Jepson WRAPAROUND TUBE SANDER 760/40 User manual

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 1 of 10

Instruction Manual

WRAPAROUND TUBE SANDER 760/40

www.drycutter.com

Instruction Manual DRUM SANDER 100

Page 2of 10

Index

1EG-Conformity Declaration ..............................2

2Specifications ....................................................2

3User Instructions...............................................3

4Safety Instructions ............................................3

4.1 Illustration of Safety Instructions .............3

4.2 General Safety Instructions ......................3

4.3 Specific Safety Rules................................5

5Functional Description .....................................5

5.1 Unpacking.................................................5

5.2 Installing the belt.......................................5

5.3 Wraparound TUBE SANDER ...................6

OPERATION: Start and Stop of the machine........6

5.4 CONTROLLING THE VARIABLE SPEED6

5.5 OPERATION............................................ 6

6Maintenance and Repair .................................. 7

6.1 Keep Tool Clean ...................................... 7

6.2 FAILURE TO START ............................... 7

6.3 Replacing Carbon Brushes ...................... 7

7Standard Accessories ...................................... 8

8Optional accessories: ...................................... 8

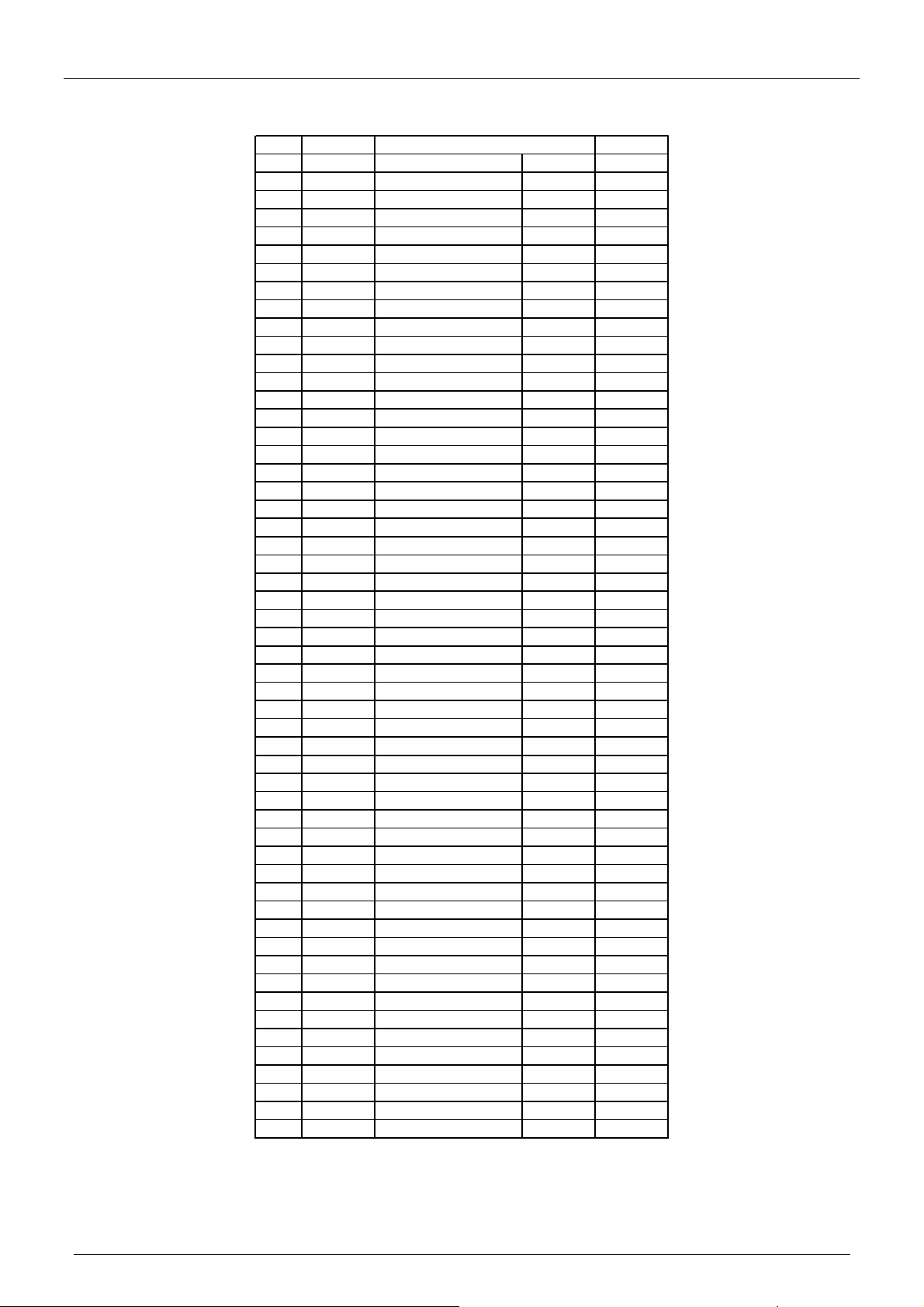

9Spare parts - List of Spare Parts ..................... 9

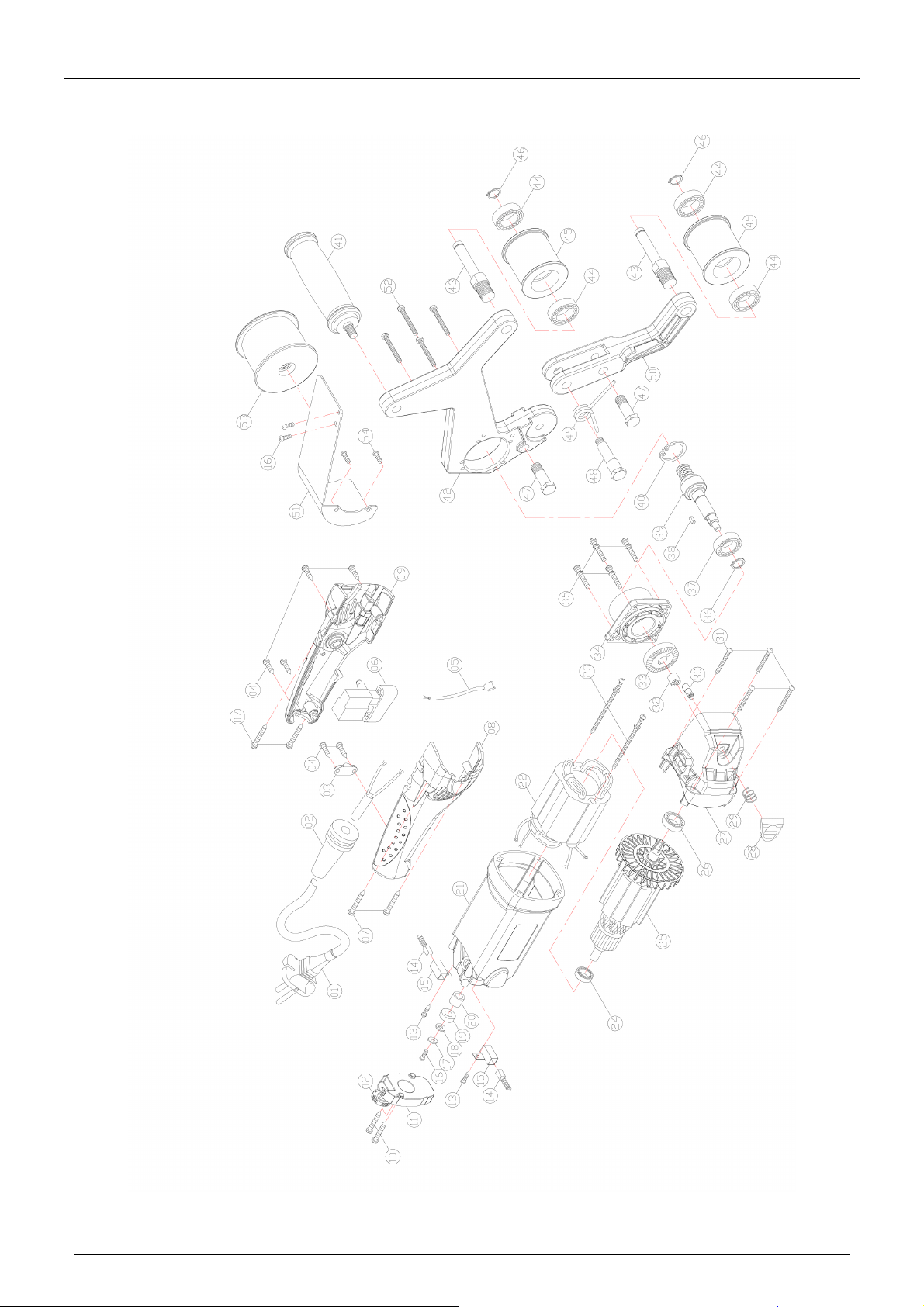

10Spare Parts Drawing....................................... 10

1 EG-Conformity Declaration

(according to Appendix IIA of the machine Directive)

