Jesco C 2700 Manual

Chlorinator C 2700

BW 2 03 01 / 1

Injection Nozzle

The chlorine injection fittings or chlorine solution injectors

are made from PVC and are fitted with a shutoff valve

(ball cock) and injection piping, which, for installation, is

shortened to half of its diameter with a 45° diagonal cut.

The injection nozzles are integrated either in water-

bearing lines or in open basins at such points where

turbulences enable a good mixture.

For injection into open basins, drains or induction

manifolds, long, perforated pipes closed at the end are

suitable, which are tied to the bottom under water. Thus

a fine and large-area distribution can be ensured.

Safety Blowoff Line

The PE tubing, which is part of the packing unit, is

connected to the center chamber of the chlorinator and

either laid outside with inclination or led to the sensor of

the gas warning device (25), depending on the local

conditions. The tubing is used to carry off chlorine gas,

if the safety valve installed in the center chamber of the

chlorinator has responded.

Gas Supply

Direct Gas Delivery

Chlorine is available in steel cylinders of 65 kg and steel

barrels of 500 and 1,000 kg. Because of the large

quantities required, we recommend to use always barrels,

as only 1 % of the contents may be delivered hourly as

gas at a temperature of 20° C. For chlorine deliveries of

up to 25 kg/h, at least 3 barrels of 1,000 kg should be

connected for direct gas supply.

Operating and Maintenance Instructions

Packing

The C 2700 equipment is packed individually because of

its size and variable accessories. Refer to the delivery

note for the actual scope of delivery.

Notes on Installation

Before installation carefully check the location in which

the chlorinator and tank are to be mounted, according to

the directions of the local authorities. In general, the

standardized safety rules for "Chlorination of Water"

apply.

—Chlorine tank and chlorinator must be located in

different rooms.

—The floors of these rooms must not be underground.

— Escaping chlorine gas must not enter other lower

rooms, wells, mines or drains.

— The chlorine rooms must not be connected to other

rooms. A fireproof and gastight separation is required.

Make sure that the doors open outwards and always

without a key from inside.

— Each room is to be provided with small ventilation

openings in the floor and ceiling. These openings

must directly lead outside, and their cross sections

should not exceed 40 cm2.

— In the case of unfavourable locations, e.g. near

schoolyards or rest-cure meadows, gas warning

devices with visual and acoustic signaling are to be

installed instead of ventilation openings. They must

be coupled with an automatic sprinkler system.

Delayed activation is admissible.

—It is important to use always appropriate tools. Make

sure that two fixed spanners are used for detaching

and connecting chlorine lines in order to avoid

unadmissible loading of the device components.

