King Canada 8362 User manual

1/4˝ LAMINATE TRIMMER

INSTRUCTION MANUAL

COPYRIGHT ©2005 ALL RIGHTS RESERVED BY KING CANADA INC.

MODEL: 8362

WARRANTY INFORMATION

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

LIMITED TOOL WARRANTY

KING CANADA makes every effort to ensure that this product meets high quality and

durability standards. KING CANADA warrants to the original retail consumer a 2-year

limited warranty as of the date the product was purchased at retail and that each product

is free from defects in materials. Warranty does not apply to defects due directly or

indirectly to misuse, abuse, negligence or accidents, repairs or alterations and lack of

maintenance. KING CANADA shall in no event be liable for death, injuries to persons or

property or for incidental, special or consequential damages arising from the use of our

products. To take advantage of this warranty, the product or part must be returned for

examination by the retailer. Shipping and handling charges may apply. If a defect is found,

KING CANADA will either repair or replace the product.

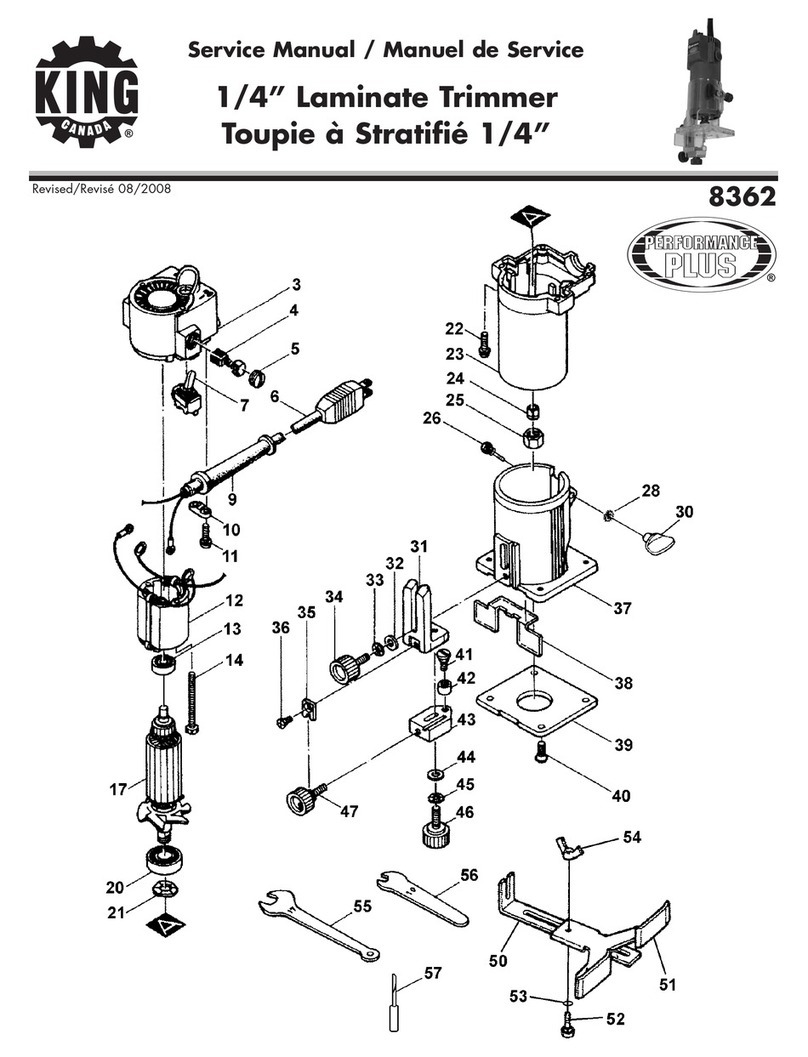

PARTS DIAGRAM & PARTS LISTS

Refer to the Parts section of the King Canada web site for the most updated parts diagram

and parts list.

2-YEAR

LIMITED WARRANTY

FOR THIS LAMINATE TRIMMER

KING CANADA TOOLS

OFFERS A 2-YEAR LIMITED WARANTY

FOR NON-COMMERCIAL USE.

GENERAL AND SPECIFIC

SAFETY INSTRUCTIONS

1. KNOW YOUR TOOL

Read and understand the owners manual and labels affixed to the tool. Learn its

application and limitations as well as its specific potential hazards.

