JessEm Tool 08350 User manual

DOWELLING JIG

OWNERS MANUAL

Model #08350/ #08350-MK

61 Forest Plain Road

Orillia, Ontario, Canada

L3V 6H1

Toll Free:1-866-272-7492

Local: 705-726-8233

Fax: 705-327-0295

Email: [email protected]

Website: www.jessem.com

Contents: #08350

•

(1) Dowelling jig.

•

(1) 3/8” Drill Bit

•

(1) 3/8” Stop Collar

•

(1) 3/8” Indexing Pin

•

(1) 1/8” Hex Key

Contents: #08350-MK

•

Dowelling Jig

•

3/8” Drill Bit, (1) ½” Drill Bit, (1) ¼” Drill Bit (1)

3/8” Stop Collar, (1) ½” Stop Collar, (1) Stop

Collar

•

3/8” Indexing Pin, (1) ½” Indexing Pin, (1) ¼”

Indexing Pin

•

(5) 3/8” Guide Bushings with mount

•

(5) ½” Guide

Bushings with mount

•

(5) ¼” Guide Bushings with mount

Thank you for choosing this product from JessEm Tool Company.

We appreciate your support and hope that our product

serves you well. This product is designed to provide many years of reliable service provided it is used as intended and taken

care of.

This user manual will assist you in assembly and general operation of this product. It is not our intent to teach you about

woodworking. It is assumed that you are a n experienced woodworker with the basic skills and experience necessary to use this

product safely. If after reading the following instructions, if you are unsure or uncomfortable about safely using this

product we urge you to seek additional information through widely available woodworking books or classes.

As part of our Continuous Product Improvement Policy, JessEm products are always advancing in design and function.

Therefore there may be differences between what is shown in our catalogs, website or at retail display and what is sold at

time of purchase. We reserve the right to make positive changes to our products at our discretion.

IMPORTANT SAFETY PRECAUTIONS

•

Before operating any hand held drill, read and understand all safety instructions in the owner’s manual that came with

the drill.

•

If you do not have a manual, contact the manufacturer and obtain one before using any power tool.

•

Always wear eye protection in compliance wi th ANSI safety standards when operating any power tool.

•

Do not wear loose clothing or jewelry that may catch on tools or equipment.

•

Unplug the tool or machine when making any adjustments.

Laying out the desired position of your dowels is important before using the jig. There are numerous configurations of hole

spacing that can be used depending on the stock thickness and desired location.

Note: Your 08350 JessEm Dowelling Jig comes

standard with a 3/8” drill bit and bushings

THERE ARE MANY VARIATIONS OF DOWEL

JOINTS POSSIBLE. WE HAVE PROVIDED A FEW

POSSIBLE JOINTS IN THIS MANUAL TO

FAMILIARIZE YOURSELF WITH THE #08350

DOWELLING JIG.

To Our Customers

2

3

4

Figure 6

Figure 5

Figure 1

Setting the Drill Bit Depth Collar:

Using the matching stop collar for the drill bit you are using, screw

the ¼”-20 set screw into the stop collar. Now slide the stop collar

over the drill bit and with the 1/8” hex key snug the set screw to

keep the collar in position. (See Figure # 1)

** Note: Locate the set screw on the largest portion of the drill bit

not in one of the chip removal flutes. (See Figure # 1)

Figure 2

Figure 3

The first joint we are going to drill has 3 rows of dowels. We are

spacing our jig ½” from the edge. Clamp the jig to your board in

this position. (See Figure #3)

Figure 4

We want three (3) holes in this first row. One (1) in the center and

one (1) in each outside hole. (See Figure # 5)

With the first row drilled, adjust the jig to the 7/8” position.

Note: Do not unclamp the Jig from your board. (See Figure

#6)

MULTIPLE ROW DOWEL JOINT

Insert the drill bit into the corresponding drill bushing and measure

the amount the drill bit protrudes (See Figure # 2). The drill bit

should be deep enough to accomodate half the dowel you are

using. For thinner stock, ensure the dowel pin does not break

through your material and compensate by drilling deeper on the

corresponding piece.