We,

Routexport Agencies SA

Visserijstraat 25, rue de la Pêcherie

1180 Brüssel

Belgien

as the manufacturer declare herewith under our responsibility that the product:

Name: Wraparound Tube Sander/Polisher Machine

Serial No. :

Manufacturing Date: 2011

complies with the following standards, directives and referenced standard documents:

2006/195/EC

2004/108/EC

2006/42/EC

Low Voltage Directive

EMC Directive

Machinery Directive

EN 60745-1 :2009+A11 :2010

EN 60745-2-4 :2009+A11 :2011

EN 62233 :2008

EN 55014-1 :2006+A1 :2009+A2 :2011

EN 55014-2 :1997+A1 :2001+A2 :2008

EN 61000-3-2 :2006+A1 :2009+A2 :2009

EN 61000-3-3 :2008

Pierre Michiels, Managing Director

Name, Position Brussels, 02.01.19

2 Specifications

Voltage 230V /50 Hz

No load speed 1600-3200/min

Power input 1200W

Surface speed 3-12 m/sec

Max belt length 760 mm

Max. belt width 40 mm

Soft start and overload

protection

with

Net weight 3.4 kg

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 3 of 10

3 User Instructions

Notes for the customer

The instruction manual includes important instructions as to how

to operate the plant safely, correctly and economically.

Observing these instructions helps to avoid risks, repair costs

and downtimes and to increase the reliability and lifetime of the

machine.

The instruction manual must be read and used by each person

who works with the electrical equipment. This applies in

particular to the "Safety Instructions" chapter. It is too late to

read the manual and safety instructions when work is actually

being carried out at the machine.

Always keep one copy of this manual next to the machine so

that it is at hand ready to be consulted!

In case of any doubt or questions, always contact the machine

manufacturer.

In addition to the instruction manual, the accident prevention

regulations which apply in the country of use and the user

location must be adhered to. In addition, the recognised

technical rules regarding accident prevention must be observed.

Liability and warranty

All the information contained in this instruction manual has been

drawn up to the best of our knowledge and belief, taking our

experience to date into consideration.

The original version of this instruction manual was drawn up in

the German language and was checked by us for accuracy of

content. The translation into the respective national/contractual

language was carried out by a recognised translation agency.

This instruction manual has been put together with the greatest

of care. However, if you should discover any incomplete items or

mistakes, please inform us in writing. Your suggestions for

improvement will help us to create a user-friendly manual.

Subsequent Orders and Copyright

Further copies of this instruction manual can be ordered from

the address below. We ask for your understanding that further

copies are subject to charge.

Jepson Power GmbH

Ernst-Abbe-Straße 5

D-52249 Eschweiler

Phone: +49 (0)2403 – 6455-0

Fax: +49 (0)2403 – 6455-15

All rights are expressly reserved. Duplication or transfer on to

third parties in any form whatsoever is not allowed without our

prior written permission.

Abbreviations

V Volt

Hz Hertz

W Watt

~ AC

/min Revolutions per minute rpm

N Newton

4 Safety Instructions

The basic prerequisite for safe handling and disturbance-free

operation of this electric tool is knowledge of the basic safety

instructions. In addition, the accident prevention rules and

regulations which apply in the user location must be adhered to,

as well as the recognised rules of the trade with regard to safety

and correct working methods.

It is not permitted to use the electric tool for other purposes than

those intended by the manufacturer. Such use could give rise to

unforeseeable risks.

Local working and safety rules and laws must always be

followed. The same applies to regulations which apply to the

environment.

Safety equipment must never by removed or bridged over.

When using oils, greases and other chemical substances, the

safety regulations which apply to the particular product must

always be observed! Contact with chemicals should be avoided

as far as possible. Before it is permissible to work with these

substances the instructions for use on the packaging must be

read and followed. This applies for all chemicals, therefore also

for cleaning media.

