JVC KS-LX200R User manual

Other JVC Car Receiver manuals

JVC

JVC KD-AR370 User manual

JVC

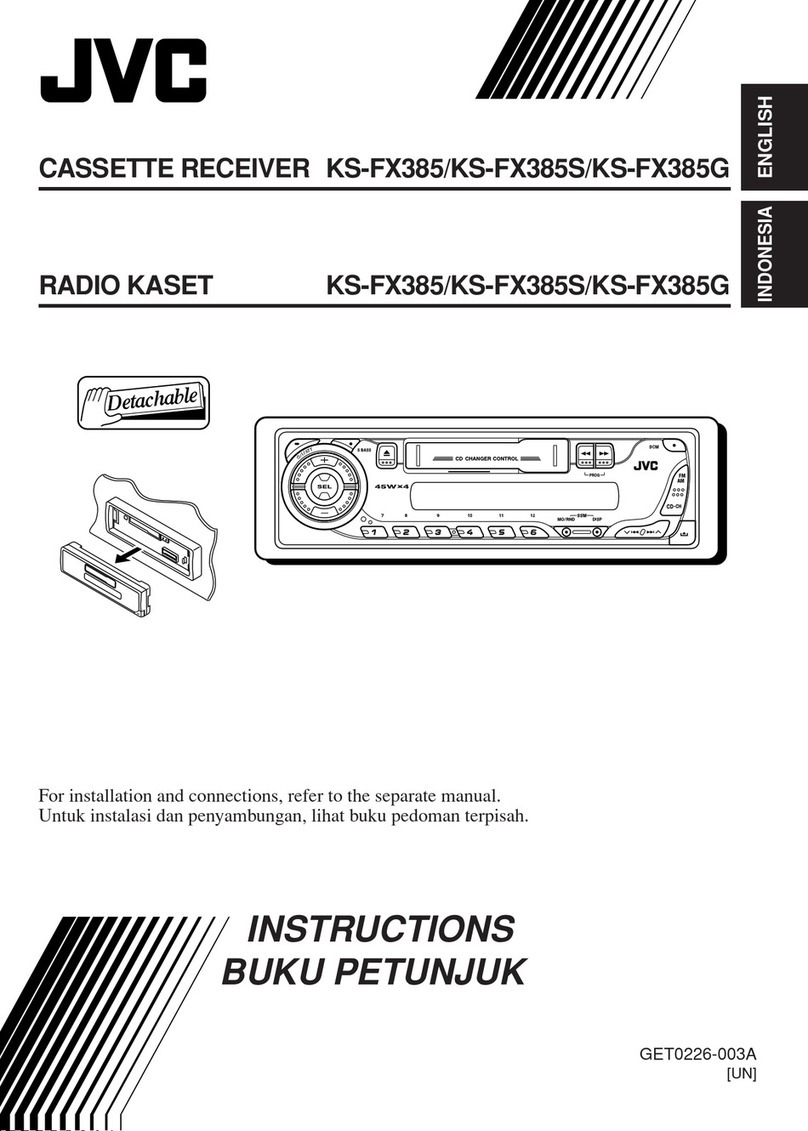

JVC KS-FX385S User manual

JVC

