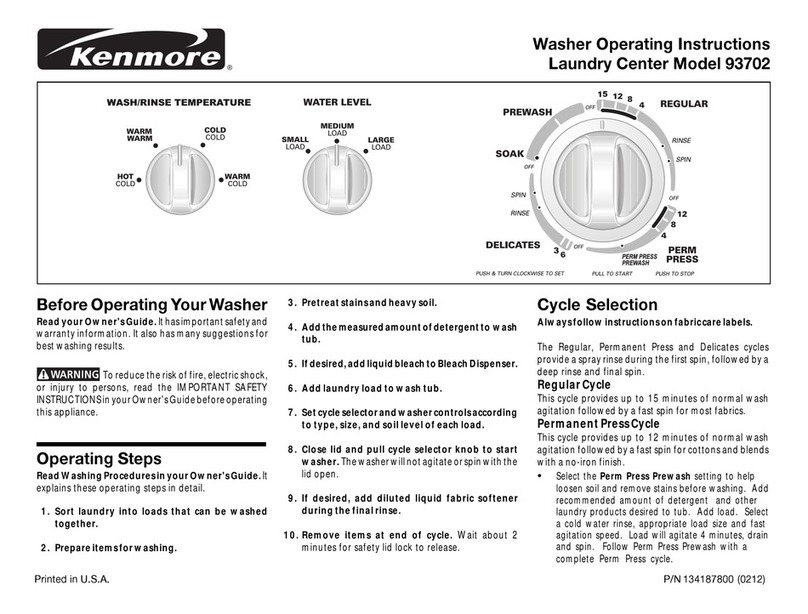

PRE-INSTALLATION REQUIREMENTS

Tools Required for Installation:

I. 1/4 in. nut driver

2. 3/8 in. socket with ratchet.

3. 3/8 in. open end wrench.

4. 7/16 in. socket with ratchet.

5. 9/16 in. open end wrench.

6. Channel-lock adjustable pliers.

7. Carpenter's level.

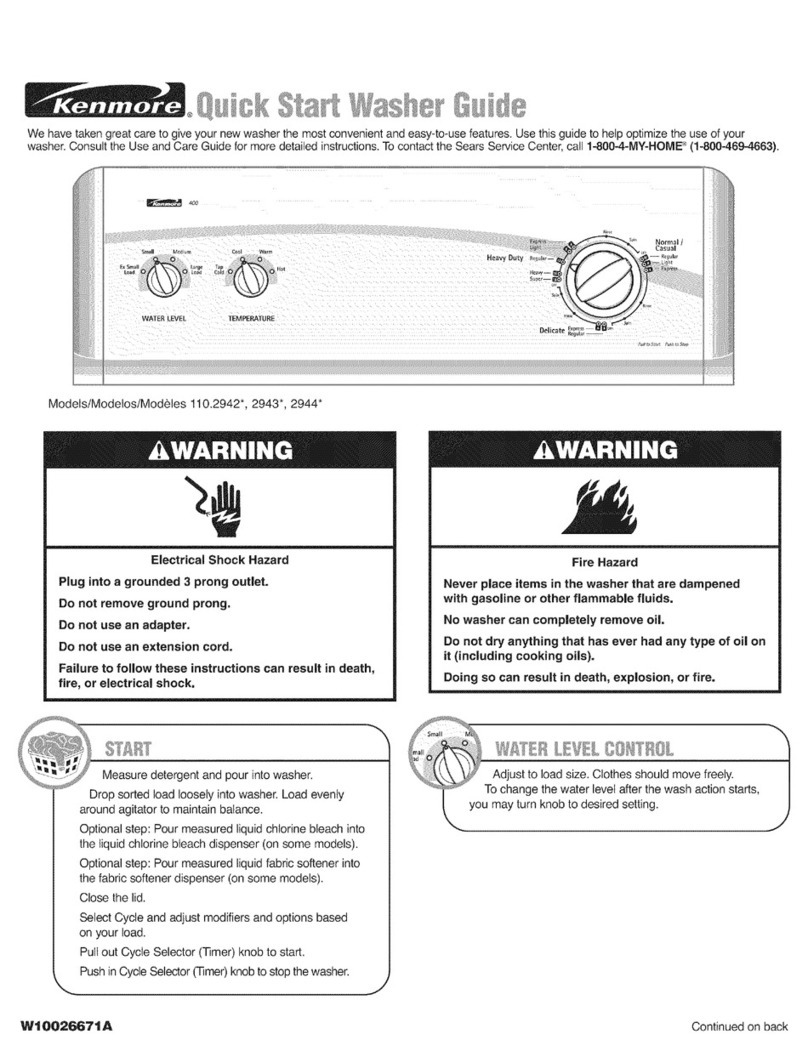

ELECTRICAL REQUIREMENTS

CIRCUIT-Individual, properly polarized and grounded 15 amp.

