14

Clean solution tank filter

Cleaning the tools

Removing and cleaning the squeegee

Cleaning the machine

Storage / parking of machine (machine is idle)

Store the machine with the tank cap slightly open, by:

• lifting the tank cap, unscrewing the sieve, and placing it in the hollow

provided.

• Then replace the tank cap on the sieve.

Service, maintenance and care

The machine's maintenance is pre-condition for trouble-free running and a long

life.

Service intervals

TASKI machines are builtto the highest quality standards. This is supported by

internationallyrecognised quality control procedures. Electrical and mechanical

parts are subject to wear or aging if used for long periods of time.

Service centre

Should you contact us due to a malfunction or for placing an order, please

always state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the

address of your nearest TASKI partner can be found on the last page of this

manual.

Blades replacement

Blade on the inner radius.

• Check the float is functioning correctly and that the suction filter (yellow) is

clean.

In case of damage or soiling of the float and suction filter, please refer to

Page 15.

• Afterdraining andcleaning,screw the redand bluecaps onagain, andhang

the hoses from their holders again.

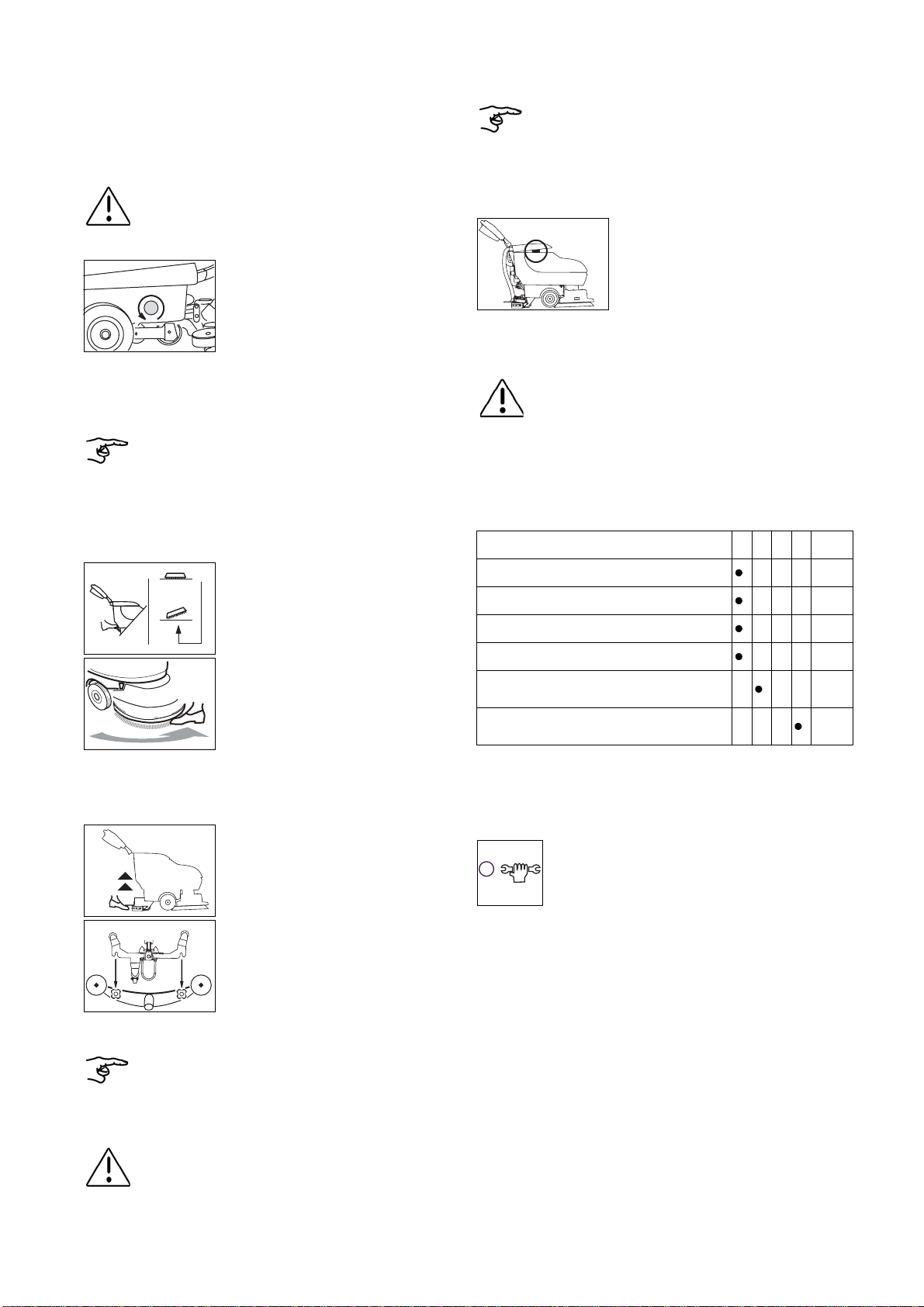

Caution:

Clogged filters reduce the flow of the cleaning solution. As a

consequence you may damage the floor coating.

• Switch the machine off. • Once the solution tank has been drained, screw

the yellow cap from the solution tank filter and

pull it away from its holder.

• Rinse the filter under running water.

If necessary, the filter should be descaled with a 10% TASKI calcacid

solution.

The filter is lower than the tank outflow. A residual amount of

solution will flow out once the filter cap has been unscrewed.

• Refit the solution filter.

• Switch the machine off using the keyswitch and remove the key.

• Press down the pedal and lock it in place to

raise the tool.

• Turn the tool anticlockwise away from the tool

coupling using your foot.

• Clean the tool with water.

• Switch the machine off.

• Pull the suction hose away from the squeegee support.

• Raise the squeegee and loosen the fixing

screws on the squeegee.

The squeegee support wheel must be in the

direction of movement.

• Remove the squeegee from the squeegee

support.

• Clean the squeegee with water using a brush.

Optimal result can only be obtained with clean and intact blades!

Caution:

Never clean the machine with high water pressure or a water

hose.

The ingress of water into the machine might cause considerable

damage to mechanical or electrical parts.

• Wipe down the machine with a damp cloth.

