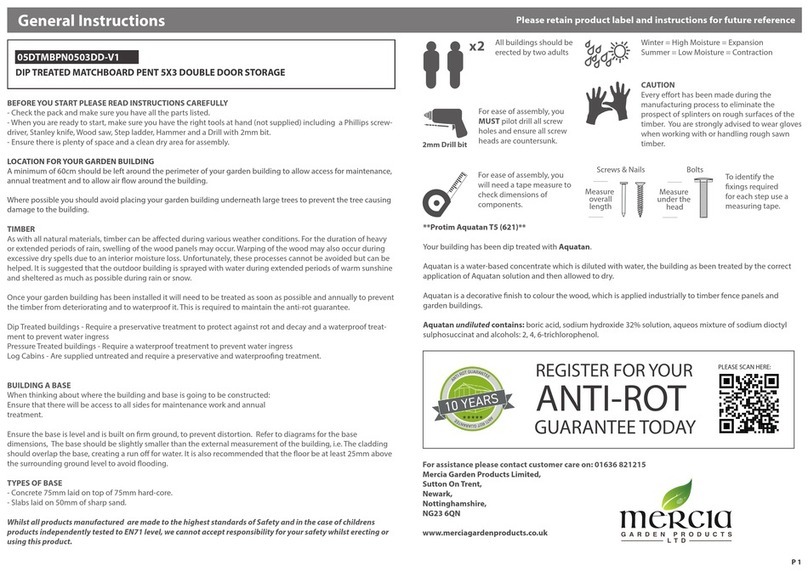

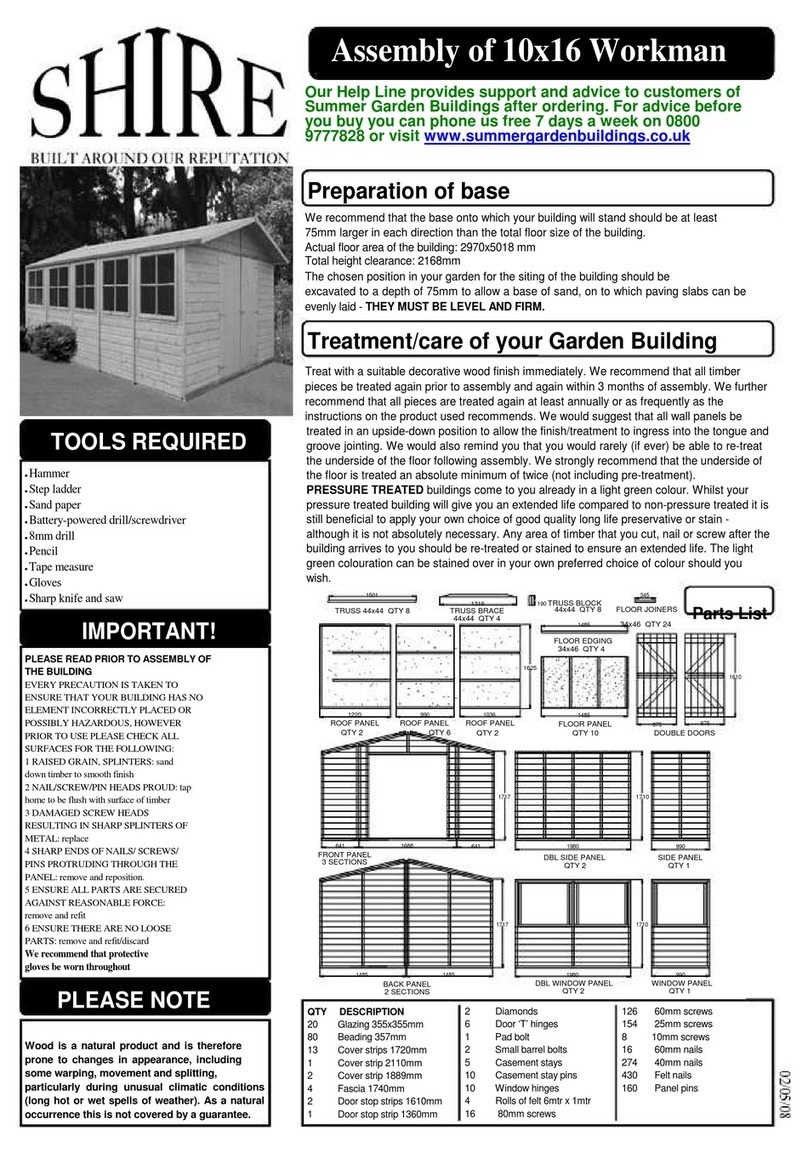

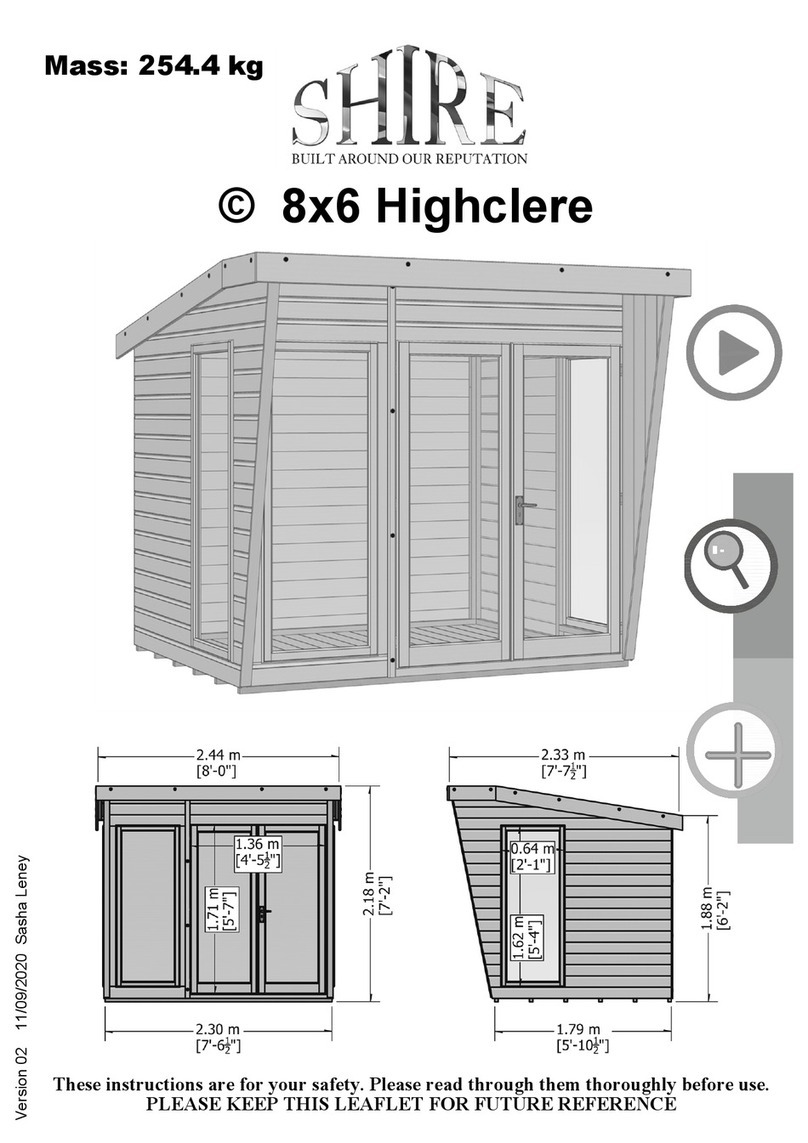

B 18/01/2011 J Shepherd

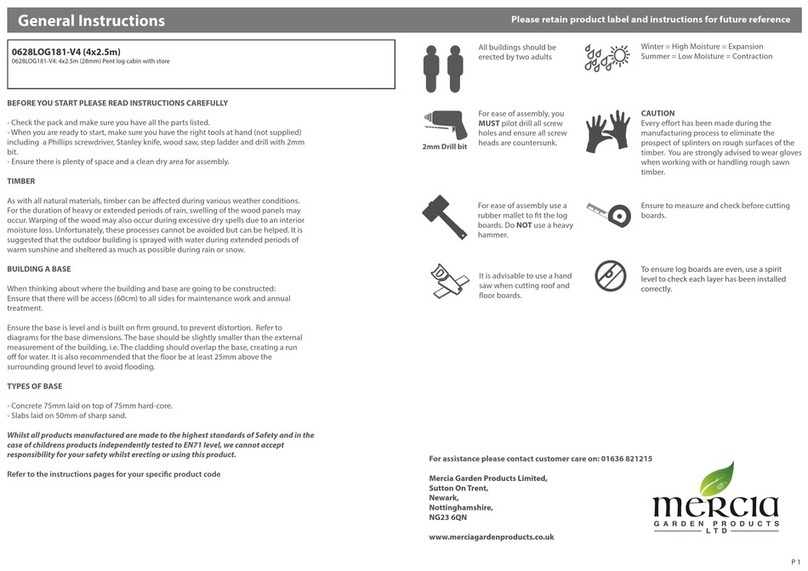

• We recommend the wearing of non-

slip protective gloves throughout

the assembly process. We also

recommend the wearing of steel

capped protective shoes,

protective head gear, safety glasses

and full length clothing. If step

ladders are to be used we recom-

mend one person holds the ladder

whilst the other is using them. If

necessary a third person should be

used. Do not attempt to erect the

building in windy conditions. Follow

any safety precautions quoted by

the manufacturer for any equipment

you use.

• Every precaution has been taken to

ensure that your building has no

element incorrectly placed or

possibly hazardous. However prior

to use please check for raised grain

or splinters and sand if necessary.

Check that all elements are secure

against reasonable force.

