JENFAB 12200283 User manual

TITLE

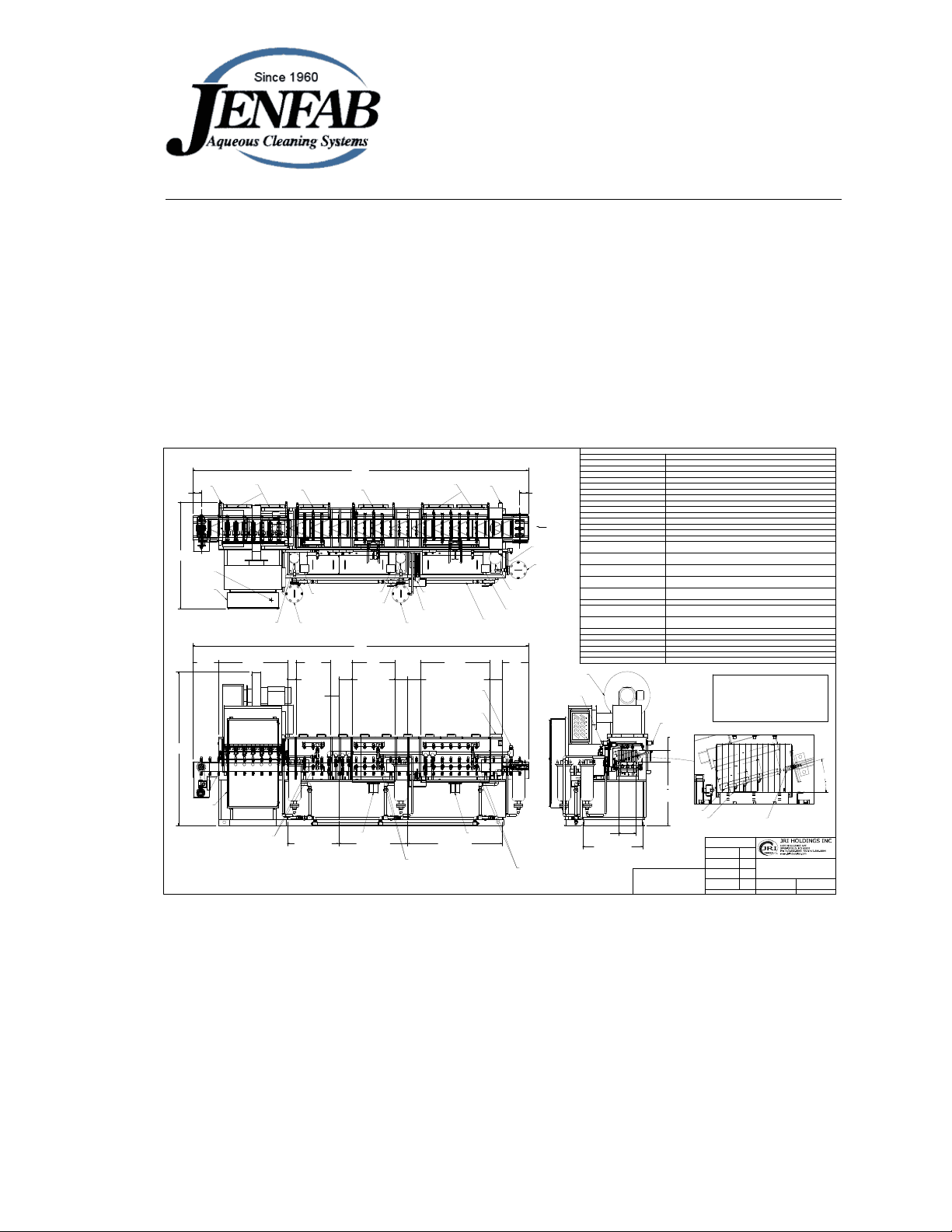

INVENTORY NUMBER DWG. NO.

SCALE NTS SHEET 1 OF 1

JOB NUMBER

APPR. ENGINEER

APPR. PRODUCTION

APPR. ESTIMATING

DRAWN BY

FINISH

DATE

DATE

DATE

DATE

THIS DOCUMENT OR OTHER DOCUMENT

CONTAINS PROPRIETARY INFORMATION OF

JRI HOLDINGS INC. AND IS NOT TO BE

USED, REPRODUCED, OR DISCLOSED

WITHOUT EXPRESSED WRITTEN PERMISSION

OF JRI HOLDINGS INC.

R.

VOESTALPINE

MCCS-4000SS2F APPROVAL DRAWING

12200283 12200283-23896-M-001

12200283

TSG 12/01/17

FRONT VIEW

PLAN VIEW

LOAD END

18 in

LOAD

9 in

ENTRY

48 in

PRE-WASH

9 in

DRAIN

9 in

ENTRY

30 in

WASH

6 in

DRAIN

48 in

BLOW-OFF

18 in

UNLOAD

234 in

12 in

BELT WIDTH42 in

PRE-WASH/WASH/

RUST INHIBIT TANK

423

4in

LOAD

HEIGHT

8 in

TUNNEL

OPENING

66 in

PRE-WASH TANK

260 GAL. APPROX.

48 in

WASH TANK

195 GAL. APPROX.

PRE-WASH

ACCESS PANELS

(2) RESTRICTIVE FLOW VALVES FOR PRE-WASH

(1) TIED TO UPPER/SIDE SPRAY

(1) TIED TO BOTTOM/SIDE SPRAY

WATER HEADER

1-1/2 in NPT CONNECTION

CPVC w/STAINLESS STEEL

SOLENOID VALVES

SPECIFICATION

VOLTAGE 460V 3PH 60Hz w/CUSTOMER SUPPLIED MAIN DISCONNECT; FLA = 202A

OVERALL DIMENSIONS 234 in L x 74 in W x 104in H

TANK CAPACITY PRE-WASH - 260 GAL. APPROX, WASH - 195 GAL. APPROX., RUST INHIBIT - 130 GAL. APPROX.

