17/9/2013

KEN DW 410

Ret til ændringer forbeholdes

General .............................................................................1

Introduction ..................................................................................................1.1

This instruction manual................................................................................1.1

Safety/environment ...........................................................2

Safety, general.............................................................................................2.1

Personal safety ............................................................................................2.1

-personal safety, continued..........................................................................2.2

The enviroment............................................................................................2.2

Disposal .......................................................................................................2.2

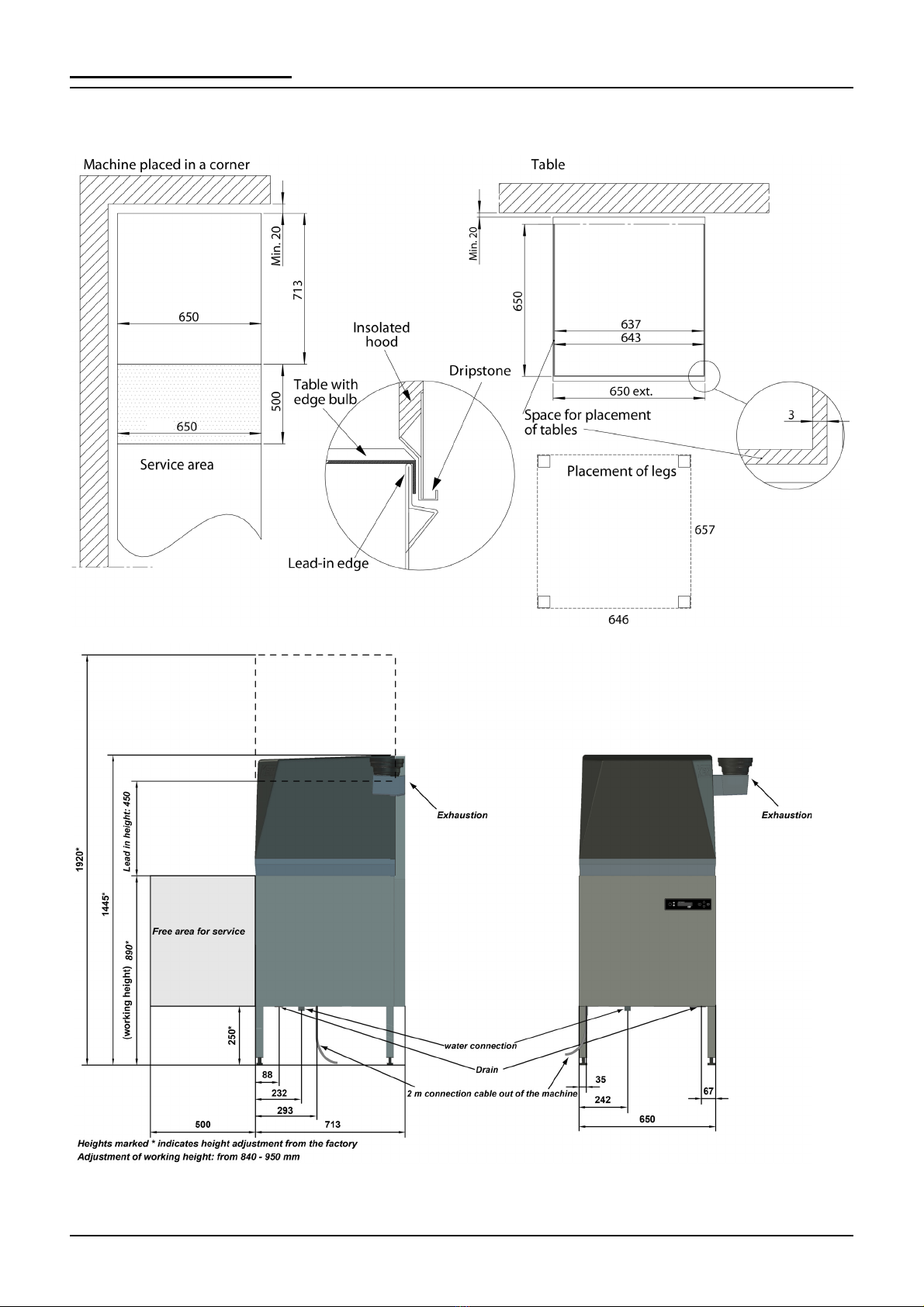

Technical description ........................................................3

Dimensional sketch:.....................................................................................3.1

Technical data ............................................................................................3.2

Installation instructions......................................................4

Receipt/transport/unpacking ........................................................................4.1

Disposal of packaging..................................................................................4.1

Installation/connection .................................................................................4.1

-installation/connection, continued...............................................................4.2

User instructions ...............................................................5

Operation panel ...........................................................................................5.1

Start-up ........................................................................................................5.1

Operation .....................................................................................................5.1

Water change ..............................................................................................5.2

Replacing the detergent can........................................................................5.2

Operating disturbances................................................................................5.2

Wash-up tips................................................................................................5.3

Program built-up................................................................6

Wash programs ...........................................................................................6.1

Wash pressure.............................................................................................6.1

Maintenance......................................................................7

Daily maintenance .......................................................................................7.1

Preventive maintenance ..............................................................................7.1

General information about stainless steel....................................................7.2

-general information about stainless steel, continued..................................7.3

Instructions -keep the good corrosion resistance of the steel......................7.3

Preventive washing with water. ...................................................................7.3

Removal of stains and discoloration on stainless surfaces. ........................7.4

Adjustments by computer control......................................8

Access to computer control .........................................................................8.1

Main Menu ...................................................................................................8.2

Service Menu - detergent consultant menu .................................................8.3

Other adjustments/inspection............................................9

Adjustment of Rinse aid pump.....................................................................9.1

Detergent consultant .........................................................10

Calibrating detergent by conductivity dosing ...............................................10.1

-calibrating detergent by condutivity dosing, continued ...............................10.2

Table of Contents