any pressure.

16. If the engine fails to start after 6 attempts, move the choke lever to

the "Run" position and repeat steps 13-15.

Important: Allow the engine to run at no load, low pressure for at least 5

minutes after each startup.

Warning: The spray gun retains high water pressure even when

the engine is stopped and disconnected. Aways discharge this by

squeezing the trigger on the spray gun, pointing in a safe direction.

15.

16.

17.

18.

12

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

STOPPING THE PRESSURE WASHER

1. Release the spray gun trigger and let the engine idle for two minutes.

2. Move the throttle control lever to the "Stop" position.

3. Always point the spray gun in a safe direction press the red button

and squeeze the spray gun trigger to release the retained high water

pressure.

4. When the engine starts, slowly move the choke lever to the "Run"

position as the engine warms up. If the engine falters during this step,

move it back to the "Choke" position, then back to the "Run" position.

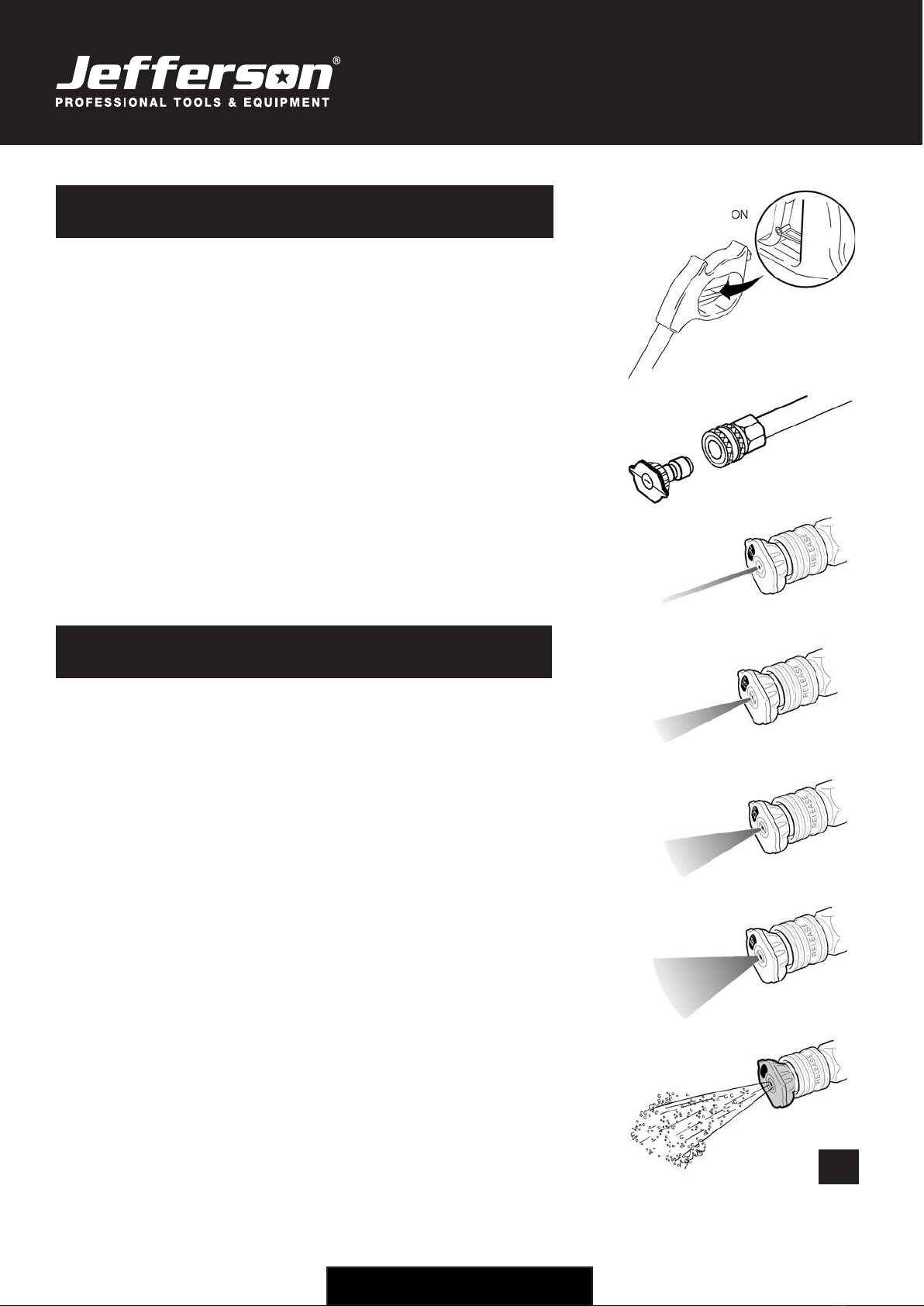

This equipment comes complete with ve different colour-coded spray

nozzles. Each nozzle delivers a specic spraying pattern for a particular

cleaning

application (see Fig 19).

The size of the nozzle determines the size of the spray jet and the pres-

sure delivered from the nozzle.

SPRAY NOZZLES

Nozzle Size Guide:

0º Nozzle - Red: This nozzle delivers a pinpoint stream of pressurised

water and is extremely powerful. It only covers a small cleaning area.

This nozzle should only be directed at surfaces that can withstand high

pressure such as metal or concrete. Do not use this nozzle to clean

wood.

15º Nozzle - Yellow: This nozzle delivers a powerful 15 degree spray

pattern for intense cleaning of small areas. This nozzle should only be

used on areas and materials capable of withstanding high pressure.

25º Nozzle - Green: This nozzle delivers a 25 degree spray for a medium

intensity cleaning over larger areas.

40º Nozzle - White: This nozzle delivers a 40 degree spray for low

pressure cleaning over large areas. This is the ideal nozzle for general

cleaning purposes.

Chemical Nozzle - Black: This nozzle is used to apply special

chemicals and cleaning solutions. This nozzle produces the weakest

pressure stream of the 5 nozzles.

