„Installation and operation manual“

The fireplace insert is a heating and decorative device, allowing construction of a complete heating

system based on distribution of hot air. It is not an autonomous heating device but a component of the

heating system. Due to the above reasons, its operation and safety largely depends on the method of

installation and materials used. Considering that, it is recommended that installation of the insert is

commissioned to an Authorised KFD Fitter, guaranteeing an appropriate standard of service.

All domestic and local regulations ought to be observed.

1Construction of the stoves..........................................................................................3

1.1 Placement of the stove ....................................................................................................................................3

1.2 Preparation and unpacking .............................................................................................................................3

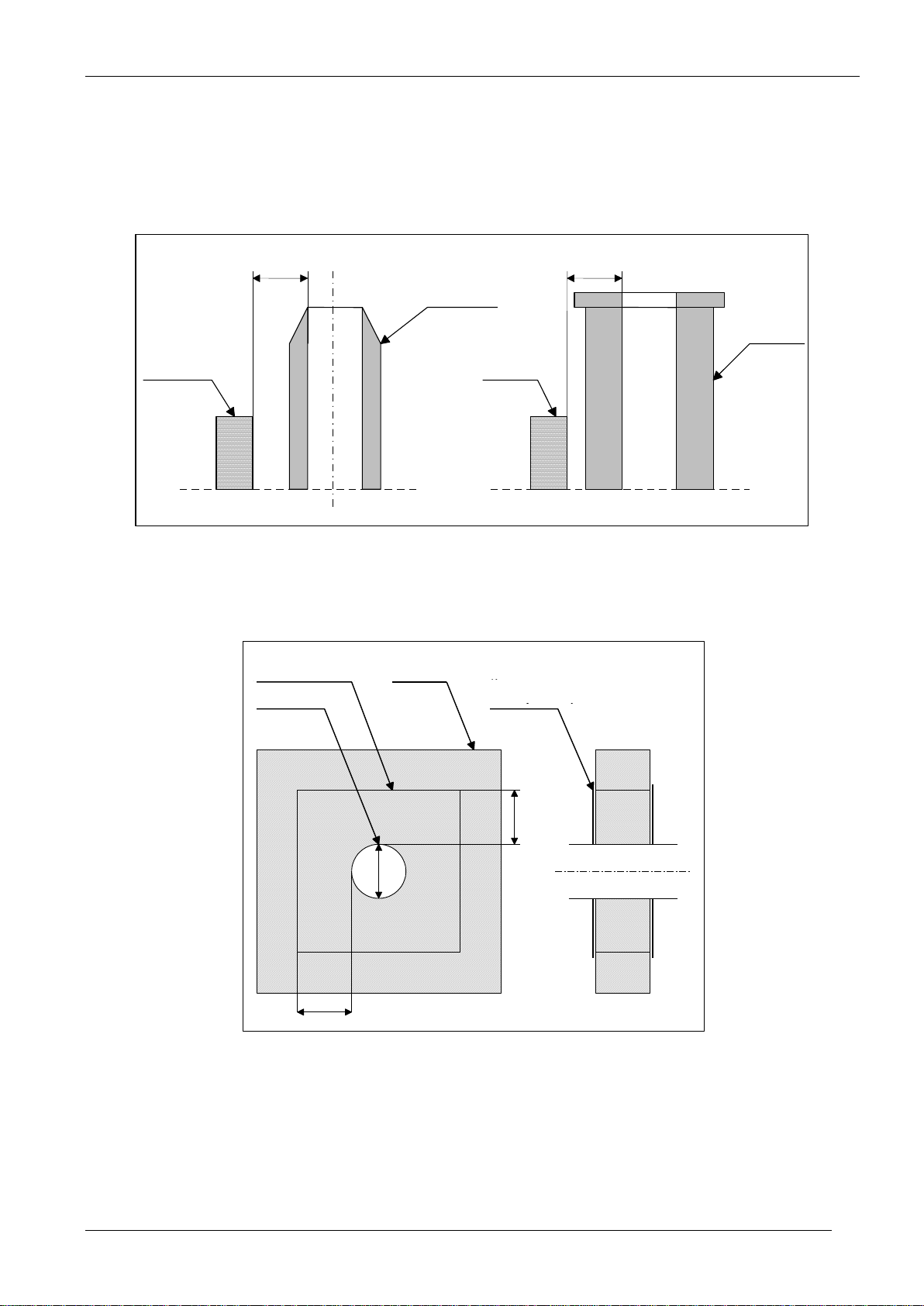

1.3 General assembly rules...................................................................................................................................3