2. DON’T USE power tools in damp or wet locations or expose them to rain. Keep work

area well lit and provide adequate surrounding work space.

3. USE RIGHT TOOL.

Don’t force the tool or the attachment to do a job for which it was not designed.

4. WEAR PROPER APPAREL.

Do not wear loose clothing, gloves, neckties or jewelry (rings, watch) because they could

get caught in moving parts. Non-slip footwear is recommended. Wear protective hair

covering to contain long hair. Roll up long sleeves above the elbows.

5. MAINTAIN TOOL WITH CARE.

Keep tool clean for best and safest performance. Follow instructions for operation and

changing accessories.

6. DISCONNECT TOOLS.

Before servicing, when changing accessories or attachments.

7. AVOID ACCIDENTAL STARTING.

Make sure the switch is in the ‘’OFF’’ position before plugging in.

8. USE RECOMMENDED ACCESSORIES.

Consult the manual for recommended accessories. Follow the instructions that

accompany the accessories. The use of improper accessories may cause hazards.

9. CHECK FOR DAMAGED PARTS.

Before further use of the tool, a guard or other parts that are damaged should be

carefully checked to ensure they will operate properly and perform their intended

function. Check for alignment of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other parts which are damaged

should be properly repaired or replaced.

SPECIFIC RULES FOR SAFE OPERATION

1. ALWAYS SWITCH OFF AND WAIT. Wait for the bit to come to a complete stop before

any type of adjustment or maintenance.

2. Before operation,examine each bit carefully for chips, cracks or damage. Replace if

damage is found.

3. Avoid cutting into nails. Check the workpiece to make sure it’s free of nails.

4. Hold the tool in both hands with a firm, tight grip.

5. Make sure that the bit does not touch any workpiece before switching on the tool.

6. Keep in mind the rotation direction of the tool bit and the direction of the way you feed

it in.

7. Do not touch the bit right after use! It will be very hot and can burn your skin.

OPERATING INSTRUCTIONS

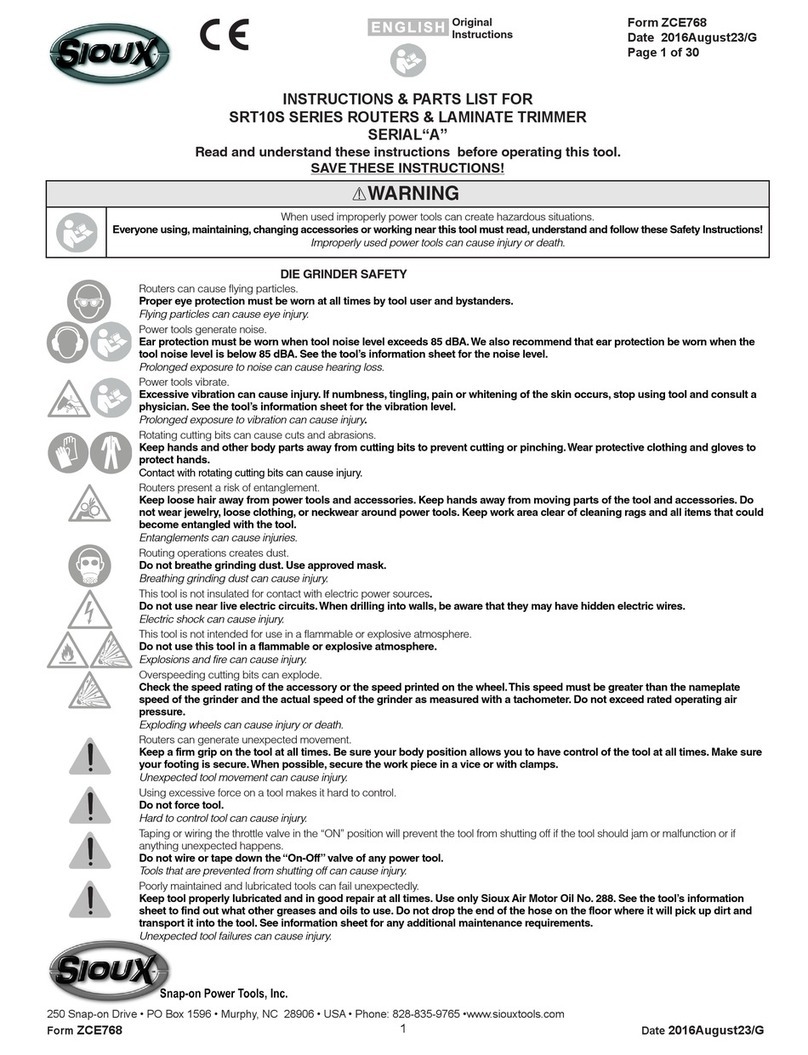

Installing or Removing Bits

Caution:Make sure the tool is switched off and

unplugged before installing or removing a bit.

