KAT TB PLUSH KIT User manual

KAT-KIT TB PLUSH KIT

Welcome to the KAT-KIT TB PLUSH Build-It-Yourself-Kit.

Firstly, a little info on the TB. For starters, the components provided are the best for the job in-hand.

They are the same components used for the builds of many KAT TB’s and Fryer Sound TB Touring,

Deluxe and Plus Treble Boosters. The circuit board has been specially designed for the kit so that the

build can be easy with all components identified on the board. The case is the same powder-coated,

silk-screened folded steel unit used for the TB Touring, Deluxe and Plus, so rugged, durable and yet,

attractive.

Sound-wise, this TB has been developed to emulate the 1980’s era of Brian May’s tone, so think

Queen from the late 70’s through to the end. Think Wembley… Think Live Aid!!

So, what’s in the kit?

Well, everything you need to successfully build the TB except for a few hand tools and a battery.

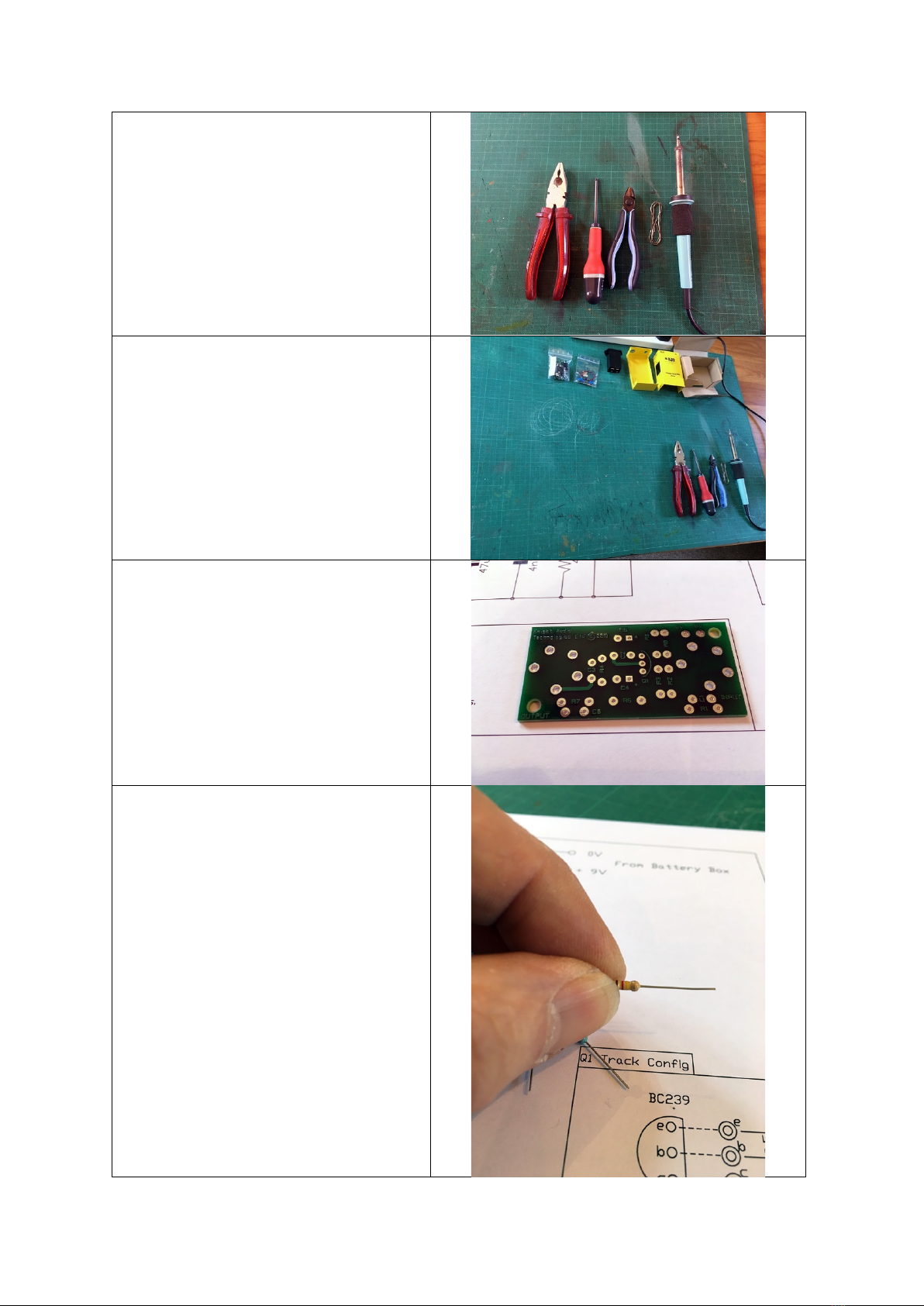

Here are the only tools you will need to

build this kit:

1. Soldering Iron (25 – 40W)

2. Multicore solder

3. Cutters

4. No. 1 Pozidriv screwdriver

5. Large pair of pliers

We would suggest that you set up on a

large piece of cardboard or cutting board

along these lines.