All notes and signs regarding safety and possible risks must be

kept in a fully legible condition.

4.1 Illustration of

Safety Instructions

The following symbols are used in the instruction manual:

Warning against possible danger of injury or

danger to life for persons

Warning

Warning against possible damage to property or

the environment

Caution

Warning against dangerous electrical voltage

Warning against hot surfaces

Ignoring these instructions can lead to serious damage to

health, up to life-threatening injuries!

This symbol indicates important information

Hazardous to the environment

4.2 General Safety Instructions

This electric tool fulfils the basic EC safety

and health regulations. Nevertheless,

dangerous situations can arise.

Warning

All safety equipment must be maintained in

perfect condition.

Warning

Always pay attention to moving parts.

These can cause injury because of their

movement or by sudden movement.

Warning

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 4 of 10

Only use the electric tool when it is in

perfect condition from the technical point

of view, and only use it for intended

purpose while being aware of safety

issues and risks, and paying attention to

the instruction manual! In particular,

have any disturbances which could have

a negative effect on safety corrected

immediately!

WARNING! It is essential to read all the instructions.

Mistakes which are made while attempting to follow the

below instructions can cause electric shock, fire and/or

serious injury. The following term "Electric tool", refers to

mains-powered electric tools (with mains cable) and

battery-powered electric tools (without mains cable).

Warning Caution

KEEP THESE INSTRUCTIONS IN A SAFE

PLACE.

Work Area Safety

Keep your work area clean and well lit. Cluttered benches

and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquid, gases, or dust.

Power tools create sparks, which may ignite the dust or fumes.

Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to lose

control.

Electrical Safety

Warning Caution

Earthed tools must be plugged into an outlet properly

installed and earthed in accordance with all codes and

ordinances. Never remove the earthing prong or modify the

plug in any way. Do not use any adaptor plugs. Check with

a qualified electrician if you are in doubt as to whether the

outlet is properly earthed. If the tools should electrically

malfunction or break down, earthing provides a low resistance

path to carry electricity away from the user.

Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body is earthed or

grounded.

Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

Don’t abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged or entangled cords increase the risk of

electric shock.

When operating a power tool outside, only use authorized

cords for outdoor work. These cords are rated for outdoor use

and reduce the risk of electric shock.

Personal Safety

Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury.

Use safety equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hardhat, or

hearing protection used for appropriate conditions will reduce

personal injuries.

Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools that have the switch on invites accidents..

Warning Caution

Remove any adjusting key or wrenches before turning the

tool on. A wrench or a key that is left attached to a rotating part

of the tool may result in personal injury.

Do not overreach. Keep a proper footing and balance at all

times. Proper footing and balance enables better control of the

tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

Tool use and care

Use clamps or other practical way to secure and support

the work piece to a stable platform. Holding the work by

handor against your body is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

Do not use tool if switch does not turn it on and off. Any tool

that cannot be controlled with the switch is dangerous and must

be repaired.

Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting the

tool accidentally.

Store idle tools out of reach of children and do not allow

persons unfamiliar with the power tool or these instructions

to operate the power tool. Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control.

Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts, and any other condition

that may affect the tools operation. If damaged, have the

tool serviced before using. Poorly maintained tools cause

many accidents.

Use the power tool, accessories and blades etc., in

accordance with these instructions and in the manner

intended for the particular type of power tool, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool may become hazardous when used on

another tool.

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 5 of 10

Warning Caution

Service

Only qualified repair personnel must perform tool service.

Service or maintenance performed by unqualified personnel

could result in a risk of injury.

When servicing tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

4.3 Specific Safety Rules

Never operate the tool in an area with flammable solids, liquids, or

gases. Sparks from the commutator/carbon brushes could cause a

fire or explosion.

WARNING! Risk of injury from high-

temperature chips!

High-temperature chips are expelled at high

speed. Never touch the tool holder and keep

all vulnerable body parts clear while the

machine is running.

Warning

Always guide the machine away from the body while working. Do

not work holding the machine above your head.

WARNING! Some dust created by power

grinding contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Warning

An example of these chemicals are: lead from lead-based paint

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well-ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed

to filter out microscopic particles.

1. Use clamps or other practical way

to secure and support the work

piece to a stable platform. Holding

the work by hand or against your

body is unstable and may lead to

loss of control.