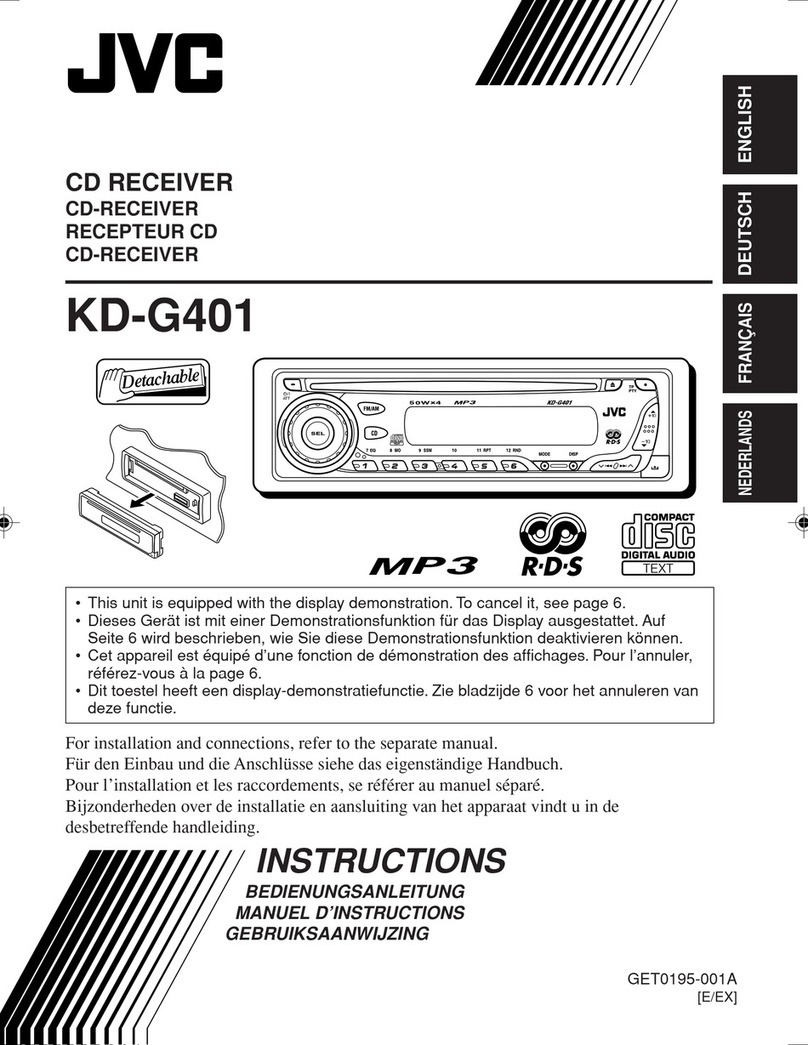

JVC GET0195-001A User manual

JVC

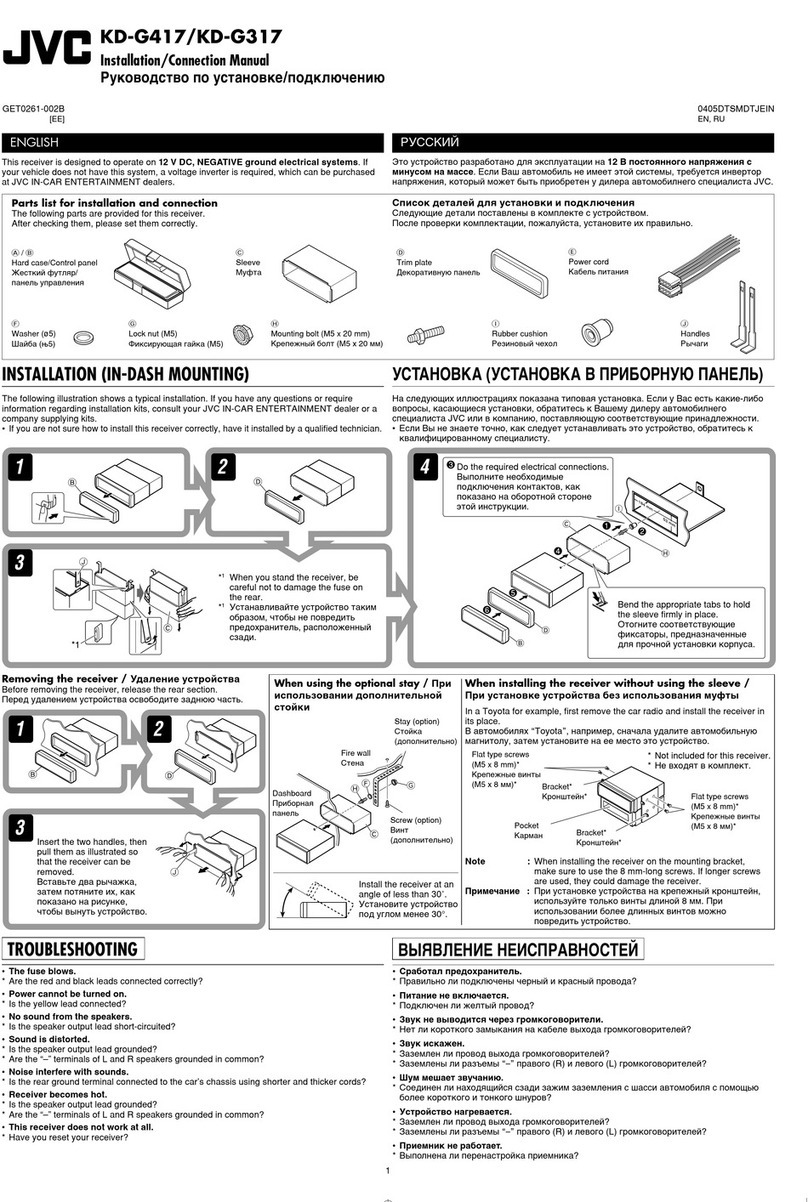

JVC CD Receiver KD-G417 Guide

JVC

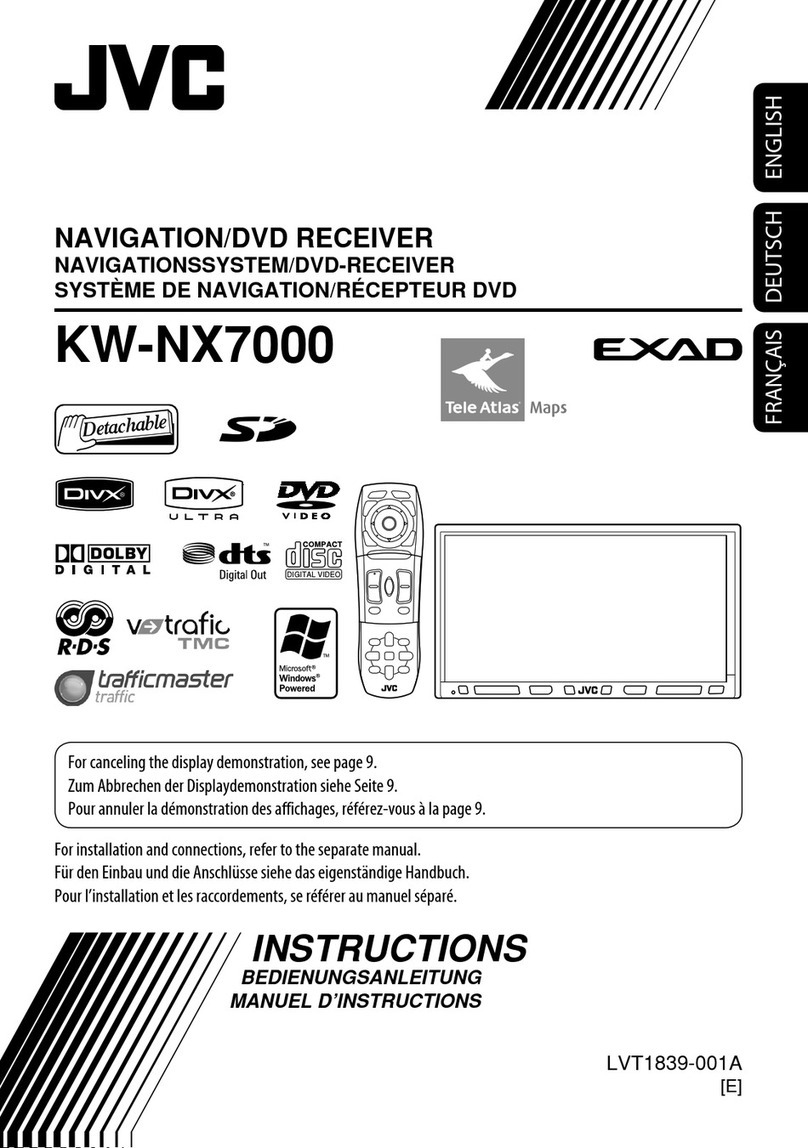