The pressure washer nozzles are stored in receptacles on the nozzle

panel with colour coded guides to indicate which nozzle goes where. 19.

13

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

Attaching Pressure Nozzles to the Spray Gun

1. Pull the slip ring on the female quick-tting on the lance backwards.

2. Insert the male quick tting on the pressure nozzle into the female tting on the spray lance.

3. Release the slip ring on the female quick tting and twist. Listen for the "click" to ensure that the ttings are

coupled securely.

4. Pull the high pressure nozzle and spray lance in opposite directions to ensure that they do not separate under

pressure.

Note: In order to prevent damage to your cleaning surface and to select an appropriate nozzle size for your

application always start with the lowest pressure nozzle size (white) and continue changing to a higher nozzle size until

the correct nozzle and pressure is identified for your task.

Warning: This equipment operates at fluid pressures and velocities high enough to penetrate human flesh.

Leaks caused by loose fittings or worn or damaged hoses can result in injection injuries. Do not direct

the spray jet towards people or animals as the jet is very powerful and serious injury can occur. Wear the

appropriate safety equipment when operating this equipment.

Do not attempt to change the nozzles when the equipment is running. Always shut down the

engine completely before changing the nozzles.

ADJUSTING SPRAY PRESSURE

As well as adjusting the spray pressure using the various nozzles

shipped with this equipment you can control the pressure on the washer

itself by turning the pressure control knob.

Turn the knob clockwise to increase the pressure and counterclockwise

to decrease it (See Fig 20).

USING CHEMICALS & DETERGENTS

Note: Only use chemicals & detergents that are suitable for use with this product and that have been approved by

Jefferson Tools. Some domestic detergents, acids, alkalines, bleaches, solvents, flammable materials or industrial

grade cleaning solutions can cause damage to the pump. Please check with your nearest Jefferson dealer for advice

if you are unsure before using chemicals and detergents with this equipment. Some detergents may require mixing

before use. Prepare the cleaning solution as instructed by the manufacturers instructions before use.