1.4 Assembly of cladding .......................................................................................................................................3

2Installation....................................................................................................................4

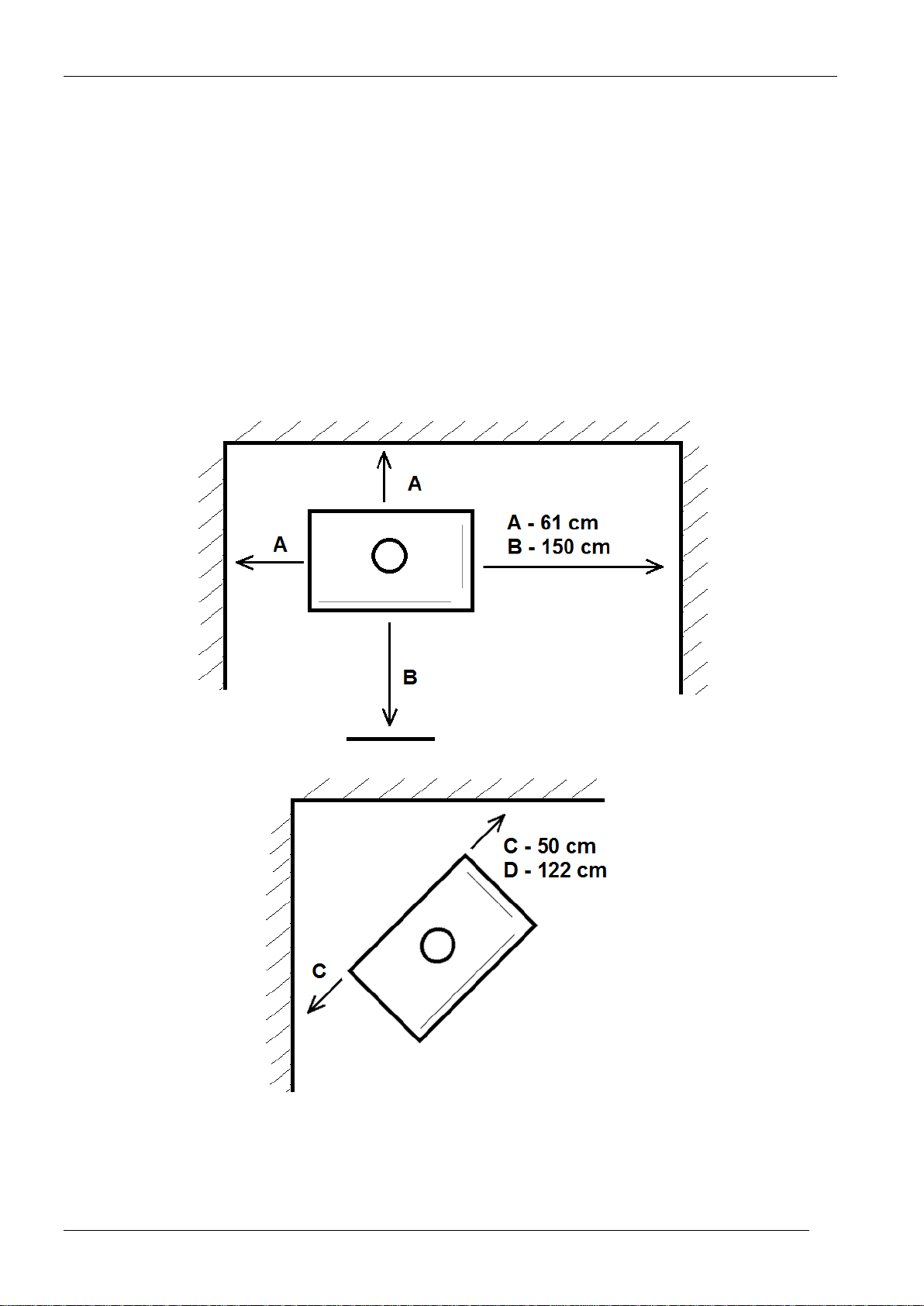

2.1 Stove placement ..................................................................................................................................................4