TUNNEL OPENING 13-1/4 in WIDE x 8 in TALL

BELT TYPE 12 in WIDE-1 in x 1 in SS

INDEXING BELT INDEX 6 in, ADJUSTABLE BELT SPEED, SET AT 4 fpm

FIXTURE SS FIXTURE NEST, INSTALLED ON 6 in CENTERS w/QUICK RELEASE CHANGE OVER

WEIGHT CAPACITY 500 lbs WEIGHT CAPACITY EVENLY DISTRIBUTED

LOAD HEIGHT 42-3/4 in APPROX.

PRE-WASH PUMP MOTOR SIZE / OUTPUT 5 HP 230/460V 3PH / 70 GPM @ 30PSI

WASH PUMP MOTOR SIZE / OUTPUT 3 HP 230/460V 3PH / 50 GPM @ 30PSI

RUST INHIBIT PUMP MOTOR SIZE / OUTPUT 3 HP 230/460 3PH / 40 GPM@ 30 PSI

FILTRATION SYSTEM FILTRATION SYSTEM, 8 x 15 SS w/SNUBBER GAUGES (PRE-WASH, WASH, & RUST INHIBIT)

OS-100SS2 OIL SKIMMER w/12 in SS WHEEL & FRAME (PRE-WASH)

CHIP BASKET SS CHIP TRAY w/SS 1/16 in PERFORATED CHIP BASKET (PRE-WASH & WASH)

TANK HEAT TYPE (1) 40 KW 460V 3PH @ 140°F - PRE-WASH, (1) 27 KW 460V3PH @ 140° F -WASH, (1)27 KW

460V 3PH @ 140° F - RUST INHIBIT

RESTRICTIVE FLOW VALVES RESTRICTIVE FLOW VALVES - ONE TIED TO UPPER/SIDE SPRAY - ONE TIED TO BOTTOM/SIDE

SPRAY (PRE-WASH, WASH, & RUST INHIBIT)

PRE-WASH, WASH, & RUST INHIBIT SPRAY CLIP ON BEX BRAND NOZZLE BASES w/SS NOZZLES, TOP, BOTTOM, & STATIONARY LOWER

SIDE SPRAY. SS NOZZLES ADJUSTABLE UPPER SIDE SPRAY

TANK WATER FILL AUTO & MANUAL FILL, INCOMING WATER LINES & VALVES CPVC w/STAINLESS STEEL

SOLENOID VALVES, 1-1/2 in NPT CONNECTION

DRAIN BLACK IRON DRAIN HEADER w/TANK DRAINS CONNECTED TO BRASS BALL VALVES, INCLUDES

PLUMBING TANK OVERFLOWS TO DRAIN HEADER, 1-1/4 in NPT CONNECTION

INSULATION INSULATE TANK, BLOWER PLENUM, & BLOWER PRESSURE DUCT - SS SKINS

ACCESS SIDE ENCLOSURE REMOVABLE ACCESS PANELS FOR EACH STAGE & TOP ACCESS

THROUGHOUT ENCLOSURE

BLOW-OFF 20 HP REGEN BLOWER - AIR KNIVES - (7) TOP, (7) BOTTOM,(3) STATIONARY LOWER SIDE

CONE NOZZLES, (4) ADJUSTABLE UPPER SIDE CONE NOZZLES

BLOW-OFF HEAT TYPE 30 KW AIR FIN TYPE @ 180° F

DRIVE MOTOR DRIVE MOTOR - 1/2 HP AC 480V 3PH - OPERATINGSPEED 1-4 fpm

SLIP CLUTCH SLIP CLUTCH 1 in BORE 190 lb

ELECTRICAL ENCLOSURE INDUSTRIAL CONTROLLED

MICROLOGIX MICROLOGIX 1400 PLC w/6 in COLOR EATON HMI

PAINT NO PAINT - 2B FINISH - MILD STEEL SURFACES TO BE PAINTED BLACK

FOR APPROVAL

APPROVED APPROVED AS MARKED

APPROVED BY ____________________ DATE __________

27 KW HEATER

40 KW HEATER

234 in

APPROX.

E-STOP

36 in

RUST INHIBIT TANK

130 GAL. APPROX.

ENTRANCE

9 in

DRAIN

6 in

ENTRY

24 in

RUST

INHIBIT

E-STOP

74 in

APPROX.

5 HP VERTICAL PUMP

STAINLESS STEEL GUSHER

70 GPM @ 30 PSI

E-STOP

E-STOP

EXHAUST RING

FOR A 8 in DIA.

DUCT CONNECTION

WASH ACCESS

PANEL

RUST INHIBIT

ACCESS PANEL

BLOW-OFF

ACCESS PANELS

20 HP HIGH

PRESSSURE BLOWER

w/30 KW HEAT

104 in

APPROX.

FILTRATION SYSTEM

8 in x 15 in 6-BOLT

STAINLESS STEEL

BLACK IRON DRAIN HEADER

1-1/4 in NPT CONNECTION

OIL SKIMMER

w/12 in SS WHEEL

& FRAME

OIL CONTAINMENT

BOX

FILTRATION SYSTEM

8 in x 15 in 6-BOLT

STAINLESS STEEL

3 HP VERTICAL PUMP

STAINLESS STEEL GUSHER

50 GPM @ 30 PSI

27 KW HEATER

FILTRATION SYSTEM

8 in x 15 in 6-BOLT

STAINLESS STEEL

3 HP VERTICAL PUMP

STAINLESS STEEL GUSHER

40 GPM @ 30 PSI

(2) RESTRICTIVE FLOW VALVES FOR WASH

(1) TIED TO UPPER/SIDE SPRAY

(1) TIED TO BOTTOM/SIDE SPRAY

(2) RESTRICTIVE FLOW VALVES FOR RUST INHIBIT

(1) TIED TO UPPER/SIDE SPRAY

(1) TIED TO BOTTOM/SIDE SPRAY

CHIP

BASKET CHIP

BASKET

A

DETAIL A

SCALED 4:1

15°

51

4in

711

16 in

107

8in

PARTS

ADJUSTABLE NOZZLES &

BLOW-OFF CONE NOZZLES

TO HAVE 6 in ADJUSTMENT

FIXTURE

6 in6 in E-STOP

ELECTRICAL

CONNECTION

ELECTRICAL

ENCLOSURE

ELECTRICAL

ENCLOSURE

1

32

54

76

98

Learning to Use

JENFAB Belt Washers

#12200283

BW–001 12/19/06

2 Learning to Use JENFAB Belt Washers

Where to Find More Information

JENFAB Aqueous Cleaning Systems provides these resources to

ensure you get the most from our products.