2. Keep hands away from rotating

parts.

3. Wear eye and hearing protection.

Always use safety glasses. Every

day eyeglasses are NOT safety

glasses. USE CERTIFIED SAFETY

EQUIPMENT.

4. Use of this tool can generate and

disburse dust or other airborne

particles including wood dust,

crystalline silica dust and asbestos

dust. Keep direct particles a way

from face and body. Always operate

tool in well ventilated area and

provide for proper dust removal. Use

dust collection system wherever

possible. Exposure to the dust may

cause serious and permanent

respiratory or other injury, including e

silicosis (a serious lung disease)

,cancer and death. Avoid breathing

the dust, and avoid prolonged

Warning

contact with dust. Allowing dust to

5 Functional Description

5.1 Unpacking

The Wraparound Tube Sander is especially designed for fast

sanding, compounding, mirror polishing and buffing of stainless

steel and aluminium open and closed tube forms. There are

different belts available in various grits. The unique feature of this

machine is its ability to contact a tubular surface and wrap around

about 180 degrees of its circumference at a time for very fast and

efficient working.

ASSEMBLY

CAUTION:

DISCONNECT TOOL FROM POWER SOURCE.

THE GUARD AND HANDLE

Warning

Place the front handle in position on the belt guard

and tighten by hand.

5.2 Installing the belt

1. Lay the machine so that it is upside down resting on the

front handle (with the handle parallel to the ground).

2. Loop belt around the drive pulley and the idler arm

(stationary) pulley.

3. While pushing the tensioner arm down against the spring

to create enough slack, slip the belt over the tensioner

arm pulley. Then release the arm.

WARNING: The machine should not be

converted or modified, e.g. for any other form of

use, other than as specified in these operating

instructions. The user shall be liable for

damages and accidents due to incorrect use

.

Warning

get into your mouth or eyes, or lay on your skin

may promote absorption of harmful material .

Always use properly fitting mask approved for

the dust explosure and wash exposed areas

with soap and water.

DANGER: Indicate an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

Indicates a potencially hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION: indicates a potentially hazardous