Insert the bit (A) Fig.1 all the way into the collet

cone, retract the bit 1/8” out of the collet cone and

tighten the collet nut (B) securely with the two

wrenches supplied. Place small wrench (C) around

the flat of the spindle and place the other larger

wrench (D) around the collet nut to tighten. To

remove the bit, follow these instructions in reverse

order.

Caution:Never tighten the collet nut without inserting a bit, or the collet cone will break.

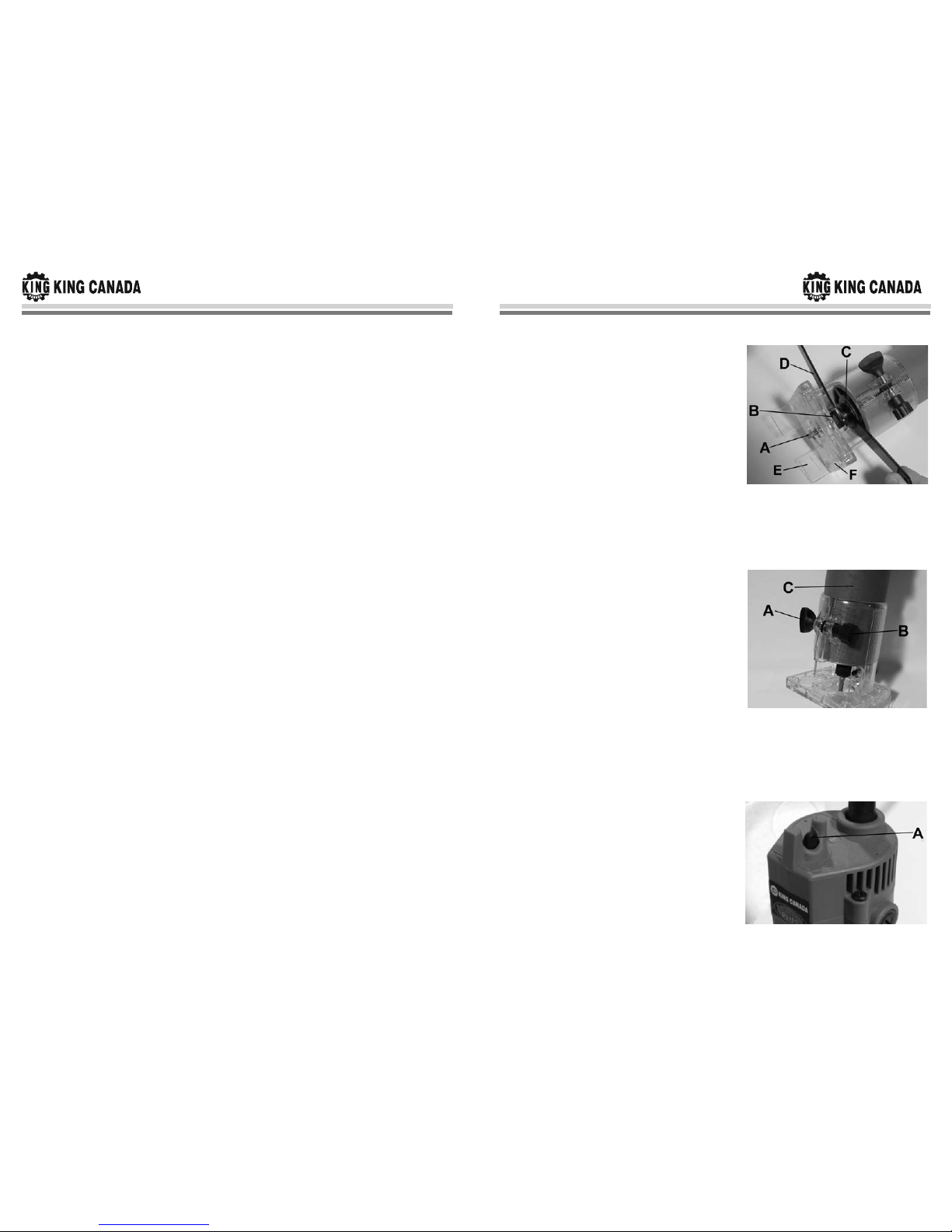

Adjusting Depth of Cut

Place the tool on a flat surface. Loosen lock knob

(A) Fig.2 and turn the adjustment knob (B) to move

the body up or down until the bit just touches the

flat surface. Now adjust the transparent base

upwards until you reach your desired depth of cut.

This adjustment can be done using the scale (C)

on the body. Retighten lock knob (A).

Caution:The depth of the cut adjustment should

not be more than 1/8” each pass when cutting

grooves. If you desire grooves greater than 1/8”

deep, make several passes with progressively deeper bit settings.

Turning Laminate Trimmer On/Off

To start the laminate trimmer, move the switch (A)

Fig.3 to the “ON” position. To stop, move the

switch to the “OFF” position.

Figure 1

Figure 2

Figure 3

OPERATION

Set the tool base on the workpiece to be cut without the bit making any contact. Then turn

the tool on and wait until the bit reaches full speed. Move the tool forward over the

workpiece surface, keeping the tool base flush and advancing smoothly until the cutting is

complete.

When doing edge cutting, the workpiece surface should be on the left side of the bit in the

feed direction (clockwise). When using the straight guide or the trimmer roller guide, make

sure to keep it on the right side in the feed direction. This will help keep it flush with the

side of the workpiece.

Caution:Moving the tool forward too fast may cause a poor quality cut, or damage the bit

or motor. Moving the tool forward too slowly may burn and mar the cut. The proper feed

rate will depend on the bit size, the type of workpiece and the depth of cut. It is

recommended to make a test cut on a scrap piece of wood. Verify the cut and check your

dimensions, adjust as necessary.

