4

WARNING

zUse this product only in the way described in the product literature and

in its manual. Before using it, verify that this product is suitable for

intended use.

zDo not modify system components. Before use, confirm that the product

has not been altered in any way.

zYour unit must be properly grounded in conformity with national or

local electrical codes. Never connect the unit to overloaded power sources.

zDo not use the unit outdoors. Current leakage or electric shock may result

if the unit is exposed to rain water.

zOnly qualified engineers or service personnel shall install the unit. The

installation by unqualified personnel may cause electric shock or fire.

zInstall the unit on a sturdy floor. If the floor is not strong enough or the

installation site is not adequate, this may result in injury from the unit

falling or tipping over.

zNever install the unit in a humid place or a place where is likely to be

splashed by water. Deterioration of insulation may result which could

cause current leakage or electric shock.

zNever install the unit in a flammable or volatile location. This may cause

explosion or fire.

zNever install the unit where acid or corrosive gases are present as

current leakage or electric shock may result due to corrosion.

zNever store volatile or flammable substances in this unit. This may cause

explosion or fire.

zNever store corrosive substances in this unit. This may lead to damage to

the inner components or electric parts.

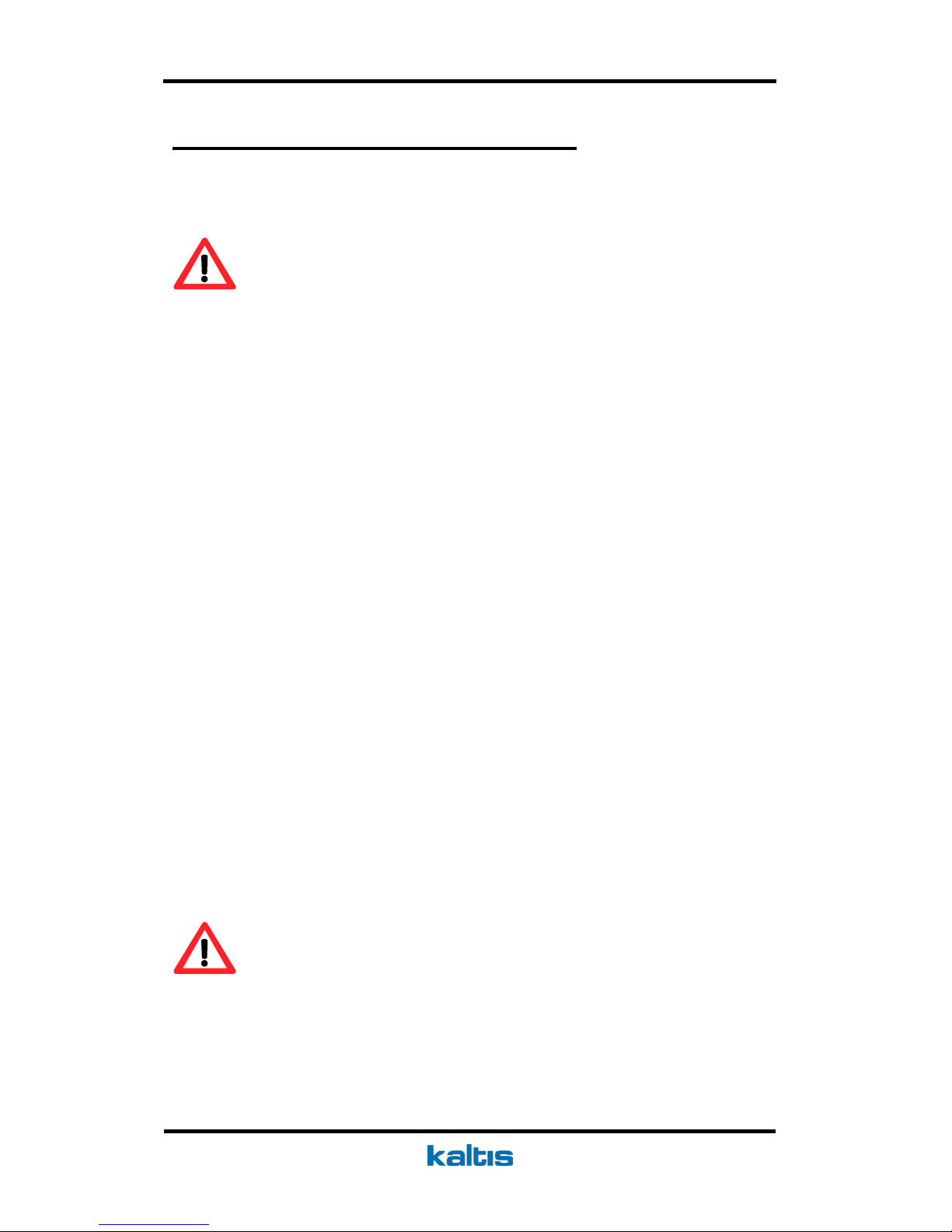

zDisconnect the power source to the unit prior to any repair or

maintenances of the unit in order to prevent electric shock or injury.

zMake sure not to inhale or consume medication or aerosols from around

the unit at the time of maintenance. This may harmful to your health.

zNever slash water directly to the unit. This may cause electric shock or

short circuit.

zNever disassemble, repair, or modify the unit yourself. Any such work

carried out by an unqualified personnel may cause fire or injury due to

malfunction.