Keithley PIO-96 User manual

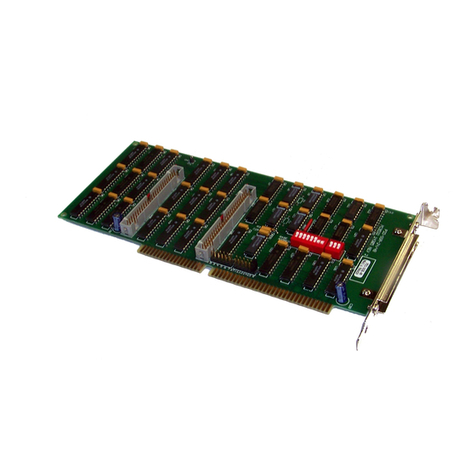

PIO-96

ISA Bus Digital I/O Board

Instruction Manual

WARRANTY

Hardware

Keithley Instruments, Inc. warrants that, for a period of one (1) year from the date of shipment (3 years for Models 2000, 2001, 2002, and 2010), the Kei-

thley Hardware product will be free from defects in materials or workmanship. This warranty will be honored provided the defect has not been caused by

use of the Keithley Hardware not in accordance with the instructions for the product. This warranty shall be null and void upon: (1) any modification of

Keithley Hardware that is made by other than Keithley and not approved in writing by Keithley or (2) operation of the Keithley Hardware outside of the

environmental specifications therefore.

Upon receiving notification of a defect in the Keithley Hardware during the warranty period, Keithley will, at its option, either repair or replace such Kei-

thley Hardware. During the first ninety days of the warranty period, Keithley will, at its option, supply the necessary on site labor to return the product to

the condition prior to the notification of a defect. Failure to notify Keithley of a defect during the warranty shall relieve Keithley of its obligations and lia-

bilities under this warranty.

Other Hardware

The portion of the product that is not manufactured by Keithley (Other Hardware) shall not be covered by this warranty, and Keithley shall have no duty of

obligation to enforce any manufacturers' warranties on behalf of the customer. On those other manufacturers’products that Keithley purchases for resale,

Keithley shall have no duty of obligation to enforce any manufacturers’warranties on behalf of the customer.

Software

Keithley warrants that for a period of one (1) year from date of shipment, the Keithley produced portion of the software or firmware (Keithley Software) will

conform in all material respects with the published specifications provided such Keithley Software is used on the product for which it is intended and other-

wise in accordance with the instructions therefore. Keithley does not warrant that operation of the Keithley Software will be uninterrupted or error-free and/

or that the Keithley Software will be adequate for the customer's intended application and/or use. This warranty shall be null and void upon any modification

of the Keithley Software that is made by other than Keithley and not approved in writing by Keithley.

If Keithley receives notification of a Keithley Software nonconformity that is covered by this warranty during the warranty period, Keithley will review the

conditions described in such notice. Such notice must state the published specification(s) to which the Keithley Software fails to conform and the manner

in which the Keithley Software fails to conform to such published specification(s) with sufficient specificity to permit Keithley to correct such nonconfor-

mity. If Keithley determines that the Keithley Software does not conform with the published specifications, Keithley will, at its option, provide either the

programming services necessary to correct such nonconformity or develop a program change to bypass such nonconformity in the Keithley Software.

Failure to notify Keithley of a nonconformity during the warranty shall relieve Keithley of its obligations and liabilities under this warranty.

Other Software

OEM software that is not produced by Keithley (Other Software) shall not be covered by this warranty, and Keithley shall have no duty or obligation to

enforce any OEM's warranties on behalf of the customer.

Other Items

Keithley warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes, and documentation.

Items not Covered under Warranty

This warranty does not apply to fuses, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

Limitation of Warranty

This warranty does not apply to defects resulting from product modification made by Purchaser without Keithley's express written consent, or by misuse

of any product or part.

Disclaimer of Warranties

EXCEPT FOR THE EXPRESS WARRANTIES ABOVE KEITHLEY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUD-

ING WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEI-

THLEY DISCLAIMS ALL WARRANTIES WITH RESPECT TO THE OTHER HARDWAREAND OTHER SOFTWARE.