Turnover Package

In addition to this user guide, we ship our belt washers with a CD

ROM that includes: (1) OEM user guides for major components,

(2) engineering drawings of the belt washer, and (3) the washer’s

control program (if equipped with automatic controls).

Materials Safety Data Sheets

Material safety data sheets provide safety information about common

cleaning chemistries and are available from JENFAB upon request.

Support Services

Call the JENFAB customer support team to receive answers to

your technical questions and order parts. You can reach the JENFAB

customer support team, Monday through Friday, 8:00 a.m. to

5:00 p.m. Eastern Standard Time at 1–860–828–6516.

Web Site

You can also learn more about our products by visiting our website,

www.jenfab.com.

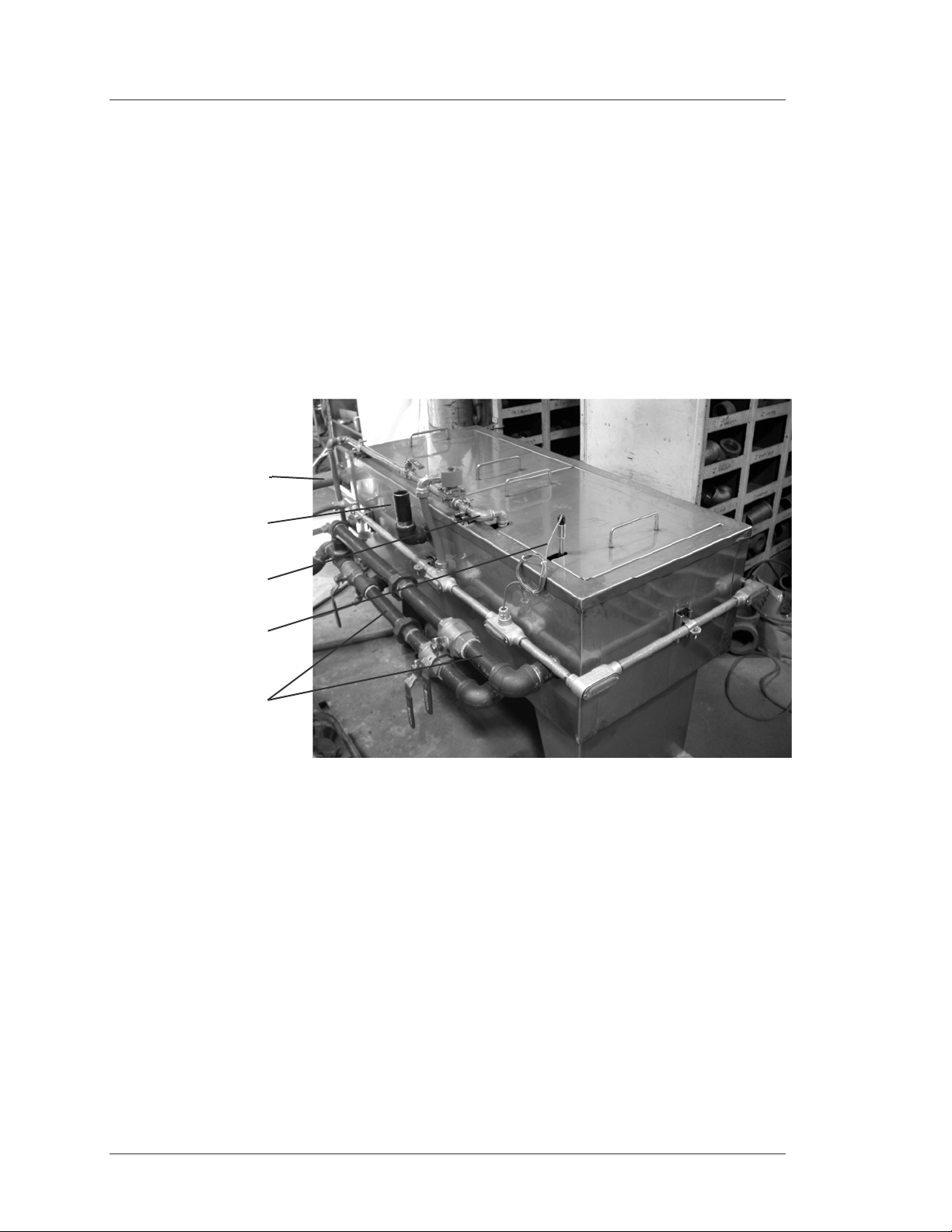

Cover Photo—Typical JENFAB belt washer

Learning to Use JENFAB Belt Washers 3

Important Information

Read the safety instructions in this manual before using your belt

washer and keep these instructions accessible for future reference.

JENFAB will provide replacement user guides upon request.

