Jimmy Jib STANTON 120 DUTCH ROLL User manual

STANTON 120 DUTCH ROLL

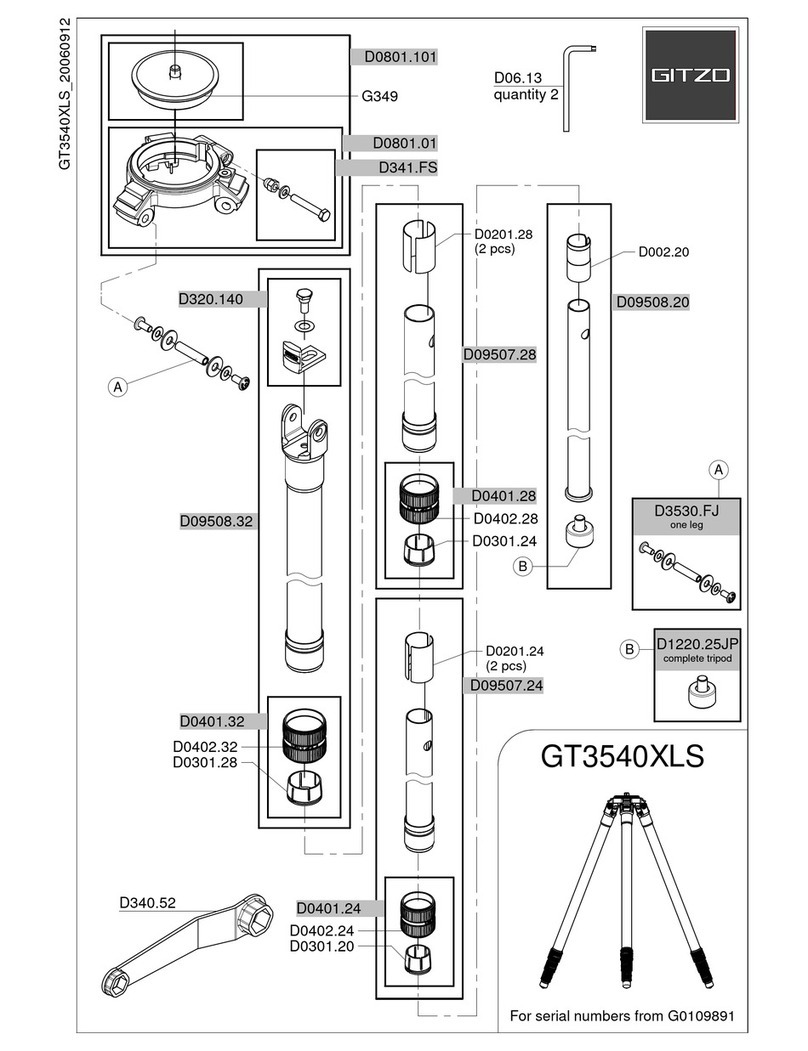

If you are missing any of the following items, please contact Stanton Video immediately (602) 49 -9505

