Jesco C7520 User manual

Pressure-type Chlorine Changeover Unit C 7520

BW 2 24 04 / 1

Lutz-JescoGmbH

Improvedchangesarealwaysreservedwithoutnotice.

Contents

1. Scope of supply

2. Installation

3. Wiringdiagram

4. Operation

5. Shutdown

6. Maintenance

7. Troubleshooting

1. Scope of supply

The C 7520 chlorine changeover unit is supplied

asaplate-mountedunitreadyforconnection.When

unpacking,ensure that the enclosedwall mounting

material is not lost.

2. Installation

The preassembled chlorine changeover unit is

mountedon the wall usingthescrews and washers

supplied.

Theinstallationlocationshouldbewithineasyreach

for the operating personnel so that the changeover

unitcanbeoperatedbyhandifnecessary. Itshould

not be exposed to direct sunlight or similarly bright

direct light, as this impairs the legibility of the

operatingdisplays.

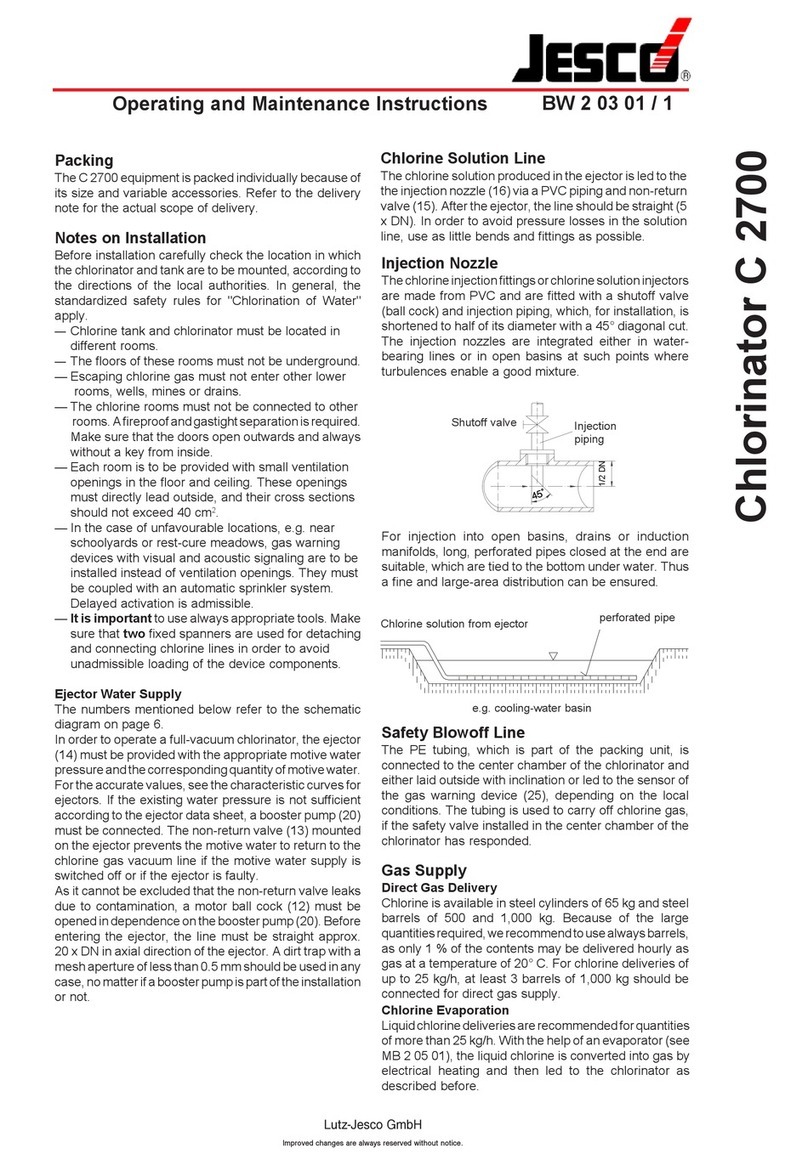

2.1 Hydraulic installation

Important!

Thechlorine changeover valvesystem is designed

for use in pressure-type chlorination installations

only! The changeover unit is resistant to pure, dry

chlorine(liquid or gaseous).

Important!

Connectionsmustbecarriedoutvery carefully.Even

small leakages allow chlorine to enter the room

atmosphere and, together with air humidity, form

corrosiveair.

The automatic chlorine changeover unit may

only be operated with two connected chlorine

gas batteries. If only one chlorine gas battery

is connected, the unused side must be tightly

closed.

Check for tightness using ammonia!