4 Learning to Use JENFAB Belt Washers

Table of Contents

Preface

Welcome to the User Guide......................................................................... 6

Belt Washer Safety......................................................................................... 6

Safety Warnings.............................................................................................. 7

Statement of Proper Use .............................................................................. 7

Product Overview

What the Belt Washer Does......................................................................... 8

Manual and Automatic Systems .................................................................. 8

Key Operating Benefits................................................................................. 8

Optional Features ........................................................................................ 11

Description of Components

Overview of the Belt Washer..................................................................... 14

Overview of Process Components ........................................................... 16

Conveyor Belt Adjuster............................................................................... 19

Optional Oil Separator (external).............................................................. 20

Manual System Controls............................................................................. 21

Installation and Setup

Preparation.................................................................................................... 23

Unpacking the Belt Washer........................................................................ 23

Choosing a Location.................................................................................... 23

Connecting Optional Equipment.............................................................. 24

Utility Requirements and Connections..................................................... 25

Operating the Belt Washer

Cold Startup—Automatic System............................................................. 30

Cold Startup—Manual System .................................................................. 33

Using the Manual Push Button Control Panel........................................ 36

Description of Controls.............................................................................. 36

Using the Dryer Temperature Controller ................................................ 38

Learning to Use JENFAB Belt Washers 5

Troubleshooting

Troubleshooting Chart................................................................................ 39

Inspection and Maintenance

Inspection, Maintenance and Cleaning Recommendations .................. 40

Cleaning the Chip Baskets.......................................................................... 41

Replacing Filter Bags................................................................................... 43

Cleaning the Mini External Coalescing Oil Separator (If Equipped) .. 45

Cleaning the 45- and 65-Gallon JENFAB External Coalescing Oil

Separators (If Equipped) ............................................................................ 47

Cleaning the Optional Disk Oil Separator (If Equipped) ..................... 48

Inspect for Salt and Debris Buildup on Tank Components ................. 49

Adjusting the Conveyor Belt Tension ...................................................... 51

Spare and Replacement Parts

How to Order Parts..................................................................................... 52

Mechanical Parts List................................................................................... 52

Electrical Parts List...................................................................................... 52

Specifications

Technical Specifications.............................................................................. 53

Appendix A—Operator Interface Windows

6 Learning to Use JENFAB Belt Washers

Preface

Welcome to the User Guide

This user guide describes how to use JENFAB belt washers.

JENFAB manufacturers numerous models of belt washers and we

modify many of them to customer requirements. Hence, this user

manual describes the use of our belt washers in general—principals of

operation, safety considerations, typical components, and descriptions

of optional equipment.

For additional information about your specific belt washer, see the

engineering drawings and OEM user guides supplied on your system’s

CD-ROM. If you have questions about operating your specific belt

washer after reading this manual and consulting the OEM user guides,

call the JENFAB technical support team for assistance before using

your belt washer.

Belt Washer Safety

To reduce the risk of fire, electric shock, and personal injury, read

the instructions in this user guide before operating your belt washer.

Follow all safety instructions. Retain this user guide for future

consultation and training.

General Safety Considerations

These are the key global safety instructions you should follow when

operating FENFAB belt washers:

In an emergency, pressing the Emergency Stop button will immediately

stop all machine functions.

Guards and interlocks protect operators from moving parts and

unintended operation. Do not operate the cleaning machine unless

all guards and interlocks are in place.

Do not run the machine with tank covers, cleanout, and inspection

covers open.

Before performing major maintenance on the machine, follow your

plant’s lockout/tagout procedures and OSHA safety procedures.

Learning to Use JENFAB Belt Washers 7

Use JENFAB washers with aqueous cleaning solutions. Do not use

flammable solvents. Cleaning chemistries should be compatible

with 304 stainless steel.

Hot cleaning chemistries can cause bodily harm. User-supplied

eye wash and emergency showers should be located near the belt

washer.

International Symbols

This symbol indicates a dangerous voltage—that may constitute

a risk of electrical shock—is present within the enclosure.

This symbol indicates that the product literature contains

important operating and maintenance instructions.

Safety Warnings

This user guide provides guidance and safety instruction using the

following notations:

Expert Advice—Expert advice flags provide you with information that

will help you use JENFAB cleaning machines in the most effective way.

Caution—Caution flags notify you of actions that could damage

the equipment or your products and provide you with information to

prevent damage.

Warning—Warning flags notify you of action that could cause bodily

harm or death and provide you with information to prevent harm.

Statement of Proper Use

JENFAB designs belt washers to clean parts using aqueous solutions

and controlled operation within the wash, rinse, and drying sections. If

you use a belt washer in a manner not specified by JENFAB, you may

impair the protection provided by the equipment.

!

8 Learning to Use JENFAB Belt Washers

Product Overview

What the Belt Washer Does

JENFAB belt washers clean parts by spraying wash and rinse solutions

on them as they travel along a conveyor belt. After washing and

rinsing, a fan dries the parts using heated air. All of the cleaning

processes take place in an enclosed, cellularized system.

Process solutions range from simple wash chemistries and plain water

rinse, to complex heated washing and rinsing chemistries that include:

prewash, wash, rinse, and secondary rinse with rust inhibitors or other

treatments.

Controls on JENFAB belt washers range from simple push button

operation to automated systems with PLC and touch screen monitors.

Manual and Automatic Systems

JENFAB manufactures both manual and automatic systems.

Manual systems use simple pushbutton and manual controls to start

and stop the washer and regulate functions such as conveyor belt

speed and process temperatures. Automatic systems use a PLC for

control of process parameters and a touch screen display to provide an

operator interface to the control system. Automatic systems usually

include several pushbuttons for control of basic operations such as

power-up, start, stop, emergency stop, and belt speed.

Key Operating Benefits

A key operating benefit of our belts washers is the high volume

of solution sprayed over the parts, which flushes away chips, soils

and oils, and keeping fresh, clean solution in contact with the parts.

Chip baskets remove large contaminants from the process streams.

Inline filters remove fine contaminants from the process streams.