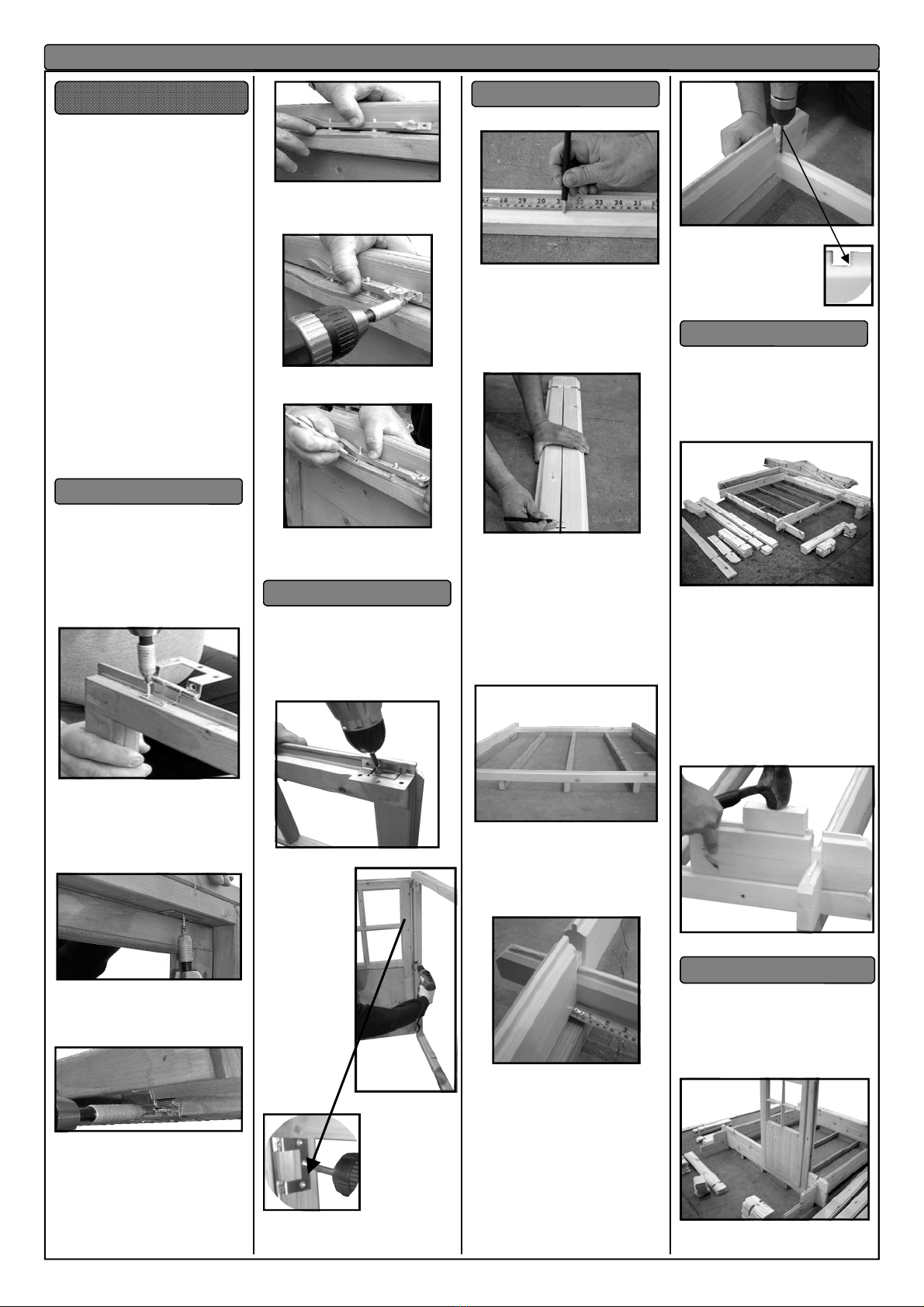

1. Place one hinge on the inner rebate

part of the window; approx. 50mm along

from the rebate edge. The rounded part

of the hinge should sit above the outer

edge of the window. Screw the inner

piece into position ( fig. 1 )using the pre

drilled holes in the hinge and 2x 25mm

screws. Repeat.