situation which, if not Avoided, may result in

minor or moderate injury or indicates

potentially hazardous situation which, if not

Warning

Warning

Warning

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 6 of 10

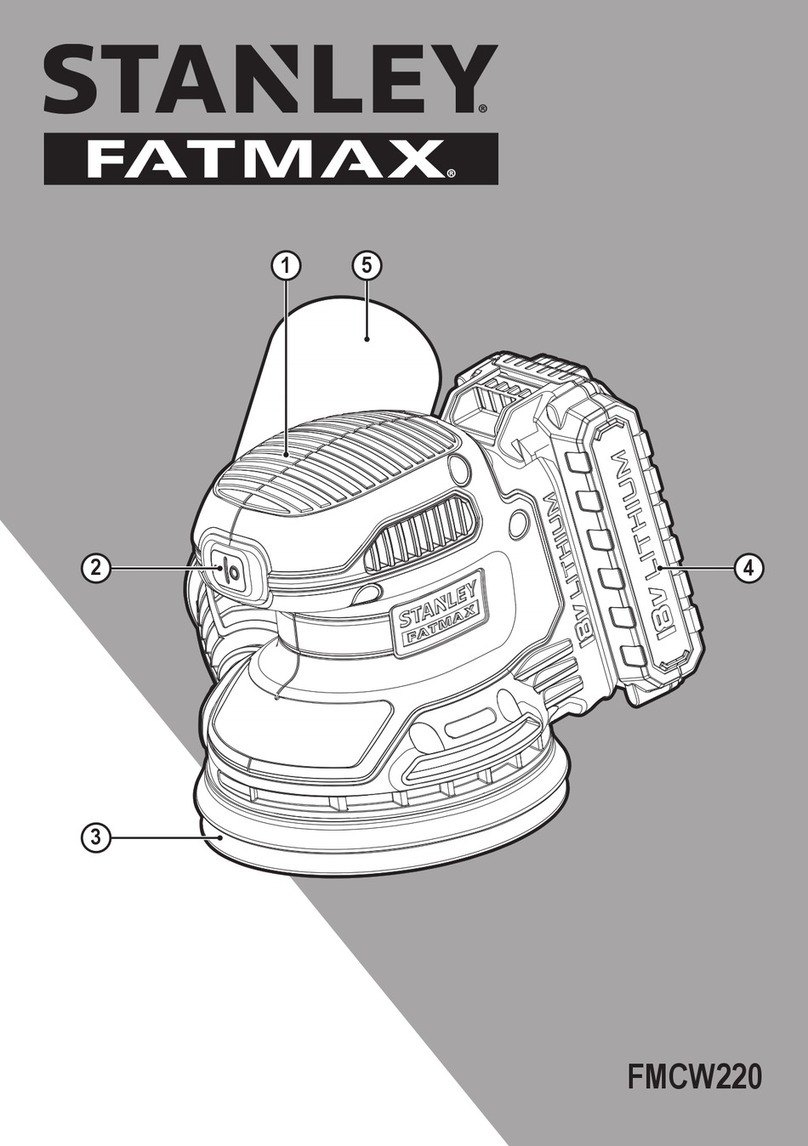

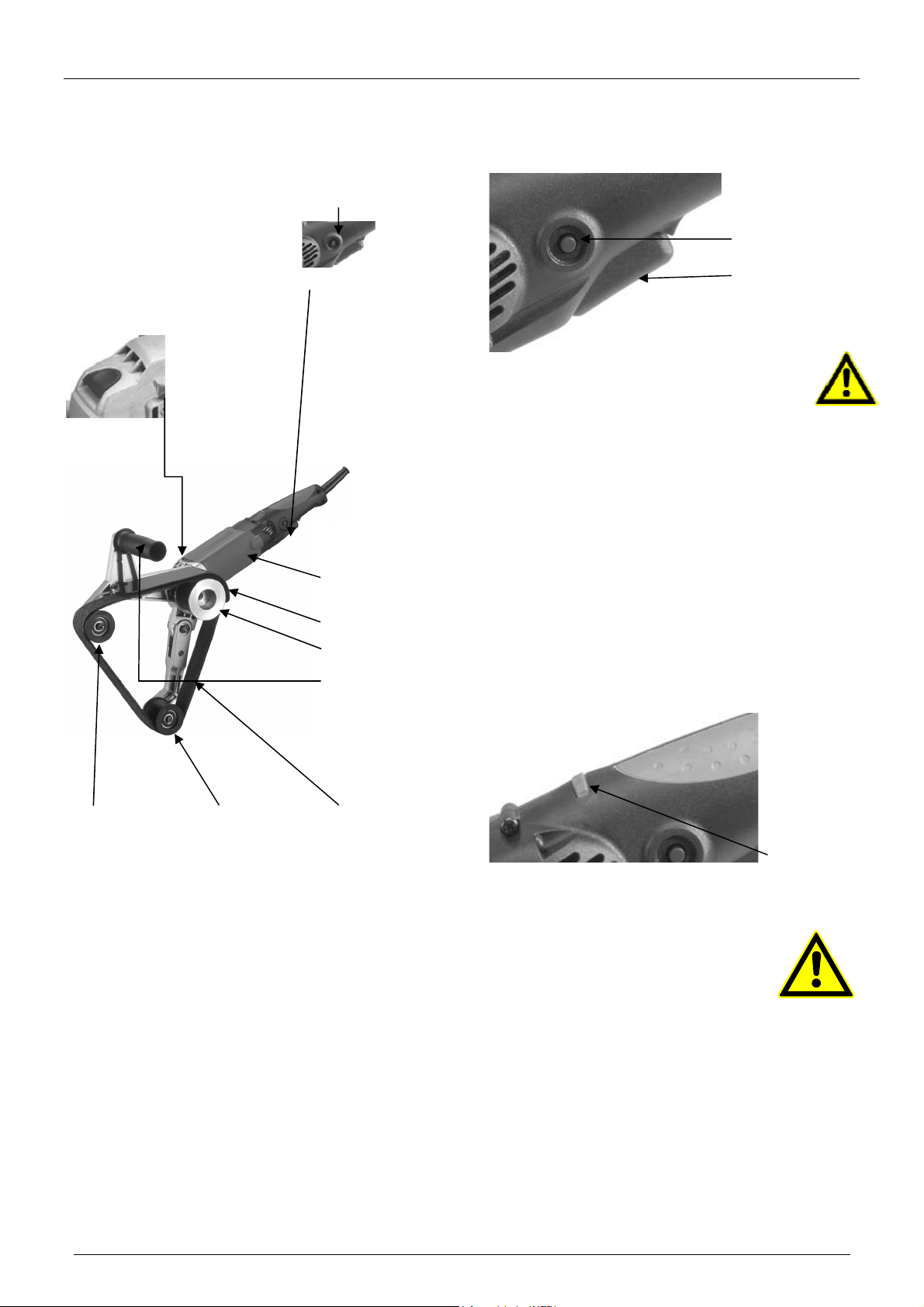

5.3 Wraparound TUBE SANDER

Do not operate this too until you read and understand the

entire instruction manual.