Set Up Procedure:

1. Attach the chemical hose onto the barbed tting situated near the

back of the high pressure hose connection. (See Fig 21).

2. Press the other end of the chemical hose (with the lter attached) into

the container holding the chemicals or detergents you are using.

3. Attach the chemical nozzle onto the lance as shown previously (See

Fig 22).

20.

21.

14

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

USING CHEMICALS & DETERGENTS

Chemical Cleaning:

Spray the chemicals onto a dry surface using the procedures outlined

in previous sections. Start at the lower portion of the cleaning area and

working upwards, using long, even, overlapping strokes. (See Fig 23.).

Always ensure that the lter is fully submerged in the cleaning solution at

all times.

Allow the detergent to soak in for 3-5 minutes before washing and

rinsing.

Re-apply as needed to prevent the surface from drying. Do not allow the

detergent to dry on to the cleaning surface to prevent streaking.

Note: Detergent cannot be applied with the high pressure spray tips

(white, green, yellow or red)

After Chemical Cleaning:

Important: You will need to flush the detergent siphoning system after each use by placing the filter into a bucket of

clean water then run the pressure washer in low pressure for 1-2 minutes.

After using chemicals, soaps and detergents it is necessary to thoroughly clean the pressure washer.

Place the chemical hose in a container of clean water.

Turn on the pressure washer and hold the trigger on the spray gun top draw clean water through the system to clean

it thoroughly.

MAINTENANCE

To ensure efficient operation and longer life of your pressure washer a routine maintenance schedule should be

prepared and followed. If the equipment is used in unusual conditions such as high-temperature or dusty conditions

more frequent maintenance checks will be required.

Warning: Before performing any maintenance be aware that the equipment should be completely shutdown,

depressurised and allowed to cool down. This will ensure that no injuries can be sustained by moving parts,

water pressure or hot surfaces.

The fuel tank contains flammable fuel do not smoke near or work near naked flames while

maintaining this equipment.

Please note: All repairs should be carried out by Jefferson approved engineers. All replacement parts

should be supplied or recommended by Jefferson. Any unapproved repairs or modifications will

invalidate the warranty.

22.

23.

15

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

Engine:

Check the engine regularly, replace oil, clean spark plugs and maintain parts as required.

Pump Oil:

Change the pump oil regularly. Change the pump oil after the first 50 hours of work and successively every 100

hours. In either case ensure that the oil is changed at least once a year.

Check with your nearest Jefferson dealer for advice on the best Pump Oil to use with this

equipment if you are unsure.

The water filter should be checked regularly and cleaned if necessary:

1. Remove the filter by grasping the end and removing it from the water inlet on the pump.

2. Clean the filter by flushing it with water on both sides.

3. Re-insert the filter in the water inlet on the pump.

Spray Gun:

If the nozzle becomes clogged with dirt and debris excessive pressure can build up. If the nozzle becomes partially

clogged or restricted the pump pressure will fluctuate and can become harmful and dangerous.

Clean the nozzle immediately and follow these instructions:

1. Shut-off the engine and turn off / disconnect the water supply.

2. Pull the trigger on the gun to relieve any water pressure.

3. Disconnect the lance from the gun.

4. Remove the nozzle from the lance - remove any obstructions with the nozzle cleaning tool provided and back

flush with clean water.

5. Direct the water supply into the spray wand end to back flush loosened particles for 30 seconds.

6. Reassemble the nozzle onto the lance.

7. Reconnect the lance to the gun and turn on the water supply.

8. Start the washer pump and place the lance into the high pressure setting to test.

Cleaning The Water Filter:

The water filter should be checked regularly and cleaned if

necessary:

1. Remove the filter by grasping the end and removing it

from the water inlet on the pump.

2. Clean the filter by flushing it with water on both sides.

3. Re-insert the filter in the water inlet on the pump.

Cleaning the Fuel Tank Filter:

The fuel tank filter should be removed and cleaned after

every 150 hours of running or every 3 months using an

environmentally-friendly water-based de-greasing agent.