Ejector Water Supply

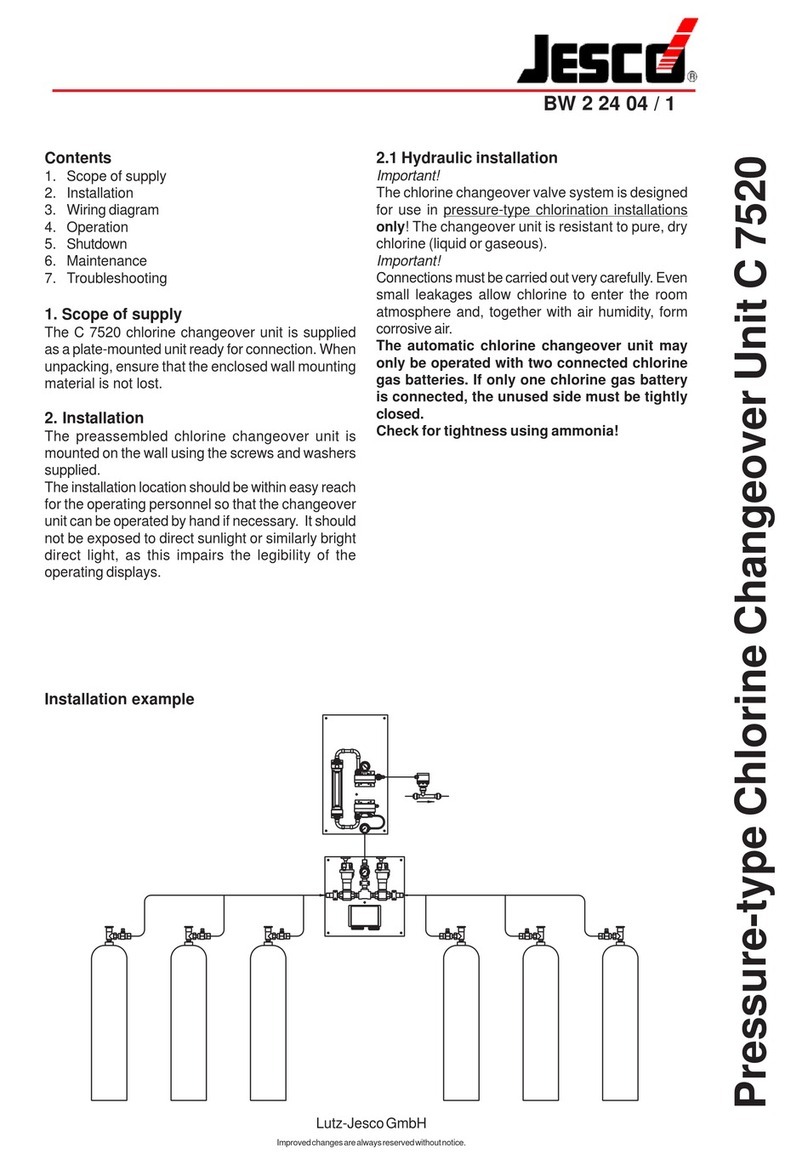

The numbers mentioned below refer to the schematic

diagram on page 6.

In order to operate a full-vacuum chlorinator, the ejector

(14) must be provided with the appropriate motive water

pressure and the corresponding quantity of motive water.

For the accurate values, see the characteristic curves for

ejectors. If the existing water pressure is not sufficient

according to the ejector data sheet, a booster pump (20)

must be connected. The non-return valve (13) mounted

on the ejector prevents the motive water to return to the

chlorine gas vacuum line if the motive water supply is

switched off or if the ejector is faulty.

As it cannot be excluded that the non-return valve leaks

due to contamination, a motor ball cock (12) must be

opened in dependence on the booster pump (20). Before

entering the ejector, the line must be straight approx.

20 x DN in axial direction of the ejector. A dirt trap with a

mesh aperture of less than 0.5 mm should be used in any

case, no matter if a booster pump is part of the installation

or not.

Chlorine Solution Line

The chlorine solution produced in the ejector is led to the

the injection nozzle (16) via a PVC piping and non-return

valve (15). After the ejector, the line should be straight (5

x DN). In order to avoid pressure losses in the solution

line, use as little bends and fittings as possible.

Chlorine solution from ejector perforated pipe

e.g. cooling-water basin

Chlorine Evaporation

Liquid chlorine deliveries are recommended for quantities

of more than 25 kg/h. With the help of an evaporator (see

MB 2 05 01), the liquid chlorine is converted into gas by

electrical heating and then led to the chlorinator as

described before.

Shutoff valve Injection

piping

1/2 DN

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Chlorinator C 2700

BW 2 03 01 / 2

Storage of the chlorine barrels and connection of the

chlorinators

The barrels have to be stored horizontally on supports.

Remove the protective cap of the valve right before

connection of the lines.

Caution:

Make sure that the gas supply of the barrel is connected

and not the liquid chlorine supply if no evaporator is

used.

The barrels are marked with a stripe which must be

horizontal when the barrel is positioned in the support.

The upper connection is always used for chlorine gas,

the lower connection delivers liquid chlorine for evaporator

operation.

Use always new sealings for the connection of lines and

fittings. The flexible copper lines must be cut off

rectangularly at both ends and inserted very carefully into

the screwings with cutting ring.