OPERATION: Start and Stop of the machine

Switch look

Trigger switch

CAUTION:

Make sure switch is OFF and power circuit voltage is

the same as that shown on the specification plate.

1. Connect tool to power source.

2. Grip machine firmly to resist start in torque

3. Squeeze trigger switch to turn tool on. Release the trigger

to shut tool off.

4. To lock the switch in the “on” position, press the lock pin

while the switch is fully on. To release the lock, press the

switch and release it.

5.4 CONTROLLING THE VARIABLE SPEED

The thumbwheel sets the maximum speed, while the trigger turns the

machine on and off. With switch in the locked ON position the

thumbwheel may be used to adjust the speed. This machine

incorporates feedback speed stabilization so that the speed will not

slow with load. It will maintain the present speed regardless of the

load.Always start at a slower speed and work up to the best speed.

Speed adjustment

5.5 OPERATION

WARNING: If the workpiece is not

attached to anything and is light

enough to be moved by the spinning

drum, it should be securely clamped or

anchored to prevent it being thrown or

flung, resulting in possible injury.

Warning

1. Hold the machine firmly by the front andrear handles,

making sure the drum is clear of foreign objects.

2. Start the machine and lower it to the work.

3. Move the machine in long overlapping strokes. DO NOT

HOLD TOO LONG IN ONE SPOT otherwise will overheat

the surface and cause uneven results.

4. Always be sure motor has stopped before setting the

machine down.

Guard clamp lever

Spindle lock

Idler arm pulley Tensioner Belt (optional)

arm pulley arm pulley

Trigger switch

Lock button

Motor

Guard

Drive pulley

Front handle

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 7 of 10

When using the machine to apply products (compounds, polishes,

waxes, cleaners, etc). always read and follow the manufacturers

directions supplied with product. In this case do not run the

machine without the drum in contact with work surface. Otherwise

the media will be thrown outwards. Start and stop the machine with

the drum against work surface.

WARNING: Do not use the same belt to apply different

grades of compound. The coarser compound will

contaminate the finer compound, causing poor

results.

Warning

6 Maintenance and Repair

6.1 Keep Tool Clean

Periodically blow out all air passages with dry compressed air. All

plastic parts should be cleaned with a soft damp cloth. NEVER

use solvents to clean plastic parts. They could possibly dissolve

or otherwise damage the material. Wear safety glasses while

using compressed air.

Wear safety glasses while using compressed air.

6.2 FAILURE TO START

Should your tool fail to start, check to make sure the prongs on the

cord plug are making good contact in the outlet. Also, check for

blown fuses or open circuit breakers in the line.

6.3 Replacing Carbon Brushes

The carbon brushes are a normal wearing part and must be

replaced when they reach their wear limit.

NOTE: Checking and replacing the carbon brushes should be

entrusted to a qualified service center.

The carbon brushes furnished will last approximately 50 hours of

running time or10,000 on/off cycles. Replace both carbon brushes s

when either has less than 1 / 4 " length of carbon remaining.

To replace:

1. To inspect or replace brushes, first

unplug the machine. Carefully

remove the 8 screws to separate

the two handle halves and remove

fr om t he m ot or housing. Remove the

left handle half first.

2. There will still be wires connected to

the rear handle, so take care that

these are not stressed. Simply hold the

rear handle off to one side.

3. Next remove the two screws holding

on the Electronics Unit to allow access

to the Brush Holder screws. Hold the

Electronics Unit off to one side and

avoid stressing the wires.

4. Unscrew the two Carbon Brush Holders

in turn and remove the Carbon

Brushes.

NOTE: When putting the Carbon

Brushes back into the Carbon Brush

Holders it is essential that both

flanges go back inside the holder.