Learning to Use JENFAB Belt Washers 9

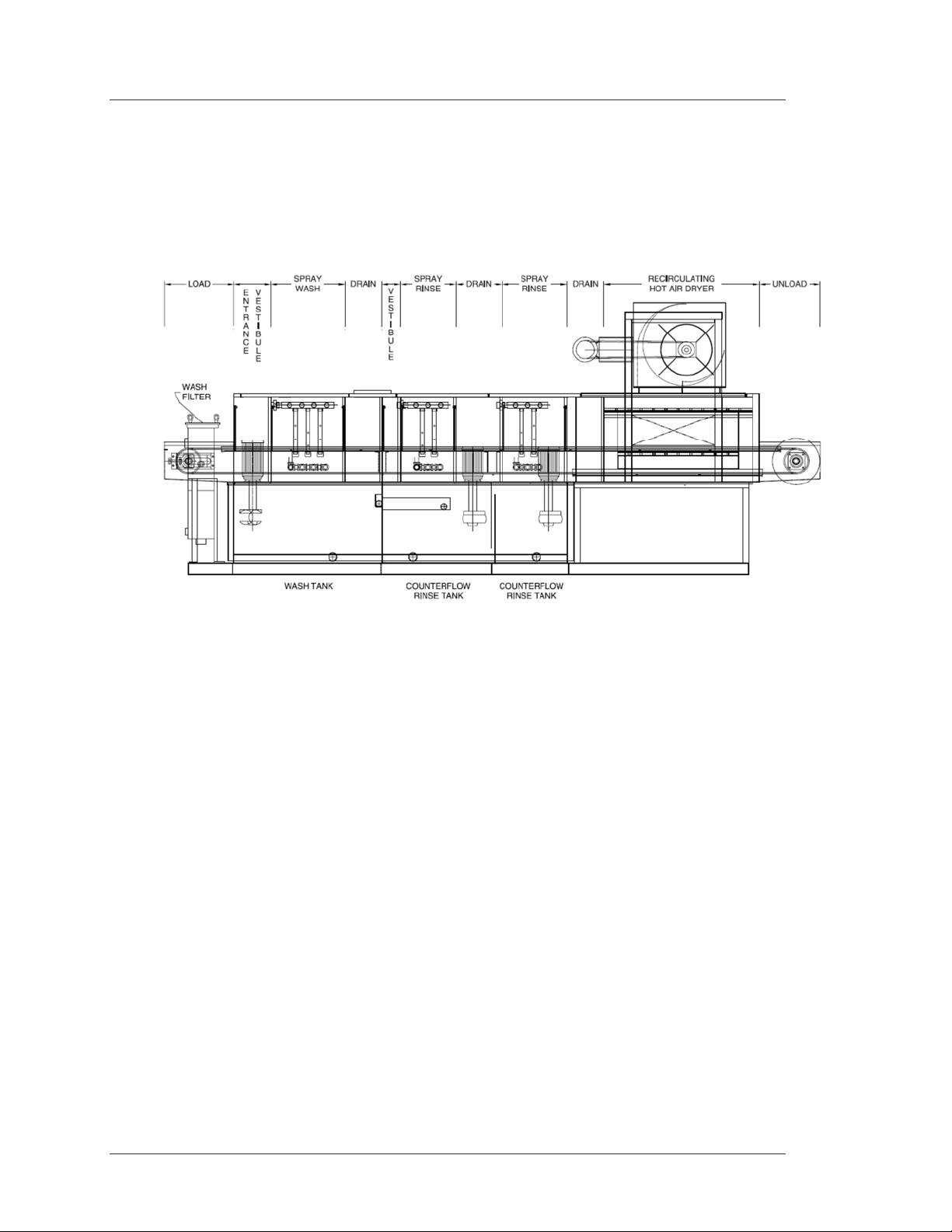

Typical Wash Sequence

As parts are conveyed through the washer, they typically are exposed

to these processes (Figure 1):

1. High pressure, high volumetric, recirculating spray from a

wash tank. The wash solution is normally heated and contains

wash chemistry.

2. Draining. Dwell time in a cellular compartment combined

with the open conveyor belt drains wash solution from parts.

Vestibule provides a cell between wash and rinse cells to

minimize contamination between wash and rinse solutions.

3. High pressure, high volume, recirculating spray rinse. Rinse

solution from standard rinse tank or counter flow rinse tank.

4. Draining. Dwell time in a cellular compartment combined

with the open conveyor belt drains wash solution from parts.

5. Optional. Second high pressure, high volume, recirculating

spray rinse. Rinse solution from counter current rinse tank or

from isolated tank that can include product treatments such as

rust inhibitors.

6. Draining. Dwell time in a cellular compartment combined

with the open conveyor belt drains wash solution from parts.

7. Drying. Recirculating hot air dryer dries parts.

10 Learning to Use JENFAB Belt Washers

Figure 1. Typical washing sequence with optional

second spray rinse section

Learning to Use JENFAB Belt Washers 11

Optional Features

The sections below describe optional equipment available on JENFAB

belt washers. Check your belt washer or your purchasing specifications

to determine which options your machine includes.

Upgrade to Automatic Controls

Belt washers are typically manual systems. Automatic control is

available as an option. Automatic systems use a PLC for control of

some process parameters. A touch screen display provides an operator

interface to the control system. Automatic systems usually include

pushbuttons for basic functions such as power-up, start, stop,

emergency stop, and drum speed control.

Oil Separators

Coalescing Type

JenFab manufactures several sizes of coalescing oil separators

(15-, 45-, and 65-gallon) for use with our belt washers. Mini (15-gallon)

separators can be built in to the belt washer or stand as an external

unit. The 45- and 65-gallon separators stand as external units and are

piped up to the belt washer.

A coalescing oil separator extends bath life by continually removing

oils from the wash solution.

In a coalescing oil separator, oleophilic (oil attracting) coalescing tubes

capture, agglomerate, and float oil globules to the surface where an

adjustable weir discharges the oil from the separator. The tubes

consistently remove oil globules of 20 microns and larger in size.

The separator removes only oil, not chemistry.

Disk Type

A disk-type oil separator can be installed in the wash tank as an option.

Disk-type oil separators use a rotating disk that is half submerged in

the wash water. As the disk rotates, it carries oil from the wash water.