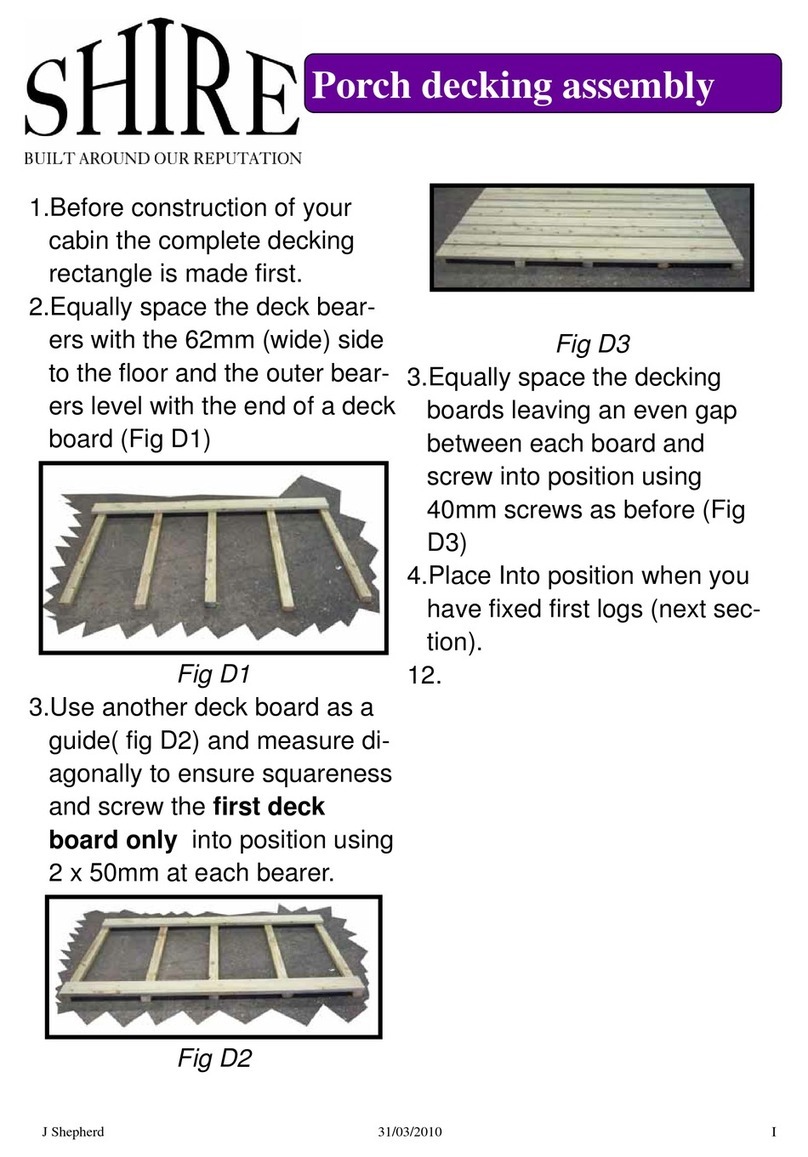

Fig 1

2. Place the window into the aperture.

Secure the window to the panel using

3x 25mm screws per hinge, (fig. 2 )

again through the predrilled holes I n the

hinge. Repeat.

Fig 2

3 From the outside, open the window

fully in order to fit a further 2x 25mm

screws per hinge ( Fig.3 ).

Fig3

4 Fitting the Casement Stay. Place

the casement stay centrally on the

inside of the window (Fig 4 ). Place the 2

pins under the casement stay.

Position so that it is not resting on the

window frame and not so high that the

pins are of no use.

Fig 4

5 Fit the Casement Stay (fig 5 ) on the

window using 2x 25mm screws.

