Hydraulic Torque Wrench Operation and Maintenance Manual

8

direction of the square drive; however, slight adjustments may be made to suit your particular application.

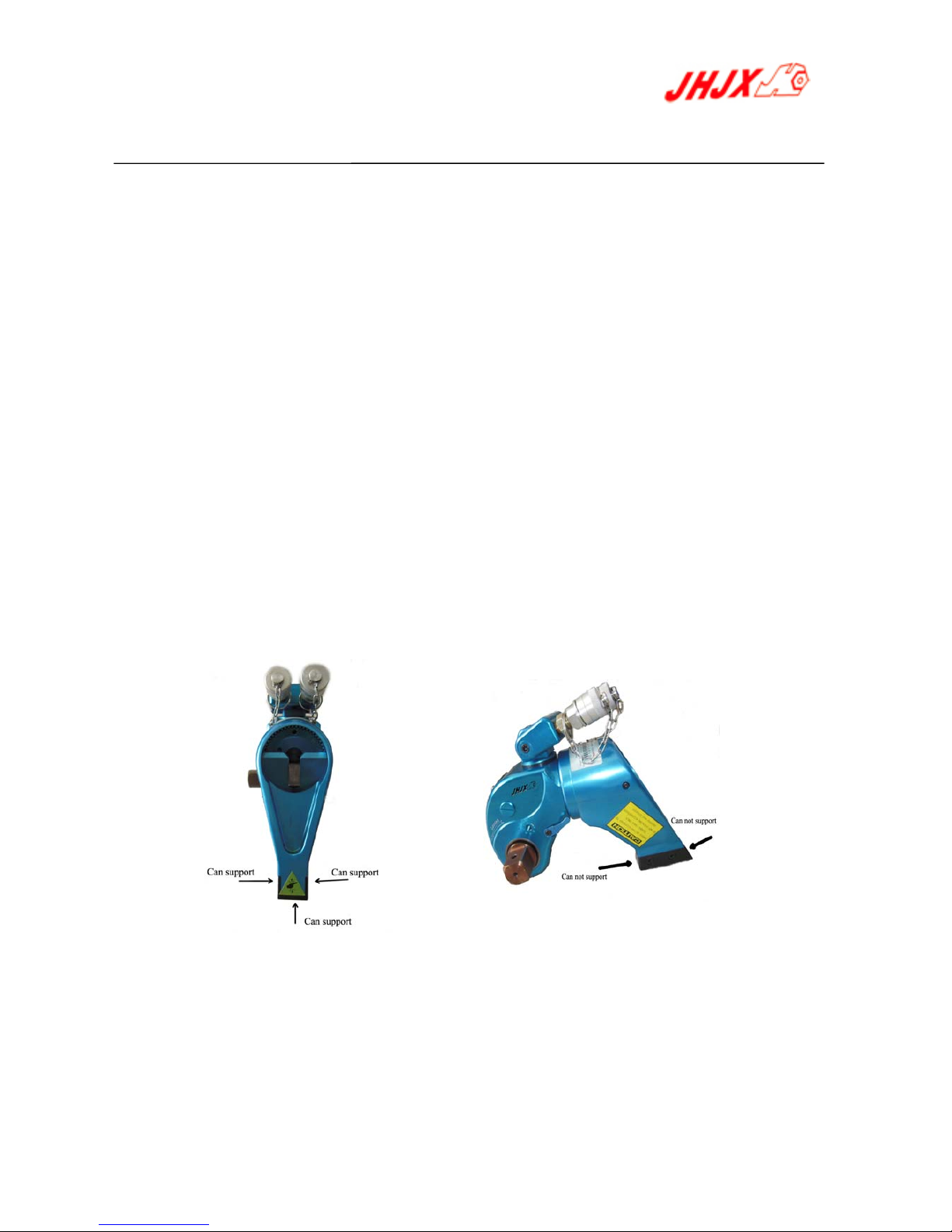

The function of a reaction:

Device is to hold the tool in position against the forces generated to tighten or loosen bolts or nuts. Hydraulic

wrenches generate tremendous force. The reaction arm can be positioned in numerous places within a

3600circle. However, for the arm to be correctly positioned, it must be set within a 900quadrant of that circle.

That quadrant is the area located between the protruding square drive and the bottom of the housing away

from the swivel inlets. It will always be toward the lower half of the housing and on one side of the housing

when tightening and the other side when loosening.