Scrapers scrape the oil from the disk, and the oil is channeled to a

user-supplied collection vessel.

12 Learning to Use JENFAB Belt Washers

Drain Station

For applications where the overflow from the belt washer cannot

drain by gravity to a drain, a drain station collects the overflow from

the process tanks and pumps it to an elevated drain or waste water

tank. The drain station includes a tank (built-in or external) with a

pump and high/low level control linked to a control system. When

the drain station tanks fills up, it is automatically pumped out,

removing the overflow from the belt washer.

Tank Clean-Out Doors

Optional manhole-size doors on the side of large wash and rinse

tanks ensure complete draining of the tanks and allow entry for

manual cleaning.

Conveyor Options

Conveyor options include entrance- and exit-end staging conveyors

or 90-degree conveyors to enable one operator to load and unload

the cleaning machine.

Part Guiding

Optional part guides installed along the length of the conveyor belt

keeps parts centered or orientated in a specific direction as they pass

through the belt washer.

Chemical Feed Option

A Dosatron injector metering valve can automatically meter chemistry

into wash or rinse makeup water, thus automatically maintaining

required chemistry strength.

Air Knife

An optional air knife located between the wash and rinse sections

helps remove wash water from the parts and belt to reduce wash water

carryover into the rinse water. Likewise, as the lower belt moves in the

opposite direction, the air knife removes rinse water from the belt and

prevents it from being carried over and diluting the wash water.

Learning to Use JENFAB Belt Washers 13

Second Rinse Section

An optional second rinse section enhances removal of washing

chemistry by providing either a fresh water, counter current, or rinse

chemistry spray to further rinse parts. The second rinse option

includes a separate spray section and rinse tank.

14 Learning to Use JENFAB Belt Washers

Description

of Components

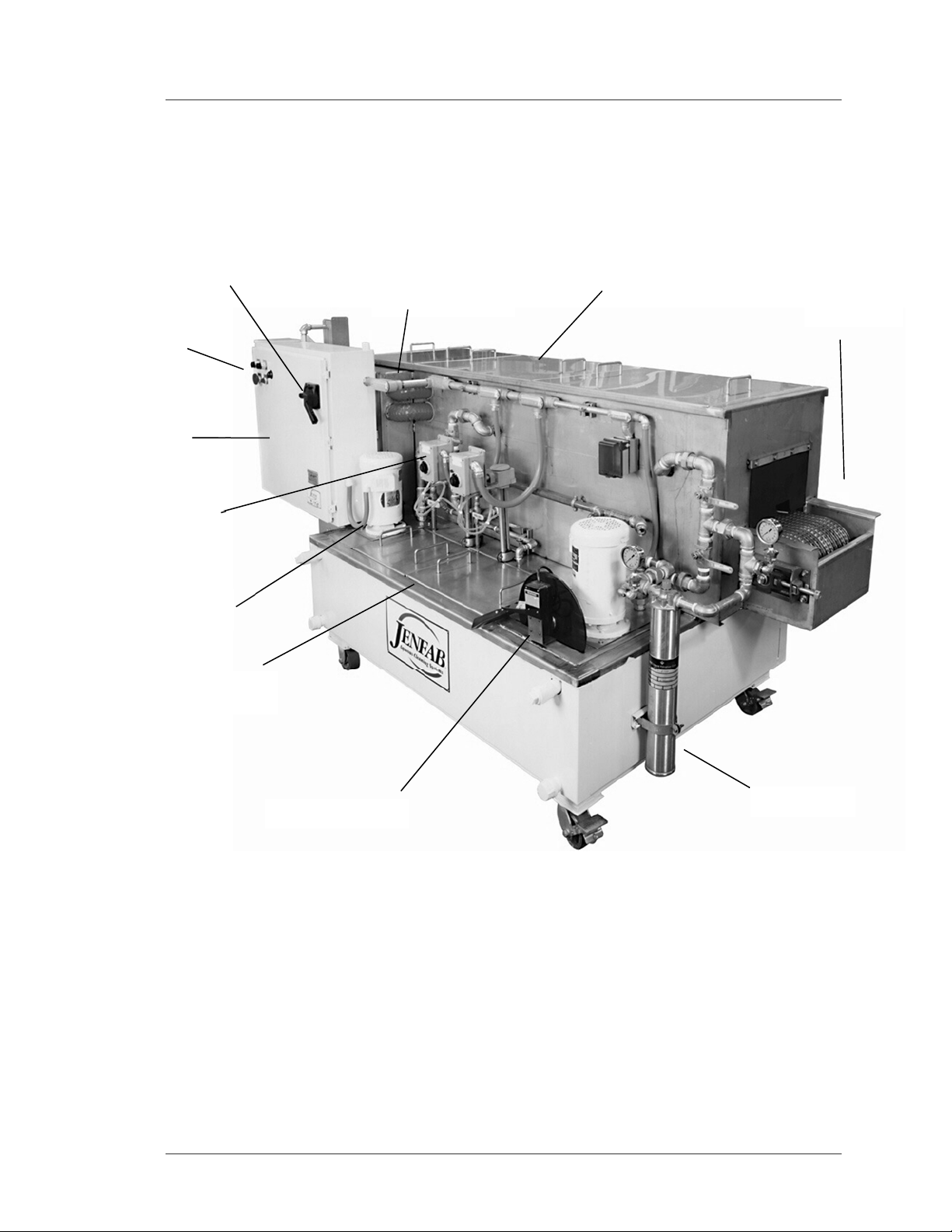

Overview of the Belt Washer

The typical features and components on a belt washer include

these (Figure 2):

Conveyor belt—open mesh stainless steel belt transports parts

through the washing, rinsing and drying sections.

Lift-off access covers—tank, side, and top covers lift off easily for

access to the machine for inspection and maintenance. Some covers

can be interlocked with the control system to prevent the belt washer

from starting when operators have the covers removed.

Main power disconnect—removes all power from system

components.