The threaded coupling is held tight with one fork wrench,

another one is used to fasten the union nut of the screwed

union. If only one barrel is used the line is connected

directly to the inlet valve of the chlorinator as described

before.

The line must always go upward.

Operating and Maintenance Instructions

Colored stripe

Cut rectangularly and

push 5 mm of the pipe

through the cutting ring

Pipe must never be out

of true at the cutting ring

right wrong

Slightly move the line during fastening

Right installation

*The liquid separator is not required if the connected

lines are dimensioned so that they can carry approx.

150 cm3of liquid chlorine without entering the chlorinator.

Twist the flexible lines like a rising coil. Thus liquid

chlorine can flow back to the barrel. If several barrels are

connected, these are linked together first by means of a

manifold (3). A main shutoff valve (4) is mounted on the

output. A steel or copper pipe connects this valve to the

inlet valve of the chlorinator. For automatic cutoff of the

chlorine gas in the case of an alarm, a solenoid valve (6)

can be installed which is controlled by the gas warning

device (25). All lines and fittings in contact with chlorine

gas must be sealed with DIACRYLAT liquid plastic.

Never use organic substances such as hemp!

If the chlorine gas is highly contaminated, we recommend

to integrate a commercial chlorine gas filter (9) in the line.

For a continuous operation, it is appropriate to install an

automatic chlorine barrel changeover device (5). It is

mounted between two barrel batteries and, in connection

with a chlorine gas contact vacuum gauge (7), ensures

uninterrupted metering. A switch box supplied with the

changeover device indicates the battery currently

connected by means of LEDs. Chlorine barrels and

chlorinators must be protected against direct sunlight

and heating by radiators. The temperature along the gas

line must never be lower than the cylinder temperature,

because recondensation of chlorine gas severely

damages the chlorinator. If chlorine recondensation is

possible, a chlorine reducing valve (8) must be installed

as close as possible to the chlorine barrels or after the

changeover valve (5).

To avoid recondensation, make sure that the temperature

of the room heating is not reduced at night because the

chlorine gas lines cool off much faster than the barrels.

Cool nights after warm summer days might have the

same effect.

Wrong installation

Possible

chlorine agglomeration

Upper connection for

chlorine gas

Lower connection for

liquid chlorine

Lay flexible copper lines

upward as shown

Liquid

separator

*

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Chlorinator C 2700

BW 2 03 01 / 3

Operating and Maintenance Instructions

below the chlorinator (10) into a water tank. Open shutoff

valve (16) and motive water line. The chlorinator is then

under vacuum. When the gas line is closed, a column of

water is primed according to the displacement volume of

the diaphragms and can be seen in the transparent

tubing.

If the device is absolutely tight, the column of water will

have a constant level. If there is a leak, the water will

continue to rise. Interrupt the test, before water enters

the chlorinator. See troubleshooting table.

Safety Valve

The safety valve installed in the center chamber of the

chlorinator is closed if the chlorine gas inlet valve is

operable. If it leaks due to contamination or wear, an

excessive pressure is produced in the lower chamber.

The safety valve opens at an excessive pressure of

approx. 0.5 bar and, via the vent line, carries the chlorine

gas outside or to the installed warning device. Check this

line using a small amount of ammonia solution (liquid

ammonia) when starting up the installation.

Replacing the Measuring Glass

For replacement, remove the measuring glass (k) together

with the receiving blocks (b). The spacer bolts (c) can be

dismounted after screwing off the cap nuts (d). After

loosening the screws (h), the receiving blocks (b) can be

removed. For assembly, proceed as follows:

Prepare both receiving blocks (b) by positioning the

flange bushing (e) in the recess of the receiving block and

by covering it with the rubber ring (f). Then the flange (g)

(still without measuring glass) is fastened manually with

screws (h). The measuring glass (k) is prepared by

inserting the float (i) with the point showing downward

and the fitting edges (l) into the measuring glas ends.