JVC KW NX7000 - Double Din Navigation User manual

JVC

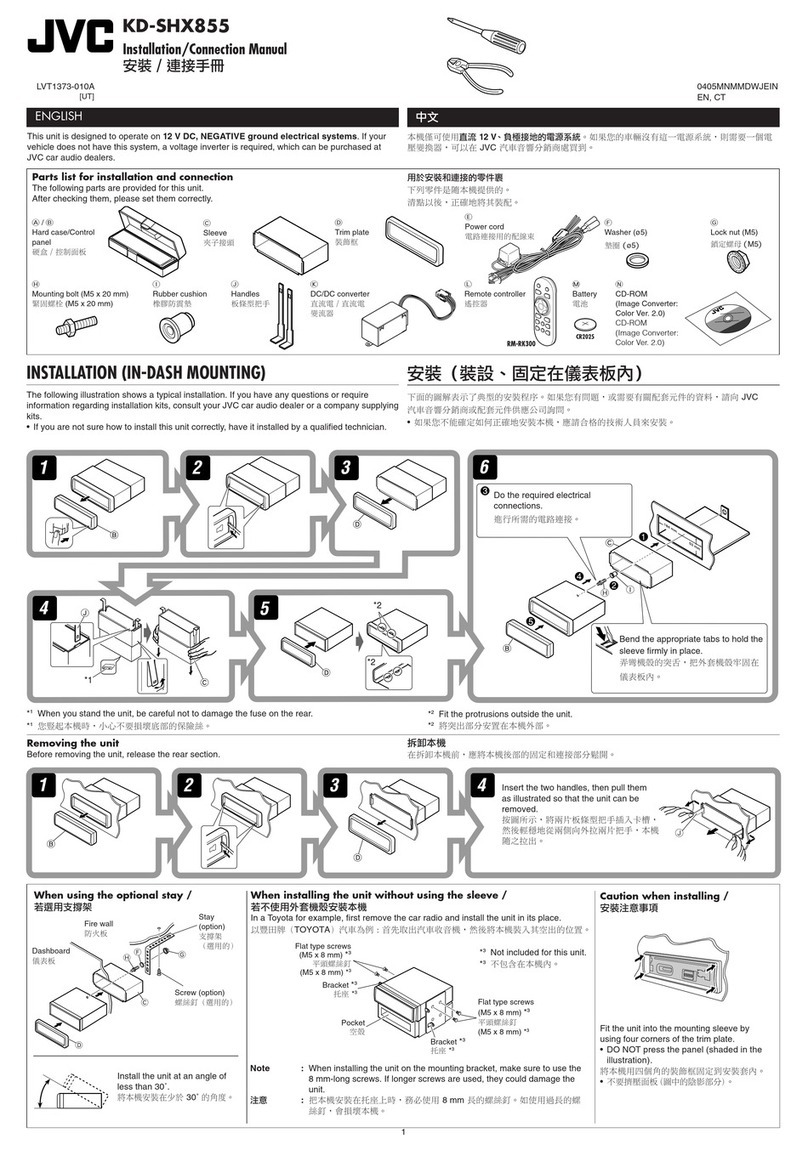

JVC EXAD KD-SHX855 Guide

JVC

JVC KW-XR810 User manual

JVC

JVC KW-R520 User manual