Fig 5

6 Mark where the ‘pins’ will be placed.

Fig 6

7 Secure into position using 4x 25mm

screws - 2 in each pin

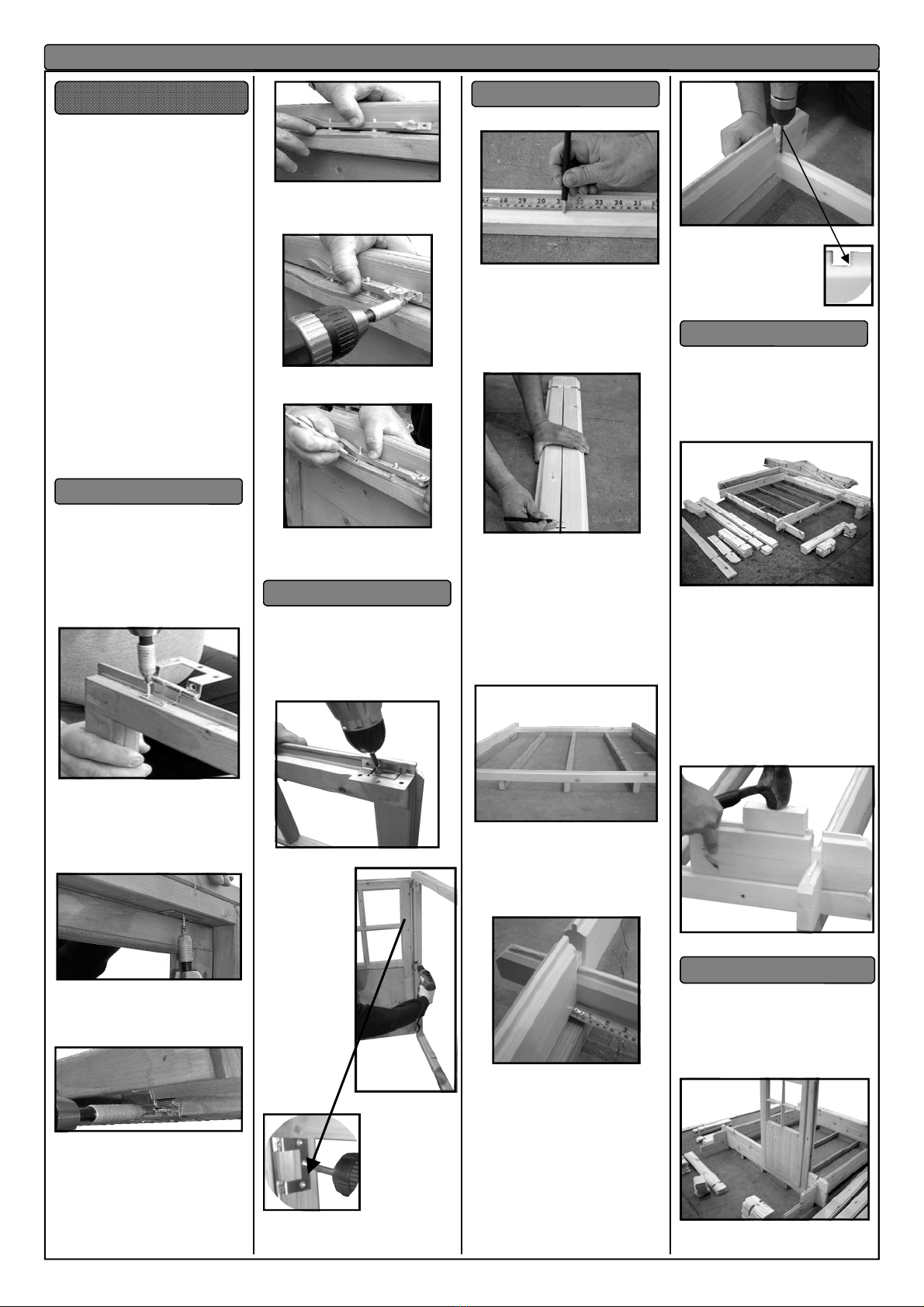

.1. Place the continuous hinge along the

length of the door (fig 7 ) making sure

that the hinge does not protrude at either

top or bottom.

2 .Fit the small inner part of the hinge to

the door using 6 x25 mm screws in total

fig 7

3 Fitting the door

to frame. Place

the door into the

aperture. Ensure

there is an equal

gap between the

edges of the door

and the aperture.

Screw into position

using 3 x 25mm

screws per hinge.

(fig 8 & 9)

Fig 8

Fig 9

See drawing pages1& 2 .

Fig 10

1. Take one of the A1 logs and mark the

895mm from one end (fig 10 ) . This is

the centre line of the middle bearer,

2. Mark 388mm either way of this line.

(This is the centre of the next two

bearers).

Fig 11

3. Place the other ’A1’ log against the

first one and transfer the lines across

(fig 11).

4. Layout pressure treated base floor

bearer timbers (See page 1 of the

drawing sheets.)

5. The bearers stand with the narrowest

edge to the floor (fig 12 ) and their ends

flush with the outside of the A1 logs.

Fig 12

6. Position the bearers that sit under the

full logs at the sides and measure 20mm

from the log to the edge of the bearer

( fig 13 ), all the way down . This is for

the floorboards to sit on.

Fig 13

8. cut notches out of the tongues on the

A1 logs ( fig 14)at centre marks (steps 1

to 3 above ) and drill through for fixing

bearers

9. Important

Measure corner to corner, as building

must be square

10 Also measure length at the centre of

the building from wall to wall (A1 toA1) to

ensure correct length

before fixing to joists with 1x 80mm

screw (fig14) at each bearer at each end.

