1

LIMITED WA ANTY

Unless otherwise specified, all commercial cooking equipment manufactured by Kaliber

nnovations LLC is warranted against defects in materials and workmanship for a period of 1 year

from the date of purchase and applies to the original purchaser only. This warranty does not

include the induction appliances which are individually covered by the appliance manufacturer.

This warranty is void if it is determined that, upon inspection by an authorized service agency, the

equipment has been modified, misused, misapplied, improperly installed, improperly maintained or

damaged in transit or by fire, flood or act of God. Warranty is void if the serial nameplate has

been removed, or if service is performed by unauthorized personnel.

ADDITIONAL WA ANTY EXCLUSIONS

Resetting of safety interlocks, circuit breakers, over load protectors, and/or fuse replacements•

is not covered by this warranty unless warranted conditions are the cause. The discharge of

the fire suppression system may damage the Valere Series Mobile Cooking Station. Warranty

is no longer valid after the fire suppression system is discharged.

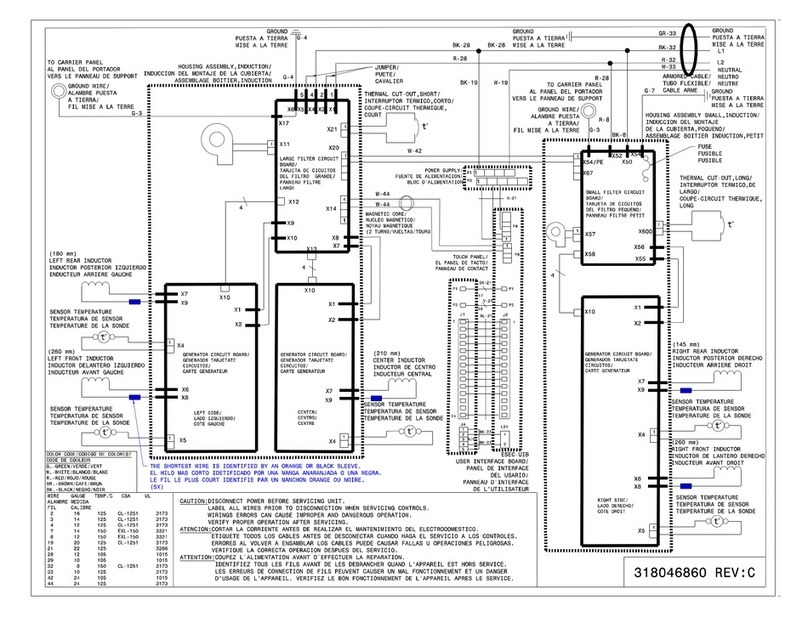

All problems due to operation at voltages or phase other than specified on equipment•

nameplates are not covered by this warranty. Conversion to correct voltage and/or phase is

the customer’s responsibility.

All problems due to electrical connections not made in accordance with electrical code•

requirements and wiring diagrams supplied with the equipment are not covered by this

warranty.

Replacement of items subject to normal wear such items as filters and normal maintenance•

functions including adjustment of micro switches and replacement of fuses are not covered by

this warranty.

Damage to electrical cords and/or plug due to exposure to excessive heat are not covered by•

this warranty.

Customer is responsible to perform and maintain a log of preventive maintenance, servicing•

and cleaning items as described in this service manual. Failure to follow proper cleaning and

servicing schedules will void this warranty.

Any use of non-genuine Kaliber parts completely voids any warranty.•

nstallation and labor are not considered warranty and are not covered by this warranty.•

Kaliber nnovations cannot assume liability for damage or loss incurred in transit. Equipment is•

carefully inspected and packaged before leaving our factory. Upon acceptance of this

shipment, the transportation company assumes full responsibility for the appliance during

transit.

This warranty is only valid in the United States and void elsewhere.•

AGENCY LISTING INFO MATION

ETL Listed in compliance with ANS /UL710B and ANS /NSF standards