JVC

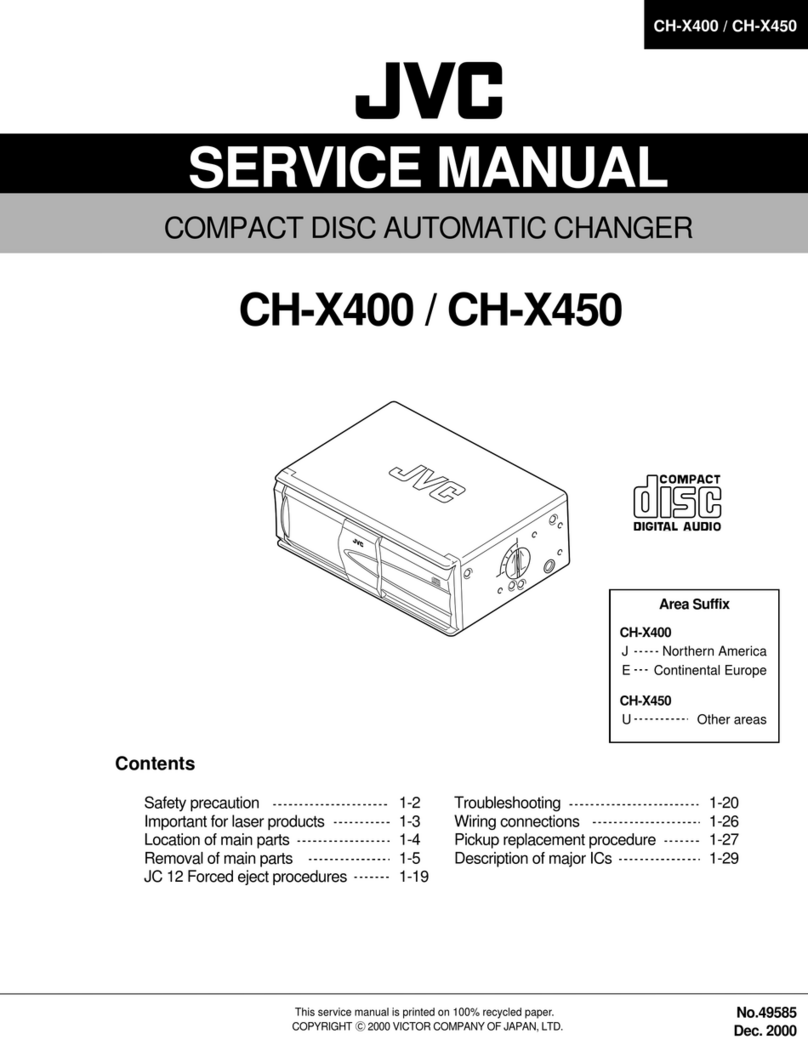

JVC CH-X400 User manual

JVC

JVC KW-AVX730 User manual

JVC

JVC KD-LX330R User manual

JVC

JVC KD-X560BT User manual

JVC

