Jegs 555-81752 User manual

1

10'' DISC SANDER

2

3

550W

4.2A

120V~60Hz

1750rpm

4

4

5

1

3 4 5

2

1 2

34

1 2 3

5

5

e

6

6

1

3

2

4

6

EN User manual

1 Introducon

Intended Use

This manual contains informaon and important instrucons

for the installaon and correct use of the Disc Sander (142009).

The sander disc is intended for the sanding of wood for non-

commercial woodworking acvies. The commercial name of

the device (see cover) is substuted with the name "machine"

in this manual.

Please read and follow the safety instrucons!

Before rst use, read this manual carefully. It will familiarise you

with the correct use of the product and prevent any

misunderstanding, and avoid any damage to the product and

the user's health.

2 Symbol claricaon

Disposal

Do not dispose of electrical appliances with your domesc

waste! According to the European Direcve 2012/19/EU,

concerning used electrical and electronic appliances and its

implementaon in naonal law, superannuated electrical

appliances must be collected and disposed of via an

environmentally suitable recycling facility.

See image 1

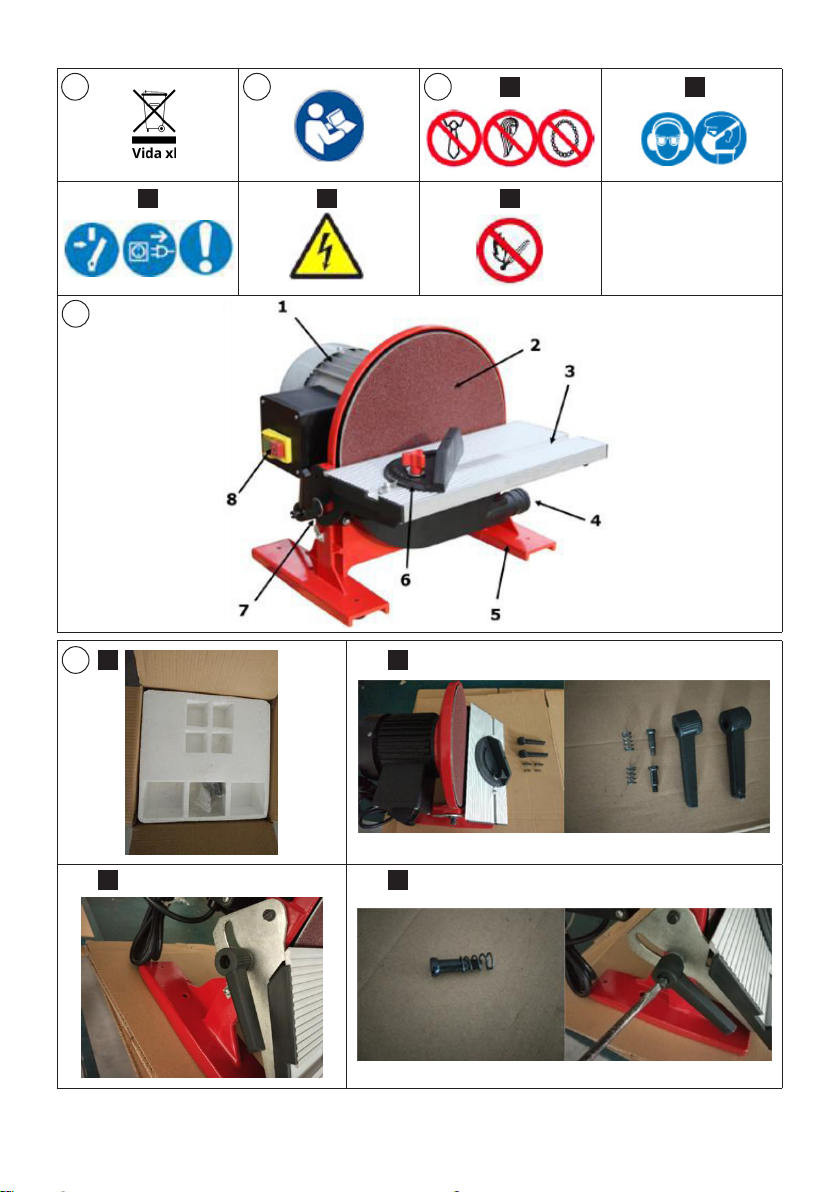

3 Parts list

See image 4

1Motor 5Base

2Sanding Disc 6Mitre gauge

3Work table 7Angle adjustment

4Dust collector connecon 8On-O-switch

4 Assembly instrucons

See image 5

1. Mounng and seng up. Ensure that the machine is

disconnected from the mains. Open the box.

2. Ensure that no parts are missing.

3. Fit locking handles on each side of the table.

4. Fasten the locking handle using the locking bolt and the

spring. Do not over ghten.

