HOW TO SET UP A WELDER:

1. Close valve on air-pressure regulator by pulling upward

on the plastic knob until a clicking sound is heard, and

then proceeding to turn the knob counter clockwise This

will prevent possible damage to the gauge from a sudden

surge of excessive air pressure.

2. Connect the regulator to a supply of either compressed air

(which should be free of oil or moisture) or inert gas. The

Kamweld air-pressure regulator is rated for 200 lbs. (90.72

kg) of line pressure. If inert gas is used, a pressure reduc-

ing is needed (obtainable from a gas supplier).

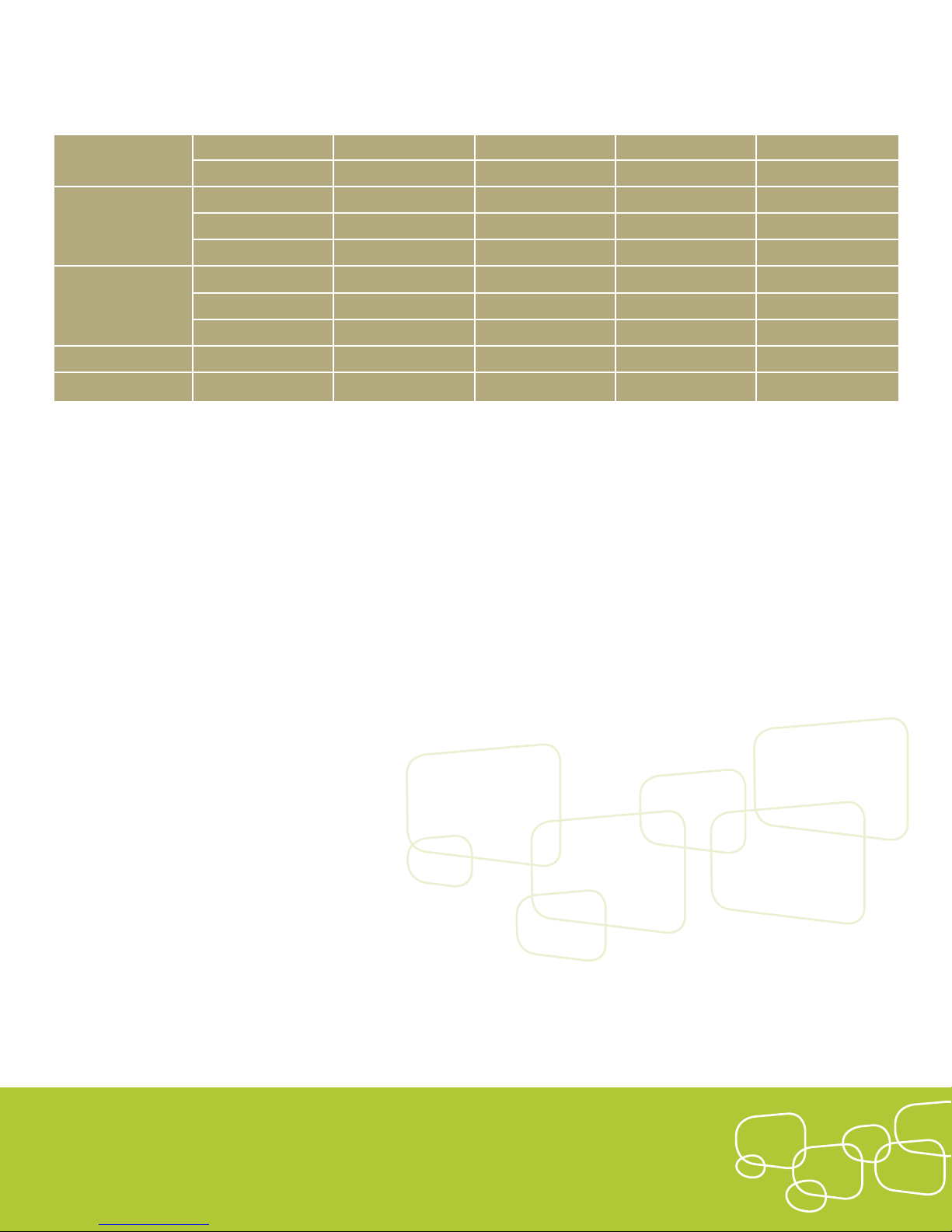

3. Turn the air supply on. The starting air pressure for each

model is indicated in the chart on the next page. Please

note that the heated air temperature depends on the

wattage of the heating element AND the air pressure. The

operating air pressure requires slightly less air. The chart

shows the approximate temperatures obtainable with 120

volt AC supply:

Caution: if the round spanner nut (which holds the barrel to the

handle) becomes too warm to the touch, the gun is overheating. If

this occurs, increase the air pressure immediately, according to the

instructions in the right column. By increasing the air pressure, the

air temperature decreases.

4. Connect the welder to a common 120 volt AC outlet. A

three-prong grounded plug is supplied with each unit and

MUST be used.

