- 5 -

6. Help menu

In the pulldown menu:

Install FTDI USB driver: If you experience connection problems, first delete the driver (under

Delete FTDI USB driver) and then reinstall.

Delete FTDI USB driver: If you experience connection problems, first delete and then reinstall

the driver (with install FTDI USB driver).

PC software owner's manual: Instructions in PDF

KEMPER KHS- Mini System Control owner's manual: Instructions in PDF

About: How to contact KEMPER

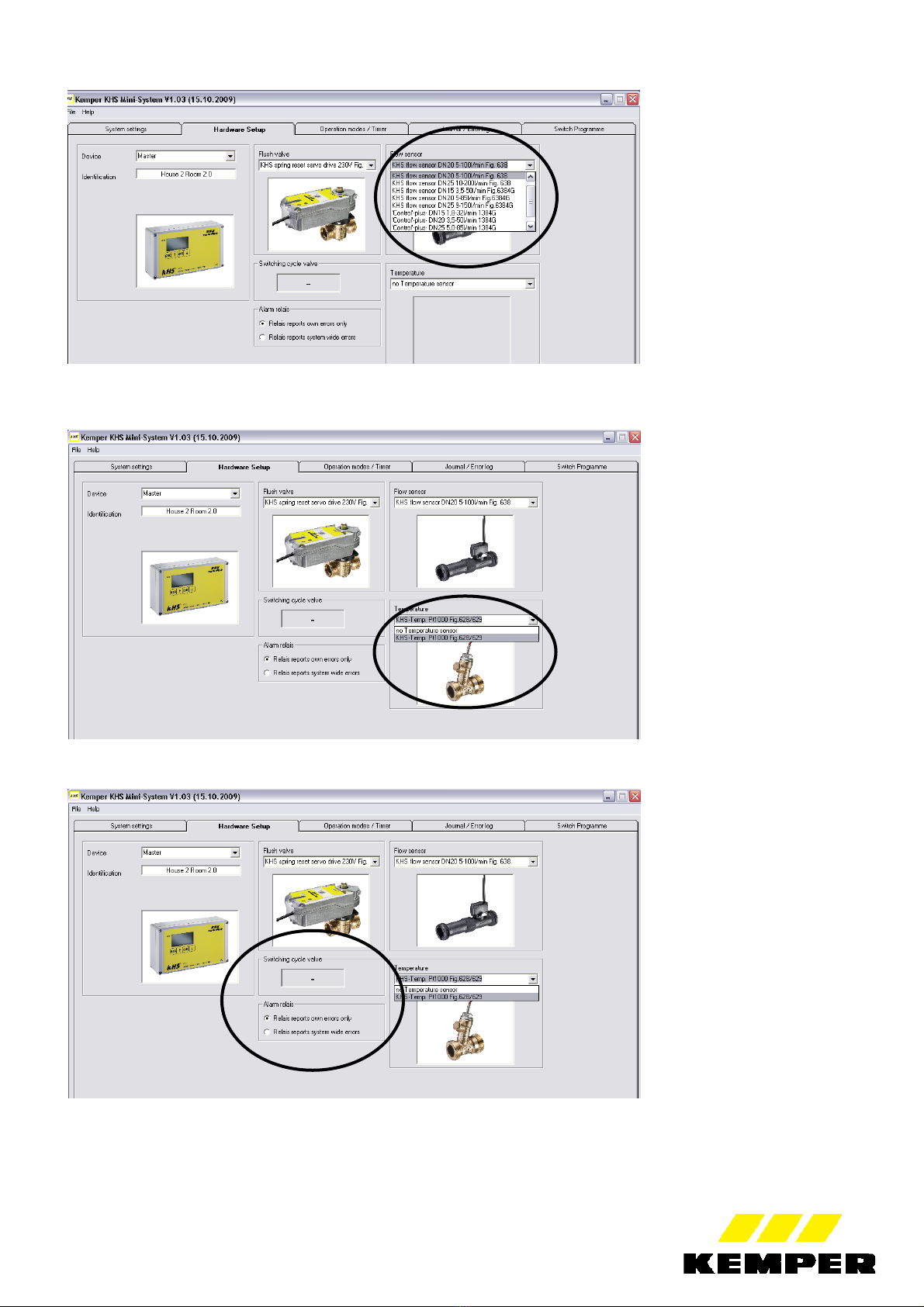

7. System - Commissioning with the PC software (configuration)

Only if commissioning with configuration has not yet been performed on the KHS-Mini System Control MASTER.

Commissioning and configuration can be performed at will, either via the KHS-Mini System Control MASTER/SLAVE or

directly with the PC software. If configuration data have already been entered into the KHS-Mini System Control, they can

be copied into the PC software as described in Point 5 "Load control".

7.1 Note for fault-free commissioning:

When installing, be sure to fill out the "System Overview" document!

To make system settings fault-free and simple, the document supplied with the KHS-Mini System Control –MASTER and –

SLAVE- installation and operating instructions, the "System Overview" (see photo), needs to be filled out correspondent to

the example during installation.

The data are subsequently transferred during system commissioning either directly on the -MASTER- or using the PC

configuration into the control.

Table 1: Extract from the "System Overview" document