Refit when clean.

16

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

MAINTENANCE

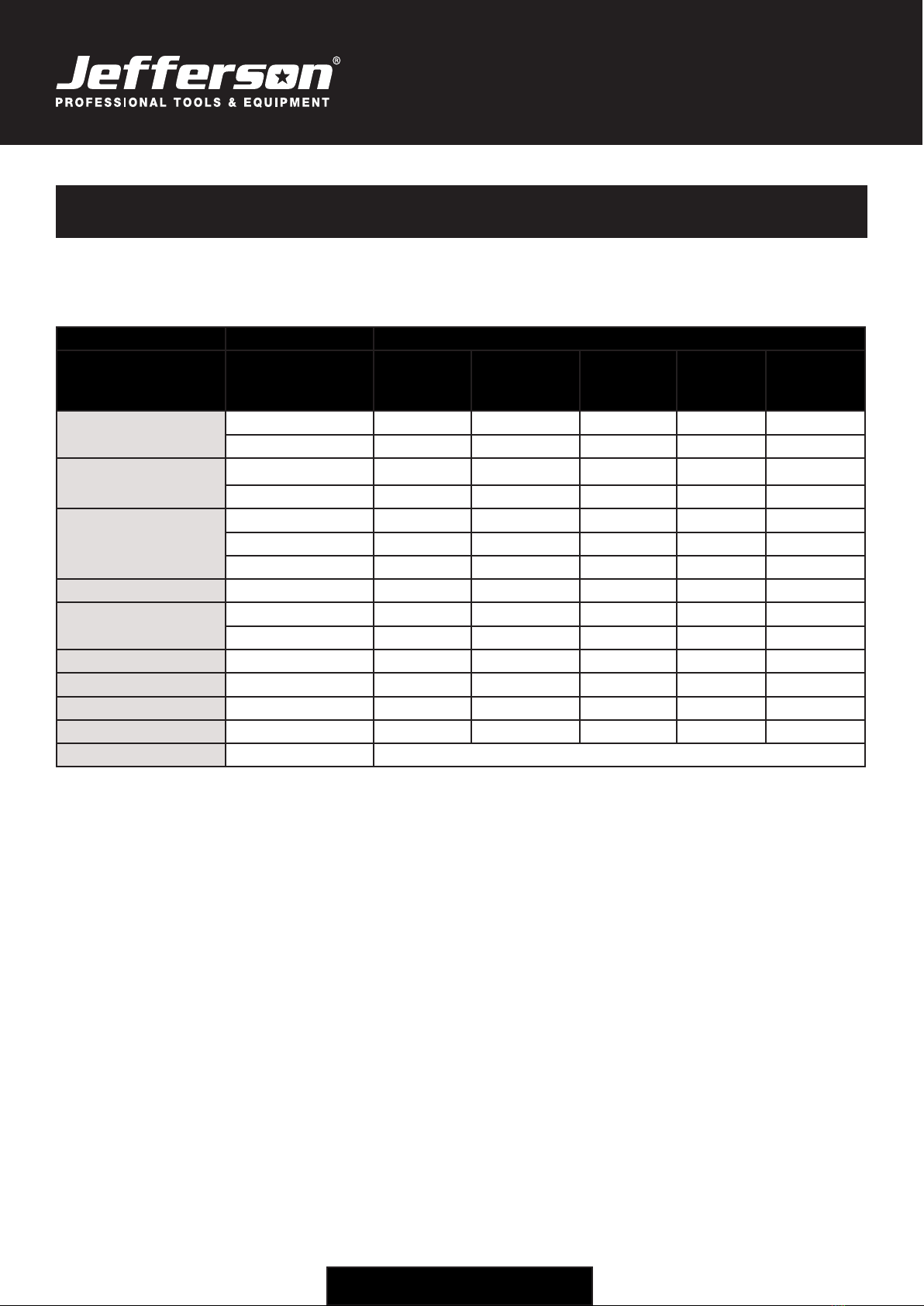

Maintenance Schedule:

Frequency

Item Task Description Each Use 1st Month

(20Hrs)

Each Season

(50Hrs)

Every

6 Months

(100Hrs)

Every

Year

(300Hrs)

Engine Oil Oil Level Check •

Replace • •

Reduction gear oil Oil Level Check •

Replace • •

Air Cleaner

Check •

Clean •x •x*

Replace •**

Deposit Cup Clean •

Spark Plug Clean, adjust •

Replace •

Spark Eliminator Clean •

Idling Check, Adjust •∆

Valve Clearance Check, Adjust •∆

Fuel Tank & Filter Clean •∆

Fuel Supply Line Check Check with your Jefferson dealer for advice if any problems are detected

Key:

* = Only for inside ventilating double core Carburetors

** = Only for paper core cleaners

x = Repeat task more often than scheduled if equipment is used in dusty working environments

∆ = Maintenance to be carried out by Jefferson approved technician

17

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

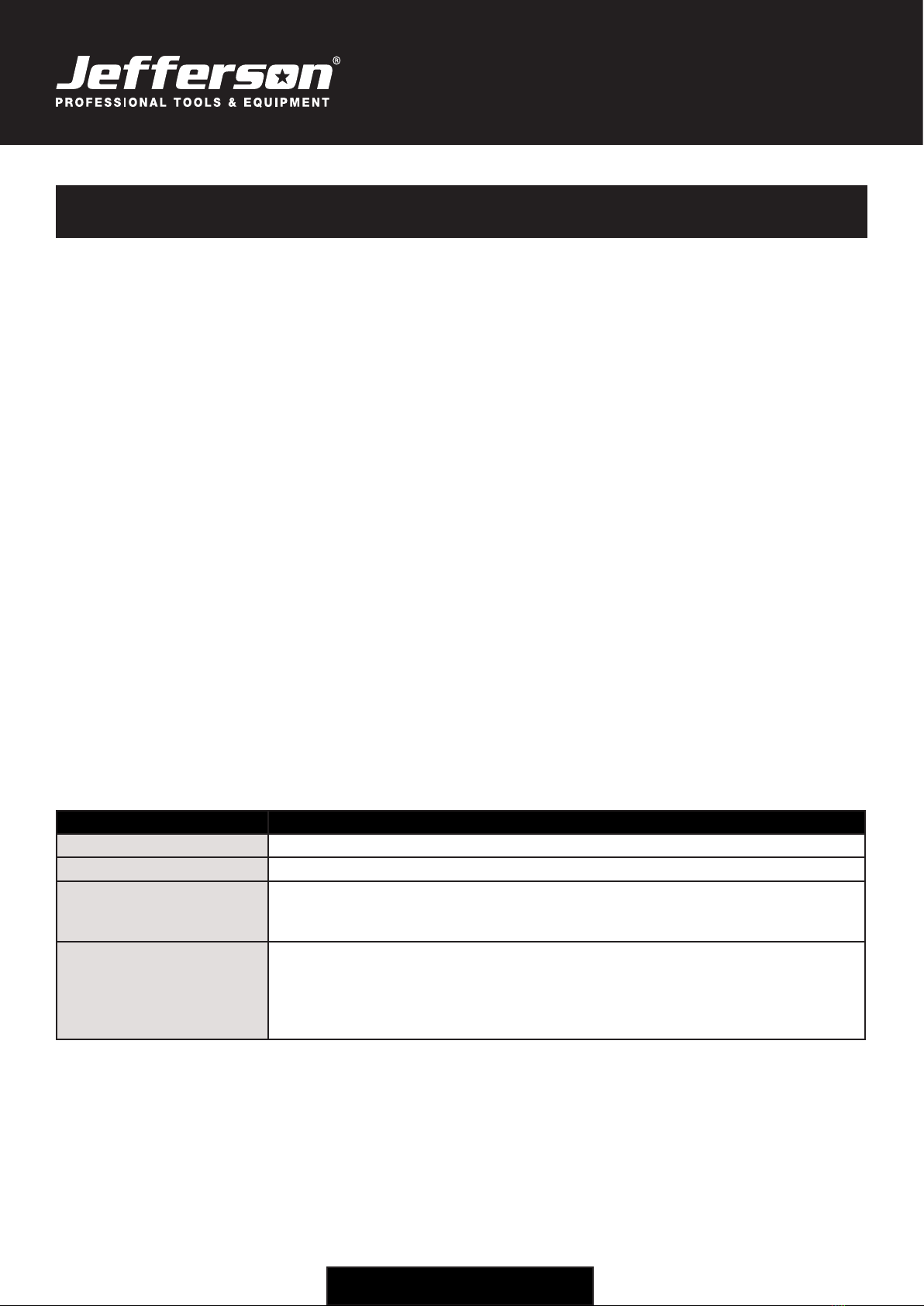

STORAGE

After General / Regular Use

1. Drain all water from the high pressure hose, coil it and hang on the cradle on the petrol washer frame. If chemicals

where used ensure the pump and chemical hose are thoroughly cleaned out.

2. Drain all the water from the gun and lance by holding the gun in a vertical position with the nozzle end

pointing down and squeeze the trigger. Store in the gun/hose holder.

Preparation for Winter and Long-term Storage

Note: It is recommended that you follow these steps to protect the internal seals of the pump when storing the

equipment for more than 30 days and or when, freezing temperatures are expected.

1. Obtain a funnel, 200ml of anitfreeze and approximately 1M of garden hose with a male hose connector

attached to one end.

2. Disconnect the spark plug wire.

3. Connect the hose to water inlet on the pump.

4. Pour the antifreeze into the hose via the funnel.

5. Pull the engine starter cord slowly several times until antifreeze comes out of the high pressure water hose

connection on the pump.

