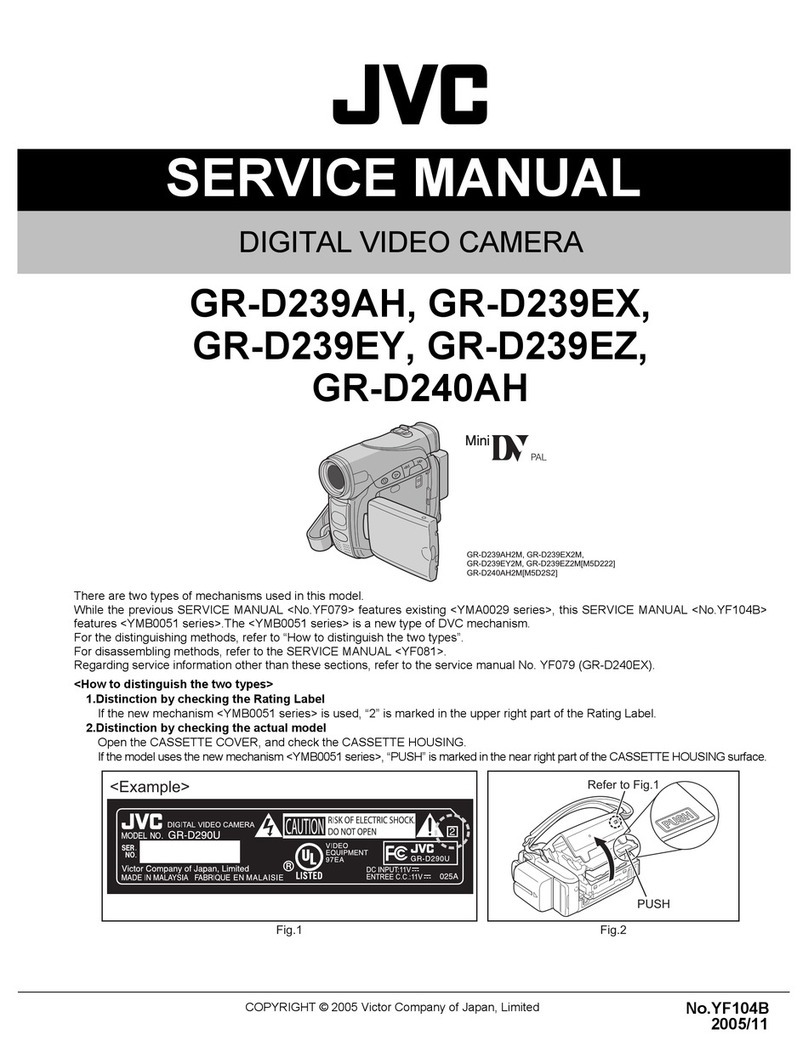

1-2 (No.YF009)

SECTION 1

DISASSEMBLY (GR-DX Series)

1.1 BEFORE ASSEMBLY AND DISASSEMBLY

1.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

specified otherwise, tighten screws at a torque of 0.088N·m

(0.9kgf·cm). However, 0.088N·m (0.9kgf·cm) is a value at the

time of production. At the time of service, perform the

procedure at a torque 10% less than 0.088N·m (0.9kgf·cm).

(See "SERVICE NOTE" as for tightening torque.)

1.1.2 Destination of connectors

1.1.3 Disconnection of connectors (Wires)

Fig.3-1-1

1.1.4 Tools required for disassembly and assembly

Fig.3-1-2

•Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

•Bit

This bit is slightly longer than those set in conventional torque

drivers.

•Tweezers

To be used for removing and installing parts and wires.

•Chip IC replacement jig

To be used for replacement of IC.

•Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

1.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

1.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

(∗1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

C = CABINET

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw

L = Lock, Release, Hook

SD = Solder

CN = Connector

[Example]

• 4 (S1a) = Remove four S1a screws.

• 3 (L1a) = Disengage three L1a hooks.

• 2 (SD1a) = Unsolder two SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

CN2a

CN2b

MAIN CN101

MAIN CN103

40

2

CONN. No. PIN No.CONNECTOR

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: The connector of the side to remove

: Wire: Flat wire : Board to board (B-B)

MONI/BW CN761

MIC CN762

B-B Connector

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

FPC Connector

Wire

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

FPC Connector

Lock

Wire

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Cleaning cloth

KSMM-01

Torque driver

YTU94088

Bit

YTU94088-003

Chip IC replacement jig

PTS40844-2

Tweezers

P-895

( 4) ( 5)( 2) ( 3)( 1)

TOP COVER ASSEMBLY

UPPER ASSEMBLY

(Inc. VF ASSEMBLY,

SPEAKER/MONITOR)

VF ASSEMBLY

Fig.C1

Fig.C2-1

Fig.C2-2

S1,2(L1)

S2a,2(S2b),3(S2c)

2(S2d),S2e,S2c

L2,CN2a,b

2(S8),L8,CN8a

-

-

NOTE 8a

NOTE 8b

[1]

[2]

[8]

STEP

No. PART NOTE

Fig.

No. POINT