Limitation of Liability

KEITHLEY INSTRUMENTS SHALL IN NO EVENT, REGARDLESS OF CAUSE, ASSUME RESPONSIBILITY FOR OR BE LIABLE FOR: (1)

ECONOMICAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR EXEMPLARY DAMAGES, WHETHER CLAIMED

UNDER CONTRACT, TORT OR ANY OTHER LEGAL THEORY, (2) LOSS OF OR DAMAGE TO THE CUSTOMER'S DATA OR PROGRAM-

MING, OR (3) PENALTIES OR PENALTY CLAUSES OF ANY DESCRIPTION OR INDEMNIFICATION OF THE CUSTOMER OR OTHERS FOR

COSTS, DAMAGES, OR EXPENSES RELATED TO THE GOODS OR SERVICES PROVIDED UNDER THIS WARRANTY.

Keithley Instruments, Inc.

• 28775Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.keithley.com

BELGIUM: Keithley Instruments B.V.

Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02/363 00 40 • Fax: 02/363 00 64

CHINA: Keithley Instruments China

Yuan Chen Xin Building, Room 705 • 12Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

FRANCE: Keithley Instruments Sarl

B.P. 60 • 3, allée des Garays • 91122 Palaiseau Cédex • 01 64 53 20 20 • Fax: 01 60 11 77 26

GERMANY: Keithley Instruments GmbH

Landsberger Strasse 65 • D-82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Keithley Instruments Ltd

The Minster • 58 Portman Road • Reading, Berkshire RG30 1EA • 0118-9 57 56 66 • Fax: 0118-9 59 64 69

INDIA: Keithley Instruments GmbH

Flat 2B, WILOCRISSA • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Keithley Instruments s.r.l.

Viale S. Gimignano, 38 • 20146 Milano • 02/48 30 30 08 • Fax: 02/48 30 22 74

NETHERLANDS: Keithley Instruments B.V.

Postbus 559 • 4200AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWITZERLAND: Keithley Instruments SA

Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: Keithley Instruments Taiwan

1 Fl. 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3572-9077• Fax: 886-3572-9031

10/99

PIO-96

ISABus Digital I/O Board

User’s Manual

©1993, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Fourth Printing, December 1999

Document Number: 73270 Rev. D

Windows and WindowsNT are registered trademarks of Microsoft Corporation.

DriverLINX is a registered trademark of Scientific Software Tools, Inc.

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revi-

sions, contain important change information that the user should incorporate immediately into the manual. Addenda are num-

bered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision C (Document Number 24812) ..................................................................................................April 1993

Revision D (Document Number 73270) ..........................................................................................December 1999

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some in-

struments and accessories would normally be used with non-haz-

ardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recog-

nize shock hazards and are familiar with the safety precautions re-

quired to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body

is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for en-

suring that operators are adequately trained.

Operators

use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instru-

ment. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel

perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replac-

ing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may per-

form them. Otherwise, they should be performed only by service

personnel.

Service personnel

are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained ser-

vice personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Users of this product must be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts,

no conductive part of the circuit may be

exposed.

As described in the International Electrotechnical Commission

(IEC) Standard IEC 664, digital multimeter measuring circuits

(e.g., Keithley Models 175A, 199, 2000, 2001, 2002, and 2010) are

Installation Category II. All other instruments’ signal terminals are

Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When con-

necting sources to switching cards, install protective devices to lim-

it fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connect-

ed to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jump-

ers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equip-

ment may be impaired.

Do not exceed the maximum signal levels of the instruments and ac-

cessories, as defined in the specifications and operating informa-

tion, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is ap-

plied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

The symbol on an instrument indicates that the user should re-

fer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or mea-

sure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The

WARNING

heading in a manual explains dangers that might

result in personal injury or death. Always read the associated infor-

mation very carefully before performing the indicated procedure.

The

CAUTION

heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instru-

ments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that se-

lected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to in-

structions. If the board becomes contaminated and operation is af-

fected, the board should be returned to the factory for proper

cleaning/servicing.

!