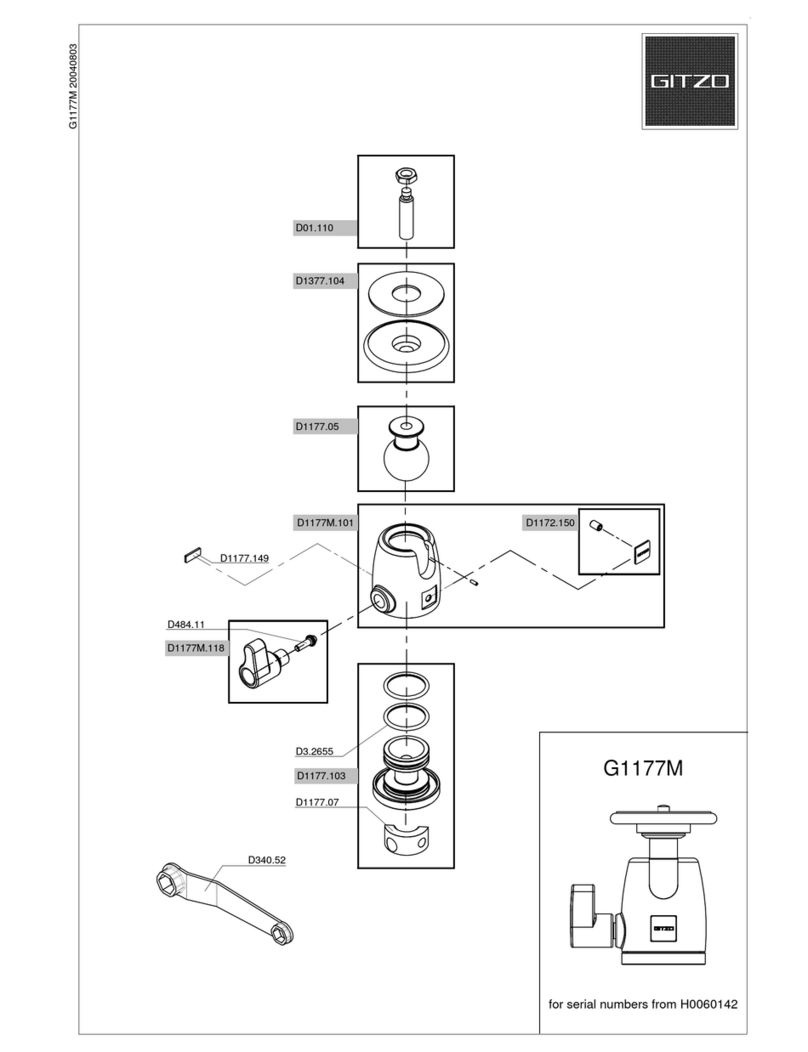

1. Cradle

2. Trolley

. Dovetail

4. Servo

5. Tilt Shaft

6. Safety Clips (2)

7. Ladder Chain

8. Counter Weight Assembly

9. Electronic Cables

10. Dutch Control Box

11. DC Power Supply

6

1

2

4

5

5

7

89

10

11 DC POWER SUPPLY

CRADLE

TROLLY

DOVETALE

SERVO

TILT SHAFT

SAFTY CLIPS

LADDER CHAIN

COUNTER WEIGHT ELECTRONIC CABLES

DUTCH CONTROL BOX

ASSEMBLY

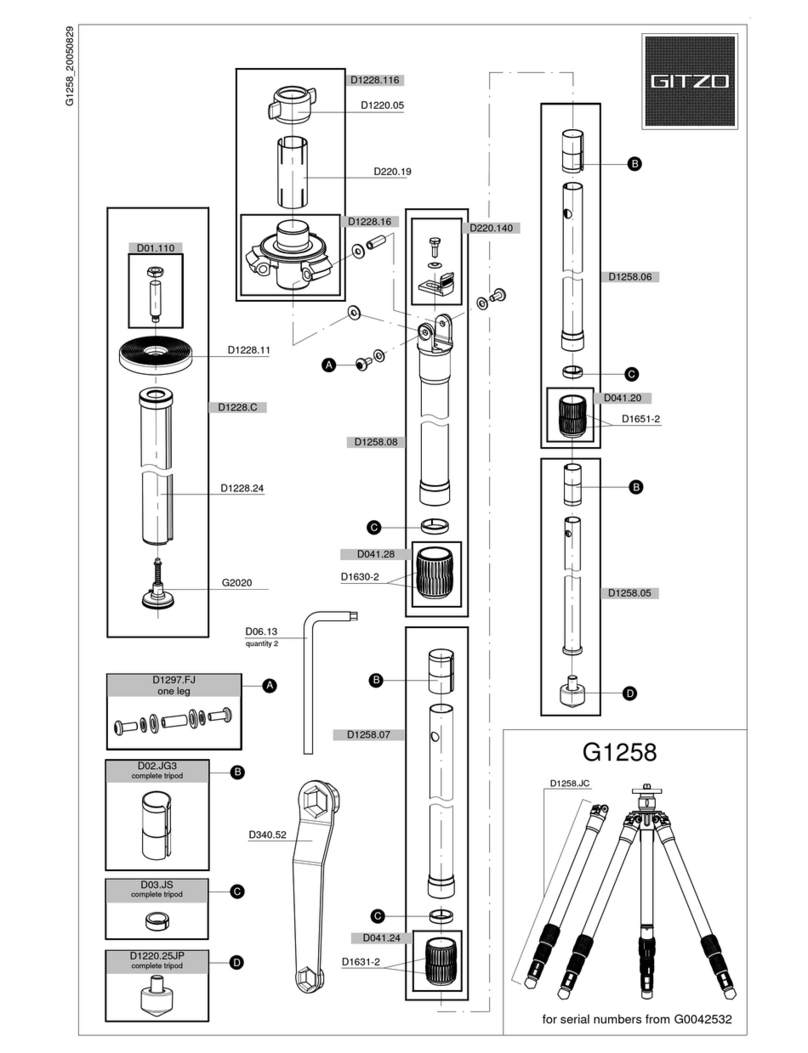

1. Remove the Swing arm and Tilt Shaft from the head by removing the Snap Ring and Pinch Clamp.

Pinch Clamp

Snap Ring

O-Ring

Swing Arm

2. Mount the Cradle by inserting the New Tilt Shaft into the cradle and secure with the Cradle

Clamp Screw and safety clip.

. Slide the tilt shaft through the needle bearings and into the head. Slide on the Pinch Clamp To lock the

Cradle in place.

4. Next slide on the Counter Weight and lock it in place. In order to clear the electronic cables the Counter

Weight should be as close to the end of the shaft as possible without covering up the Safety Clip hole.

5. Insert the Safety Clip into the hole at the end of the shaft. Once you have correctly positioned the

Counter Weight this position will not change and no further adjustment should be necessary.

Counter Weight

NOTE: The Cradle has been balanced at the actory so it should not be necessary or you to

per orm this adjustment. The Cradle is balanced i you can rotate the cradle to any

position and it will stay in that position.

NOTE: With some cameras it may be possible to balance the camera without using the counter

weight.

6. Balance the Cradle by sliding the Counter Weight on the shaft and locking it in place with the Locking