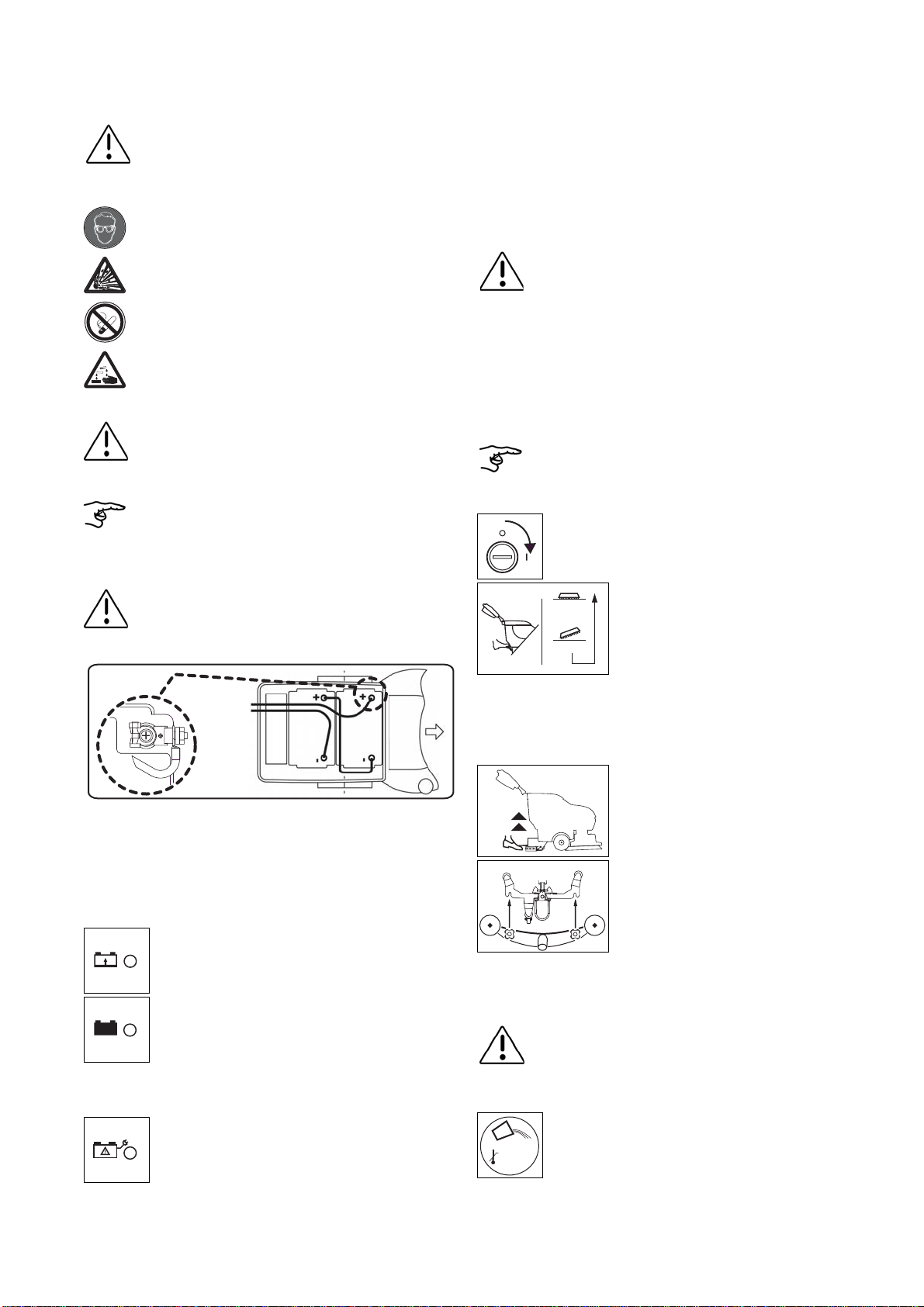

We recommend that you disconnect the battery from the machine

using the battery disconnectionsocket when storing / parking the

machine and when charging the battery.

The sieve holds the tank lid slightly open,

allowing the tank to dry out. As a result, the

formation of mould and unpleasant smells can

be reduced.

Caution:

Only TASKI branded spare parts must be used, otherwise

warranties and liabilities will be omitted!