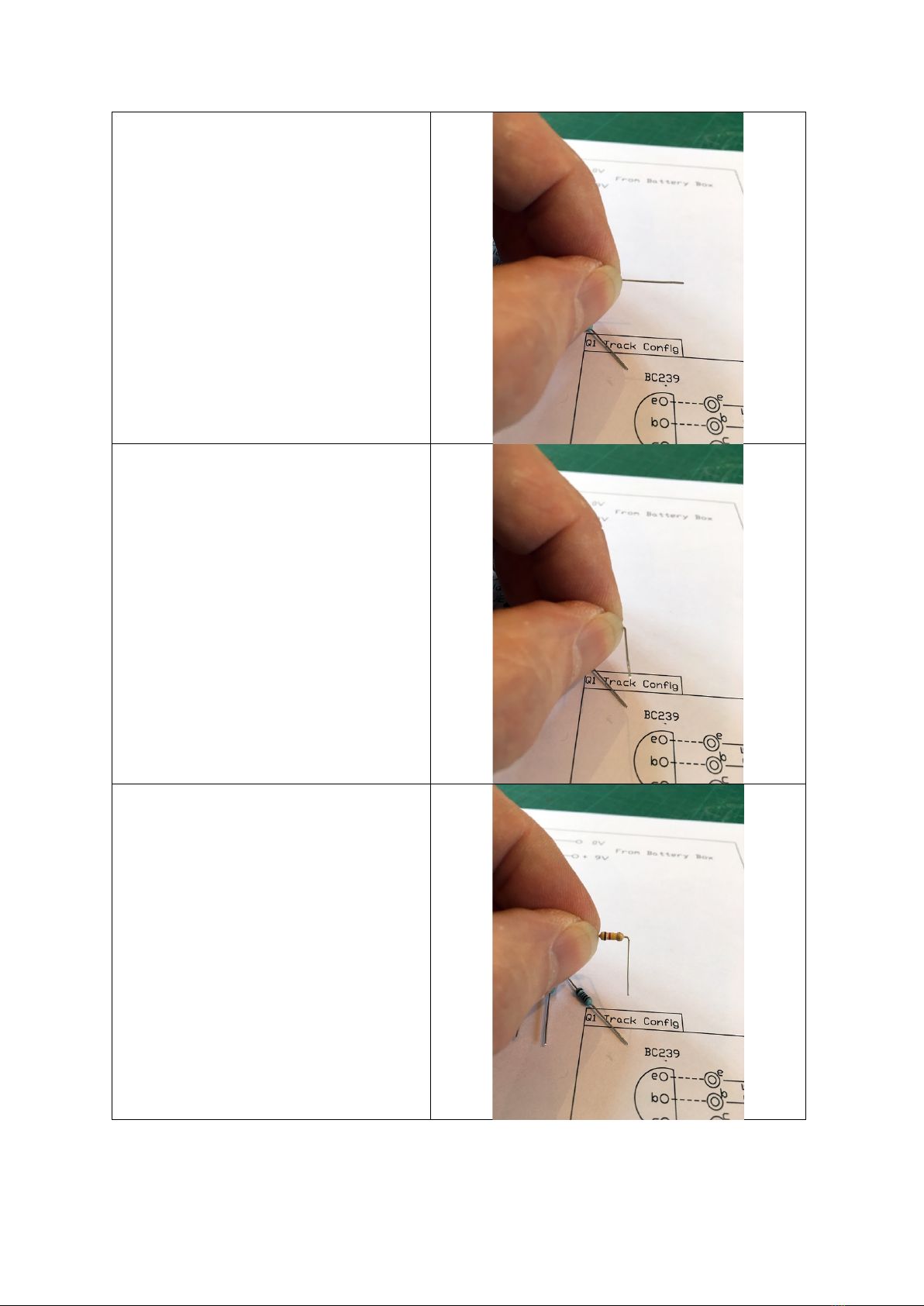

So, Let’s start with the circuit board. It is

double-sided with plated tracks and solder

resist to stop solder going where it’s not

wanted. The top of the board has

component idents and orientation marks

to assist the build.

