SERVICE MANUAL

LCD DATA PROJECTOR

No.PA014

Apr. 2001

COPYRIGHT C2001 VICTOR COMPANY OF JAPAN, LTD.

LX-P1010ZU/ZE

LX-P1010ZU/ZE

Optical mechanisms

Display Method Poly-silicon LCD panel × 3 units, Lens × 1,

RGB shutter method, using Translucent TN liquid crystal panels

Optical System

Dichroic mirror separation, Dichroic prism composition

LCD panels Poly-silicon TFT(Thin Film Transistor)

LCD panels × 3 (4:3 Aspect Ratio panels)

Display method :Translucent TN liquid crystal panels

Material : Poly-Silicon

Panel size : 0.7" (diagonal)

Drive method :TFT(Thin Film Transistor) active matrix panel

No. of pixels :480,000(800 × 600)

stripe pixels × 3 panels (1,440,000 pixels)

Pixel Configuration : Stripe

Projection lens

Manual zoom/focus lens (1:1-1:1.3), F2.3-2.6, f=28mm-37mm

Lens axis shift 6:1 Low position (fixed)

Keystone distortion correction

±15˚

Screen size 30"-300" diagonal (aspect Ratio: 4:3)

Screen aspect ratio 4:3 (16:9 compatible)

Installation desk, front/rear (menu selection)

Projector lamp AC 130Watts UHM Lamp

No. of colors 16,777,216 colors (Full color)

Brightness 700 lumen / ANSI

Light output uniformity 85%

Contrast ratio 300:1

Resolution RGB 800 × 600 pixels, Video 500 TV lines

Electrical system

PC-RGB input Display :RGB/Y • P

B

• P

R

IN

1pin : R/PR, 2pin:G/Y, 3pin:B/PB,

12pin : DDC data, 13pin:HD/SYNC,

14pin :VD,15pin:DDC clock

(Jack also used for component video

input.Signal type is selected on-screen.)

Type : D-sub HD 15-pin ×1

Input signal : Analog RGB standard input level

0.7(p-p)/75Ωterminated

Dot clock frequency :135MHz or less

Scanning frequency : f

H

24kHz-80kHz, f

V

50Hz-86Hz

HD/SYNC :TTL level, positive/negative(compatible)

DV :TTL level, positive/negative(compatible)

S-video input Display :SVIDEO IN

Type : Mini Din 4-pin ×1

Input signal :Y(luminance signal) 1.0V(p-p),

sync negative, 75Ωterminated

C(chrominance signal) burst 0.286V(p-p),

75Ωterminated

Scanning frequency : f

H

15.75kHz, f

V

60Hz

(NTSC/NTSC4.43/PAL-M)

f

H

15.63kHz, f

V

50Hz

(PAL/SECAM/PAL-N)

Composite video input Display :VIDEO IN

Type : RCA jack (yellow) ×1

Input signal : 1.0V(p-p)/75

Ω

terminated

Scanning frequency : Refer to S-video

Component video input Display :RGB/Y • P

B

• P

R

IN

(Jack also used for composite video input.

Signal type is selected on-screen.)

Input signal :

Y(luminance signal) 1.0V(p-p)/75Ωterminated

P

B

,P

R

0.7V(p-p)/75

Ω

terminated

Scanning frequency : f

H

15.75kHz, f

V

60Hz (480i),

f

H

15.63kHz, f

V

50Hz (625i),

f

H

31.5kHz, f

V

60Hz (480p),

f

H

45kHz, f

V

60Hz(720p),

f

H

33.75kHz, f

V

60Hz (1080i)

Audio input Display :AUDIO IN

(Jack used for audio of PC-RGB input,

S-video input and composite video input.)

