Table of Contents

SUPRAECO W – 6 720 646 161 (2012/04)

2

Table of Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Information about the appliance . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

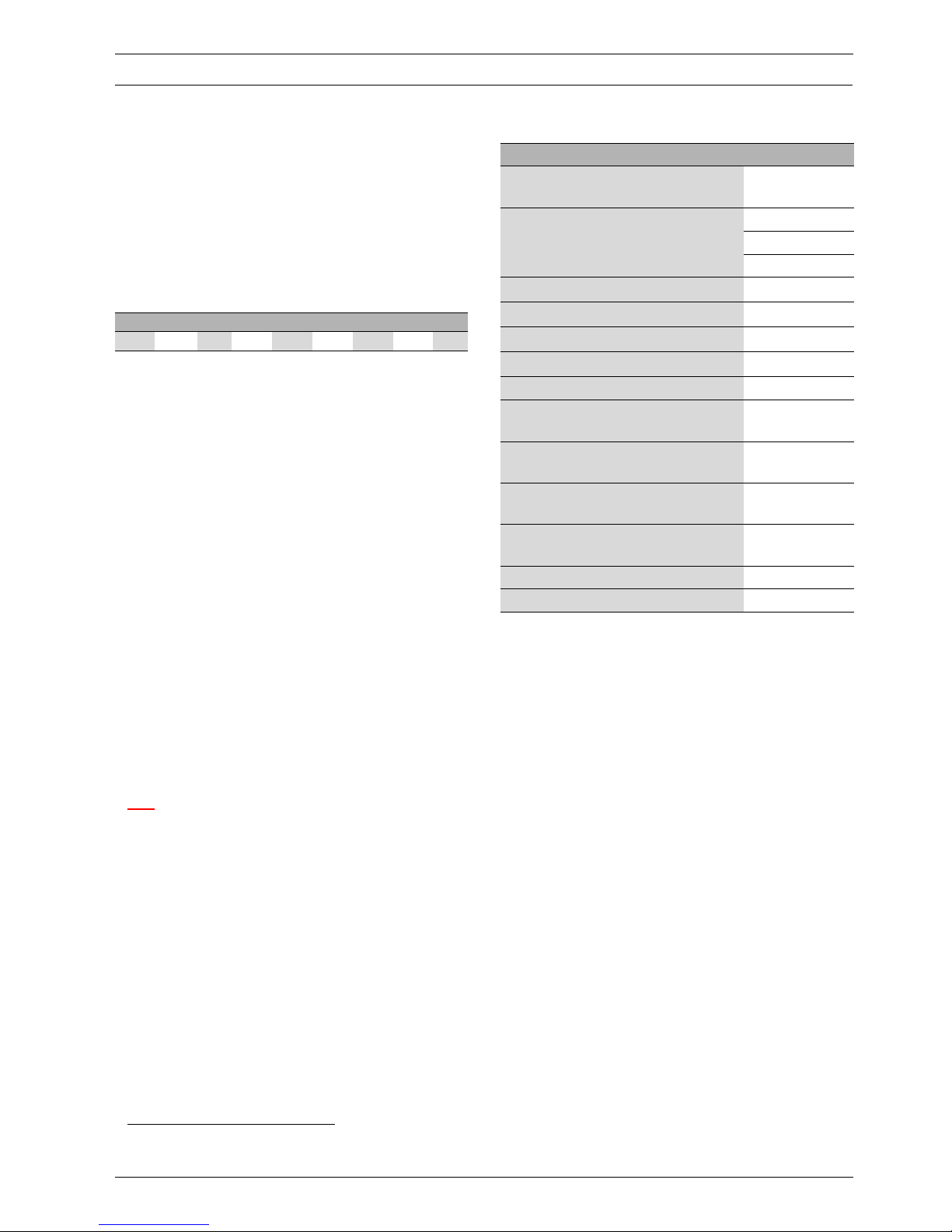

3.2 Overview of boiler types . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Description of appliance . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Accessories (not included in standard delivery) . . . . . . 5