branch circuit fused with 15 amp. time delay fuse or circuit breaker.

POWER SUPPLY- 2 wire, with ground, 120 volt, single phase, 60

Hz,Alternating Current. NOTE:The useof this washer with power

created by gas powered generators, solar powered generators,

wind powered generators or and other generator other than the

local utility company is not recommended.

OUTLETRECEPTACLE- Properly grounded 3-prong receptacle to

be located sothe power supply cord isaccessiblewhen the washer

is in an installed position. NOTE:GFI (Ground Fault Interrupter)

receptacle isnot required.

DRAIN REQUIREMENTS

Models equipped with drain pump:

I. Drain MUST be capable of eliminating 17 gals (64.3 L) per

minute.

2. A standpipe diameter of 1-1/4 in. (3.18 cm) minimum.

3. The standpipe height above the floor should be:

__ BACK

.-- _ .._..----

96 in.

(244 cm)

Max.

24 in.

(61 cm)

Mino

GROUNDING REQUIREMENTS

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check with a

licensed electrician if you are in doubt asto whether the appliance

isproperly grounded.

1. The washer MUST be grounded. Inthe event of malfunction

or breakdown, grounding will reduce the risk of electrical

shock by a path of least resistance for electrical current.

2. Since your washer is equipped with a power supply cord

having an equipment-grounding conductor and a grounding

plug, the plug MUSTbe plugged into an appropriate, copper

wired receptacle that is properly installed and grounded in

accordance with all local codes and ordinances or in the

absence of local codes, with the National Electrical Codes,

ANSI/NFPA 70 (latest edition). If in doubt, call a licensed

electrician.

DO NOTcut off or alter the grounding prong on the power supply

cord. Insituations where a two-slot receptacle is present, it isthe

owner's responsibility to have a licensed electrician replace it

with a properly grounded three prong grounding type

receptacle.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42 inches

(107 cm) of your washer's water inlet. The faucets MUST be 3/4

inch (1.9 cm) garden hose type so inlet hoses can be connected.

Water pressure MUSTbe between 10 and 120 pounds per square

inch (maximum unbalance pressure, hot vs. cold, 10 psi.) Your

water department can advise you of your water pressure.

NOTE:

Drain hose attached to the washer can reach a 58 in. (147 cm)

high standpipe. For higher standpipe use hose P/N 134592701,

available from an authorized parts distributor. If drain is less

than 24 in. (61 cm), install a siphon break kit, available at your

local hardware store.

Models equipped with gravity drain:

1. FloordrainMUSTbecapableof eliminating 17gals(64.3 L)

per minute.

2. Floor drain diameter must be at least 1/2 inch larger than

drain hose.

LOCATION OF YOUR WASHER

DO NOTINSTALL YOUR WASHER:

I. In an area exposed to dripping water or outside weather

conditions. The ambient temperature should never be below

60 degrees F(15.6 degrees C) for proper washer operation.

2. In an area where it will come in contact with curtains or

drapes.

3. In an area (garage or garage-type building) where gasoline

of other flammables are kept or stored (including

automobiles).

4. On carpet. Floor MUST be solid with a maximum slope of

I/2 in. per foot (1.27 cm per 30.5 cm). Toensure vibration or

movement does not occur, reinforcement of the floor may

be necessary.

IMPORTANT MINIMUM INSTALLATION CLEARANCES

When installed in alcove: Sides, Rear,Top = 0 in (0 cm).

When installed in closet: Sides, Rear, Top = 0 in (0 cm),

Front = 1 in (2.54 cm).

Closet door ventilation openings required: 2 louvers each 60 in2

(387 cm2)- 3 in (7.6 cm) from top and bottom of door.

4