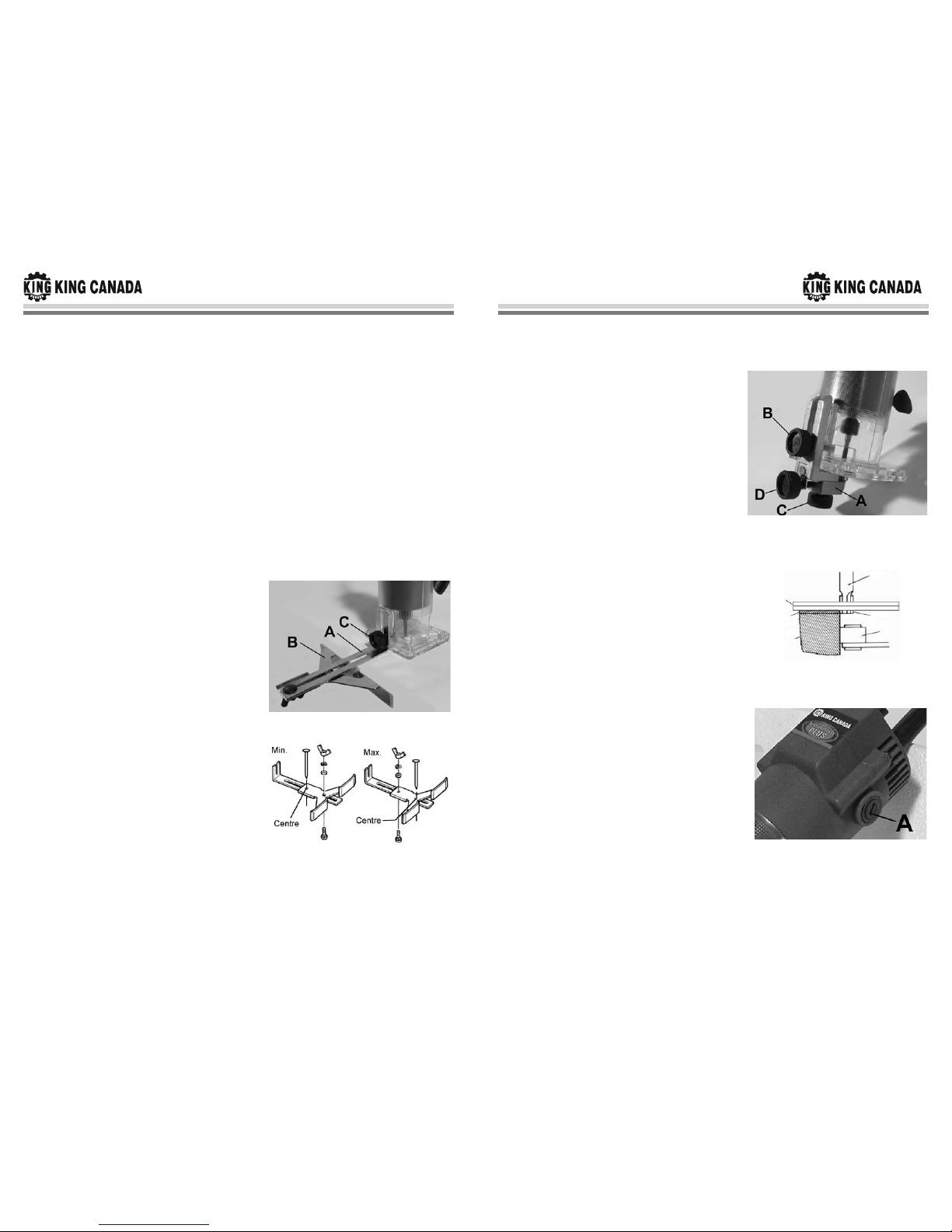

Straight Guide

The straight guide is used for straight-line cuts

when chamfering or grooving.

Attach the guide plate (A) Fig.4 to the straight

guide (B) with the bolt, flat washer, wave washer

and wing nut as shown. Remove the chip deflector

(E) Fig.1 by removing the 4 countersunk screws

which hold in place the transparent base plate (F)

Fig.1. Replace the base plate in position once the

chip deflector is removed. Attach the straight guide

assembly with the front mounted lock knob (C).

Loosen the wing nut on the straight guide and

adjust the distance between the bit and the

straight guide. At the desired distance, tighten the

wing nut securely.

When cutting, move the tool with the straight

guide flush with the side of the workpiece.

Circular Cutting

Circular cutting may be accomplished if you

assemble the straight guide and guide plate as

shown in Fig 5. (Min. 2-3/4” to 4-3/4”, Max. 4-3/4”

to 8-11/16”). Minimum radius is 2-3/4” and maximum radius is 8-11/16”. Note: Circles

between 6-3/4” and 7-5/16” in radius cannot be cut using this guide.

Align the centre hole in the straight guide with the centre of the circle to be cut. Drive a nail

less than 1/4” in diameter into the centre of the hole to secure the straight guide. Pivot the

tool around the nail in a clockwise direction.