5. Set the table to a horizontal posion. Check the pointer to

the 0°scale, ghten both locking handles.

6. Mounng and seng up. Make sure that the machine is

disconnected from the mains socket. Fit the locking handles

on each side of the table using a washer, locking bolt,

locking handle, a spring and a screw through the angle

bracket underneath the table. Set the table in the horizontal

posion, ghten both locking handles. Secure the machine

to a rm surface using bolts (not included) through the four

mounng holes. The machine must be placed on the level

surface to avoid any vibraon during use.

5 Operaon Guide

Check if all parts according to the parts list are included and

without damage as soon as the machine is delivered/purchased.

Each visible defect and in parcular wrong amounts and

transport damages must be clearly noted on the delivery

documents. Otherwise, the goods shall be considered as taken

and fully accepted under the sole responsibility of the customer.

• Warning: Perform all machine sengs with the machine

disconnected from the power supply! Always use the

correct type of sandpaper disc according to the type of

work. Keep hands and tools clear of the sandpaper disc

when in use.

• Aenon: Please observe the following operang

instrucons so that their work can be performed safely and

has the expected results.

5.1 Noce

1. Check before starng work

• All cables and plugs.

• Table and safety fence on ght t.

• The free and centred run of the sanding disc.

2. The sanding

• Always use proper abrasives in working condion. (Change

worn down abrasives immediately!) With the abrasive in

good condion, you will obtain a good grinding result.

• Do not exert too much pressure on the sanding abrasive.

• The maximum distance between the table and the sanding

disc: 2mm!

• The machine has no clamping opportunity, so it is important

to steady the work-piece on the worktable and maintain a

rm grip!

The connecon of the machine to the electric power supply

and the following checks must be carried out by a trained

electrician only.

1) The electronic connecon of the machine is designated for

operaon with a grounded power socket.

2) The mains supply must be secured with a 16A circuit

breaker.

7

3) If the connector plug doesn't t or if it is defecve, only

qualied electricians may modify or replace it.

4) The grounding wire should be connected to green-yellow.

5) A damaged cable must be replaced immediately.

6) Aer connecng, check the correct running direcon.

7) Make sure that a possible extension cord is in good

condion and suitable for the transmission of power. An

undersized cord reduces the transmission of power and

heats up.

8) A damaged cable must be replaced immediately.

5.2 Operaon

See image 6

1. On/O

• To turn the machine ON, press "I" (green).

• To turn the machine OFF, press "O" (red).

2. Table

• To lt the worktable loosen the quick release, bring the

work table to the desired posion and ghten the quick

release again.

• Use a protractor to set it at exactly 90°.

3. Mitre gauge

• The metre gauge is provided for use on the grinding table.

• The metre gauge can be used for angles of up to 45°, to the

le or right, by releasing the locking buon and adjusng

the metre gauge to the desired angle. The buon must be

ghtened again.

4. Dust collecon connecon

• The machine is equipped with a dust collector plug with a

diameter of 35 mm.

• Always use a suitable dust collector (e.g., vacuum cleaner)!

6 Maintenance and cleaning

6Aenon: Don't clean or do maintenance on the

machine while it is sll connected to the power supply. The

machine may be damaged and injuries might occur due to

the unintended switching on of the machine! Therefore,

switch the machine OFF and disconnect it from the power

supply before any maintenance works or cleaning is carried

out.

The machine does not require extensive maintenance. If

malfuncons and defects occur, contact a qualied technician

only. Before the rst operaon as well as aer every 100

operaon hours, you must lubricate all connecng parts (if

required, remove all debris and dust with a brush beforehand).

Check the condion of the security labels regularly. Replace

them if required. Check the condion of the Sanding Disc

regularly. Store the machine in a locked, dry locaon.

