Kicker 19417164 User manual

Other Kicker Subwoofer manuals

Kicker

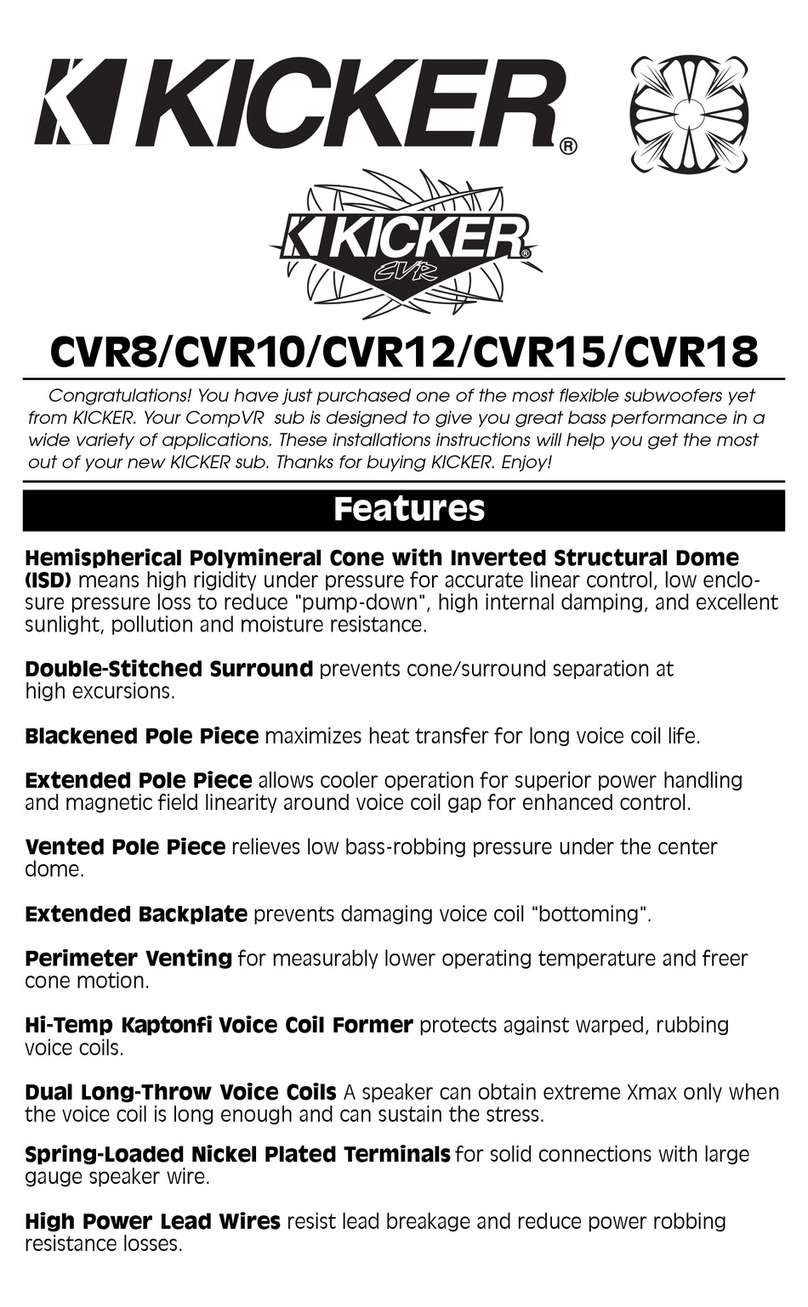

Kicker CompVR CVR8 User manual

Kicker

Kicker CVX COMPVX10 User manual

Kicker

Kicker CompC Series User manual

Kicker

Kicker Q-CLASS CompQ12 User manual

Kicker

Kicker Solo-Baric S8L7 User manual

Kicker

Kicker CompVR CVR10 User manual

Kicker

Kicker COMPVT CVT124 User manual

Kicker

Kicker CompVR CVR12 User manual

Kicker

Kicker Comp DC12 User manual

Kicker

Kicker PTRTP10 User manual

Kicker

Kicker L7T8 User manual

Kicker

Kicker SOLO-BARIC DS12L3 User manual

Kicker

Kicker BassStation PT8 User manual

Kicker

Kicker S12L5 User manual

Kicker

Kicker CompVR CVR10 User manual

Kicker

Kicker Q-CLASS CompQ10 User manual

Kicker

Kicker SOLOX User manual

Kicker

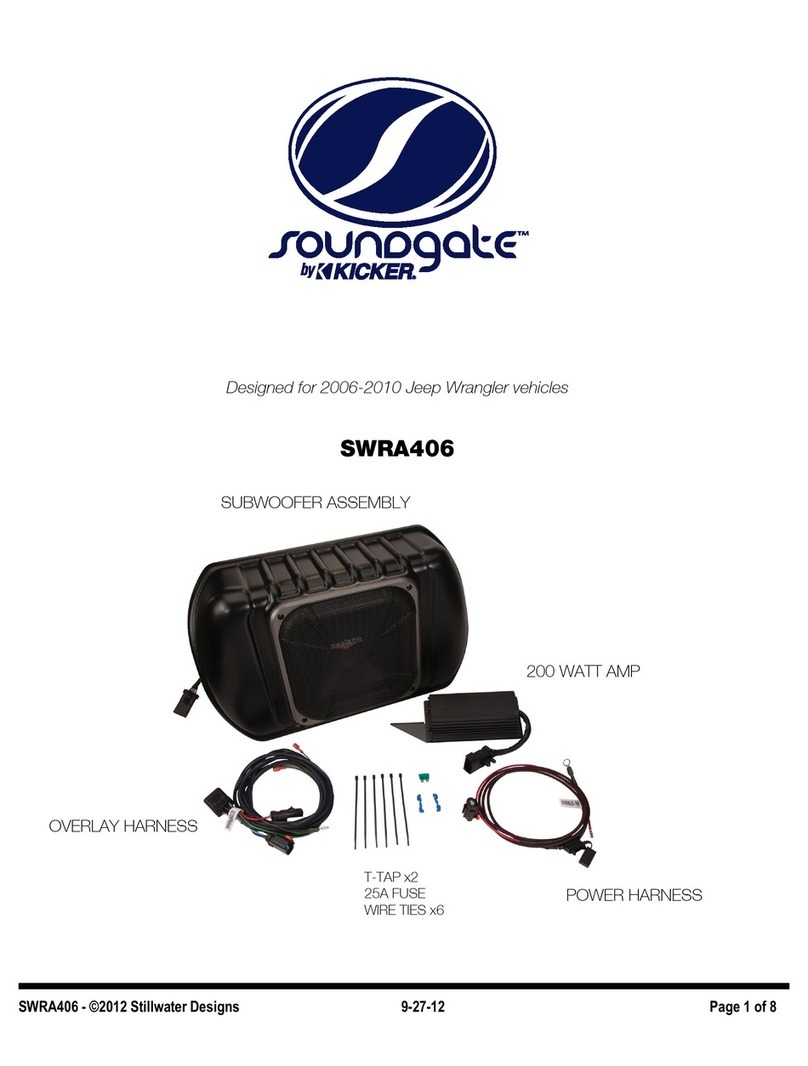

Kicker Soundgate SWRA406 User manual

Kicker

Kicker Comp C10 User manual

Kicker

Kicker Comp C10 User manual