Screw. The weight is used to counter balance the Cradle only; you must remove the Trolley before

performing this process.

Locking Screw

Safty Screw

Move weight until

cradle is balanced.

Warning: The Dutch head should never be operated without the counter balance SAFETY SCREW in

place.

7. For transportation it is necessary to disengage the Ladder Chain and slide the Servo forward. This is

accomplished by removing the Drive sprocket.

Cradle

Roller Guides

SERVO SERVO

Slide motor forward for Transport Slide motor back for Operation

8. The Ladder Chain is threaded through the Sprockets as shown below. The Idler sprockets should be as

close to the Track way as possible. The Clutch Knob should be loosened so that the Drive Sprocket can

“Free Wheel”.

Clutch Knob

Drive Sprocket

Spring

Washer

Idler Sprocket

Trackway

9. The blue Ladder Chain is tensioned at the factory. If it becomes loose you will find it necessary to tighten

it. In order to tighten the Ladder Chain, first make sure the gap between the Idler Sprocket and the Track way is

as small as possible.

Chain Clamp

Clamp

Screws

Trackway

Gap too large

Idler Sprocket

10. Loosen the Chain Clamp Screws and while pulling on the chain, re tighten the screws.

MOUNTING THE CAMERA

1. Remove a Safety Screw, loosen the Dovetail Locks and slide out the Dovetail.

Safty Screw

Dovetail

Dovetail Lock

Camera Screws

2. Mount the Dovetail to the Camera Quick Plate using the provided Button Head Screws; use two screws if

possible. If you are mounting a heavy film or High Definition Camera two screws should always used.

Quick Plate

. Reinsert the Dovetail and the Safety Screw. If the Dove Tail should slip the Safety Screws will prevent

the Camera from slipping out.