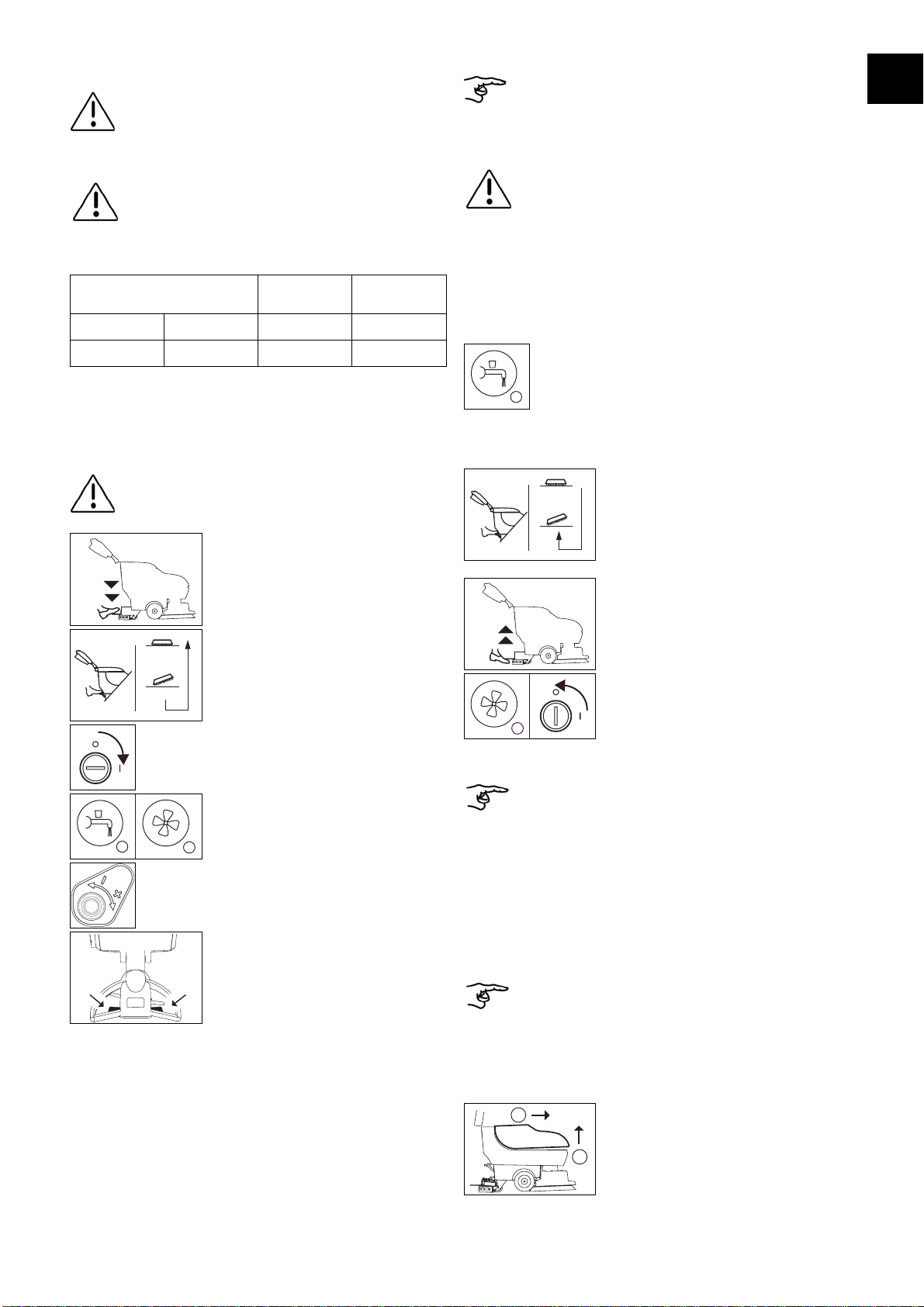

Symbols:

◊= After use, ◊◊ = Every week, ◊◊◊ = Every month,

⊗= Service light

Activity ◊◊◊◊◊◊⊗ page

Recharge batteries 12

Clean all parts marked yellow

Drain and clean the tanks 13

Wipe down the machine with a damp cloth 14

Clean the tank lid seal, check for cracks and

replace if necessary

Maintenance programsby TASKI service made by

TASKI technician

• In order to maintain operational reliability and

availability for use, the service must be carried

out after 450 working hours (option: only with

installed operating hours counter) or at least

once a year.

Underroughor extremeworkingconditionsand /or insufficientmaintenance,

shorter intervals may be necessary.