Installation example

Pressure-type Chlorine Changeover Unit C 7520

BW 2 24 04 / 2

Lutz-JescoGmbH

Improvedchangesarealwaysreservedwithoutnotice.

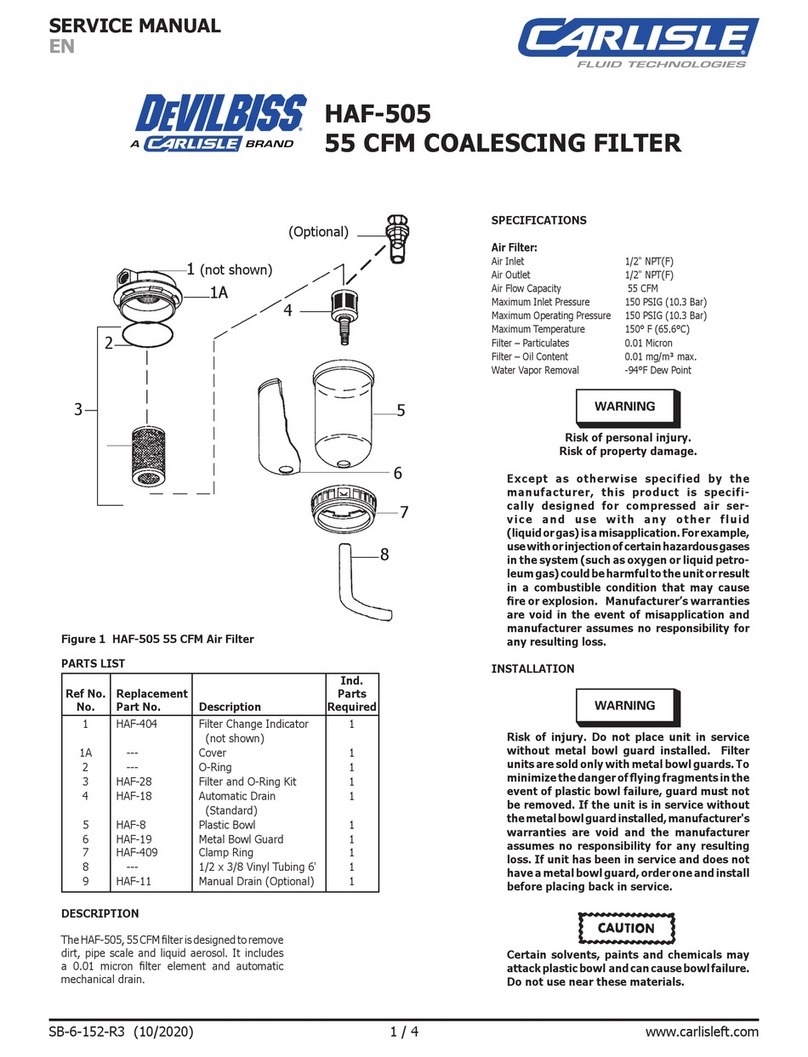

3. Wiring diagram

2.2 Electrical installation

Beforeconnectingthepowersupply please check if

the operating voltage of the motor ball valves

correspondstolocalmainsvoltage.Thecontrol unit

itselfhasawide-rangepowerpackfor100 –240VAC

50-60Hz.

If the motor valves do not comply with the local

mains voltage they might be destroyed!

The changeover unit is operational as soon as the

power supply is connected. Only for remote

signaling of an empty cylinder/battery and the

external alarm contact another connection is

required. The terminal assignment and function of

the individual terminals can be seen in the wiring

diagram.

The external alarm contact (terminals 27 and 28)

causes both motor valves to close in the case of a

chlorine gas alarm (signaled by the chlorine gas

sensor).

Afteran interruption of thepowersupply the control

unitwillswitchautomaticallytothe side used before

in order to stick to the change rhythm and to keep

the standby battery 100% full.

Unused cable glands in the control unit must be

sealedinordertomaintainthedegreeofprotection.

Set jumper: jumper closed =

functionactivated

Forpressure operation setthejumpers as follows:

JP1Schnell: open=

nooverlapping-

motorvalvesare operated one

aftertheother

JP3Überdruck: closed=

setupfor excesspressure

operation

JP5Restentleerung:open=

periodicaloverallemptyingoff

L1

N

PE

1

100-240V/ 50-60 HzMotor 2

PE

N

Motor 1

L1(

right

)

L

1()

PE

N

L1( )

alarm

com

off

on

empty

com

off

on

GND

GND

GND

GND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

L1( )

N

L1

PE

Slot RS 485

(Slot of programming)

JP1

JP3

JP5

JP2

15

1

Relay

Switching

power pack

right

right

right

left

left

left

gauge

Pressure

device

Gas warning

Motor 1

signal

Repeating

Motor 2

signal

Repeating

Pressure-type Chlorine Changeover Unit C 7520

BW 2 24 04 / 3

Lutz-JescoGmbH

Improvedchangesarealwaysreservedwithoutnotice.