Rev. 10/99

Table of Contents

i

1 General Description

The board ........................................................................................................................................................... 1-2

Supporting software ........................................................................................................................................... 1-3

2 Installation

Inventorying required installation resources ...................................................................................................... 2-2

Installing DriverLINX software and documentation ......................................................................................... 2-2

Configuring your installation ............................................................................................................................. 2-4

Preparing and installing your board ................................................................................................................... 2-5

Unpacking and inspecting the board .......................................................................................................... 2-5

Setting the base address switch .................................................................................................................. 2-5

Setting the wait-state jumper ...................................................................................................................... 2-6

Connecting cables to the board .................................................................................................................. 2-7

Installing the board ..................................................................................................................................... 2-7

Checking your installation ................................................................................................................................. 2-8

Wiring to external circuits .................................................................................................................................. 2-8

Identifying I/O connector pin numbers ...................................................................................................... 2-9

Using a screw terminal accessory .............................................................................................................. 2-9

Wiring PIO-96 power to external circuits ................................................................................................ 2-10

3 Programming

A Specifications

Logic inputs and outputs ................................................................................................................................... A-2

Power consumption ........................................................................................................................................... A-2

Mechanical and environmental ......................................................................................................................... A-2

B I/O Address Map

Data ports .......................................................................................................................................................... B-3

Control port ....................................................................................................................................................... B-3

C User-Serviceable Parts

ii

List of Illustrations

iii

2Installation

Figure 2-1 Base address switch values ........................................................................................................................ 2-6

Figure 2-2 Board component locations ........................................................................................................................ 2-6

Figure 2-3 Pin assignments for a PIO-96 I/O connector and corresponding terminal assignments for a

connected STA-50 accessory ..............................................................................................................2-9

iv

List of Tables

v

B I/O Address Map

Table B-1 I/O address map ........................................................................................................................................ B-2

Table B-2 Control register bit functions for each 8255 chip ...................................................................................... B-3

Table B-3 Example control bytes for mode 0 ............................................................................................................ B-4

vi

1

General Description

1-2 General Description PIO-96 User’s Manual

The board

The PIO-96 board is a 96-line parallel digital I/O interface board. The combined board and sup-

plied software installs and runs in any IBM PC-compatible computer that runs the Microsoft

Windows® 95/98/NT operating system (Pentium®-series processor recommended).

The PIO-96 board is built around four industry-standard Intel 8255, 24-bit, programmable

peripheral interface (PPI) adapter chips. Each 8255 includes the three TTL/CMOS-compatible

digital I/O ports PA, PB, and PC. The PA and PB ports are byte-wide (8 bits) and configurable as

inputs or outputs. The PC port is also byte-wide but can be divided into two separate 4-bit ports:

PC lower and PC upper (each of which can be set up as either inputs or outputs). The PIO-96

supports the full set of operating configurations of the 8255 PPI as set by its Control Register.

On power-up, or whenever the computer’s hardware-reset line is asserted, all ports are cleared

and set in a digital-input mode.

The PIO-96 uses 16 consecutive I/O addresses within the computer I/O address space (four

addresses for each 8255 chip). The base address of the PIO-96 board is set by a base address

switch. More than one PIO-96 may be installed in a single computer. However, each installed

PIO-96 uses 16 I/O addresses (base address +0 through base address +15), and no two boards

can use the same address.

The PIO-96 also includes a wait-state generator that insures a 300ns I/O cycle time, minimum,

as required by the 8255. If your computer does not require the wait-state generator, it can be dis-

abled by setting the wait-state jumper to the OFF position.

The computer power supplies provide +5V power through the I/O connectors for use in external

applications, such as the addition of pull-up resistors. The +5V supply may also be used to

power external accessories, as long as you observe the total-available-power limits of your com-

puter and ensure that each connector pin current is limited to less than 1A.

NOTE

Do not connect the +5V outputs to an external +5V supply.

I/O connections for each 8255 port use a 50-pin, 0.1-inch header connector. This configuration

assures maximum shielding and minimum cross-talk by placing a ground wire in the cable

between each I/O conductor. The mating connector socket is the 3M 3425-6050 (one required

for each 24-bit port), or you may purchase a ready made 24-inch cable with connectors on both

ends as Keithley part number CACC-2000. Longer cables are available by specifying Part #

CACC-20NN, where NN is the number of feet added to the standard two-foot cable. Wiring

accessories are also available.

General areas of application for the PIO-96 include all parallel-digital I/O requirements, such as

communicating with peripherals, operating relays, reading switch inputs, etc.

PIO-96 User’s Manual General Description 1-3

Supporting software

DriverLINX software is supplied by Keithley with the PIO-96 board. DriverLINX provides con-

venient interfaces to configure and set I/O bits without register-level programming.

Most importantly, however, DriverLINX supports those programmers who wish to create cus-

tom applications using Visual C/C++, Visual Basic, or Delphi. DriverLINX accomplishes fore-

ground and background tasks to perform data acquisition. The software includes memory and

data buffer management, event triggering, extensive error checking, and context sensitive online

help.

