2

Directory

Chapter I overview ………………………………………………………………………….3

1.1 Product name ……………………………………………………………………………………. ………….. 3

1.2 Specification and parameters ……………………………………………………………………… ….…...3

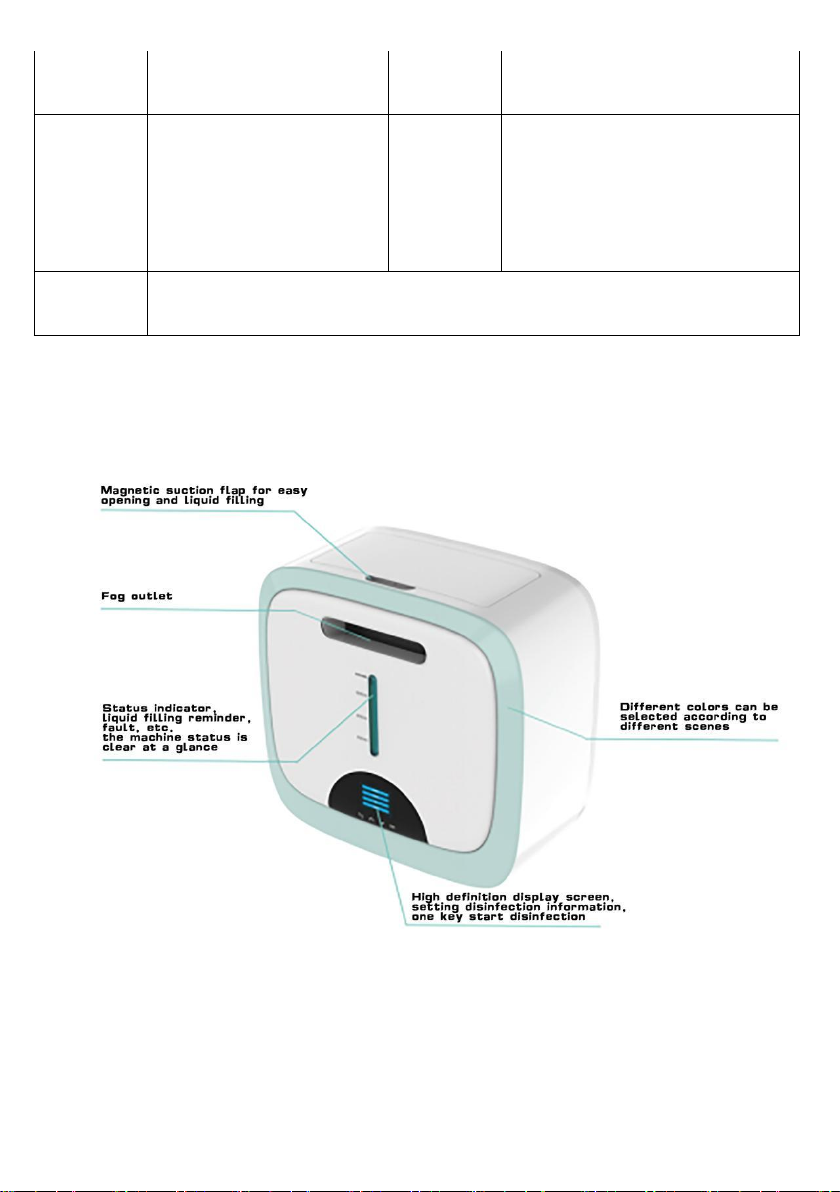

1.3 Equipment appearance and structure………………………………………………………… ……...…4

1.4 Execution Standard ……………………………………………………………………………….….…………..6

1.5 Equipment function introduction ……………………………………………………….….. ...…………6

1.6.1 working principle …………………………………………………………………………………… ……...6

1.6.2 Scope of application…………………………………………………………………………………………...7

1.6.3 Main functions and features………………………………………………………………………… …….7

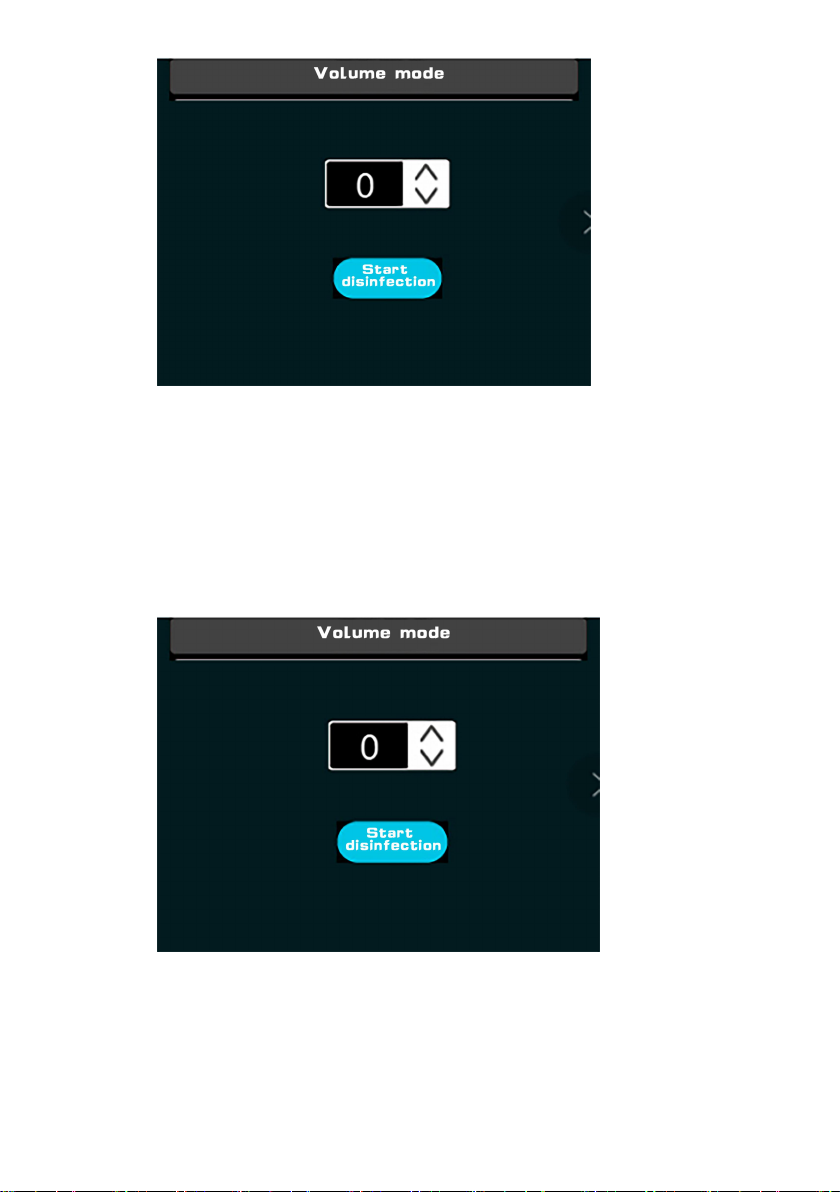

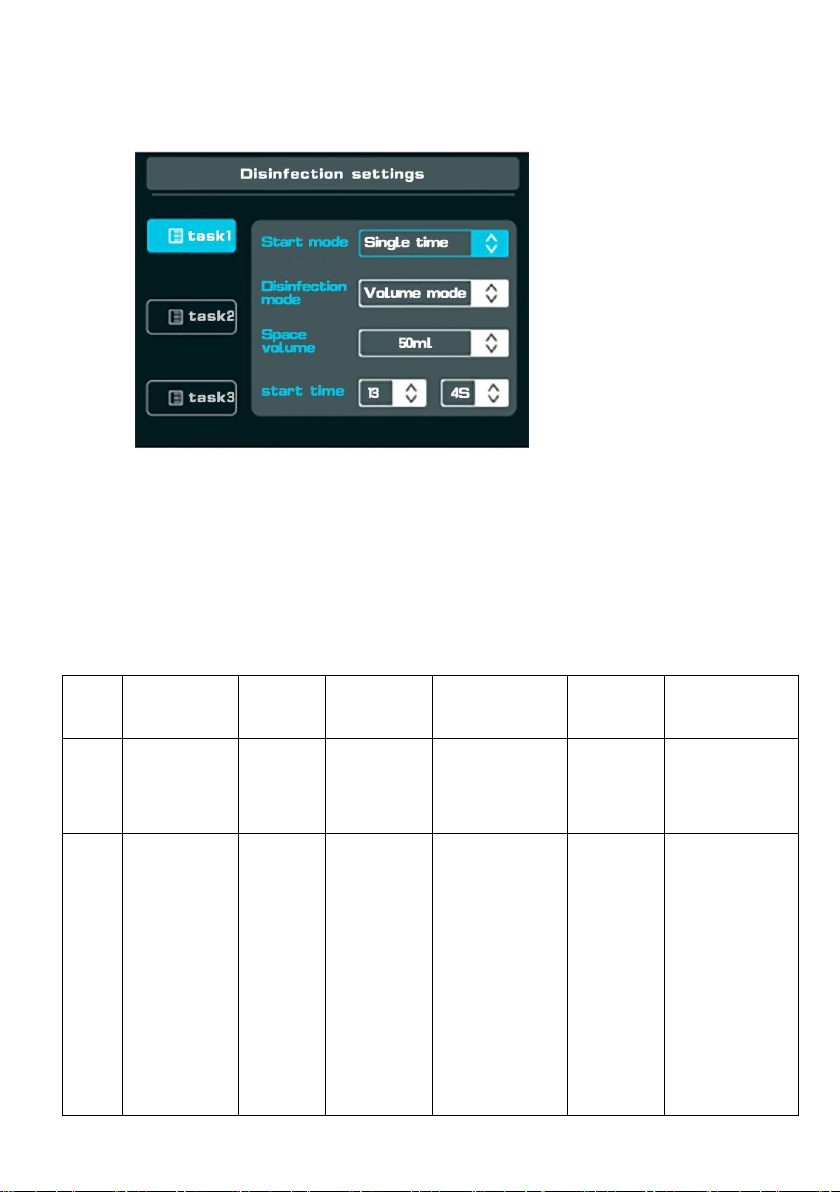

1.6.4 Use Method …………………………………………………………………………………….…....……………7

1.6.5 Service life ………………………………………………………………………………………...…… …… … 11

1.6.6 Disinfection solution description.............................................................................11

1.6.7 Transport and Storage ……………………………………………………………………………… … ……12

Chapter II matters needing attention ………………………………………………. 13

2.1 matters needing attention........................................................................................13

Chapter III Daily maintenance…………………………………………………………….14

3.1Shutdown………………………………………………………………………………………………………… ……14

3.2Clean it up………………………………………………………………………………………………………………14

Chapter IV Faults and Solutions …………………………………………………… ...15

4.1 Troubleshooting………………………………………………………………………………………………… …15

Chapter V Appendix ………………………………….............................……….16

5.1After-sales sales...........................................................................................................16