We have predetermined that we want the first row of dowels

spaced 3/8" of an inch in from the edge. Loosen the adjustment

knob and adjust the jig to the 3/8" position. (See Figure # 4)

5

We are drilling two (2) holes here. One (1) hole to the left

and right of the centre hole. (See Figure #7)

Now adjust the jig to the 1-3/8” position. (See Figure

#8)

We are now drilling a three (3) hole pattern as done in the

first row.

The holes in the first board are now complete.

We follow the same procedure to drill the holes in the

mating piece. In this joint you woulld like the first board to be

stepped back ¼”. Set the jig to 5/8”, 1- 1/8” and 1-5/8” for

each row. These are the same settings as drilled in the first

board plus ¼”. This will give the ¼” offset.

Figure 8

Figure 10

Figure 11

Figure 7

Figure 9 Figure 12

6

The next joint we are showing is the joining of two boards

to make a larger panel. Mark the lines on the board

where you would like to place the dowels and clamp the

jig centreline to the board on this line. (See Figure #14)

With all of the holes drilled in the first board, clamp this

board to the mating board with the edges lined up and install the

dowels in the holes previously drilled. Using the alignment slot in the

jig, you can align the jig on the mating board using the dowels in the

first board and clamp in this position. (See Figure #16)

All of the holes are now drilled. (See Figure #18)

Figure 13

Figure 15

Figure 16

Figure 17

Figure 18

FLUSH JOINING BOARDS

With the drilling completed in the second board, all we

need to do is test fit the joint. (See Figure # 13)

Drill a hole in the centre bushing and repeat for all of the

holes.

Figure 14

Now, drill a hole in the centre bushing. (See Figure #15)

7

Test fit the joint. (See Figure #19)

We are now going to join a shelf board to the mating piece.

We marked a centreline on the shelf and aligned and

clamped the jig in this position. (See Figure #20)

Drill a hole in the centre bushing. (See Figure #21)

We are using the indexing pin and the centre hole previously

drilled to position the jig for the third hole. (See Figure #23)

Figure 19

Figure 20

Figure 21

Figure 22

Figure 23

Figure 24

Joining a Shelfboard

Drill the third hole in the far right bushing. (See Figure #24)

We are using the indexing pin in the centre hole previously

drilled to position the jig for the second hole. (See Figure #22)

We are going to drill a hole in the far left bushing.

8

The distance from the front edge of the jig is 2” from the

centre of the bushings. Mark a line where you want the

dowels and also 2” from this point. Clamp the shelf board

on the 2” line.

Figure 30

Figure 25

Figure 26

Figure 27

Figure 28

Figure 29

The shelf board is now complete. (See Figure #25)

Install dowels in the shelf board and using the alignment

slot, align and clamp the jig in position. (See Figure #26)

Drill using the centre bushing and repeat for each location.

(CAUTION: ADJUST THE DRILL BIT DEPTH COLLAR

TO ENSURE NOT TO DRILL COMPLETELY THROUGH

YOUR BOARD. (See Figure 27, 28 and 29)

With the holes drilled, test fit the joint. (See Figure #30)

9

JESSEM TOOL LIMITED WARRANTY

●Repairs or alterations made or attempted by anyone other than JessEm Tool

Company or an authorized JessEm service professional

●Normal wear and tear.

●Abuse, misuse or neglect.

●Improper care or maintenance.

●Continued use after partial failure.

●Products that have been modified in any

way.

●Products used with improper accessories.

●Premature thread wear due to adjusting

height with electric or cordless drill.

All JessEm products are warranted to be free from defects in material and

workmanship. JessEm will repair or replace any product which upon inspection

proves to be defective for a period of (1) year from dated receipt and proof of

purchase. All warranty claims should be made direct to JessEm Tool Company.

Contact JessEm for a warranty claim return authorization and instructions to

proceed. The consumer is responsible for shipping costs to return product to

JessEm Tool Company. We will repair or replace the product at our discretion

and JessEm Tool will return shipment to you at no charge.