Fig 14

See drawing pages 2,3,4,5,6,7

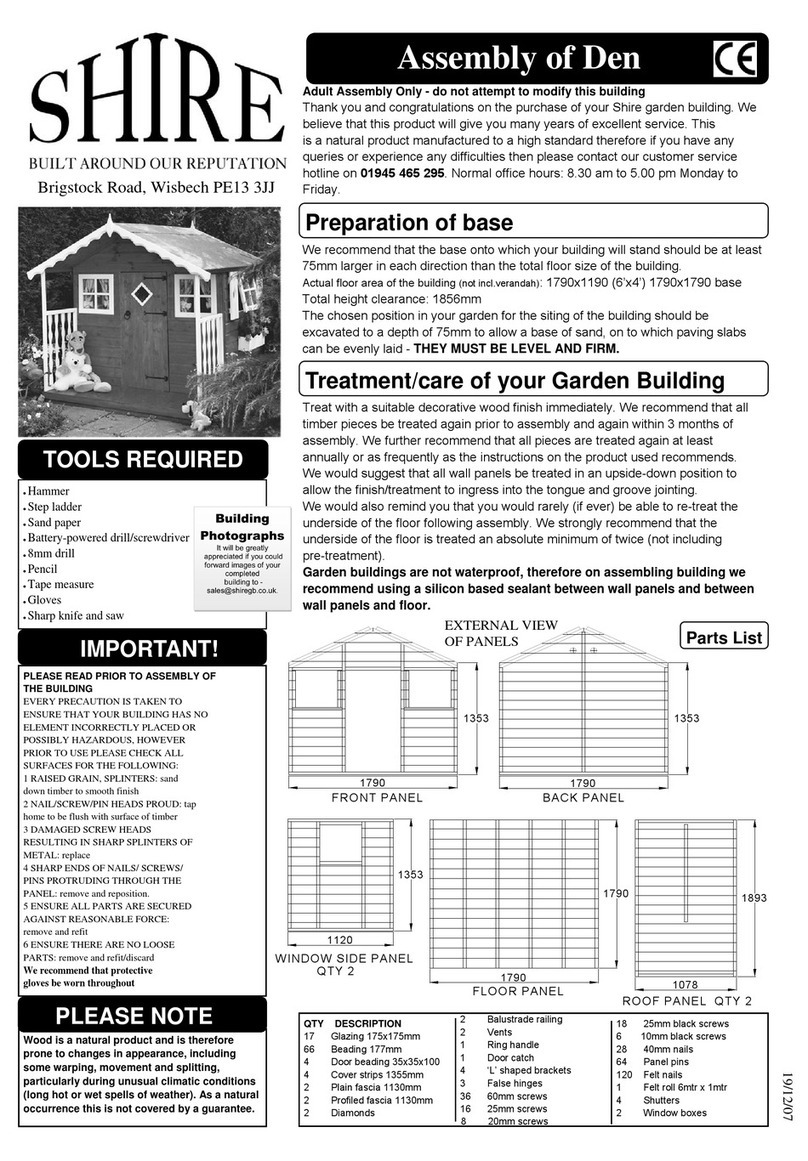

1 Using parts list for each wall layout

correct quantity (fig 15 ) of each

component

for relevant wall (i.e. front, back) in

suitable position for ease of assembly.

Fig 15

2. This is the bottom of all four walls

now ready to be built upon.

3. The walls can now be assembled

as per pages 2,3,4,5 and 6.start

building walls either anti-clockwise

or clock-wise direction.

4. The logs are assembled with the

tongues upwards

9 Each log needs to be tapped home

to log below using timber block

supplied and a rubber mallet (fig 16).

Fig 16

1 Door unit must be placed into

position after the first two layers of

full logs have been assembled

2 Slide unit into aperture from above

(Fig 17& 18) ensuring unit is

completely down and in position.

Fig 18

IMPORTANT SAFETY INFORMATION

A Hinges-windows

B Fit door

C Base frame

D Walls

E Inserting windows and doors

Assembly of playhouse –please read instructions prior to assembly