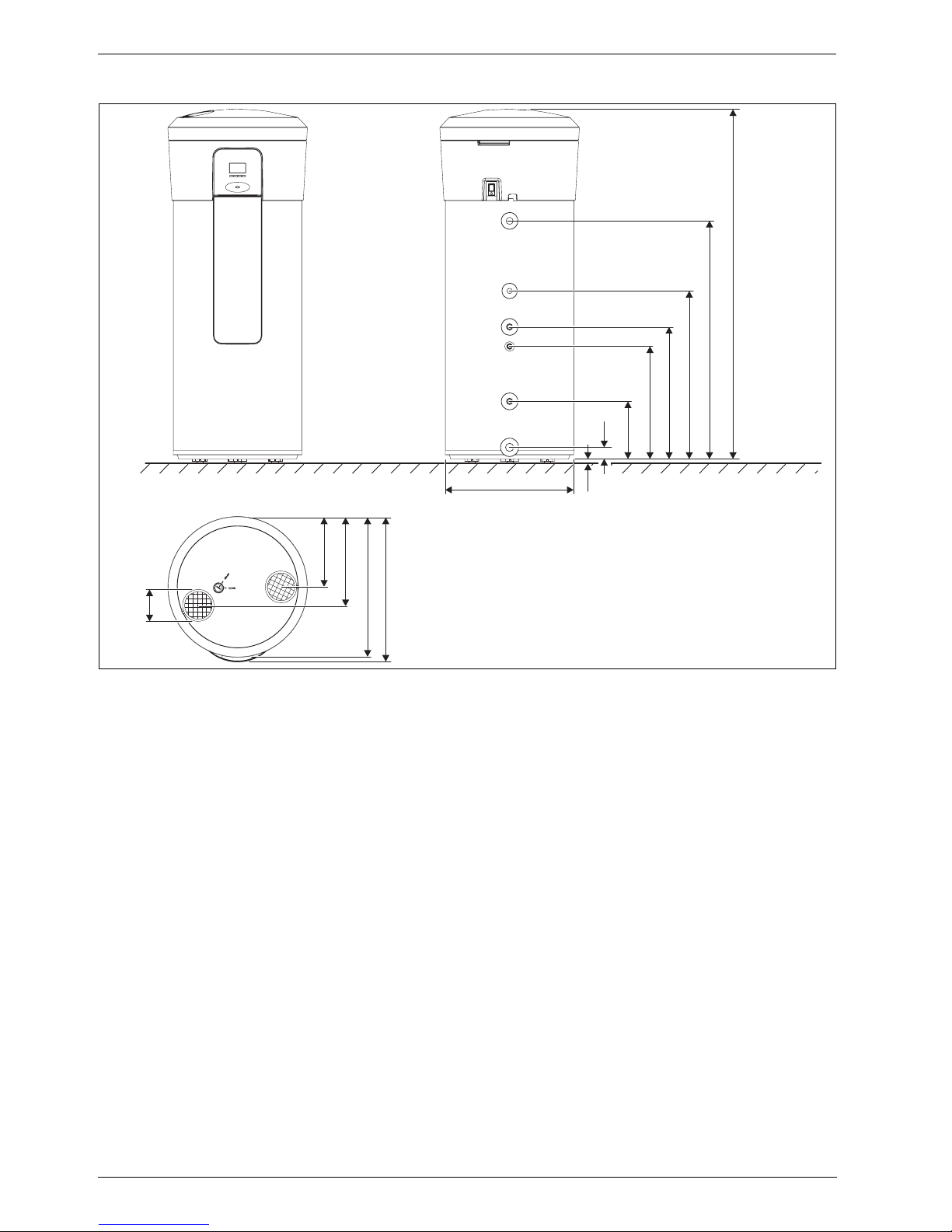

3.6 Dimensions and minimum clearances . . . . . . . . . . . . . . 6

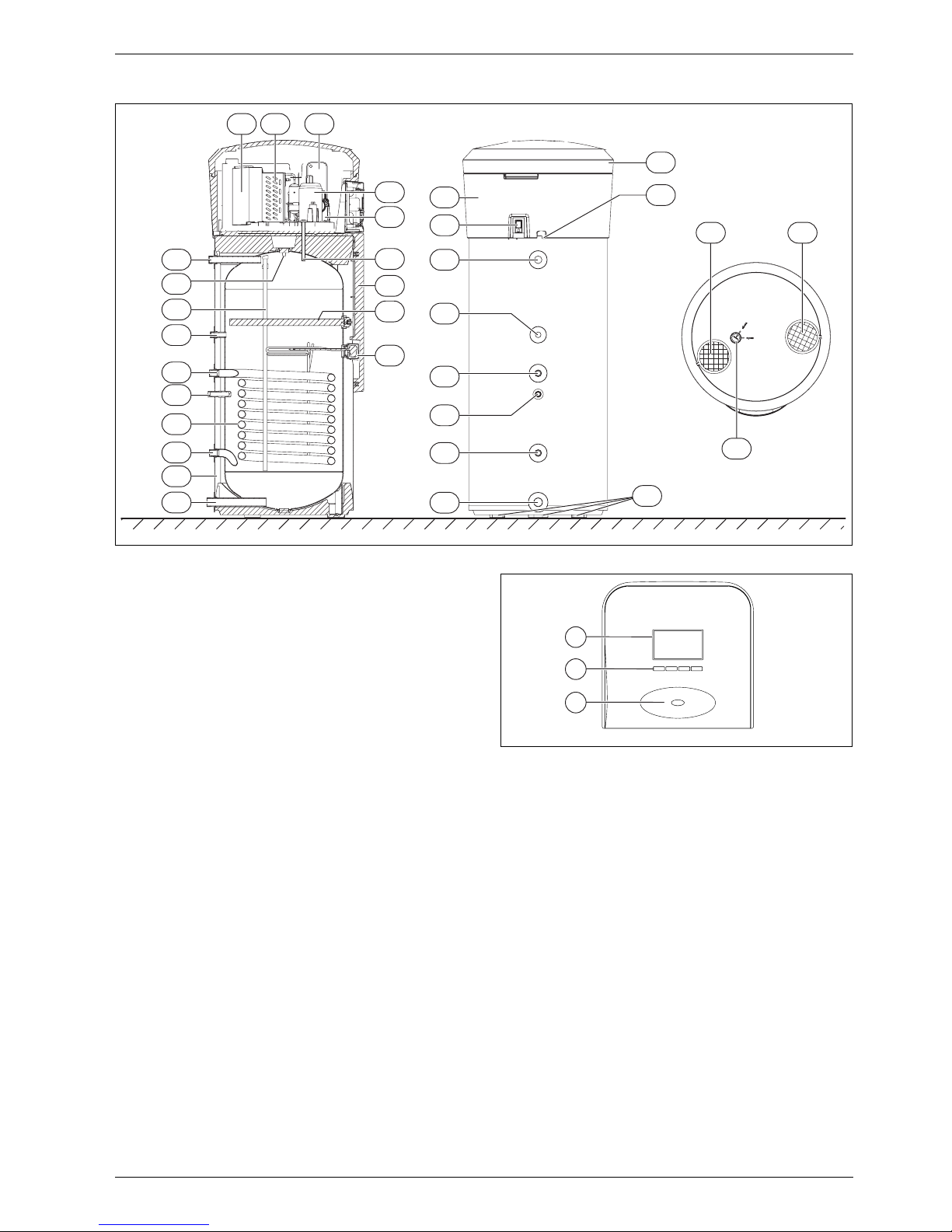

3.7 Appliance layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

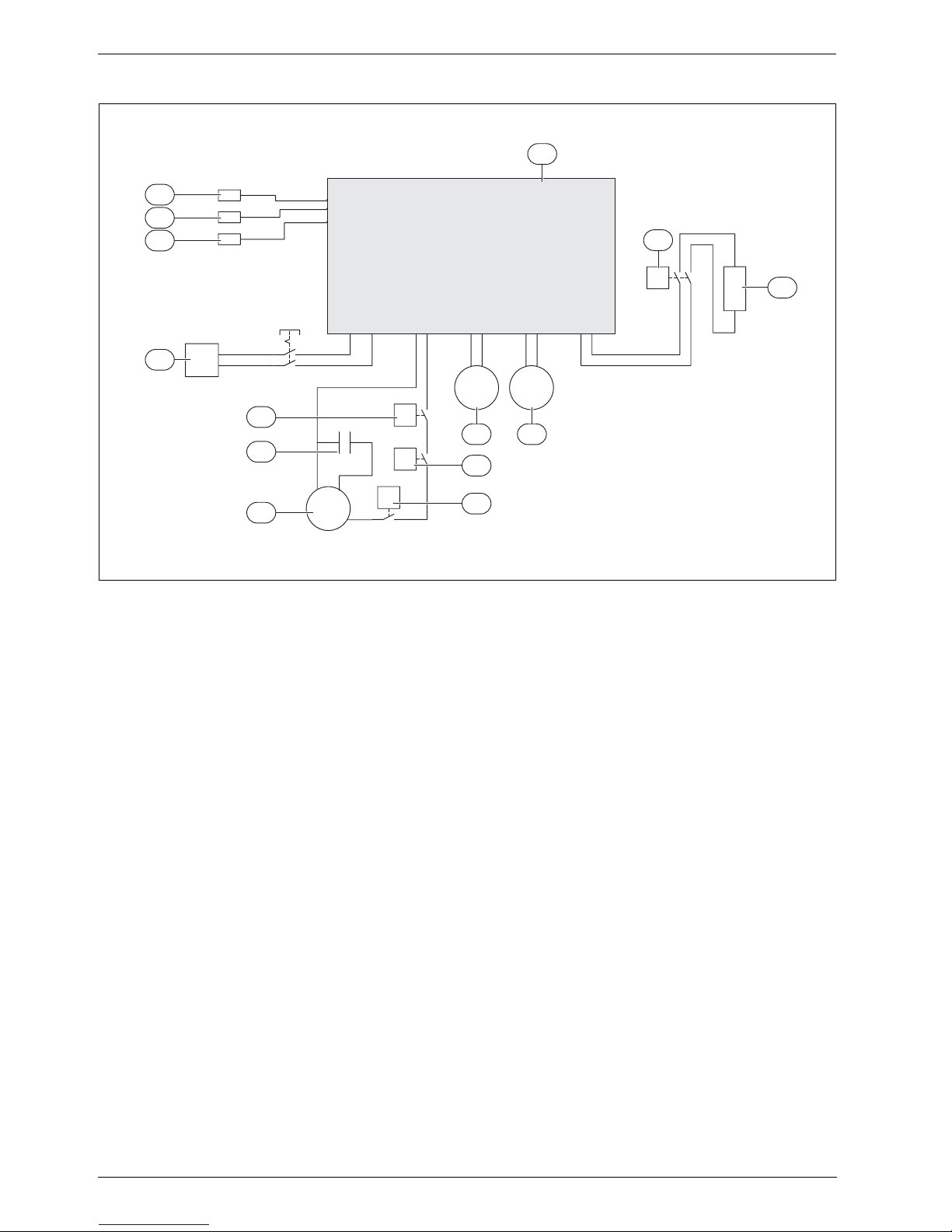

3.8 Electrical wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . 8

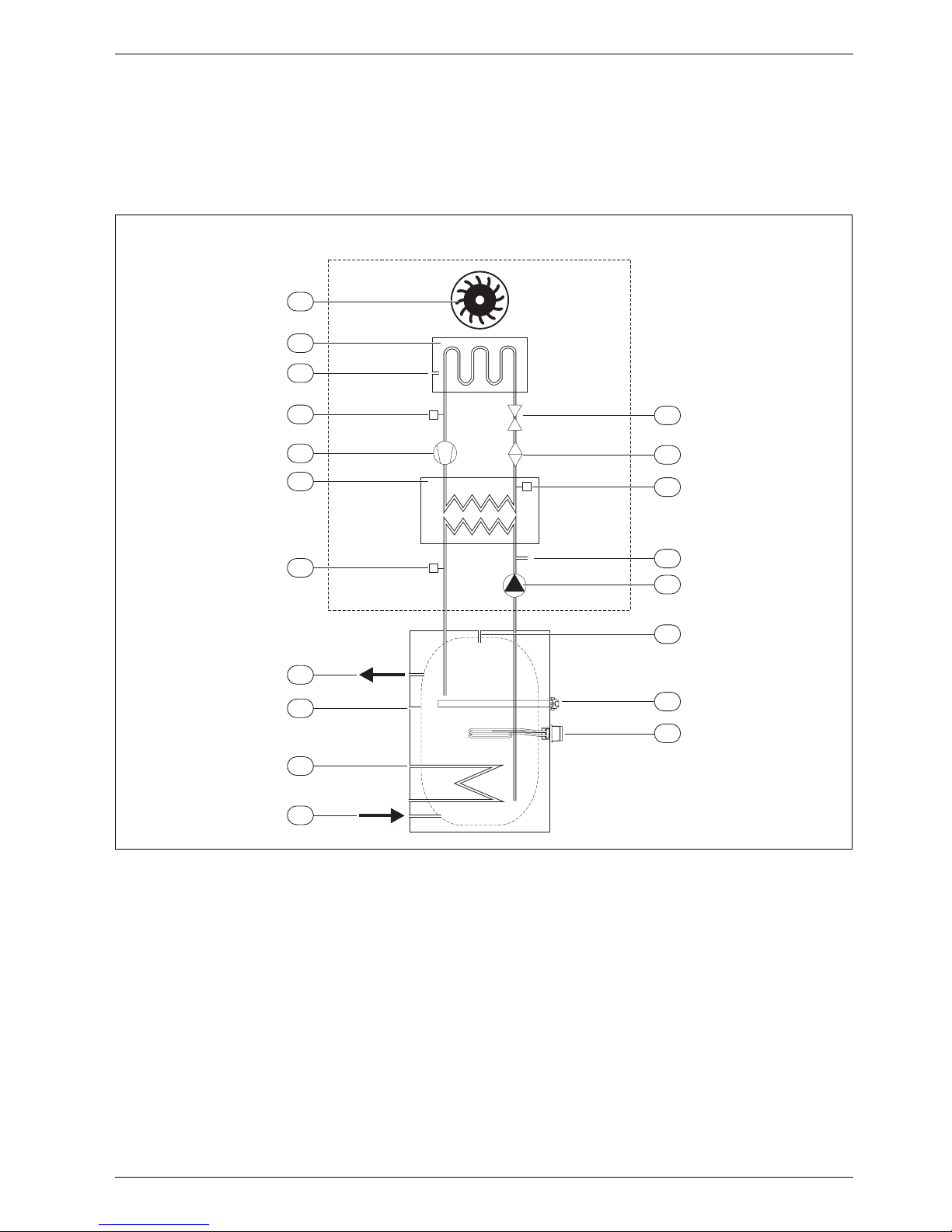

3.9 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.10 Safety, control and protective devices . . . . . . . . . . . . 10

3.10.1 High-pressure/low-pressure pressure switch . . . . . . 10

3.10.2 High limit safety cut-out . . . . . . . . . . . . . . . . . . . . . . . . 10

3.10.3 Temperature sensor for air inlet . . . . . . . . . . . . . . . . . 10

3.11 Corrosion protection . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.12 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.13 System scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.13.1 Heat pump for DHW heating with boiler support . . . . 12

3.13.2 Heat pump for DHW heating with solar thermal