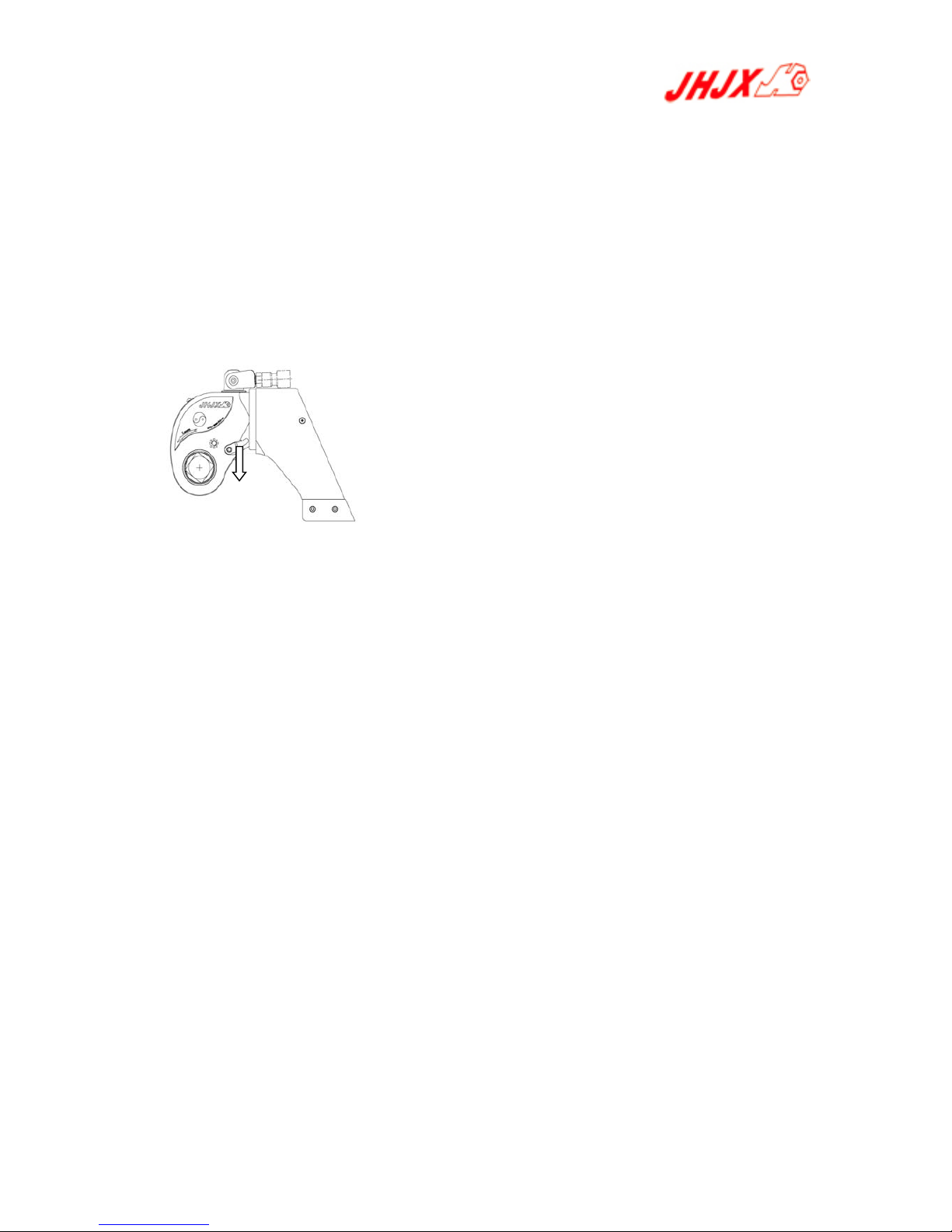

SETTING THE SQUARE DRIVE FOR ROTATION

The position of the square drive when looking toward the shroud will determine if the tool is set to tighten or

loosen the nut. When the square drive extends to the left when looking at the shroud with the inlets away

from you, the tool is set to loosen the nut. When the square drive extends to the right, the tool is set to

tighten the nut. To change the direction of rotation for JHM series wrenches simply push the square drive

into the housing until the drive projects out the opposite side of the tool.