Then the preassembled blocks are slid onto the measuring

glass ends. Insert the spacer bolts (c) and fasten with

nuts (d) by turns so that the receiving blocks are parallel

to each other. The prepared measuring set is fixed to the

base plate. Now tighten the spacer bolts (c) gently by

turns. Fasten the flanges (g) with the screws (h) and

connect the lines.

Chlorinators

The chlorinators are installed perpendicularly, because

the measuring glass must be vertical for accurate

indication. The motive water and solution lines have to be

connected to the injection nozzles, in accordance with

the ejector nominal widths and free of tension. In the case

of long solution lines, the pressure loss must be considered

as back pressure of the ejector.

Sprinkler System

All rooms storing chlorine should have a sprinkler system

(24), which cleans the air if chlorine gas escapes. The

system can be switched on outside the room by means

of a hand valve (23) with an extended spindle or by a

solenoid valve (22) controlled by the gas warning device

(25).

Tests Before Startup And For Maintenance

Purposes

Motive Water And Solution Line

If the existing motive water pressure is lower than 10 bar,

the shutoff valve (16) can be closed for the pressure test.

Open the motive water valve slowly and check for leaks.

Fasten the screwed PVC joints manually. Leaking

cemented connections must be renewed with balanced

lines. At motive water pressures of more than 10 bar, the

shutoff valve (16) must always be open in order to protect

the ejector. The system pressure prevailing at the injection

nozzle becomes effective.

Ejector Non-Return Valve

For pressure test, close shutoff valve (injection nozzle)

and open motive water line slowly. Disconnect suction

tubing at the joint of the non-return valve (13). The valve

must not leak. If it is leaking, dismount the valve and

eliminate the error.

Vacuum LeakageTest of the Chlorinator

Plunge the end of more than 3 m of transparent PE vent

line (17) coming from the center chamber approx. 1.5 m

approx. 1.5 m

vertical height

transparent

tubing (3 m)

Water

k

i

g

f

b

h

l

c

e

d

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Chlorinator C 2700

BW 2 03 01 / 4Operating and Maintenance Instructions

Checking the Adjusting Screw

For sealing, the flow volume adjusting screw is fitted with

an O-ring at the front end. During operation, it can be

checked if this O-ring leaks. Move the adjustment knob

laterally. As long as the O-ring is in the adapter, the

display of the measuring glass must not change

considerably. If it does, however, remove the adjusting

screw and equip it with a new O-ring. Before screwing it

in place again, coat it slightly with silicon lubricant.

Gas Pressure Line

The leakage test of the parts in contact with chlorine gas

is realized by blowing-in of the lines and especially the

fittings with (liquid) ammonia. The chlorine tank must be

shortly opened for this purpose in order to pressurize the

system. If chlorine escapes, white smoke occurs. Due to

the extreme corrosiveness of humid chlorine gas, leaks

will grow larger in course of time.

Consequently, even the smallest leak must be

eliminated!

Barrel/Cylinder Connecting Valves

If the barrel connecting valve (2) leaks the gland stud

must be retightened by about a quarter turn. For this

purpose the handwheel of the valve must be removed.

This can be done under gas pressure, as the valve stem

cannot drop out. For detailed instructions, see

ET 2 22 01.

Attention!

The valve stem has a very fine thread. Please make sure

that it is not damaged when the handwheel of the valve

is dismounted.

Silicon lubricant

Vaseline or Silicon lubricant makes installation easier

Gland stud

Cylinder auxiliary

valve X = 23 mm

Barrel auxiliary

valve X = 35 mm

Inlet Valve

Plug the valve seat assembly incl. the PTFE bush (2) with

O-ring (3) into part (6) and tighten it with part (4) and

screw (5). Insert stem (1) with spring (8) and prestress it

with the help of part (7) until the latter is countersunk in

part (6) (approx. 5 mm).

Test:

Connect the valve to compressed air (6 bar) and plunge

it into water. Air bubbles must not occur.

Setting the External-Air Valve

The external-air valve is set so that the vacuum does not

exceed 0.5 bar absolute. Detach part (17). Hold part (18)

with a screw driver and turn part (16) (turn right to reduce

the absolute suction pressure).