WARRANTY LIMITATIONS

This warranty does not cover:

JessEm Tool Company

Toll Free: 1-866-272-7492

Fax: 705-327-0295

Email: [email protected]

10

Mast R Lift Excel II ™

Rout R Lift™ II

Mast R Lift™ II

Other Products From

JESSEM TOOL COMPANY

www.jessem.com

Clear Cut Stock Guides

Model # 02202

Model #02120

Model # 02310

Model # 04215

Tools That Make A Difference!

Find Out More About Our High

Performance Tools At

www.jessem.com

Tools That Make A Difference!

This manual suits for next models

1

Table of contents

Other JessEm Tool Tools manuals

Popular Tools manuals by other brands

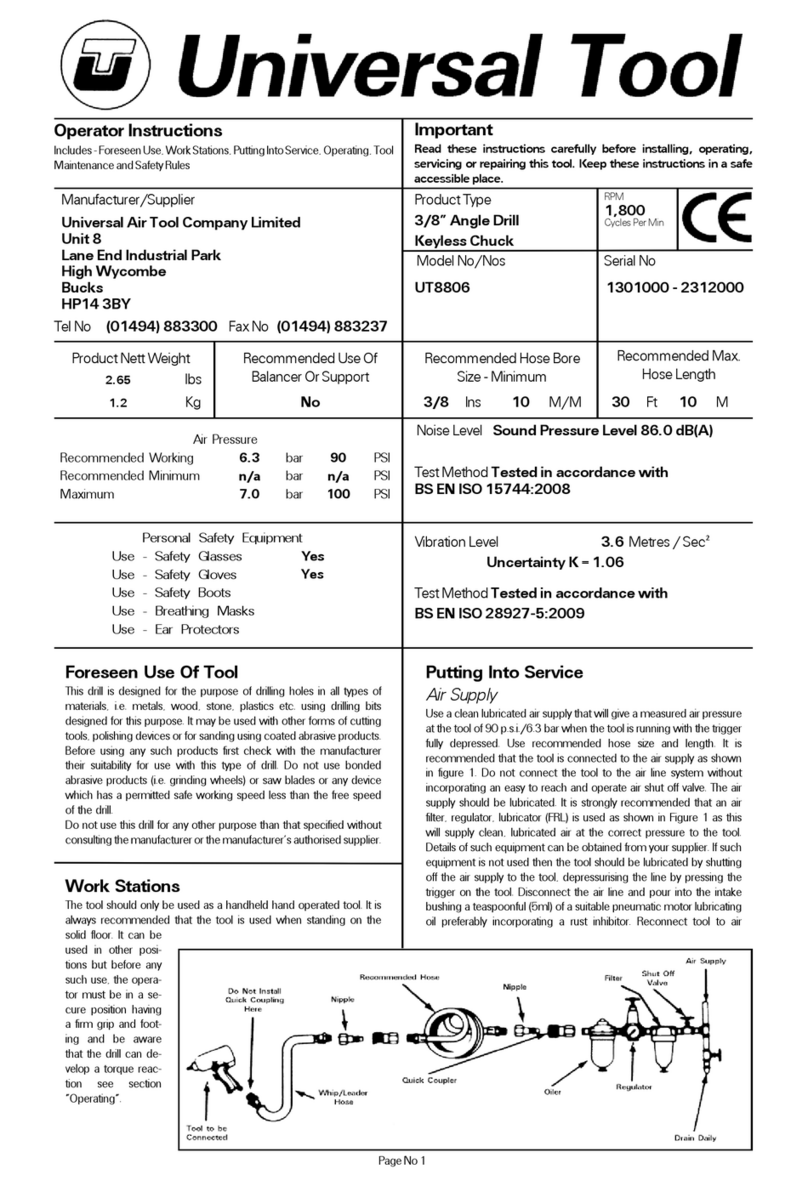

Universal Tool

Universal Tool UT8806 Operator instructions

Balcrank

Balcrank Signature Series Operation, installation, maintenance and repair guide

Cornwell Tools

Cornwell Tools CAT820 operating instructions

Kett

Kett KD-446L Safety rules

Stanley

Stanley Bostitch T55 Series Operation and maintenance manual

Parkside

Parkside PDT 40 C2 Operation and safety notes