Safty Screw

Dovetail Lock

4. Loosen the Slide Knobs and move the Dove Tail to its Lowest point of travel then mount the camera to

the Quick Plate.

Slide Knob Slide Knob

FRONT TO BACK CAMERA BALANCE

Too Far to the Front Too Far to the Back Balanced

1. Make Sure the Pan and Tilt Motors are disengaged from the 4 in. gears.

2. Slide the camera forward or rearward on the dove tale until the camera will maintain a level position

. Make sure you tighten the Dove Tail Locks to prevent the dove tail from sliding out of position.

Dove Tail Lock Dove Tail Lock

VERTICAL CAMERA BALANCE

1. Balancing the camera vertically is done in the same way as with the Standard Head.

2. Slide the camera up until you find the vertical position of equilibrium. In this position you will be able to tilt

the camera into any angle and it will stay in that position.

. Make sure you tighten both Slide Knob Screws.

SLIDE

SLIDE KNOB

HORIZONTAL ADJUSTMENT

Horizontal (Side to Side) Adjustment is the placing of the camera’s center of mass in the center of the

trolley. This adjustment is not as critical as Vertical or Front to Back balancing. Normally, video cameras do not

require any Horizontal Adjustment. If this adjustment is too far off it will affect VERTICAL BALANCE and you will

start to have problems with the Tilt Axis.

To test for proper adjustment first make sure the Trolley is free to easily roll in the Cradle. Make sure the

Servo Clutch is loose. The camera and Trolley will not stay in a vertical position if camera is not perfectly

balanced horizontally.

When you perform this test you will probably find that the camera will not stay vertical as shown in the

example above. It is impractical to try and completely eliminate this condition but complete elimination is also not

necessary. Because most video cameras are light in weight and have their mounting points close to their center of

mass, side to side adjustment is almost never necessary.

35mm FILM: These cameras tend to be 40 to 50 lbs is weight and will probably require side to side adjustment

Button Head Screws

Dove Tail

SERVO CONTROLLER

RAMP This is an acceleration ramp and works exactly the same way as the Ramp Adjustment on the

main Control Box.

LIMIT Controls the range of Dutch movement and provides movement limits to prevent the Trolley from

hitting the ends of the track.

GAIN Helps soften the movement of the Trolley but if turned down too far may effect the accuracy of the

move.

GAIN

LIMIT

RAMP

REMOTE DIRECTION POWER POWER LITE

CONTROL KNOB

FOLLOW FOCUS BOX

REMOTE Switches control of the Dutch movement from the Control Knob to an external or remote source.

The Follow Focus Box can be used as a remote source.

DIRECTION Changes the relationship of Trolley direction to Control Knob rotation.

POWER ON and OFF switch.

Follow Focus The Follow Focus Box can be plugged into the Control Box to provide a Memory Position. By

switching (Remote Switch) between the Control Knob and Follow Focus the Trolley can be made

to “Dutch” between two set points. Normally one of the Set Points would be the center position

so that the Head can seek a vertical position.

ELECTRICAL CABLES

HEAD CABLE

GAIN

LIMIT

RAMP

DC POWER SUPPLY

EXTENSION

DUTCH SERVO

Dutch connector on Head

The Cables that come with the Dutch Head Kit allow the Kit to be used on all Jib sizes out to the Extreme.

The Dutch Head cannot be used on the Jimmy Jib II (solid bar stock head).

NOTE: If you find it necessary to run the Dutch on battery power it will be necessary to power it from a

separate battery pack. It was found that when trying to power the Dutch and the Stanton Head from

the same battery pack caused power to drop so quickly that it was impractical to power them both

from a single battery.

HEAD CABLE On newer systems the Dutch Head Cable has been installed at the factory and is labled as such.

Routing the Head Cable through the Pan Shaft (on older systems) is the neatest method of attaching the

cable. The cable will then not require a large slack Loop and will always remain on the Head. It will,

however, require you to either cut the cable or remove a connector so that the cable can be routed through

the pan shaft.

Table of contents