X

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Chlorinator C 2700

BW 2 03 01 / 5

Operating and Maintenance Instructions

Operating the System

Before startup, check once again if the number of chlorine

tanks connected is sufficient for the chlorine consumption.

Then the flow meter can be fully opened. Rule of thumb:

Maximally 1 % of the filling weight of a chlorine tank may

be delivered as gas per hour. If an evaporator is used for

gas supply, it must be preliminarily heated for operation.

In this case, 20 % of the liquid chlorine contents may be

taken from the tank per hour.

Startup

For startup, first open the main and auxiliary valves (2) of

the chlorine tanks and then the shutoff valve (16) (injection

nozzle) and motive water line. Under perfect operating

conditions, a vacuum is produced in the ejector, which is

propagated via the ejector non-return valve (13), the ball

cock (12) and the suction line to the chlorinator and

causes the chlorine gas inlet valve to open. Chlorine gas

starts to flow and is mixed with motive water in the ejector.

The exact chlorine gas quantitiy required can be set at

the adjusting screw. The chlorine quantity is read at the

top edge of the float.

Switching Off the System

The cylinder/barrel connecting valves (2) are closed. To

switch off the system the float must be on zero level (and

the system must not contain chlorine gas under excessive

pressure anymore).

Caution!

Before longer periods of standstill, the lines and devices

carrying gas must be flushed with nitrogen for about

5 minutes. All dismounted devices, lines and fittings in

contact with chlorine must be cleaned and dried and

protected against humid air by inserting plugs. Empty the

water-carrying parts if there is danger of frost.

Maintenance

Regular maintenance avoids problems. We recommend

a maintenance contract.

If there are no rules/specifications (e.g. GUV 8.15) or

special annotations prescribing shorter maintenance

intervals, all JESCO chlorinators have to be maintained

and tested by an authorized specialist firm at least once

a year. Preferably this should happen at the beginning

of a high-rate period, prior to a downtime or a restart.

General

The vacuum systems described need little maintenance.

Nevertheless, a chlorination installation must not be

without observation. Even the smallest leak is growing

larger within a short time due to the aggressiveness of

humid chlorine gas and causes other parts to corrode.

Therefore stop the installation immediately if a leak is

detected and eliminate the error.

Working on the gas pressure line, replacing the

cylinder/barrel

If a defective part has been detected, close the chlorine

cylinder/barrel valves and suck off the gas by switching

on the system. Dismount the defective part and protect

the remaining gas line against humiditiy (e.g. put a dry

cloth into the pipe end).

HUMIDITY IN THE PIPING CAUSES LOCALIZED

CORROSION!

Close main valve tightly before exchanging the chlorine

cylinder/barrel and disconnect it from the main valve

using a fork wrench. Mount the protective cap of the

chlorine cylinder/barrel. Do not bend the flexible copper

line when dismounting it. Position full barrel on the

support and remove protective cap. For further

information, see item 1.8.

Provide the auxiliary valve with a new sealing and open

the main valve shortly. Check with ammonia whether the

connection is gastight. For recommissioning, make sure

that the new cylinder/barrel has room temperature. and

never exceeds it.

Cleaning the installation

Before working on the chlorination installation, it is

absolutely necessary to close the chlorine cylinder/

barrel valves and suck off the chlorine gas until the flow

meter and chlorine pressure gauge show zero.

Disassembling the flow meter

Carefully remove the limiting plugs of the measuring

glasses (observe float) and clean them with water only.

The floats must not be damaged. Clean the glasses and

floats with water or isopropyl alcohol. Dry parts completely!

When assembling the flow meter, the upper and lower

seals must be concentric.