system support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Secure the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Installing the air ducts . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.1 Open flue operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.2 Functioning with outside air . . . . . . . . . . . . . . . . . . . . 15

5.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Connection for the internal indirect coil . . . . . . . . . . . 16

5.6 DHW circulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.7 Condensate hose connection . . . . . . . . . . . . . . . . . . . 16

5.8 Expansion vessel (accessories not included in

standard delivery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.9 Filling the storage tank . . . . . . . . . . . . . . . . . . . . . . . . 16

5.9.1 Water characterisitcs . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Appliance's electrical connection . . . . . . . . . . . . . . . . 18

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Switching the appliance on/off . . . . . . . . . . . . . . . . . . 18

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1 Working display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.2 Working modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3 „Operating“ menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3.1 „manual“ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3.2 „P1“, „P2“ and „P3“ modes . . . . . . . . . . . . . . . . . . . . . . 19

8.3.3 „Full“ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3.4 „Off“ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Setting the DHW temperature . . . . . . . . . . . . . . . . . . . 19

8.5 „Main“ menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.5.1 „Mode“ function - heating modes . . . . . . . . . . . . . . . . . 20

8.5.2 „Prog“ function - Timetable operation programming . 21

8.5.3 „Leg“ function - automatic thermal disinfection . . . . . 22

8.5.4 „Set“ function - adjustments . . . . . . . . . . . . . . . . . . . . . 23

8.5.5 „Purg“ function - purge . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.5.6 „Info“ function - information . . . . . . . . . . . . . . . . . . . . . 23

8.6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.7 Factory configurations . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.8 Selecting the temperature units - „°C“ or „°F“ . . . . . . . 24

8.9 Setting the time and day of the week . . . . . . . . . . . . . . 24

8.10 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.1 General inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.2 Performance check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.3 Checking/replacing the magnesium anode . . . . . . . . . 26

10.4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.5 Condensate hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.6 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.7 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.8 High limit safety cut-out . . . . . . . . . . . . . . . . . . . . . . . . 27

10.9 Draining the storage tank . . . . . . . . . . . . . . . . . . . . . . . 27

11 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.1 Faults that are shown on the display . . . . . . . . . . . . . . 28

11.2 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28