Always start a build with the smallest parts

first, which, in this case is the resistors.

There is a resistor colour-code chart at the

end of this set of instructions to help you

identify each one, so let’s start with R1.

This is a 120Kohm resistor (4 band colours,

so Brown/Red/Yellow – Gold).

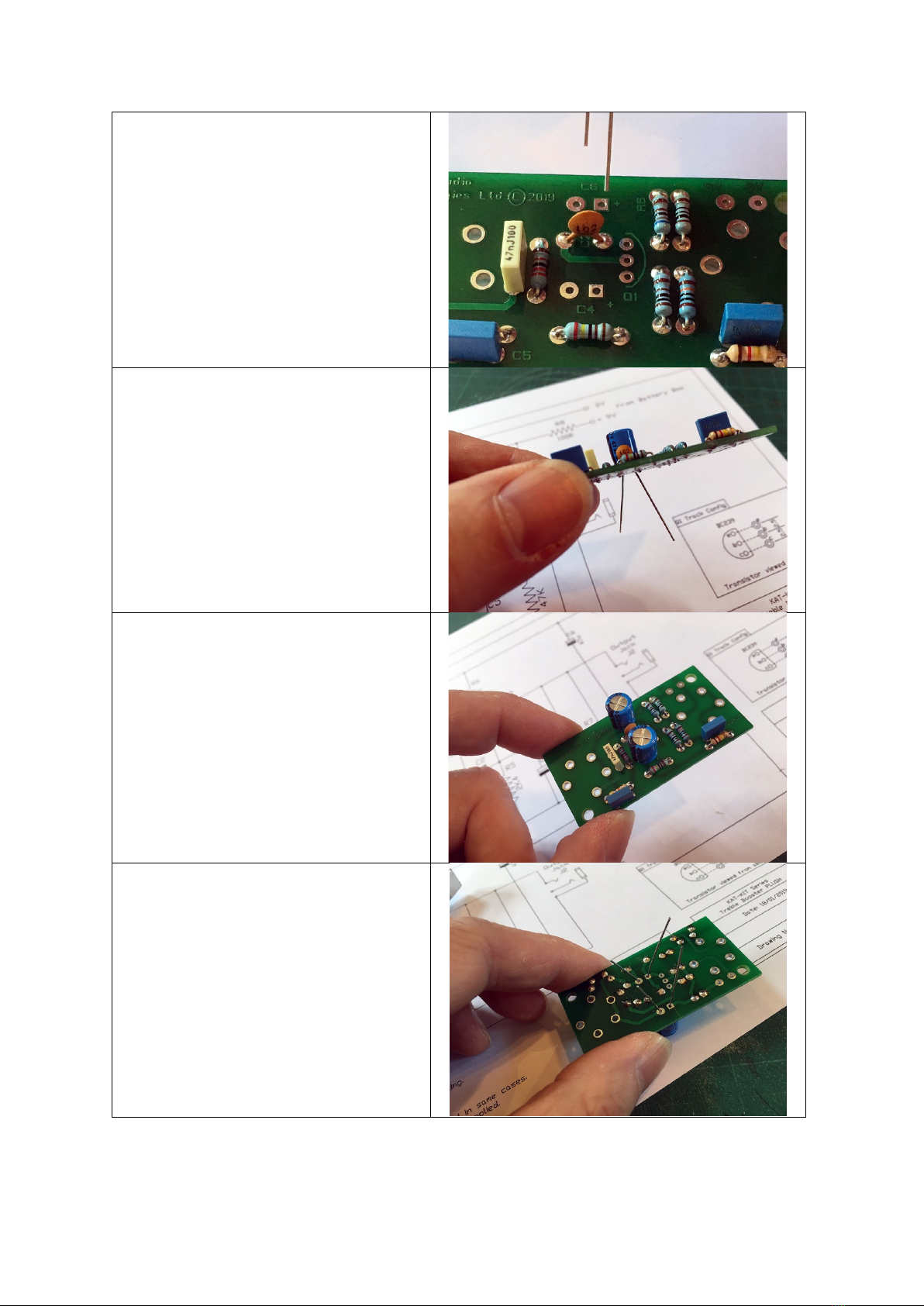

The first thing we need to do is pre-form

(bend) the legs ready to insert the device in

the board. To do this, hold the resistor in

your hand with your thumb nail resting on

the end of the resistor body:

With your finger, bend the leg towards you

at 90 degrees so that the lead is formed

around your thumb nail.