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Chlorinator C 2700

BW 2 03 01 / 6

Operating and Maintenance Instructions

Schematic Diagram

1. Chlorine barrel MB 2 21 01

2. Chlorine barrel valve with flexible coupling MB 2 22 01

3. Manifold MB 2 23 01

4. Main shutoff valve MB 2 24 01

5. Electrical chlorine changeover valve MB 2 24 01

6. Safety solenoid valve MB 2 25 01

7. Pressure gauge for changeover device MB 2 40 01

8. Pressure reducing valve MB 2 27 01

9. Chlorine gas filter MB 2 26 01

10. Chlorinator MB 2 03 01

11. Electrical chlorine gas control valve MB 2 07 10

12. Shutoff ball cock

13. Ejector non-return valve MB 2 32 01

14. Ejector MB 2 31 02

15. Non-return valve

16. Shutoff valve with solution injection MB 2 34 01

Legend

17. Safety blowoff line

18. Filter

19. Shutoff valve MB 2 29 04

20. Booster pump MB 2 29 01

21. Control cabinet

22. Solenoid valve for sprinkler valve MB 2 36 10

23. Manual shutoff valve for sprinkler system

accessible from outside MB 2 36 10

24. Sprinkler jet MB 2 36 10

25. Sensors of the gas warning device MB 2 36 05

Note:

Not all of the system components shown are absolutely

necessary. The scope of installation should be planned carefully

by a specialist.

Chlorine deposits may cause servere problems. To avoid

these, use a pressure reducing valve (8).

14

13

12

10

25

78

9

5

11 24

3

446

17

15

21

22

23 19 19

20

18 16

21

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Chlorinator C 2700

BW 2 03 01 / 7

Operating and Maintenance Instructions

Type of fault Possible cause Remedy

No display or Chlorine barrel empty, indicated by Connect new barrel.

insufficient display low chlorine gas pressure.

on flow meter Connecting valve closed. Open valve.

Chlorine gas line bent or blocked. Close chlorine barrel,

drain off line and device,

stop motive water supply, dismantle chlorine

gas line and clean or replace it.

Blocked filter before inlet valve, Clean or replace filter.

indicated by low chlorine volume

despite high vacuum.

Motive water pressure too low. Compare ejector characteristics sheet with

acutal pressure values, install booster pump,

if necessary.

Open reducing valve.

Back pressure too high.

Excessive pressure drop in dirt trap Remove dirt trap from reducing valve

of motive water. and clean filter.

Also flush water lines.

Ejector blocked, contaminated or Remove ejector, clean PVC inlet nozzle and outlet

encrusted by deposits (possibly caused borehole using hypochloric acid and rinse well in

by decarbonization in the diffusor). water. If possible, apply higher concentration of

chlorine (1...2g/m3) in the solution to obtain more

HCL. Set motive pressure before ejector as low as

possible but make sure that the maximum chlorine

still be metered.

Block solution injection fitting. Remove and clean solution injection fitting and

check if the valve is fully open.

Excessive back pressure caused by bent Lay line with sufficiently large bends: PVC

or blocked solution line. Excessive lines may have restricted cross-sections due to

pressure losses due to friction in pipes wrong gluing.

or fittings. Check joints.

Float stuck in flow meter glass. Clean flow meter as described under

Maintenance.

Components under vacuum prime Check the joints of the suction line, the ejector

external air. non-return valve and the flow meter glass holder.

Metered volume Inlet valve blocked. Remove inlet valve as described under

does not increase Maintenance.

when adjusting screw

is opened.

Vacuum primed by the ejector is too low. See above.

Float stuck in the flow meter glass. Clean the flow meter glass as described under

Maintenance.

Chlorine odor in the Gas lines leak. Close barrel connecting valve immediately and drain

room. off lines using the ejector. Leakage test as described

under Startup.

Safety valve integrated in device blows Remove and clean inlet valve as described under

off. Inlet valve is dirty or damaged. Maintenance. Replace damaged parts.

Vent line primes Diaphragm suspension leaking or Dismantle device and check all parts.

constantly air. diaphragm torn. Reassemble very carefully.

Water in the device. Ejector non-return valve defective. Remove and dismantle non-return valve.

Clean it and replace defective parts. Install

motor ball cock (see flow diagram, item 12).

End of vent line not protected Lay vent line correctly. Line end must show down.

against entry of water.