4. Operation

As the chlorine supply battery empties, the

decreasing pressure causes the contact of the

pressuregaugeto make(withexistingliquidchlorine

phasethecontainer pressure amountsto6.8bar at

20°C and to 4.5 bar at 5°C - if the liquid phase is

used up, the container pressure drops rapidly on

further withdrawal). The corresponding LED at the

control unit changes from green to red. The

changeoverisinitiatedbytheservomotors. Whenit

iscomplete,thegreenLEDlightsupfortheoperation

of the now active chlorine supply battery. The LED

for the status of the motor valve shows green for

open,yellow duringthechangeoverprocessand red

forclosed.

Afterreplacingthe empty chlorine containersbyfull

ones, the RESET button for the corresponding

chlorinebatterymust be pressed atthecontrolunit.

The corresponding LED changes back from red to

green and indicates that this battery is again ready

for operation when required.

Manual changeover to the desired cylinder battery

is possible by pressing the corresponding key (left

or right cylinder).

Important!

Automatic changeover can only be made if the

cylinderRESETbutton is pressed after exchanging

the cylinders. If both Ready indicators are red, the

changeover unit will remain on the side connected

last until a RESET button is pressed.

Adjustment of the switch contact

The switch contact of the pressure gauge is set to

approx. 4 bar by the manufacturer. The switching

point may have to be brought into line in the plant.

The front panel of the pressure gauge must be

unscrewedforthispurpose.The switching point can

thenbeadjustedbymovingtheredmarkbetween1

and6bar.

Manual changeover (emergency operation)

The changeover valve can be operated by hand if

necessary(e.g.power failure). For thispurpose the

switch lever for manual / automatic operation at

the drive is shifted to manual. Now automatic

changeover is not possible. In any case please

switch back to automatic operation afterwards.

Slightly turn the lever until it locks.

Chlorine gas alarm

In the case of an chlorine gas alarm (only with an

alarm contact connected) both motor valves are

closedto preventfurtherchlorinegasfrom escaping.

All LEDs are flashing red. For resetting press the

RESET button. Depending on which button is

operated the changeover unit switches to the

correspondingchlorinecontainer.

5. Shutdown

Chlorinegasis hygroscopic and formshydrochloric

acid when exposed to atmospheric humidity.

Hydrochloric acid has a destructive effect on the

meteringequipment. Forthisreason,allconnections

must be sealed carefully when shutting down the

chlorination plant. All piping and valves should be

flushedwith dryair or nitrogen.

It is advisable to store the devices in a heated, dry

room if the system is to be shut down for extended

periods of time. The lines have to be tightly sealed

forthereasonsstatedabove before dismantling the

devices. When recommissioning the system,

attention must be paid in particular to any

condensation in the lines.

If necessary, this water must be expelled with dry

airor nitrogen.

6. Maintenance

ThetypeC7520 chlorine changeover unitisalmost

maintenance-free. During the annual maintenance

work,onlyavisualandfunctionaltestmustbecarried

out.Thesealsat the compression glands andinthe

ball valves must be replaced or regreased, if

necessary.

Important!

Seals may only be greased slightly with silicone

grease! Vaseline hardens in contact with chlorine

gas and will cause the ball valve to become stiff.

Particles may also be entrained by the flow of

chlorine gas and impair the correct functioning of

other valves in the system.

Pressure-type Chlorine Changeover Unit C 7520

BW 2 24 04 / 4

Lutz-JescoGmbH

Improvedchangesarealwaysreservedwithoutnotice.

7. Troubleshooting

melborpfoerutaNesuacelbissoPnoitcadednemmoceR

hctiwstonseodevlavrevoegnahC enirolhcdetcennocehthguohtlare

vo sienollufadnaytpmesiyrettab .edisrehtoehtotdetcennoc

eguagerusserptcatnoC .evitcefed erusserptcatnoceht

ecalpeR .eguag

lla(detpurretniylppusrewoP .)!kraderasDEL .ylppusrewopehtetavitcaeR

erasevlavrotomhtobroenO ."noitarepolaunam"ottes .noitarepocitamotuaotteS

.evitcefedevlavrotoM.evlavrotomecalpeR

revosehctiwstinur

evoegnahC ehthguohtlanoitarepolamrongnirud .llufllitserasreniatnocenirolhc

ehtfotniopgnihctiwsehT tessieg

uagerusserptcatnoc .yltcerrocni

ebdluohstniopgnihctiwsehT ehtwolebrab1yletamixorppa lamronroferusserpreni

atnoc .noitarepo

sisagenirolhcfowolF tonfoesuaceb.g.edetceffa ,sretimilwolf,sevlavnepoylluf .strapenilrosr

etlifytrid

wolfevomer,yllufsevlavnepO

.