SETTING THE TORQUE

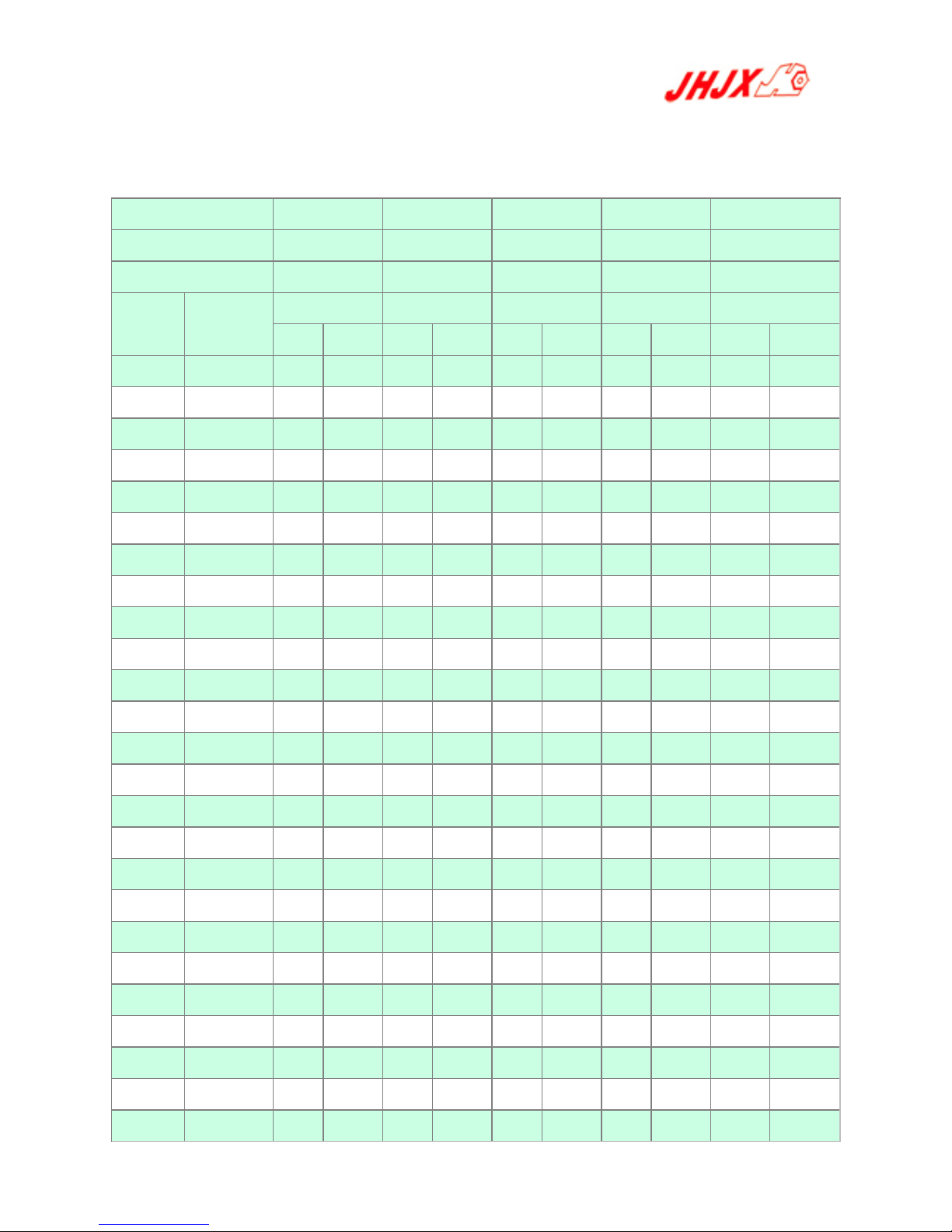

After determining the desired torque, use the torque conversion charts to determine the pressure that is

necessary to achieve that torque.

1. Connect the tool to the power supply and turn the pump on.

2. Depress the advance remote control button causing the pressure to be shown on the gauge.

3. Adjust the pressure by first loosing the nut that locks the pressure adjustment handle and then rotate

the handle clockwise to increase the pressure and counter clockwise to decrease the pressure. When

decreasing pressure, always lower the pressure below the desired point and then bring the pressure

gauge back up to the desired pressure.

4. When the desired pressure is reached, retighten the lock nut and cycle the tool again to confirm that the

desired pressure setting has been obtained.

OPERATING THE WRENCH

1. Place the square Drive in the socket, insert the socket retainer ring and pin, and place the socket to the

nut. Make certain the square drive and socket are the correct size for the nut and that the socket fully

engages the nut.

2. Position the reaction arm against an adjacent nut, flange or solid system component.

Make certain that there is clearance for the hoses and swivel couplings. Do not allow the tool to react

against the hoses, or swivel couplings. When reacting directly off the tool body with reaction arm removed.

Do not react off the exposed end plug spigot.

3. After having turned the pump on and presetting the pressure for the correct torque, depress the remote

control advance button to advance the piston assembly.

4. When the wrench is started, the reaction surface of the wrench or reaction arm will move against the

contact point and the nut will begin to turn. Once the piston reaches the end of its stroke depress the

remote control return button to retract the piston.

FIG 6