Re-liquefied chlorine Temperature in eqiupment room too low Increase temperature in the equipment room.

indicated by yellow in comparison to chlorine storage room. Install heating block or pressure reducing valve.

liquid in measuring Install drop separator.

glass and decomposed

PVC parts.

Icing. Chlorine consumption too high. Connect more chlorine barrels.

Troubleshooting

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Table of contents

Other Jesco Water Filtration System manuals

Popular Water Filtration System manuals by other brands

US Water Systems

US Water Systems Raptor manual

Sagola

Sagola 5000X Series instruction manual

Yamato

Yamato WG 203 instruction manual

LG

LG WAW73J Series manual

Everpure

Everpure Coldrink Series Installation and operation guide

Marlo Incorporated

Marlo Incorporated AFC Series Installation, operation and maintenance manual

Frizzlife

Frizzlife MK99 installation guide

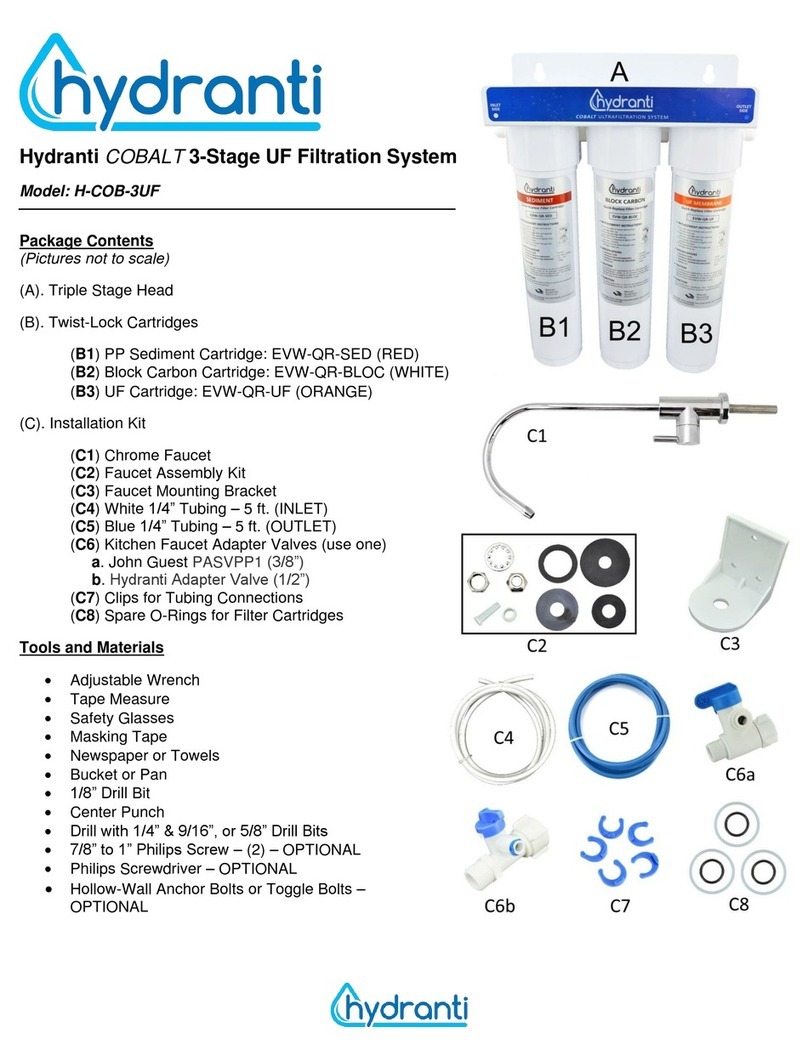

Hydranti

Hydranti COBALT H-COB-3UF manual

Everpure

Everpure QC7I Single-MH2 Catalog

IEM

IEM Umwelt 3 Installation and instruction manual

Aqua Optima

Aqua Optima myLAICA FB1001 Instructions and warranty

WaterGroup

WaterGroup Aquaflo H-PR-10BV-34 Installation and operating instructions