– 5

Attach hand nozzle (optional accesso-

ry) instead of the floor nozzle.

With sensitive materials, use less deter-

gentandspraythesurfaceatadistance

of approx. 200 mm. Then simply vacu-

um off.

– Highly soiled spots should be pre-

soaked and the detergent solution

should soak 5 to 10 minutes.

– Always work from the light to the shade

(from the window to the door).

– Always work from the cleaned to the un-

cleaned surface.

– Themoresensitivethesurface(oriental

rugs, berbers, upholstery material) the

lower the cleaning solution concentra-

tion should be.

– Rugs with jute backing can shrink if too

much water is used and can bleed col-

ours.

– Brush high-fiber rugs in the direction of

the weave after cleaning (using a fiber

brush or a scrubber).

– Water-proofing the fabric using Care

Tex RM 762 after the wet cleaning pre-

vents a quick resoiling of the textile sur-

face.

– Do not step on cleaned surfaces until

they have dried and do not place furni-

ture on them to avoid pressure spots or

rust stains.

– When cleaning previously shampooed

carpets, foam will be generated in the

dirt water reservoir. In such a case add

Foam ex RM 761 to the dirt water reser-

voir.

For further information, please request

product information sheet and EU safety

data sheet of the relevant detergent.

몇CAUTION

Risk of injury and damage! Observe the

weight of the appliance when you transport

it.

Grab the appliance by the chassis and

by the sliding bow to load it.

Pull the device behind you at the carry-

inghandlefortransportingitoverlonger

distances

When transporting in vehicles, secure

the appliance according to the guide-

lines from slipping and tipping over.

몇CAUTION

Risk of injury and damage! Note the weight

of the appliance in case of storage.

This appliance must only be stored in inte-

rior rooms.

DANGER

Danger of injury by electric shock.

Firstpull out theplugfrom the mainsbefore

carrying out any tasks on the machine.

Note: With normal use, clean the flat pleat-

edfilterweekly,orevenearlierifthesuction

performance is decreasing.

Note: Use a commercially available house-

hold sponge made of soft material in order

to avoid damaging the coated lamellae.

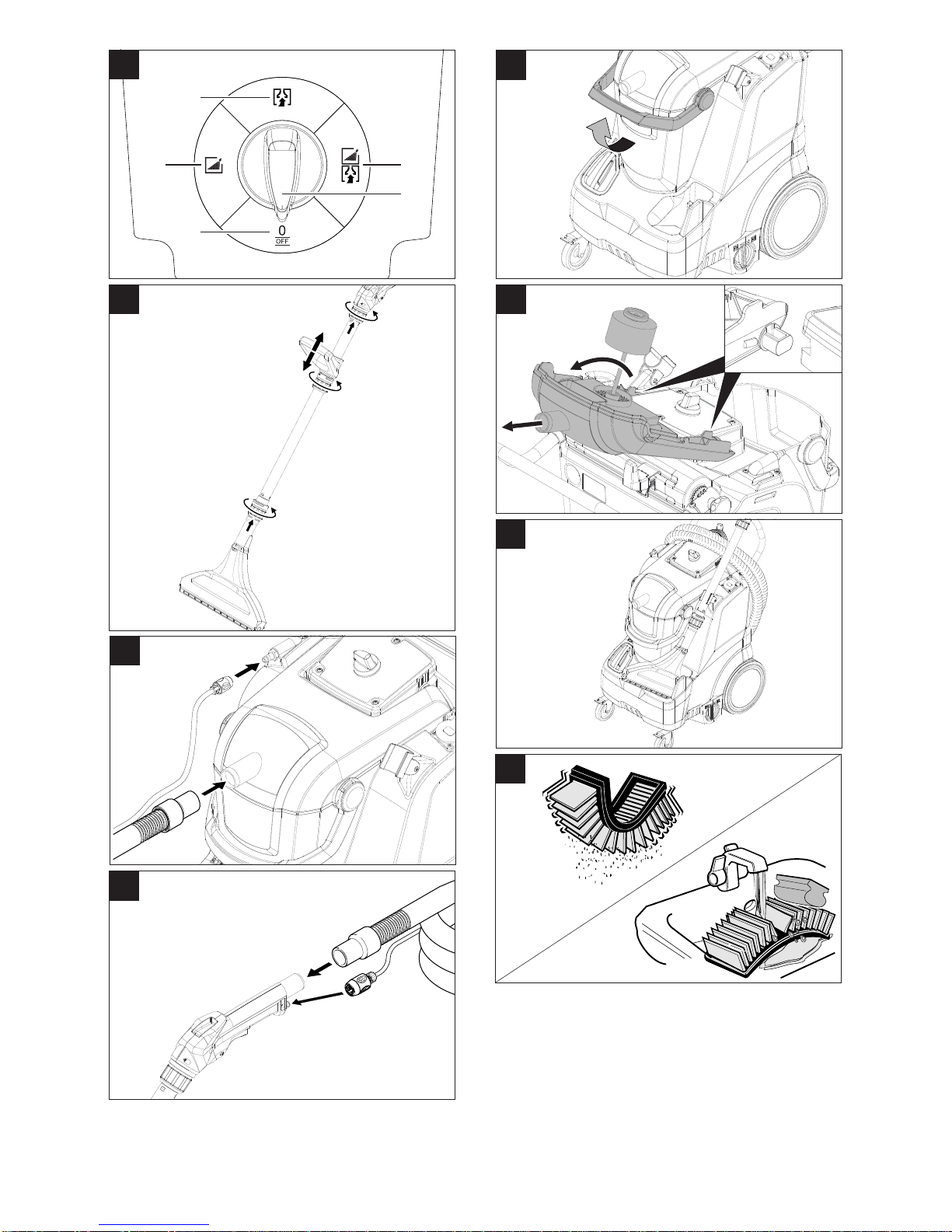

Unlock the bonnet, swivel it upwards

and snap it in place at the locking devic-

es.

Unlock and remove the filter casing.

Take out the flat folded filter.

Illustration

Clean the individual lamellae of the flat

pleated filter under running water using

the sponge.

Allow the filter to dry completely.

Upholstery cleaning

Cleaning tips

Detergent

Carpet and upholstery

cleaning RM 760 powder

RM 760 tabs

RM 764 liquid

Defoaming RM 761

Waterproofing carpets RM 762

Transport

Storage

Maintenance and care

Cleaning/replacing the flat pleated

filter

17EN