Manual system operator controls—operator controls on a manual

system can consist of pushbuttons, switches, dials, and simple

temperature controllers.

Electrical control panel—houses electrical and control equipment.

Inline filter—belt washers can include one or more inline filters

to filter the wash and rinse solutions.

Oil separator—belt washers can include three types of optional oil

separators including disk oil separators

In-tank vertical pumps—these pumps provide the best performance

for pumping wash and rinse solutions to the spray nozzles.

Tank heating controls—manual systems include dial controllers for

regulating tank heating

Dryer blower—a blower circulates heated air to dry the parts

Learning to Use JENFAB Belt Washers 15

Figure 2. Typical belt washer components (manual

system)

Lift-off tank

covers

Inline filter

Electrical

control panel

In-tank sealless

vertical pumps

Lift off covers

Conveyor

belt

Operator

controls

Disk oil separator

Main power

disconnect

In-tank sealless

vertical pumps

Dryer blower

16 Learning to Use JENFAB Belt Washers

Overview of Process Components

Inline Filters

Belt washer can include wash and rinse water inline filters to remove

contaminates, thus improving cleaning performance and extending the

life of wash and rinse solutions (Figure 3). The inline filters use cloth

bag filters that you replace periodically based on the inlet/outlet

differential pressure.

Figure 3. Belt washer inline filters

Wash Tank Components

Bleed line

Filter inlet

Inlet valve

Filter drain line

Filter outlet

Inlet pressure gauge

Learning to Use JENFAB Belt Washers 17

Typical wash tank components include heating element, temperature

probe and transmitter, and low and high level floats and transmitters.

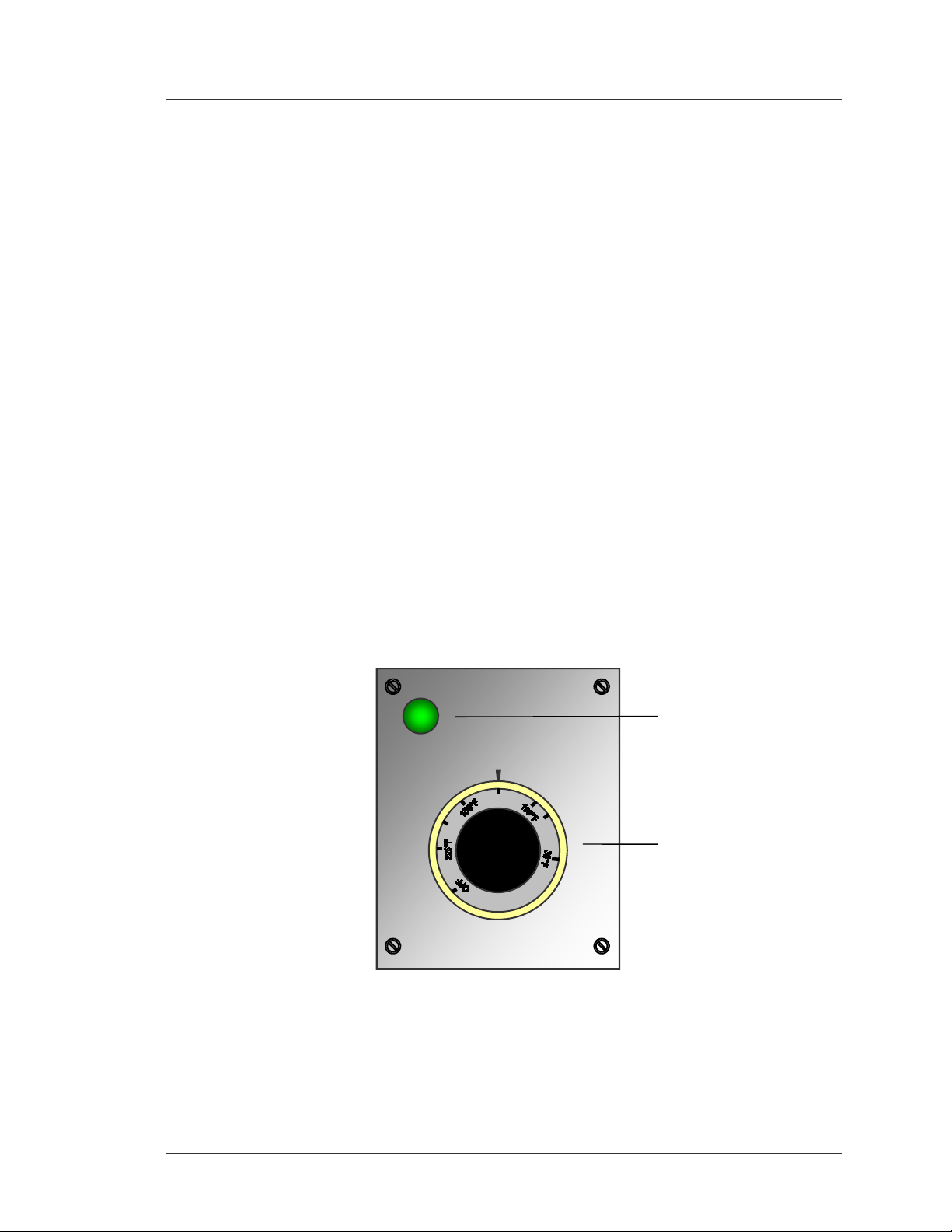

Manual System Process Tank Components

Temperature Control—In manually-controlled systems, the process tanks

usually include electric heating elements controlled by a manual,

dial-type temperature controller mounted above the tank .Operators

turn the temperature control knob to the desired temperature setting,

and the controller regulates the heating

elements to maintain the desired temperature. Heating systems can

also be powered by electricity, steam, or gas.

Liquid Level Control—If the liquid level in the tank falls too low, a low level

float and transmitter shut off the heating element and stop the pump

to prevent damage to the heating elements and pump.

Chip Baskets—Most wash and rinse tanks include chip baskets that

remove chips from the wash or rinse stream. You can remove the

chip baskets for cleaning.