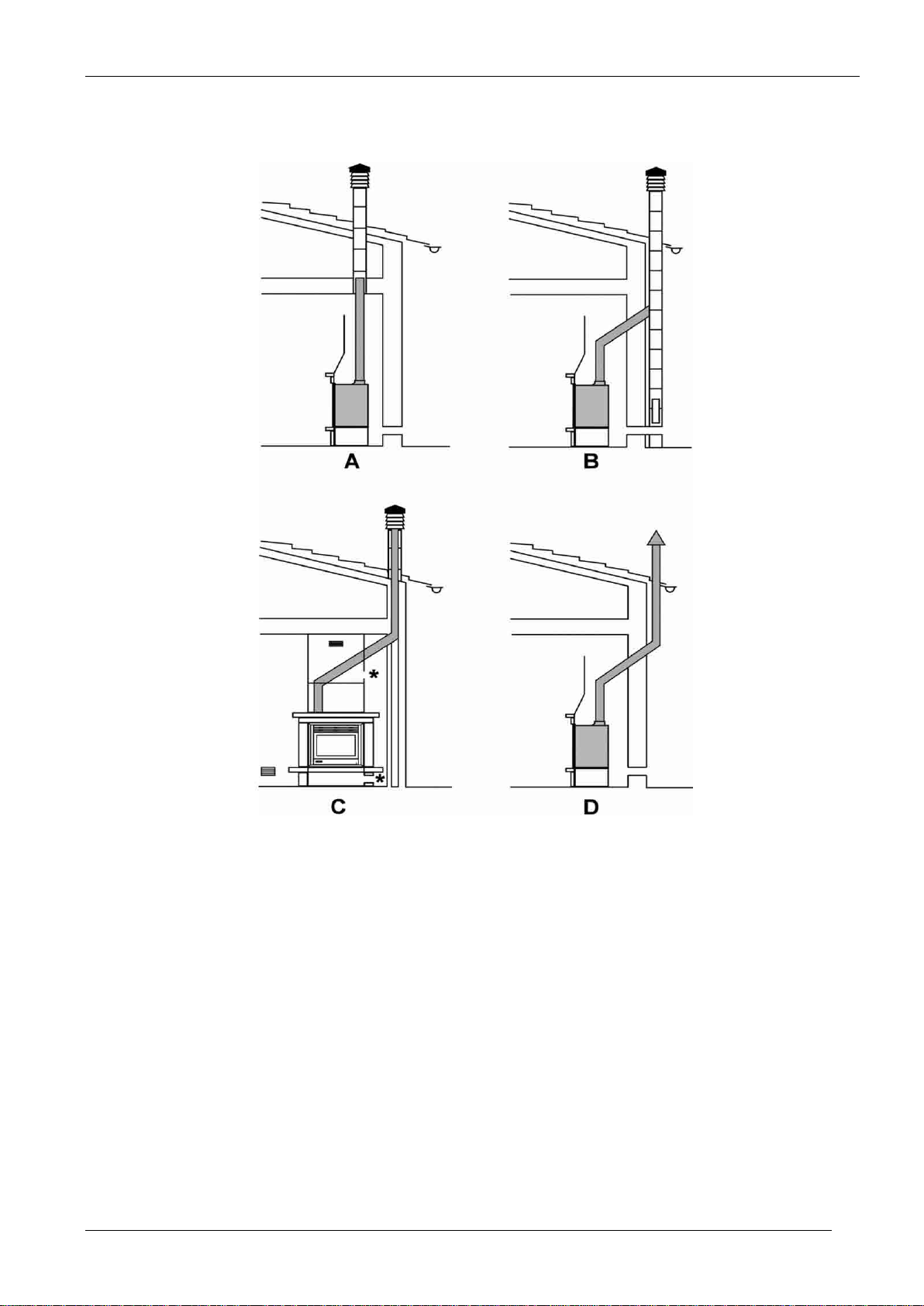

2.2 Chimney.............................................................................................................................................................5

