CONTENTS

Safety Instructions ---------------------------------------------------------------------------------------------------3

Specific Safety Rules For Pole Chain Saws-------------------------------------------------------------------4

Safety Symbols--------------------------------------------------------------------------------------------------------5

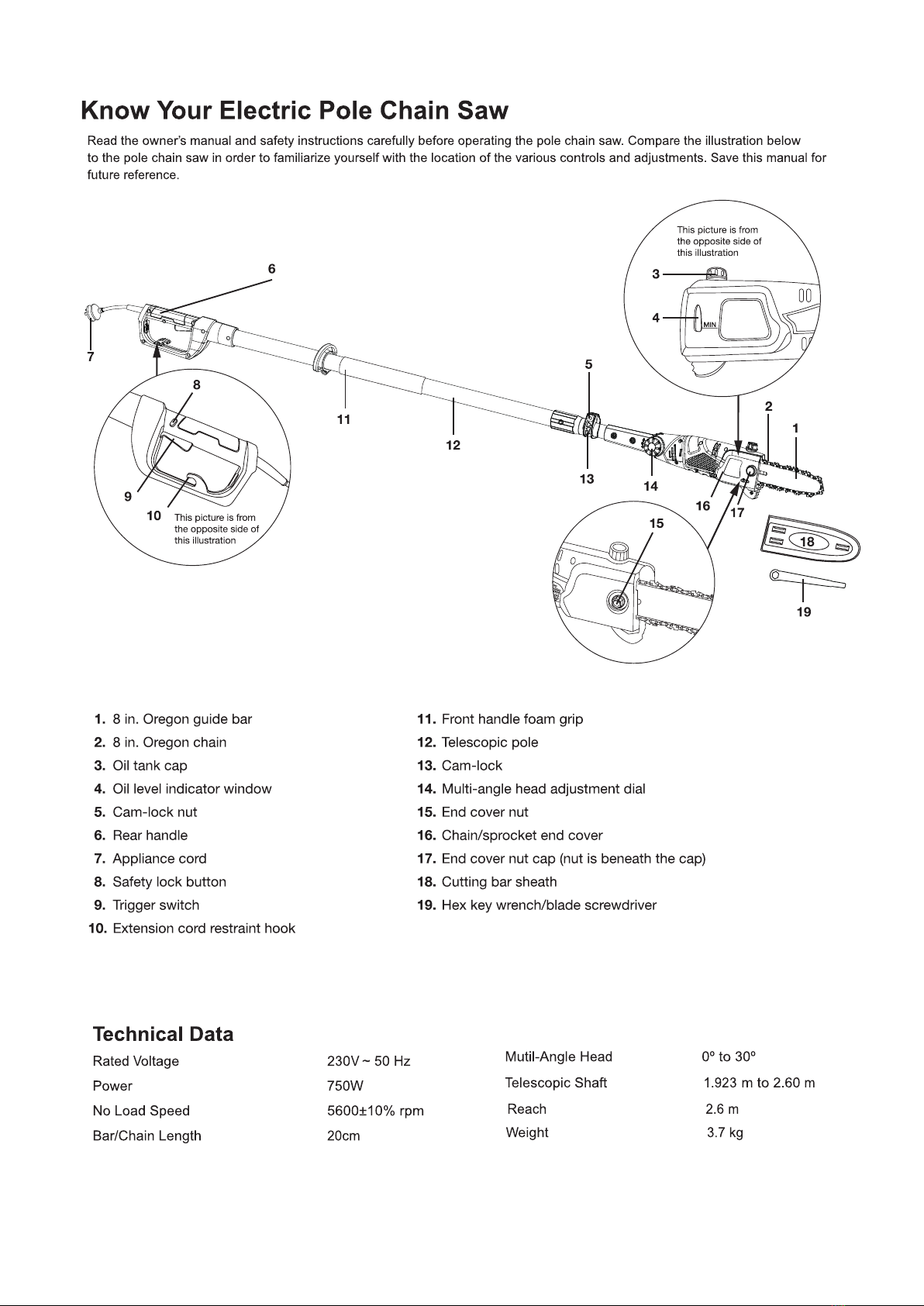

Know your Electric Pole Chain Saw------------------------------------------------------------------------------6

Daily Checklist, Cleaning and Storage--------------------------------------------------------------------------16

Accessories------------------------------------------------------------------------------------------------------------17

Warranty Policy-------------------------------------------------------------------------------------------------------18

2