When screwing or nailing be careful not to set the fastener too close to the edge,

or the end, of a piece of wood. Corners and casings should have 3" between a

fastener and the end of the piece to prevent splitting.

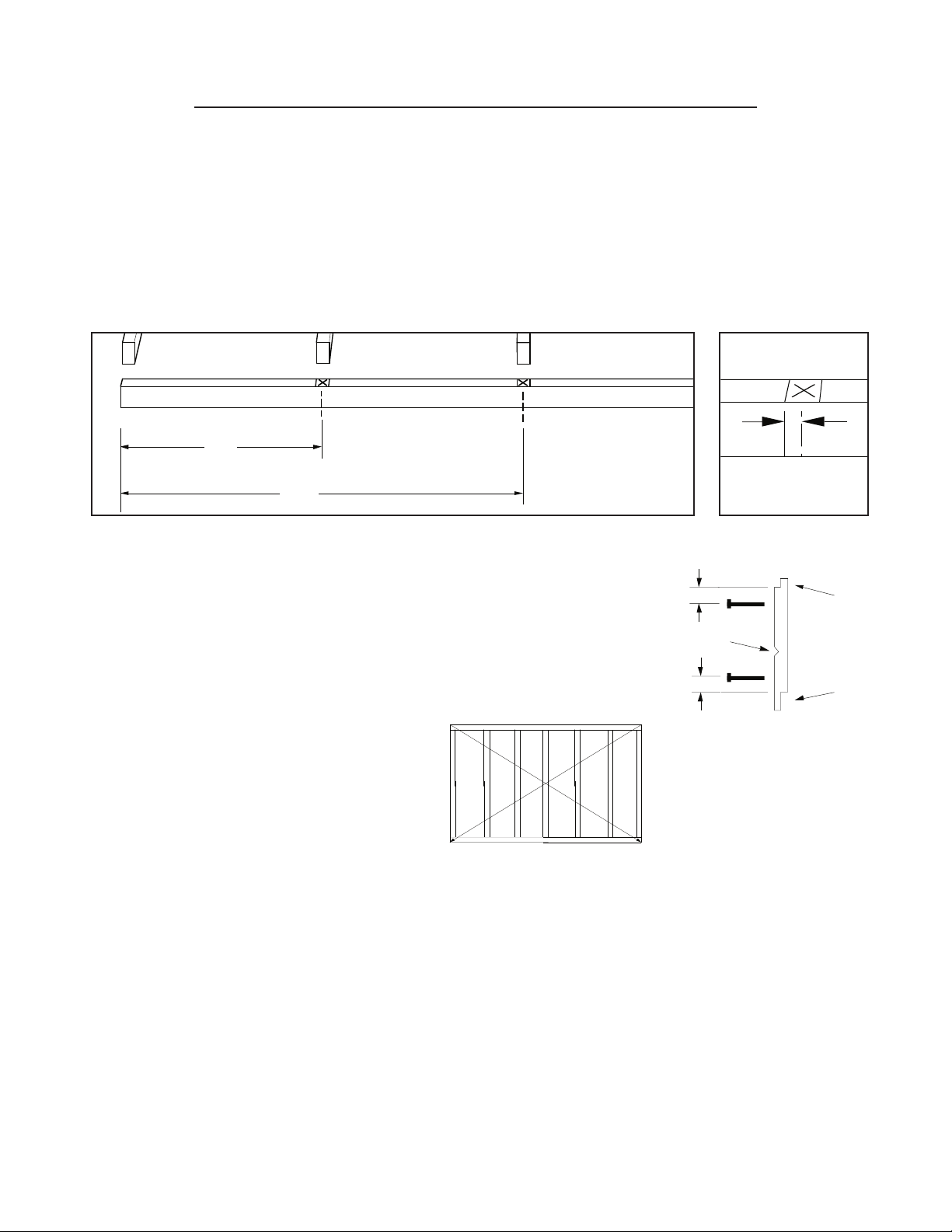

When nailing the cedar channel siding smooth side out to the 2x4framing, place

the nails so that they penetrate the thicker part of the board, set in at least 3/4"

from the overlap and underlap. For Canexel models use the nailing strip.