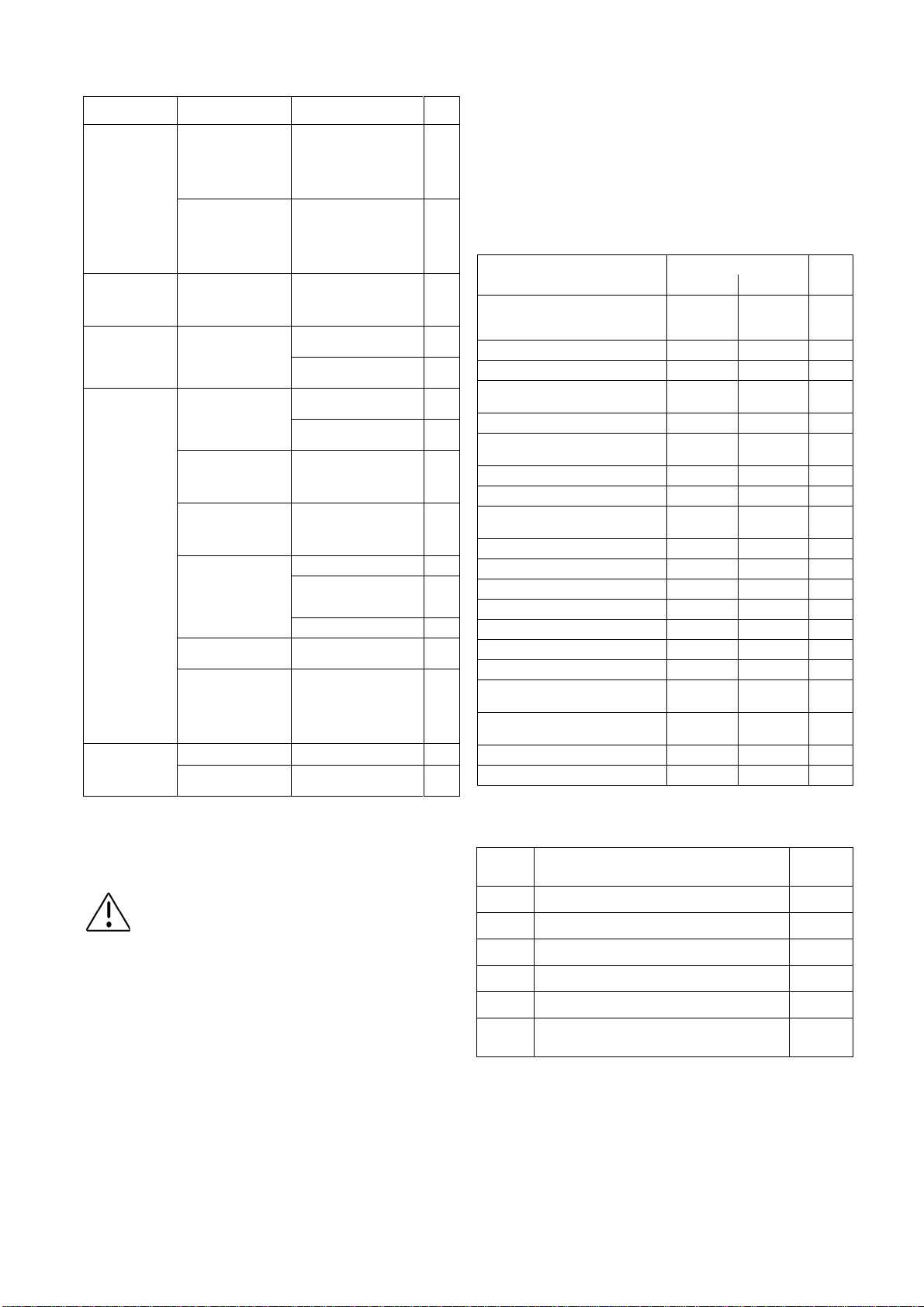

• Place the clean squeegee unit with the outer radius face down on a solid

surface e.g. table, floor.

• Press one hand onto the squeegee body by the hose connector.

• Grasp the blade with your thumb and forefinger inthe middle of the arch and

pull strongly until the metal band clicks open andthe blade is released from

the squeegee body.

• Release the metal strap and pull the blade off the squeegee body.

• Clean squeegee (body, metal straps and blades) with a brush.

• Mount the "rotated" or replaced blade onto the squeegee body.