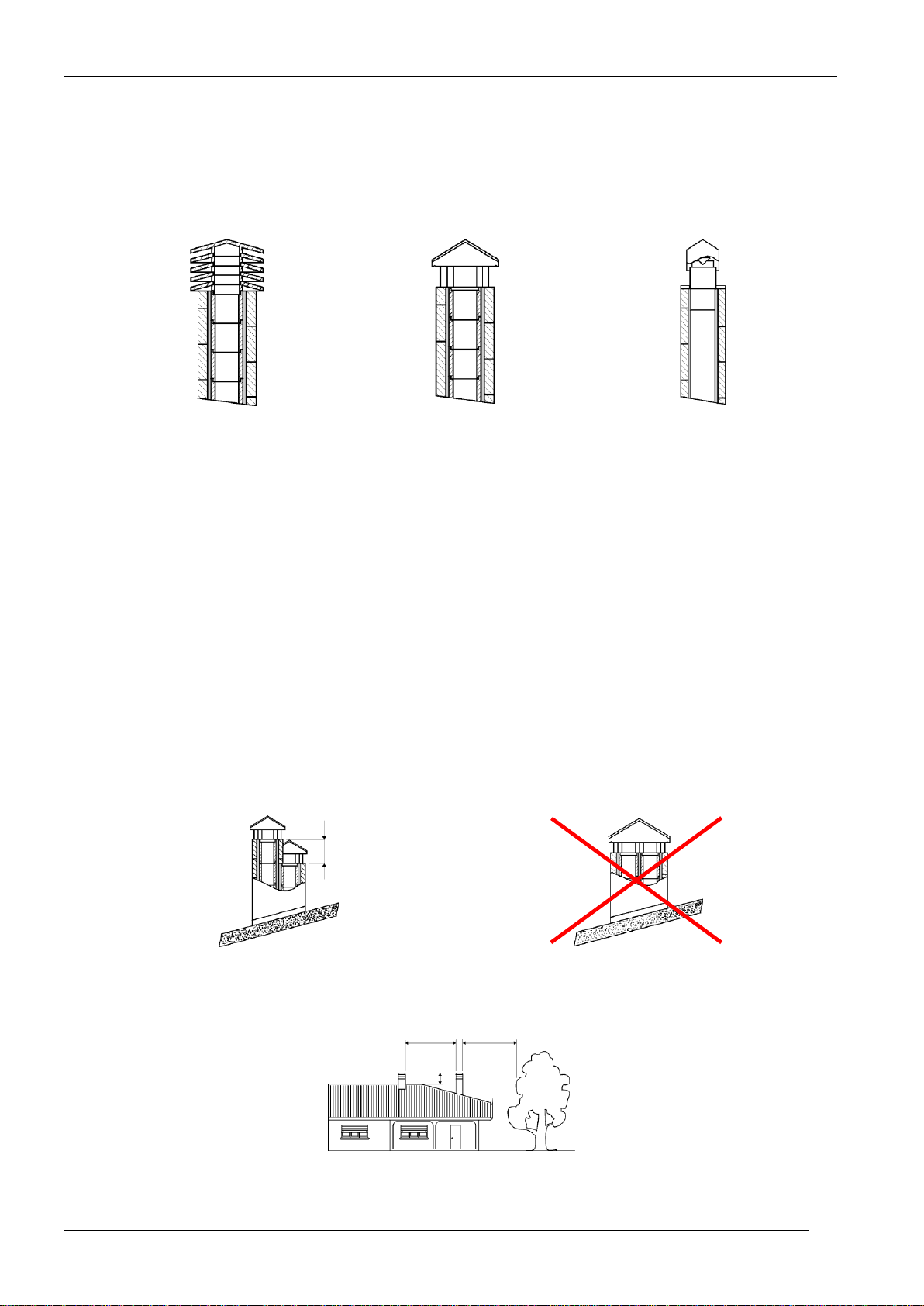

2.3 Tip of the chimney ............................................................................................................................................8

2.4 Connection to the external air intake.............................................................................................................9

3Stove operation..........................................................................................................10

3.1 Lightning ...........................................................................................................................................................10

3.2 Flame control.....................................................................................................................................................10

3.2.1 In case of emergencies...................................................................................................................................................................... 11

3.2.2 Glass.................................................................................................................................................................................................... 11

3.2.3 Cleaning out the ashes...................................................................................................................................................................... 11

3.2.4 Removing and cleaning of deflector................................................................................................................................................. 11

3.2.5 Summer break in device usage........................................................................................................................................................ 12

3.3 Fuel for the stove............................................................................................................................................12

3.4 Hints for users.................................................................................................................................................12

4Parameter selection for flue pipe .............................................................................14

5Technical specifications............................................................................................15

6Troubleshooting.........................................................................................................17

7Inspection log.............................................................................................................19