NivicoO

SERVICE

MANUAL

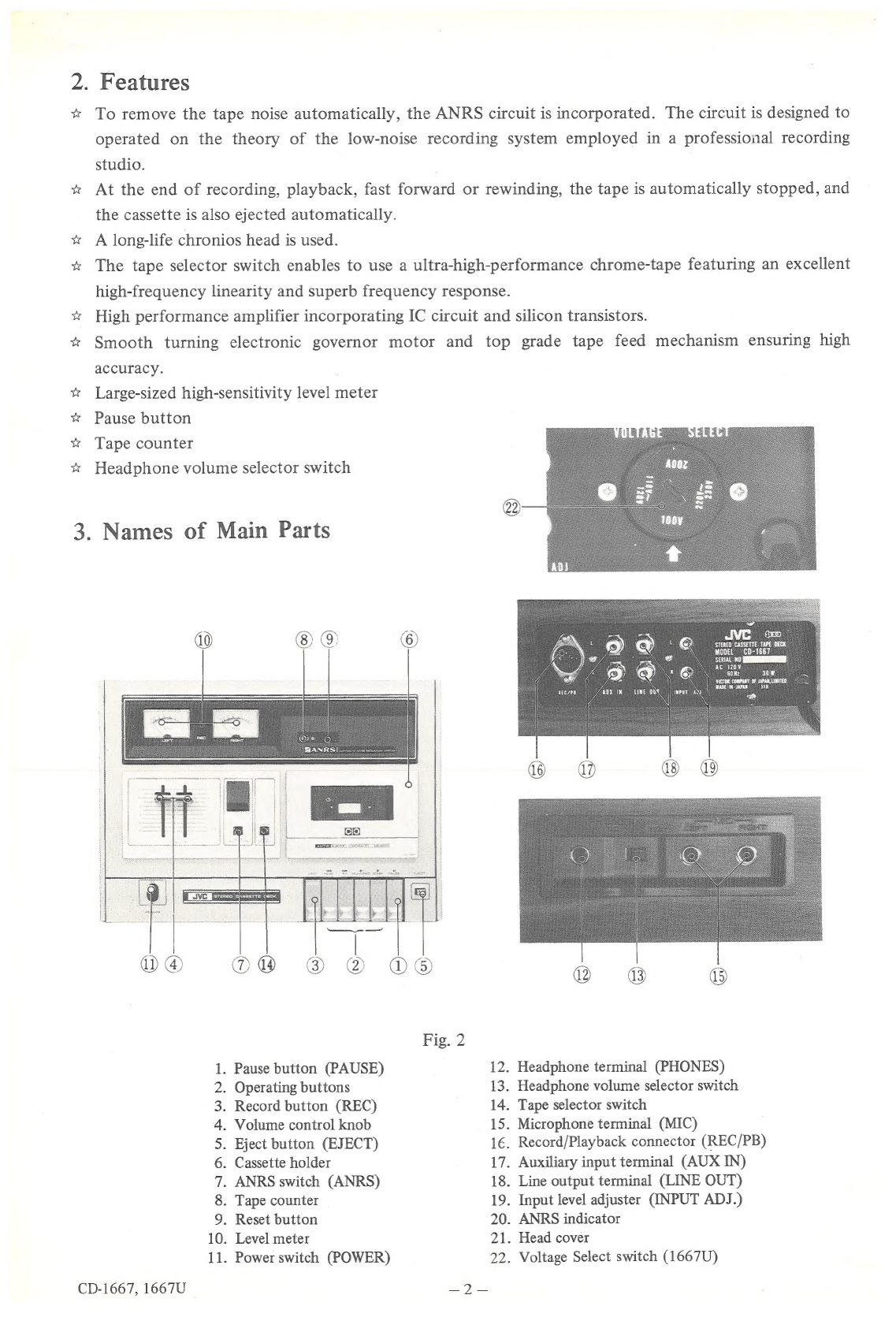

Fig.

1

MODEL

CD-1667

1667U

STEREO

CASSETTE

TAPE

DECK

Dimensions:

12.0

(H)

x

38

(W)

x

26.5

(D)

cm

(4-3/8"

x

14-15/16”

x

10-7/16")

Weight:

4.6

kg

(10

Ibs)

*

In

this

Service

Manual,

frequency

is

indicated

in

Hz.

*

In

this

tapedeck,

ISO

screws

are

used.

No.

4073

July,

1972

PUTTAR

TARTU

RLUCGLURORAAMAUUMERERRLUCRCGUORLUOMUCCUORALLUULLLOOR

MU

LULU

sd

po

=O

Mam

Ov

AWM

KODA

CSAIL

LUILILERALLLULTLOREEELLUULILLARLLULLLLURRLLUULLCLARLLLLULLECOOEL

LCL

Power

source:

AC

120V,

60Hz

(CD-1667)

AC

100V,

110

~

120V,

200V,

220

~

230V

(50,

60H,

)

(1667U)

Fuse

capacity:

1.8A,

0.8A

Power

consumption:

30W

(CD-1667)

15W

(1667U)

Track

system:

2-channel,

4-track

Cassette:

C-60,

C-90,

C-120

Tape

speed:

4.8cm/sec.

(1-7/8ips)

Recording

system:

AC

bias

95kHz

Erasure

system:

AC

erasure

Recording

time:

60

min.

for

double

pass

(C-60)

Fast

forward

time:

100

sec.

or

less

(C-60)

Rewinding

time:

100

sec.

or

less

(C-60)

Transistors:

20

:

IC:

4

30

~19,000Hz

(Chrome-tape)

0.7mV,

10ka

20mV

(Signal

source

80ka)

80mV,

330ka

0.5V,

5ka

1V,

3.3ka

Diodes:

17

Frequency

response:

Crosstalk:

60dB

or

more

S/N

ratio:

50dB

Total

harmonic

4%

ot

less

distortion

:

rievhuracteriste!

1590uS,

120uS

Input:

Microphone

DIN

input

AUX.

IN

Output:

DIN

LINE

OUT

Headphones

0.5mW/0.12mW,

82

FOOUVT

TTPO

ATTRA

ETT

TEA

TTT

VICTOR

COMPANY

OF

JAPAN,

CTD.

|IIMIIIIIIINNEILIIINONNILIU

NOE

ILI

HUTT

TERNI00

(TU

CCQNDIILUTIROETTHITT

=

CD-1667,

1667U