More specifically, DriverLINX provides application developers a standardized interface to over

100 services for creating foreground and background tasks for the following:

•

Analog input and output

•

Digital input and output

•

Time and frequency measurement

•

Event counting

•

Pulse output

•

Period measurement

In addition to basic I/O support, DriverLINX also provides:

•

Built-in capabilities to handle memory and data buffer management

•

A selection of starting and stopping trigger events, including pre-triggering, mid-

point triggering and post-triggering protocols

•

Extensive error checking

•

Context-sensitive on-line help system

DriverLINX is essentially hardware independent, because its portable APIs work across various

operating systems. This capability eliminates unnecessary programming when changing operat-

ing system platforms.

1-4 General Description PIO-96 User’s Manual

2

Installation

2-2 Installation PIO-96 User’s Manual

This section contains the following procedures, in the order in which they are to be performed:

•

Inventorying installation resources

•

Installing the DriverLINX software needed to operate your PIO-96 board

•

Configuring the installation in software

•

Unpacking and inspecting the board, setting the base address of the board, and installing the

board in your computer

•

Checking the installation

•

Wiring to your external circuits

NOTE

Install the DriverLINX software before installing the PIO-96 board.

Otherwise, the device drivers will be more difficult to install.

Inventorying required installation resources

Before installing DriverLINX and the board, do the following:

1. Inventory your PIO-96 board’s configuration settings.

2. Determine the resources your PIO-96 board requires.

3. Inventory your computer’s resources already allocated to other installed devices.

4. Determine whether your computer has sufficient resources for your PIO-96 board.

5. Determine whether your PIO-96 board can use your computer’s free resources.

6. Continue with the next section, “Installing DriverLINX software and documentation.”

NOTE

The DriverLINX Installation and Configuration Guide, Section 1,

amplifies the inventory process in checklist items 1-5. (Ignore the rest of

the checklist items for now.) To display this manual from your

DriverLINX PIO Series CD-ROM, open the Windows Explorer, then

double click on

X:\Drvlinx4\Docs\Instconf.pdf

, where

X

= the letter of

the CD-ROM drive. Acrobat Reader must already be installed on the

other system. If necessary, you can first install Acrobat Reader directly

from the CD-ROM by double clicking

X:\Acrobat\setup.exe

.

Installing DriverLINX software and documentation

Even if DriverLINX versions other than the PIO Series version are already installed on your sys-

tem, you must also install the PIO Series DriverLINX version. In the process, some DriverLINX

capabilities shared by all boards may be upgraded (test utilities, for example).

This section discusses installation of drivers, interfaces, and documentation. The component

installation options provided by the DriverLINX setup program are as follows:

•

Install Drivers

— This required component installs only the files you need for configuring

your hardware and running third-party data-acquisition applications that require

DriverLINX.

•

Install Interfaces

— This optional component installs the files and example programs that

you will need to develop custom applications for DriverLINX using C/C++, Visual Basic,

and Delphi.

•

Install Documentation

— This optional component installs electronic documentation for

DriverLINX that you can read, search, and print using the Adobe Acrobat Reader.

•

Install Acrobat

— This optional component installs the Adobe Acrobat Reader for the

DriverLINX electronic documentation.

PIO-96 User’s Manual Installation 2-3

Install the DriverLINX software and board as follows:

1. Place the DriverLINX PIO Series CD-ROM in your drive and wait a few seconds. On most

systems, setup starts automatically. If not, run the setup.exe file, found in the root directory

of the CD-ROM.

A DriverLINX Browser Introduction screen

appears. Thereafter, the

DriverLINX CD Nav-

igator screen appears automatically after waiting a few seconds or after clicking

Next

.

NOTE

On the DriverLINX CD Navigator and other DriverLINX Browser

screens, place the cursor over a menu item to see an explanation. A star

next to a menu item means that it was selected previously.

Before continuing with this installation, Keithley suggests clicking

Read

Me First

on the DriverLINX CD Navigator and reviewing the brief

information that appears.

2. On the DriverLINX CD Navigator screen, click

Install DriverLINX

. An Install These

DriverLINX Components screen appears.

3. Click

Install Drivers

, and then follow the series of on-screen instructions. When done, the

Install These DriverLINX Components screen reappears.