OPERATION INSTRUCTIONS

Figure 4

Figure 5

Trimmer Roller Guide

Trimming curved cuts can be done easily with the

trimmer roller guide. The roller guide rides the

curve and assures a fine cut.

Install the trimmer roller guide (A) Fig.6 on the tool

base and lock into place with front mounted lock

knob (B). Loosen the lock knob (C) and adjust the

distance between the bit and the trimmer roller

guide by turning the adjust knob (D). At the

desired distance, tighten the lock knob to secure

the trimmer roller guide in place. When cutting,

move the tool with the guide roller riding the side

of the workpiece.

MAINTENANCE

Caution:Always make sure that the tool is

switched off and unplugged before attempting to

perform an inspection or maintenance.

Replacing Carbon Brushes

Remove and check carbon brushes regularly.

Replace when they wear down to the limit mark.

Keep the carbon brushes clean and free to slip in

the holders. Both carbon brushes should be

replaced at the same time.

Use a screwdriver to remove the brush holder

caps (A) Fig.8. Take out the worn carbon brushes,

insert new brushes and secure the brush holder

caps.

OPERATION INSTRUCTIONS

&MAINTENANCE

Figure 6

Figure 8

Figure 7

Bit

Roller guide

Laminate

Base

1/8”

Sub-straite

Table of contents

Other King Canada Laminate Trimmer manuals