6. Remove the short hose from the water inlet on the pump.

7. Reconnect the spark plug wire.

Service After Storage

Before reusing the equipment after storage, you should carry out the following to keep the equipment in good

condition.

Storage Time Service Task

Within one month No service required

One - two months Drain out the existing fuel out of the fuel tank and fresh fuel

Two months - one year Drain out the existing fuel out of the fuel tank and fresh fuel

Drain the fuel out of the Carburetor*

Empty the deposit cup**

Over a year Drain out the original fuel of the fuel and refuel

Drain the fuel out of the Carburetor*

Empty the deposit cup**

Start the engine and allow to run for a few minutes

Key:

* = Unscrew the drain plug and drain out the fuel in the Carburetor

** = Turn engine switch to the off position, disconnect the deposit cup and empty contents safely

Note: Do not dump oil vessels or discarded engine oil onto the ground. Take all discarded engine oil in a closed

container to your nearest recycling station.

18

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

TROUBLESHOOTING

19

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

20

USER MANUAL v2.1

JEFWASPGRO65HP

6.5HP Gearbox Petrol Washer

www.jeffersontools.com

PRESSURE WASHER MAIN ASSEMBLY - PARTS LIST & DIAGRAM

# Description Qty # Description Qty

1Gun Holder and Hose Hook 1 18 Wand 1

2Plain Washer 1 19 Rubber Foot 2

3Fix Nut 1 20 Plain Washer 2

4Grommet 5 21 Fix Nut 2

5Nozzle Set 5 22 Engine Fixing Bolt 4

6Decal 1 23 Spring Washer 4

7 Filter 1 24 Plain Washer 4

8 Chemical Inlet Hose 1m 25 Fix Nut 4

9Pump Fixing Bolt 4 26 Spring Washer 4

10 Spring Washer 4 27 Axle Fix Nut 2

11 Pump Gear Reduction Assembly 1 28 Spring Washer 2

12 Engine 1 29 Plain Washer 2

13 Key 1 30 Axle 2

14 Thermal Protection Valve 1 31 Clip 2

15 Frame 1 32 Wheel 2

16 High Pressure Hose 10m 33 Plain Washer 2

17 Spray Gun 1 34 Wheel Fix Nut 2

Table of contents