3/4"

Throughout the instructions reference is made to various lumber dimensions. Please remember that planing at the

sawmill has reduced to size of dimensioned lumber such as 2x3, 2x4, 2x6, 1x6 etc. These materials are 1/4" to 1/2"

thinner and narrower that stated (ie 2x3 is actually 1 1/2" x 2 1/2", 1x6 is 3/4" x 5 1/2"). In cases where a depth or

width is given for material that we have machined (trim, door casing, etc.), the measurements are usually as stated.

Keep in mind that wood is a natural material and is prone to swelling and shrinkage, therefore the size of some parts

many vary slightly from the dimensions given. This may result in some minor joint variations, but should not be cause

for concern.

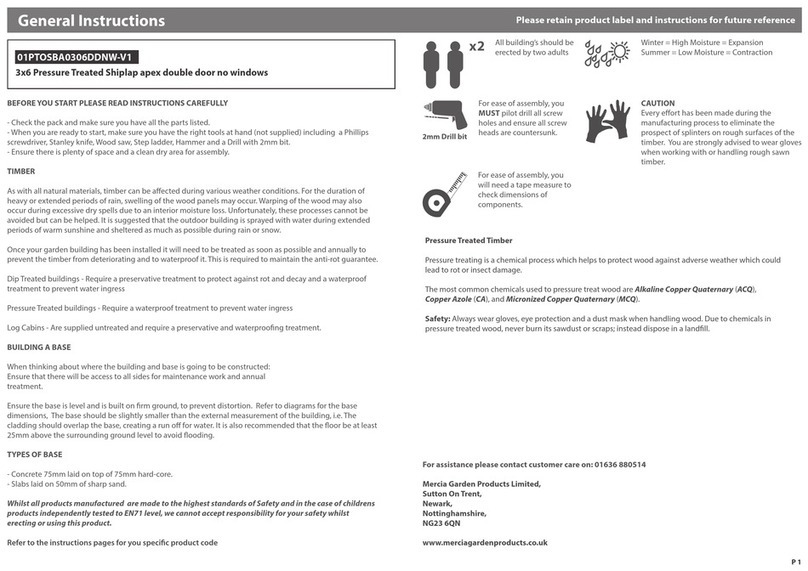

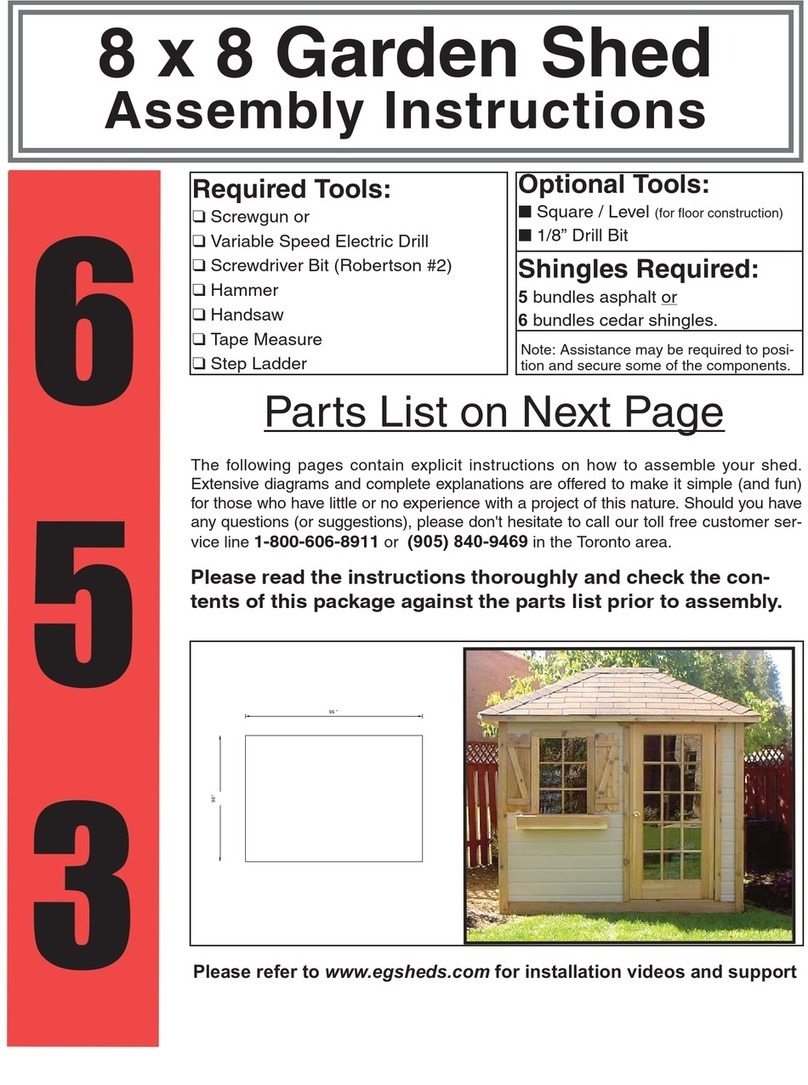

Squaring a Frame

A) General Instructions and Helpful Hints

Please read the instructions BEFORE beginning assembly

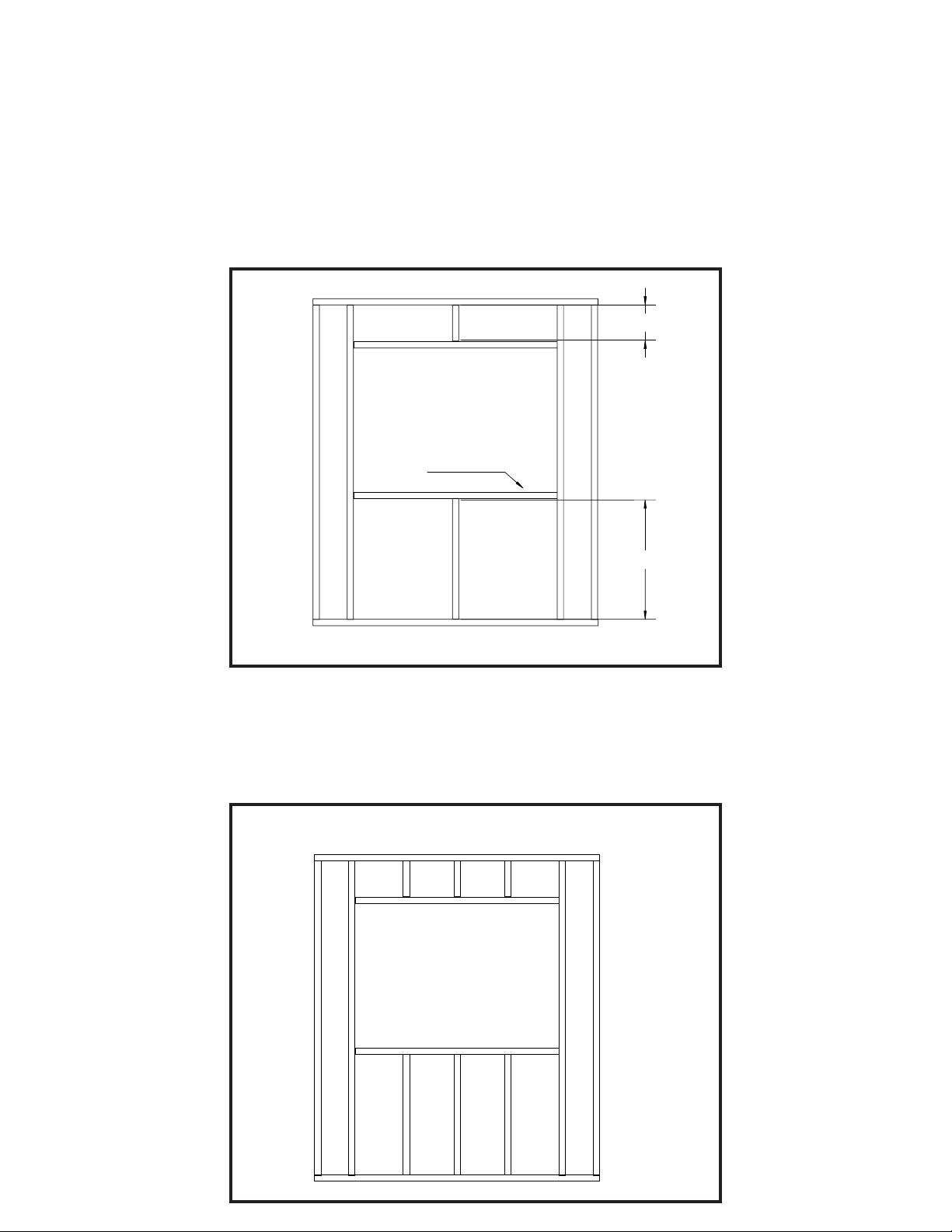

The framing dimensions for stud placement given in these instructions are "on center" measurements. The distances