senildnasretlifnaelc,sretimil

eguagerusserptcatnoC .evitcefed erusserptcatnocehtecalpeR .eguag

ehtretfaeno

nurtonodsevlavrotoM .ylsuoenatlumistubrehto gnippalrevokciuqrofrepmuJ )llenhcs(desolcsirevoegnahc

.

elbatotgnidroccarepmujteS

otyllacidoirepsehctiwslortnocehT .yrettabytpmeydaerlaeht signiyptmellarevorofr

epmuJ .desolc

.

elbatotgnidroccarepmujteS

noitisopevlavrotomfonoitacidnI lautcaehtotdnopserroctonseod .eno

gulpronoitcenn

ocelbaC .detpurretni .tcatnocekaM

.evitcefedevlavrotoM.evlavrotomecalpeR

Other manuals for C7520

1

Other Jesco Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Acqua Brevetti

Acqua Brevetti PuliMATIC FT360 Installation and operating instructions

Osmosis

Osmosis MT Technical manual

Axi

Axi STS 6000 P-35 INSTRUCTION, OPERATING, & MAINTENANCE MANUAL

Midea

Midea JL1850S-RO Service manual

MARIMEX

MARIMEX ProStar Profi 4 instruction manual

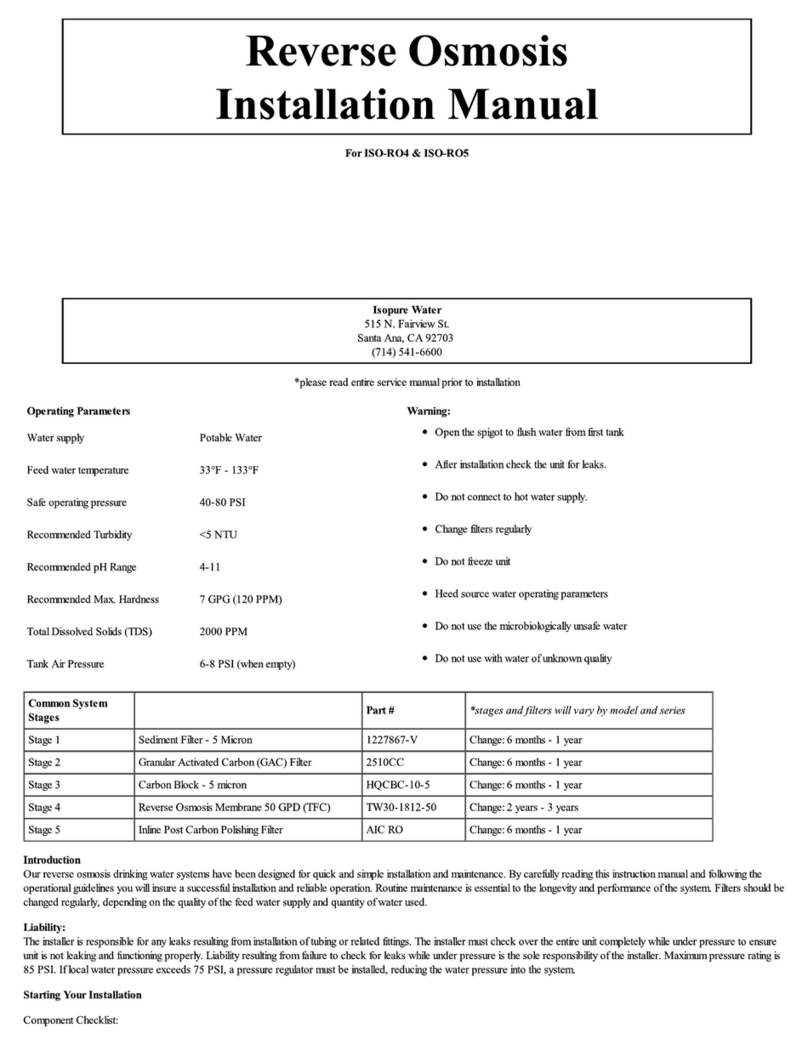

Isopure Water

Isopure Water ISO-RO4 installation manual