JVC KS-FX490 - Radio / Cassette Player User manual

JVC

JVC KD-S811R User manual

JVC

JVC KD-R856BT User manual

JVC

JVC KD-SX950J User manual

JVC

JVC KS-FX822R User manual

JVC

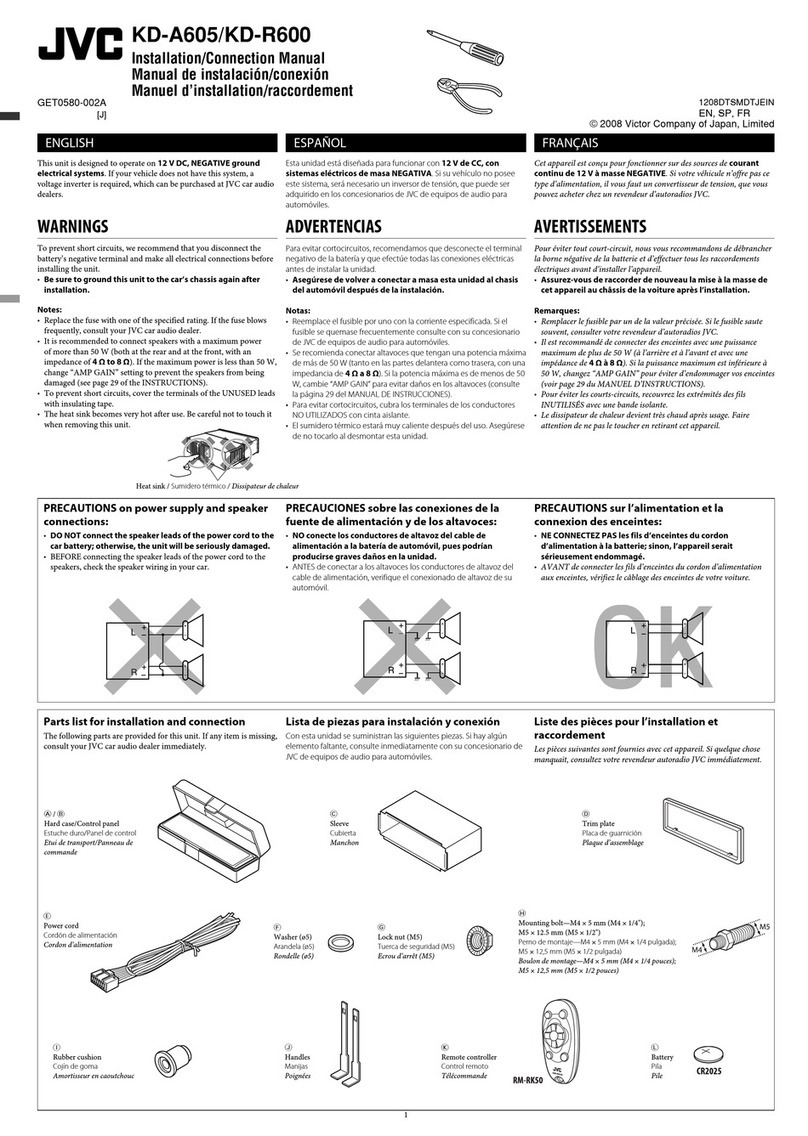

JVC KDA605 - KD Radio / CD Guide

JVC

JVC KW-AVX840 User manual

JVC

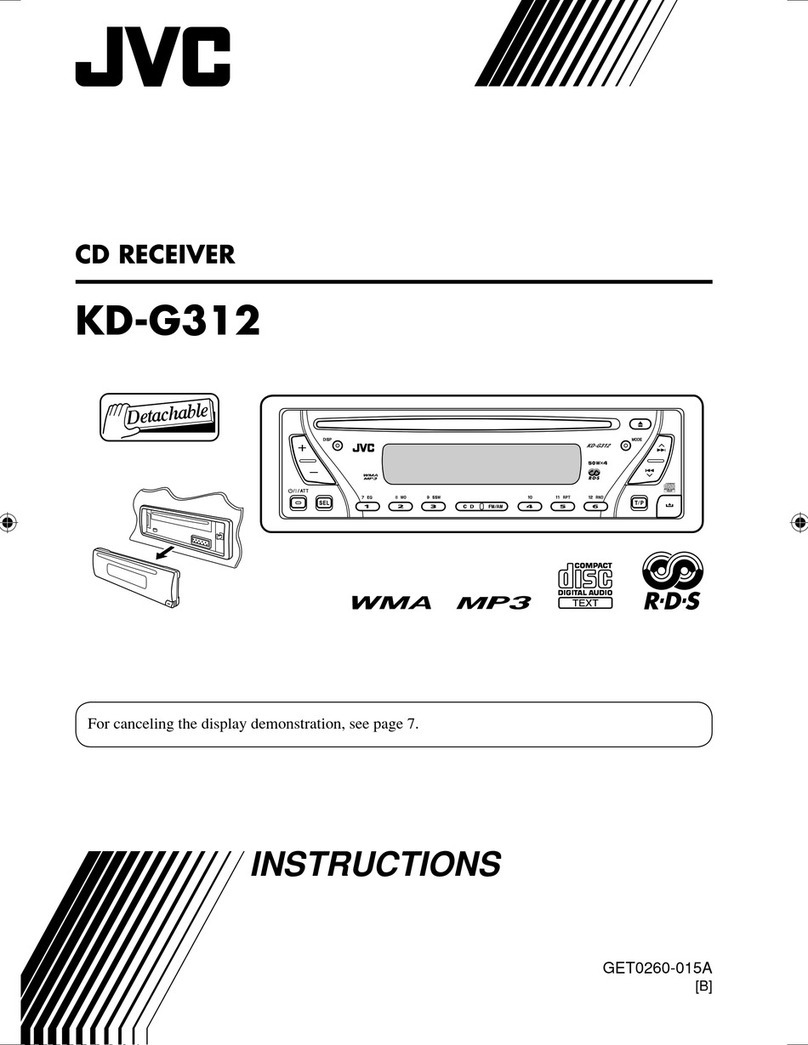

JVC GET0260-015A User manual