shown are measured from the end of the plate to the middle of the stud. Studs are 1 1/2" wide when stood on edge,

so the edges of the stud are 3/4" on each side of center. When placing studs it is often convenient to mark the stud

center first, and then make a mark 3/4" away on one or both sides of the center mark. Indicate the center mark with

an "X" so as not to confuse it with an edge mark.

Marking the Plates

Assembly Instruction Organization

Page 3

The instructions are organized into eleven sections. It is strongly recommended that you assemble your cabana in the

order presented. Our experience has shown that assemblers meet with the most success when all the kit parts are

identified and sorted according to the section prior to assembly. Please refer to the parts checklist on page A.

When marking plates for the walls, both the top and bottom plates can be marked at the same time by laying them

side by side. Use a square to transfer the marks from one plate to the other.

Screwing and Nailing

rev. 04/06/16

overlap

underlap

groove

3/4"

3/4"

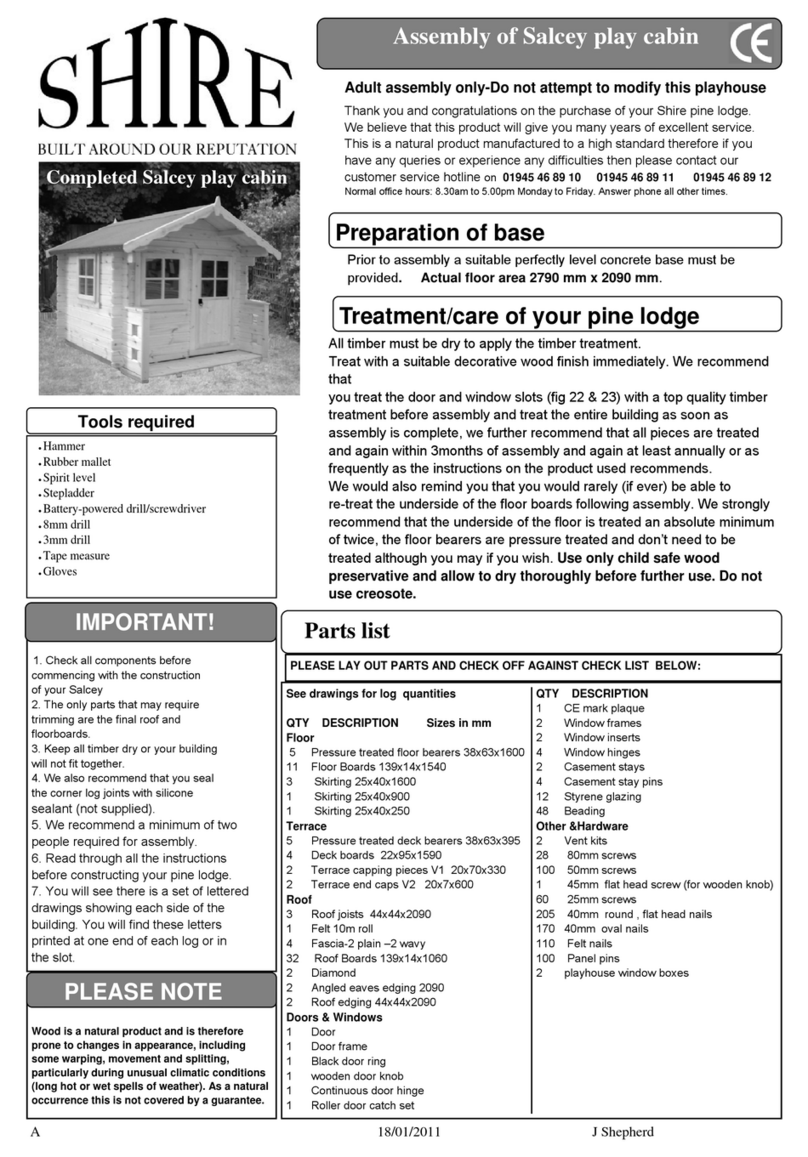

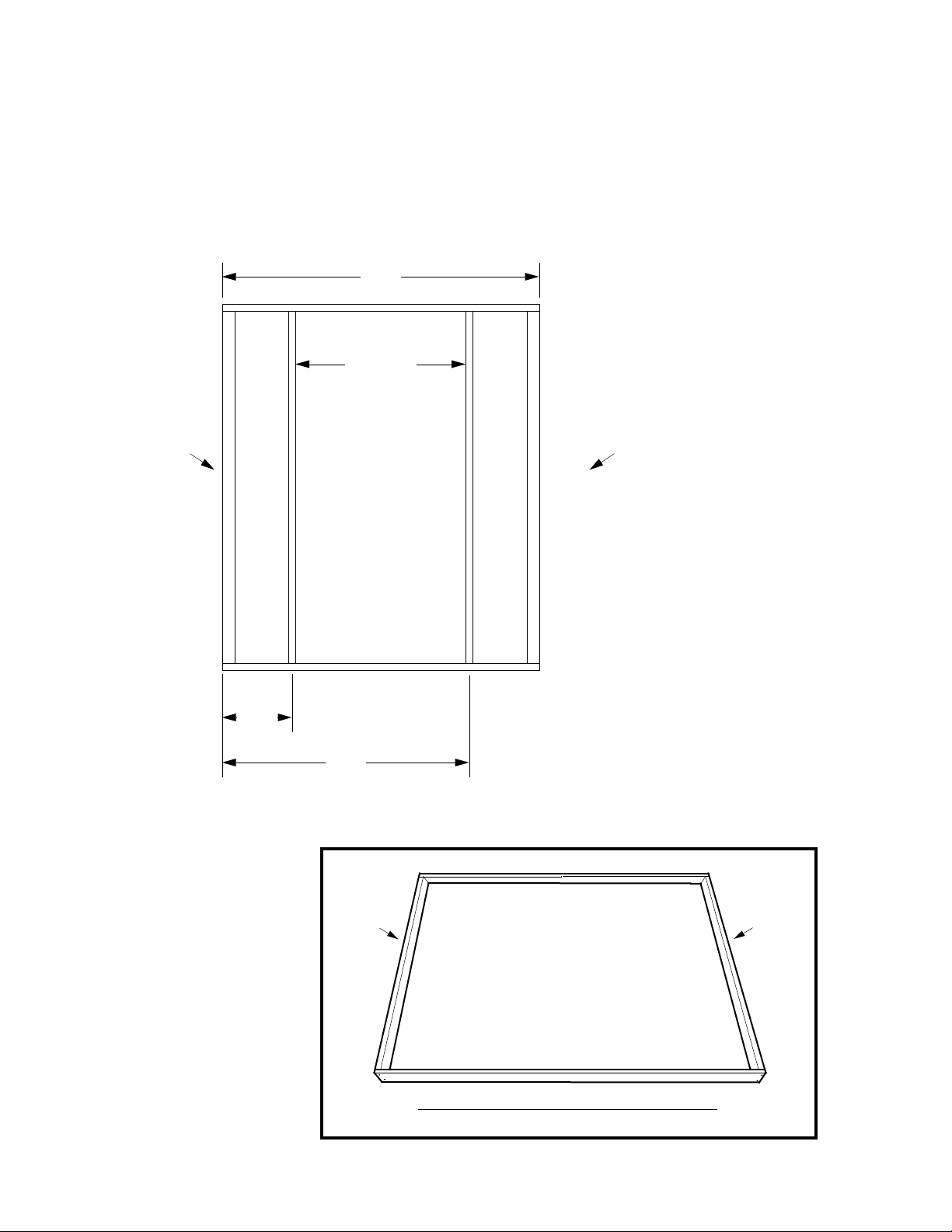

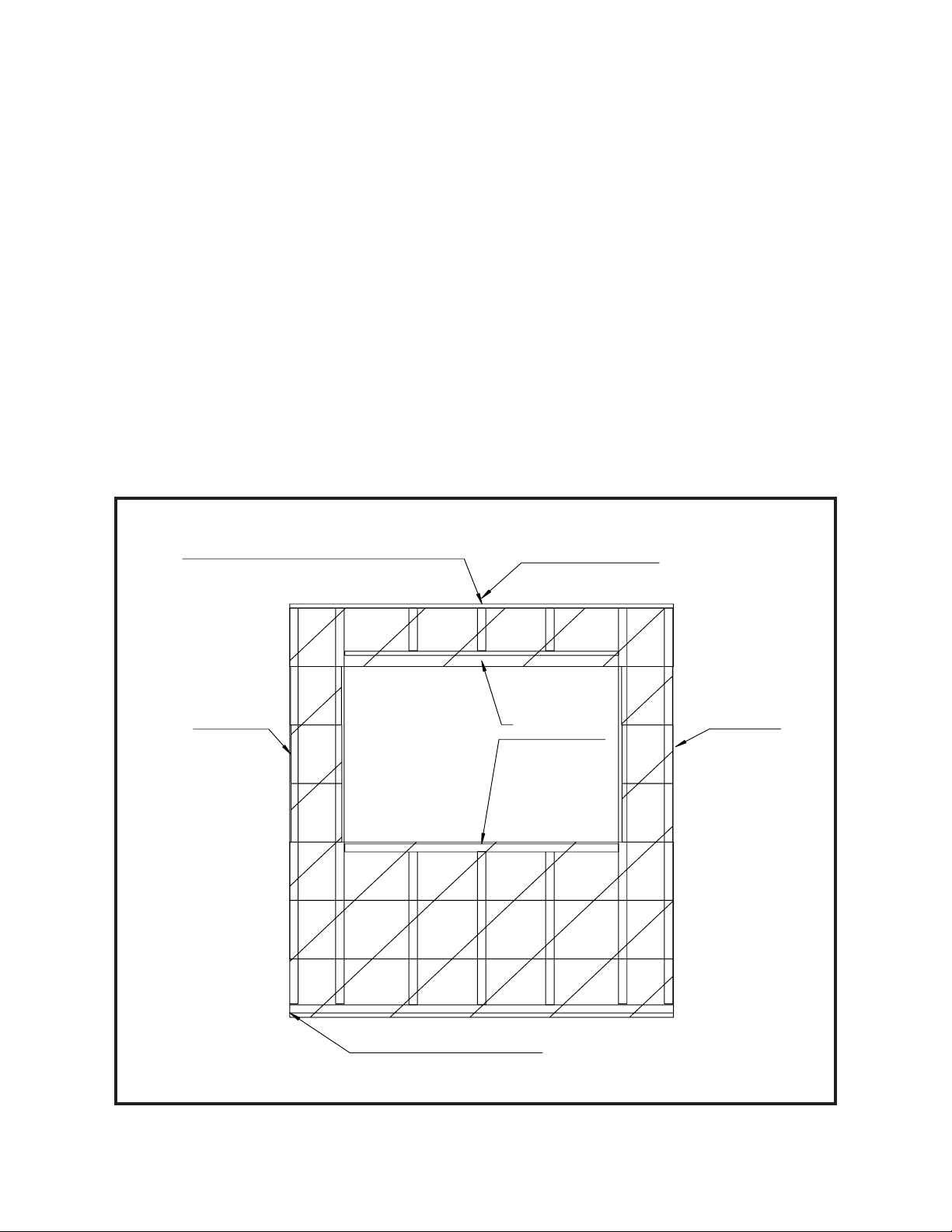

To square a frame, measure the diagonals (from

corner to corner each way) checking that the

two measurements are the same. If they are

not, push or pull the corners accordingly so that

the two measurements become the same.

Measurement A

should equal

Measurement B

Your Canexel Maintenance Free siding is a high quality maintenance free finish that does not require painting.

The PVC trim is also maintenance free.

Recommended Finish

A Word about Pool Cabanas

If you intend to use your cabana as a facility to house gas fired pool heating equipment, be sure to consult with your local gas

service person on the placement of your equipment before erecting your cabana. This will ensure that all clearances are

adhered to, and that you are able to position the roof trusses so that they don't interfere with the stack on your gas heater.

A Note on Lumber Dimensions and Wood Properties

AB

24"

48"