4. If you do not plan to develop custom application software for your PIO-96 board, then skip

to Step 5. If you do plan to develop custom application software, you must install Driver-

LINX interfaces before writing the software. Install them now by clicking

Install Inter-

faces

and following the series of on-screen instructions. When done, the Install These

DriverLINX Components screen reappears.

5. Click

Install Documentation

and follow the series of on-screen instructions. This step

installs the manuals. When done, the Install These DriverLINX Components screen reap-

pears.

6. If Acrobat Reader is not already installed on your system, install it now. You need Acrobat

Reader to read the manuals, a section of which you must access in step 9. Click on

Install

Acrobat

and follow the series of on-screen instructions. When done, the Install These

DriverLINX Components screen reappears.

7. Click

Exit.

Then, on the screen

that appears saying “Thank you for using DriverLINX,”

click

Done

. The System Settings Changed dialog box appears.

8. On the System Settings Changed dialog box, click

No

. (The system will be rebooted and

configured later under “Configuring your installation” on page 2-4.) The screen returns to

the Windows desktop.

9. Print out one section of a DriverLINX manual that you will briefly review later during sys-

tem configuration. Proceed as follows:

a. In the

Start

menu under

Programs

→

DriverLINX,

click

On-line Manuals.

A menu

document appears

b. In the menu document, scroll until you find the major category

Configuration

.

c. Under

Configuration

click

Hardware References

. A list of documents appears.

d. In the list of documents, click

Keithley PIO Series

. Acrobat Reader opens and the

manual entitled

Using DriverLINX with Your Hardware—Keithley PIO Series

appears.

2-4 Installation PIO-96 User’s Manual

e. Print the following section from the

Using DriverLINX with Your Hardware—Keithley

PIO Series

manual: “Configuring the PIO Series.”

NOTE

If your data acquisition system is not connected to a printer, you can dis-

play and print the Using DriverLINX with Your Hardware—Keithley

PIO Series manual sections from another system, directly from the CD-

ROM (without installing anything). To display the manual, open the

Windows Explorer, then double click on

X:\Drvlinx4\Docs\Notes\kmb-

pio.pdf

, where

X

= the letter of the CD-ROM drive. Acrobat Reader

must already be installed on the other system. If necessary, you can first

install Acrobat Reader directly from the CD-ROM by double clicking

X:\Acrobat\setup.exe

.

10. Continue with “Configuring your installation.”

Configuring your installation

Configure your installation as follows:

1. Locate and briefly review the DriverLINX manual section, “Configuring the PIO Series,”

that you printed earlier during step 9 of “Installing DriverLINX software and documenta-

tion.” Reviewing this section will help prepare you to input information and select options

when configuring your installation.

NOTE

Be sure to note and follow all configuration differences between installa-

tions for Windows NT and Windows 95/98.

2. Reboot your computer. The DriverLINX Plug and Play Wizard appears on your screen

automatically at the end of the boot cycle.

NOTE

If you do not run the DriverLINX Plug and Play Wizard now, it will not

reappear during the current computer session, although it may appear

after a subsequent reboot. If you wish to configure your board sometime

later, you can start the Plug and Play Wizard manually from a batch file.

In the Windows Explorer, double click

X:\Drvlinx4\Help\kmbpio.bat

,

where

X

is the letter of the drive on which DriverLINX is installed.

3. On the Plug and Play Wizard, click

Wizard

and follow the series of on-screen instructions

that appear. The Wizard will lead you through the steps of installing your hardware—from

a software viewpoint—and configuring it.

NOTE

If your operating system is Windows NT, use Windows NT Diagnostics to

find the free resources that the Plug and Play Wizard asks you to assign.

However, if your board requires an interrupt, to reliably find a free ISA

interrupt you may need to 1) configure your computer as having as a

non-Plug and Play operating system, using BIOS setup, and then 2)

individually assign the interrupt to the ISA bus.

4. Continue with “Preparing and installing your board.”

Table of contents

Other Keithley I/O System manuals

Keithley

Keithley DAS-1800HC Series User manual

Keithley

Keithley PIO-12 User manual

Keithley

Keithley KPCI-PIO96 User manual

Keithley

Keithley 7022 User manual

Keithley

Keithley SSIO-24 User manual

Keithley

Keithley KUSB-3160 User manual

Keithley

Keithley KPCI-PIO24 User manual

Keithley

Keithley PIO-SSR Series User manual

Keithley

Keithley SRA-01 User manual

Keithley

Keithley KUSB-3160 Parts list manual