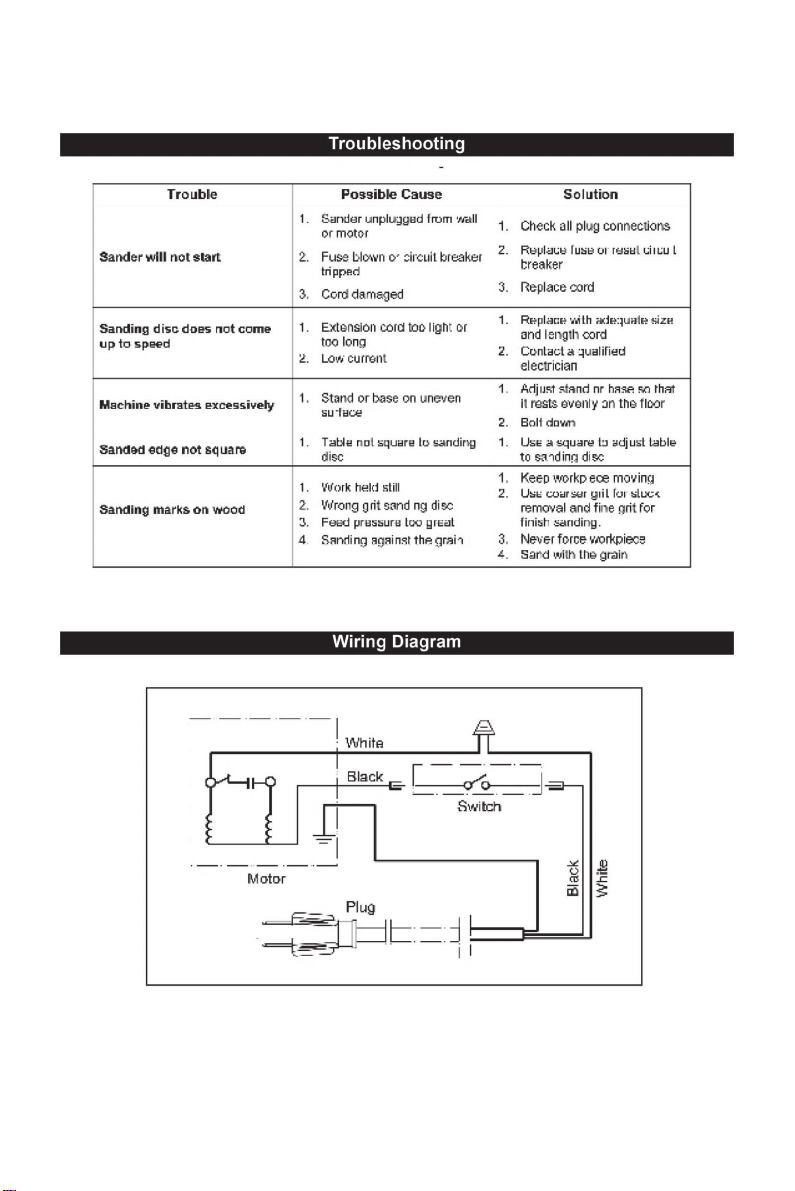

6.1 Troubleshoong

Before you start checking for defects by eliminaon disconnect the machine from power supply.

Problem Possible cause Soluon

The machine stops or

will not start. • ON/OFF switch is damaged.

• Grinder unplugged - Overload tripped.

• Fuse has blown or circuit breaker tripped.

• Cord damaged.

• Check the switch.

• Check all power connecons.

• Allow motor to cool down and reset by pushing

OFF switch.

• Change fuse or reset the circuit breaker.

• Change cable.

The machine slows

down while working. • Exerng too much pressure on the sanding

disc.

• Exert less pressure on the work-piece/sanding

disc.

Bad grinding results. • Abrasive too coarse.

• Grained.

• Use a less coarse abrasive.

Rapid wear of the

abrasive. • Abrasive too ne.

• Grained.

• Use a more coarse abrasive.

Grinding angle is

wrong. • Adjusted angle is wrong. • Readjust the angle.

Sanding disc runs out

of round. • Sanding disc is not centrally mounted. • Mount the sanding disc centrally.

Work-piece burns

during the working

process. • Abrasive is dirty with oil. • Change abrasive.

8

• Too much pressure. • Reduce pressure.

Many potenal sources of malfuncons can be cleared by a proper connecon to the electrical grid.

6.2 Maintenance plan

• Aer each work shi: Remove chips and sanding dust from

the device. Aer 10 hours of operaon: Check all screw

connecons and ghten if necessary.

6.3 Changing grinding disc

• If the grinding disc (e) is worn, pull it o the grinding plate.

Place the new disc with suitable adhesive on the centre and

push it onto the grinding plate. Remove the grinding disc if

it does not run circularly. Readjust it.

See image 7

6.4 Storage

• Store the machine in a clean and dry, away from the reach

of children.

6.5 Cleaning

• Clean the machine aer each work shi. Remove chips,

dust, etc. with a suitable tool. Do not remove them by hand

(cung injury!).

6.6 Noce

• Clean your machine regularly aer every usage. It prolongs

the machines operang life and is a prerequisite for a safe

working environment.

• Repair jobs must be performed by properly trained

professionals only!

• The usage of certain soluons containing ingredients

damaging to metal surfaces as well as the use of scrubbing

agents will damage the machine surface!

• Clean the machine surface with a wet cloth soaked in a mild

soluon.

9

10

11

12

exploded view

Spare Parts List

13

Table of contents

Popular Sander manuals by other brands

Alpha Professional Tools

Alpha Professional Tools AIR-680UW instruction manual

CombiSteel

CombiSteel 7531.0200 user manual

DeWalt

DeWalt DW443 Original instructions

Chicago Pneumatic

Chicago Pneumatic RediPower RP35 Series instruction manual

Skil

Skil SR1 3745 Series Original instructions

Ferm

Ferm BGM1003 Original instructions