Figure 4. Manual heat controller for process tank

Turn the temperature

control knob to the desired

temperature to adjust the

temperature in the tank

Indicator light illuminates

when heating element is

receiving power

120°F

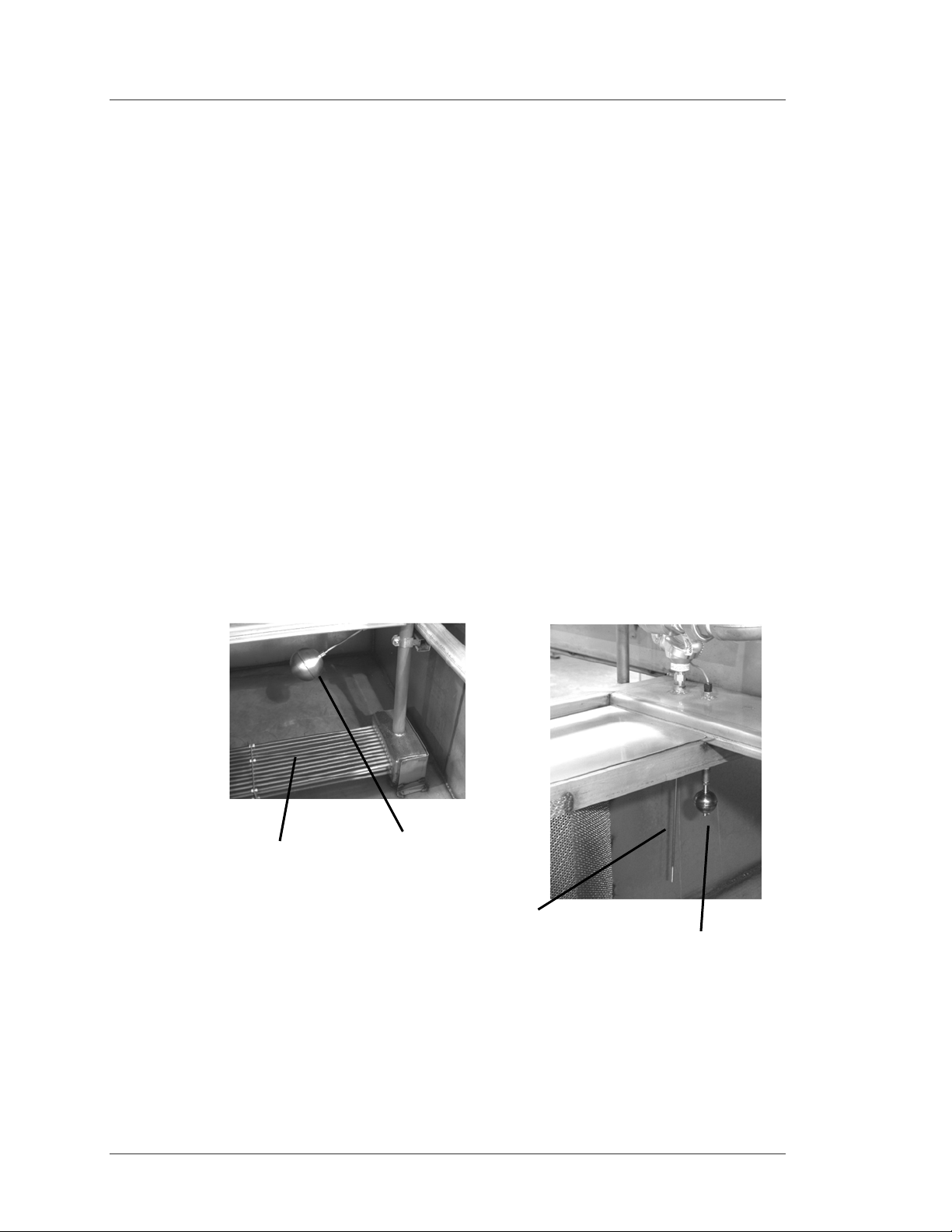

18 Learning to Use JENFAB Belt Washers

Low level float

Heating elements can

be electric, steam, or

even gas operated

Water makeup float

Temperature probe and

transmitter send temperature

readings for display on the

control panel and for automatic

temperature control.

Automatic System Process Tank Components

Temperature Control—The wash tanks in automatic systems include:

heating elements, temperature probes and transmitters, and liquid level

floats and transmitters. Tank heating is automatically controlled based

on the setpoints entered into the control system. Operators can

control the heating process manually when running the control system

in manual mode. Heating systems can also be powered by electricity,

steam, or gas.

Liquid Level Control—The water makeup soleniod and transmitter trigger

water makeup into the tank as the water level decreases. The low level

float and transmitter automatically cut power to the heating elements

and stop the pump if the tank level falls too low.

Chip Baskets—Most wash and rinse tanks include chip baskets that

remove chips from the wash or rinse stream. You can remove the

chip baskets for cleaning.

Figure 5. Typical tank components

Learning to Use JENFAB Belt Washers 19

Conveyor Belt Adjuster

Conveyor belts are usually chain driven and include tension adjusters

on the feed end of the machine. See page 51 to learn how to adjust the

belt tension.

Figure 6. Conveyor belt adjuster

Belt tension

adjusting screw

Belt pulley shaft

Conveyor belt

20 Learning to Use JENFAB Belt Washers

Optional Oil Separator (external)

A typical, optional, external oil separator used on belt washers is

a 45-gallon JENFAB coalescing oil separator (Figure 7). The oil

separator includes coalescing elements, oil skimmer, and a weir to

separate the oil from the wash solution. A return line and pump return

the cleaned wash water back to the wash tank.

Figure 7. Typical JENFAB coalescing external oil

separator

Skimmed oil outlet

Liquid level transmitter

Fresh water makeup inlet

Drain lines

Clean wash

water return

and pump on

back side (not

shown)

Gravity supply line

Table of contents