Type : L/R, M3 stereo mini jack ×1

Input signal : 0.32V(rms)

Serial port Display :RS-232C

Type : Mini Din 8-pin ×1

Others

Built-in speaker Size : 36mm round type

Output power :0.5 Watts, Mono

Power supply 100V-240V AC, 50/60 Hz

Power consumption

210 Watts (standby mode*: 15 Watts) *with fan stopped.

Usage temperature 0˚C-40˚C(0˚F-104˚F)

Usage humidity 20%-80% (no condensation)

Storage temperature -20˚C-40˚C (-4˚F-104˚F) , 40˚C-60˚C(104˚F-140˚F)

Storage humidity 5%-85% Normal humidity(non-condensing)

Card remote control unit Battery : Lithium battery (CR2025), DC3V

Range for operation : approximately 7m

Dimensions :(W)276mm ×(H)74mm ×(D)208mm

(Legs are not included)

Mass :2.5kg

Specifications

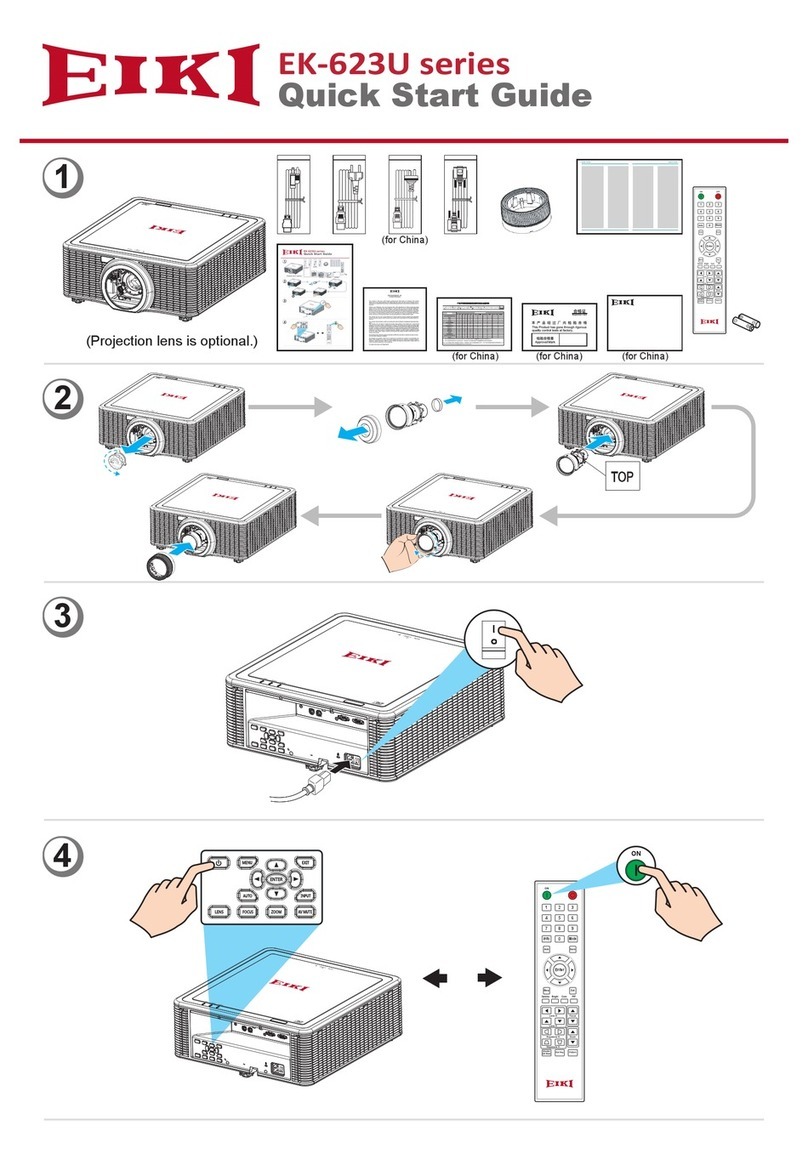

Accessories

•Card remote control unit •Lithium battery (CR2025) •Power cord •VGA cable •Video cable •Audio cable •Swivel stand unit •Carrying bag

•Inst.book (Quick reference manual) •Inst.book (CD-ROM)

Note:

The attached card remote controller becomes

necessary to adjust the following.

Keep the card remote controller also together

with the product to be repaired.