So, it looks like this. Then do the same to

the other leg so both are now bent in the

same direction:

Your formed legs now looking like this and

ready to be dropped into the board.

Find the location of ‘R1’ on the board and

drop the resistor into the holes from

above. It is good practice (but not

necessary) to orientate the resistors so

that the colour codes either read from left

to right, or from bottom to top. This just

makes repairs and fault-finding further

down the line a little easier…

With the resistor dropped in, make sure it

is seated all the way down and touching

the top of the board at both ends. Now

gently bend the legs open underneath so

as to temporarily hold the component in-

place whist you load the rest.

You should now have a board populated

with 8 resistors. There is a ‘check picture’

further along in these instructions if you

want to check you have the correct

components in the correct place before

you solder. If you are colour-blind in any

way, or have sight impairment, you can

check values with a multi-meter touched

across the ends of each resistor in turn.

Now carefully turn the board over so that

all the resistors are flat against the work

surface. If you apply gentle pressure to the

board as you solder, you will find that all

the components are perfectly seated once

soldered.

So, here’s the board with the resistors just

soldered in and ready for the leads to be

trimmed. Each solder joint should have a

concave shape (slightly sunken), rather

than convex (pudding shaped). If your

joints are convex, you are applying too

much solder. Your solder-time per joint

should not exceed 3 seconds. If in doubt,

count 1 (apply soldering iron to joint), 2

(feed in solder), 3 (remove iron).

Once you have soldered the leads and

checked the solder joints for quality, you

can then trim off the leads with your

cutters. Bad solder joints will have a dull

grey look to them, good joints will be

shiny. Make sure there are no gaps in the

solder around the lead at the pad. The

solder pad hole should be full with solder.

Now it’s time to move on to the small

polyester and ceramic capacitors. The

value of which is either written on the

front or the top of each device. Again,

further help can be found at the back of

this piece.

As per the resistors, you can drop the four

capacitors into their respective holes as

detailed.

Once again, bending the legs below the

board to temporarily hold them in place

before soldering:

The small capacitors are now in and ready

for soldering. Time to flip the board and

rest it on the top of the new capacitors.

Board inverted ready for soldering.

Small capacitors now soldered in, you can

cut the excess leads off with your cutters.

Your board should now look like this!..

Now for the larger Electrolytic capacitors.

There are two in this circuit and both are

the same value, so you don’t need to worry

about fitting the wrong one. There are two

types of Electrolytic capacitor used in these

kits: the blue one (shown) and a silver one.

Electrolytic capacitors are polarised and

have to be inserted the correct way

around. They have a plus leg and a minus

leg. The plus leg is the longest and the

minus leg the shortest. The minus side of

the cap also has a black (-) band down the

side.

The board also has polarising orientation

marks within the idents. The square solder

pad is the plus and the round, the minus.

On these boards, the plus side also has a

(+) symbol next to it. So, as per the pic to

the right, the long leg goes in the square

hole!..

Again, as before, bend the leads outwards

to hold the component in place.

Both Capacitors now in place. Check

polarity one more time before you turn the

board over to solder.

Capacitors ready to be soldered.

Capacitors and resistors now installed.