5. Allow the welder to warm up at the recommended

STARTING pressure according to the temperature chart on

the following page. It is essential that either air or inert gas

ows through the welder at all times, (from warming up to

cooling o), to prevent burn-out of the heating element

and/or further damage to the gun. AT NO TIME SHOULD

THE ELECTRICITY BE CONNECTED WITHOUT AIR FLOW-

ING THROUGH THE GUN.

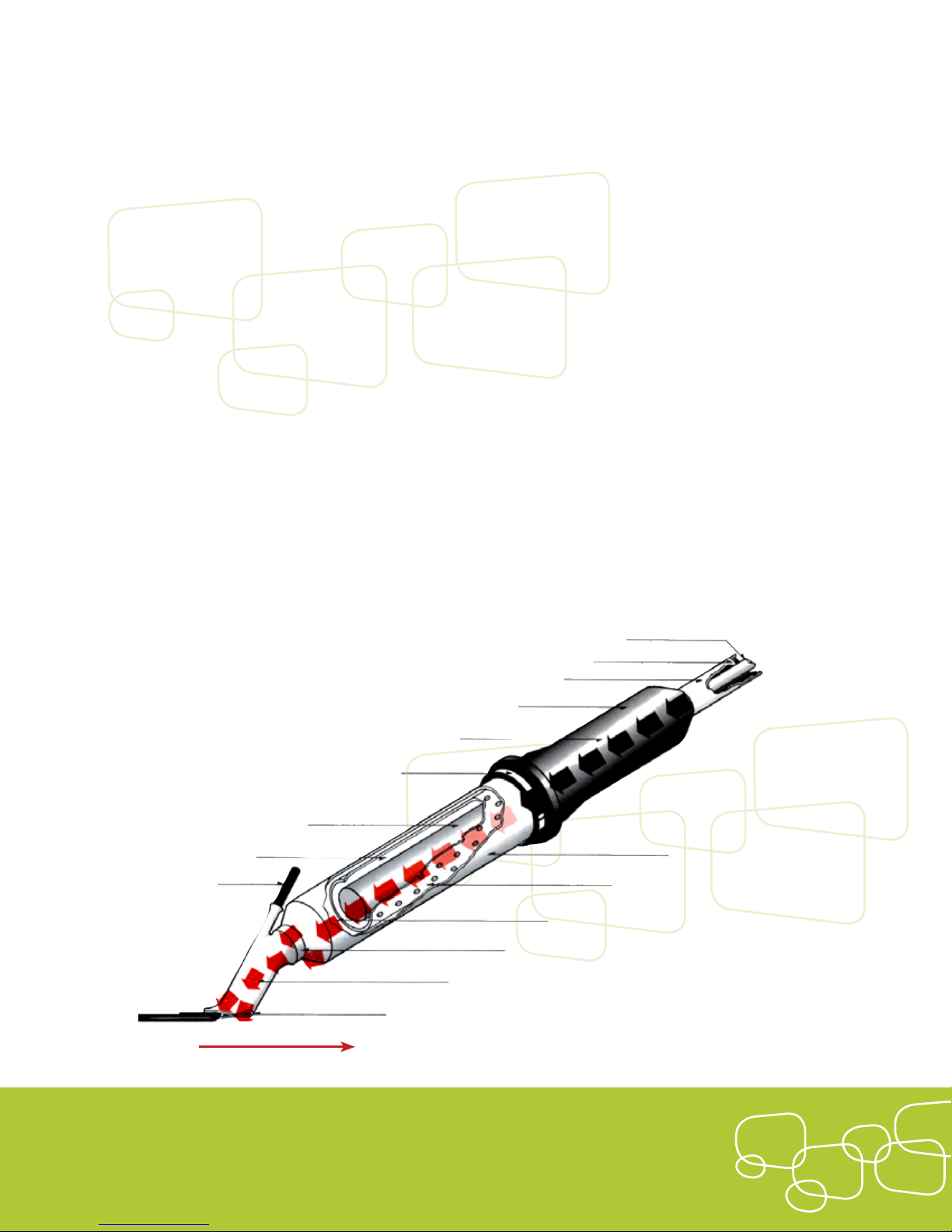

6. Select the proper welding tip and install it into the thread-

ed outer barrel with pliers to avoid touching the tip and

barrel while they are hot. After the tip has been installed,

the temperature will increase slightly due to back pressure.

Allow two to three minutes for the tip or outer barrel to

reach the required operating temperature.

7. If you nd the temperature is too high to weld the mate-

rial you are working with, increase the air pressure slightly

until the temperature decreases. If the temperature is too

low for your application, decrease the air pressure slightly

until the temperature rises. When increasing or decreasing

the air pressure, allow at least two or three minutes for the

temperature to stabilize at the new setting. Damage to the

welder or heating element will not occur from too much air

pressure: however, the element can become overheated

by too little air pressure. When decreasing the air pressure

from the recommended starting pressure, never allow the

spanner nut to become too hot to the touch. This is an

indication of overheating. Maximum operating tempera-

ture with the minimum air pressure is obtained when the

spanner nut is only slightly warm to the touch. A partial

clogging of the dirt screen in the regulator or a uctuation

in the line voltage can also cause over or under heating.

5