NOTE: To reinstall the same brushes ,

first make sure the brushes go back

in the same way they came out.

Otherwise a break –in period will

occur that will reduce motor

performance and increase brush

wear.

Replacing is the reverse of removal. Replace the Brush Holder

screws, then the Electronics Unit screws.

When Replacing the rear handle to the motor housing, take great

care that all wires are in place and not in a position to be pinched

when it is retightened.

It is recommended that, at least once a year, you take the tool to an

Authorized Service Center for a thorough cleaning and lubrication.

If the replacement of the power supply cord is necessary,

this has to be done by the manufacturer or their agent in

order to avoid a safety hazard.

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 8 of 10

7 Standard Accessories

10 arbor spacer discs ( for fitting smaller wheels to the arbor)

8 Optional accessories:

Surface Conditioning belt

120 grit Sandpaper belt

Sanding Sponge Belt-Fine

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 9 of 10

9 Spare parts - List of Spare Parts

No . Pa r t . No . QT ' Y

1.) WS001 POWER SUPPLY CABLE 0.75 x 2C x 3M 1

2.) WS002 CORD A RMOR 1

3.) WS003 CA BLE CLIP 1

4.) WS004 SCREW M4 x 14 6

5.) WS005 WIRE LEAD 1

6.) WS006 SWITCH 1

7.) WS007 SCREW M4 x 25 4

8.) WS008 RIGHT HA NDL E COV ER 1

9.) WS009 LEFT HANDLE COVER 1

10.) WS010 SCREW M4 x 20 2

11.) WS011 ELECTRONICS UNIT 1

12.) WS012 THUMB WHEEL 1

13.) WS013 BRUSH SCREW M4 x 8 2

14.) WS014 CA RBON BRUSH 2

15.) WS015 CA RBON BRUSH HOLDER 2

16.) WS016 SCREW M4 x 8 3

17.) WS017 FLAT WASHER M4 1

18.) WS018 PLASTIC WASHER φ4 x φ11 x 1 1

1 9 . ) W S0 1 9 PIC KUP MA G NET φ8 x φ15 x 5 1

20.) WS020 SPACER φ8 x φ12 x 10.5 1

21.) WS021 MOTOR HOUSING 1

22.) WS022 STATOR 220 Volt 1

23.) WS023 STATOR SCREW M4 x 60 2

24.) WS024 BALL BEARING 608-2RS 1

25.) WS025 ARMATURE 220 Volt M1.0 6T 1

26.) WS026 BALL BEARING 6000-2RS 1

27.) WS027 GEA R CA SE 1

28.) WS028 SPINDLE LOCK BUTTON 1

29.) WS029 SPRING φ0.9 x φ10 x 13.

5

1

30.) WS030 SPINDLE LOCK 1

31.) WS031 SCREW M4 x 30 4

32.) WS032 NEEDLE BEA RING HK0608 1

33.) WS033 BEVEL GEAR M1.0 46T 1

34.) WS034 GEAR PLATE 1

35.) WS035 SCREW M4 x 20 4

36.) WS036 EXTERNAL CIRCLIP S-12 1

37.) WS037 BALL BEARING 6001-2RS 1

38.) WS038 PARALLEL KEY 4 x 4 x 8 1

39.) WS039 SPINDLE 1

40 .) WS0 40 INTERNA L CIRCL IP R- 28 1

41.) WS041 FRONT HA NDLE 1

42.) WS042 IDLER ARM 1

43.) WS043 AXLE 16*17 2

44.) WS044 BALL BEARING 6200-2RS 4

45.) WS045 PULLEY 2

46.) WS046 EXTERNAL CIRCLIP S-10 2

47.) WS047 BOLT M10 x P1.5 x 12 2

48.) WS048 PIVOT BOLT M8 x P1.25 x 7.7 1

49.) WS0 49 HA IRPIN SPRING φ2.8 x φ14.5 x

4

1

50.) WS050 TENSIONER ARM 1

51.) WS051 GUARD 1

52.) WS052 SCREW M4 x 25 4

53.) WS053 DRIVE PULLEY 1

54.) WS054 SCREW M5 x 8 2

De s cr ip t i p n

Instruction Manual WRAPAROUND TUBE SANDER 760/40

Page 10 of 10

10 Spare Parts Drawing

Table of contents

Other Jepson Sander manuals