Your board should look like this!…

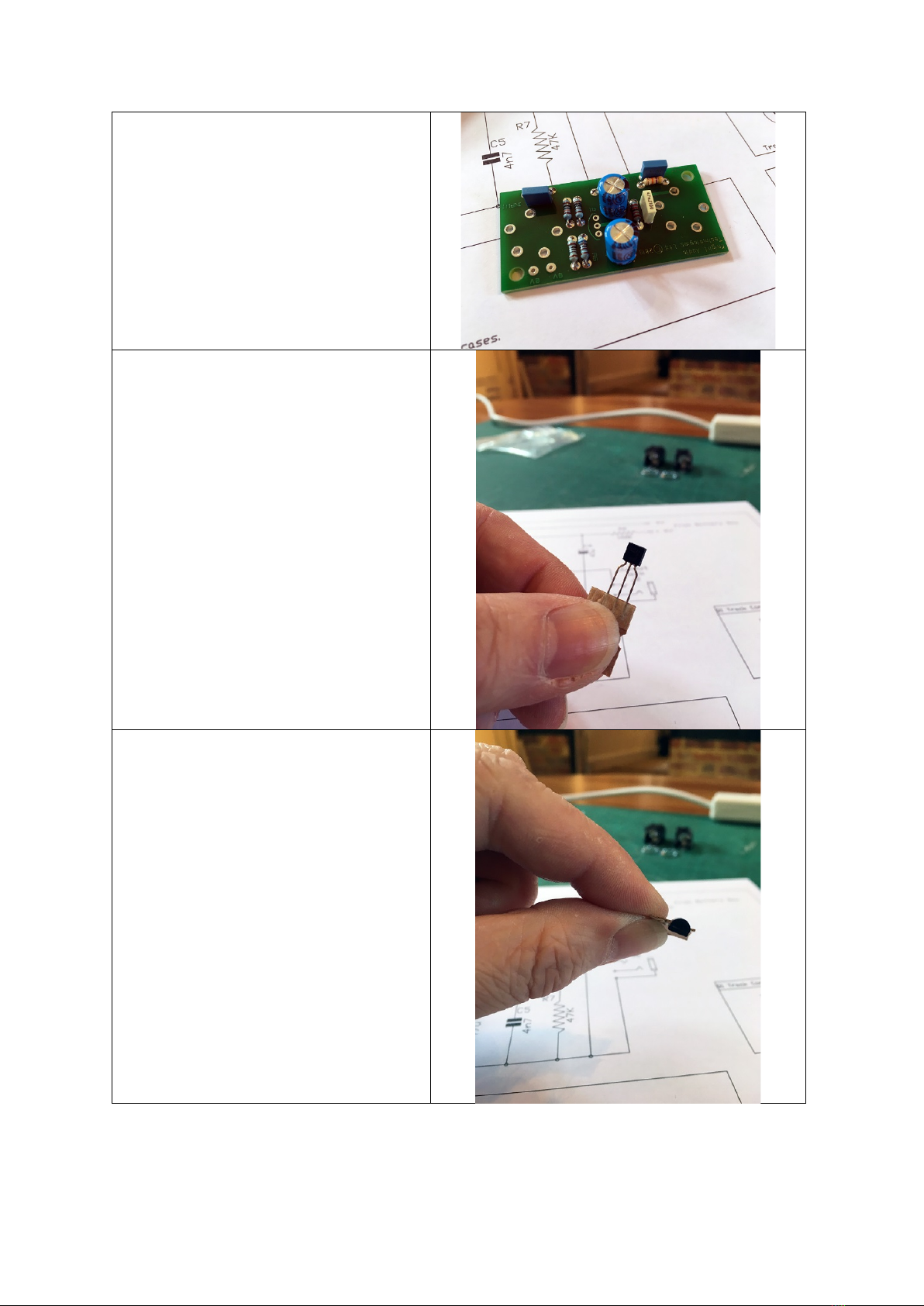

Transistor-Time!...

The transistor is the ‘engine-room’ of the

Treble Booster. They are all different, have

different responses and gains and can be

right diva’s if not handled with care. Firstly,

they HAVE to be oriented the correct way

around FIRST TIME, otherwise they will self

-destruct on power-up! Some can be a

little sensitive to static, so try not to handle

the leads too much (especially if you’ve

been walking across a nylon carpet)!!.

They are also heat sensitive, so we have to

be careful when soldering them in!

But first, let’s get your transistor in to the

board the correct way around. If you look

at the transistor, you’ll note that it has a

round body with a flat on one side.

If you now look at the board, you’ll notice

that we have put a curved ident on the

board to one side of the holes. This curved

ident signifies the round side of the

transistor.

Here is the board with the transistor

dropped in.

In order to set the correct length of the

transistor leads, turn the board over and

rest it on the tops of the large Electrolytic

capacitors. Then lower the transistor back

through the holes so that its body also

rests on the worksurface. In other words,

the top of the transistor is set to the same

height as the tops of the large capacitors.

The transistor leads are now straight and

ready for soldering. My general rule is this:

Solder the middle lead first. Let it cool for

10 seconds. Then solder the left-hand lead.

Let that cool for ten seconds. Then solder

the final lead.

This process stops heat build-up in the core

(junction) of the transistor. If you stick to

the 3 second rule detailed earlier and set

the height as mentioned, you shouldn’t

need any heatsinks on the leads.

Other KAT Amplifier manuals