KINROAD 150 SERVICE MANUAL VERSION 1, DEC., 2005

10

FOAM FILTER MAINTENANCE

1. Remove the foam filter from steel cage

2. Wash in non-flammable cleaning solvent

3. Submerge in oil and squeeze to remove excess oil

4. Install the element back into the air box.

NUTS AND BOLTS IN THE CHASIS

Inspect first week and every month thereafter.

Always pay attention to the nuts and bolts. Some loosening after use is a normal situation and should be

checked regularly.

TIGHTENING TORQUE TABLE

Conventional marked bolt 8.8 marked bolt

Bolt

Diameter

(mm) N·m Kg·m lb-ft N·m Kg·m lb-ft

4 1-2 0.1-0.2 0.7-1.5 1.5-3 0.15-0.3 1.0-2.0

5 1-4 0.2-0.4 1.5-3.0 3-6 0.3-0.6 2.0-4.5

6 4-7 0.4-0.7 3.0-5.0 8-12 0.8-1.2 6.0-8.5

8 10-16 1.0-1.6 7.0-11.5 18-28 1.8-2.8 13.0-20.0

10 22-35 2.2-3.5 16.0-25.5 40-60 4.0-6.0 29.0-43.5

12 35-55 3.5-5.5 25.5-40.0 70-100 7.0-10.0 50.5-72.5

14 50-80 5.0-8.0 36.5-58.0 110-160 11.0-16.0 79.5-115.5

16 80-130 8.0-13.0 58.0-94.0 170-250 17.0-25.0 123.0-181.0

18 130-190 13.0-19.0 94.0-137.5 200-280 20.0-28.0 144.5-202.5

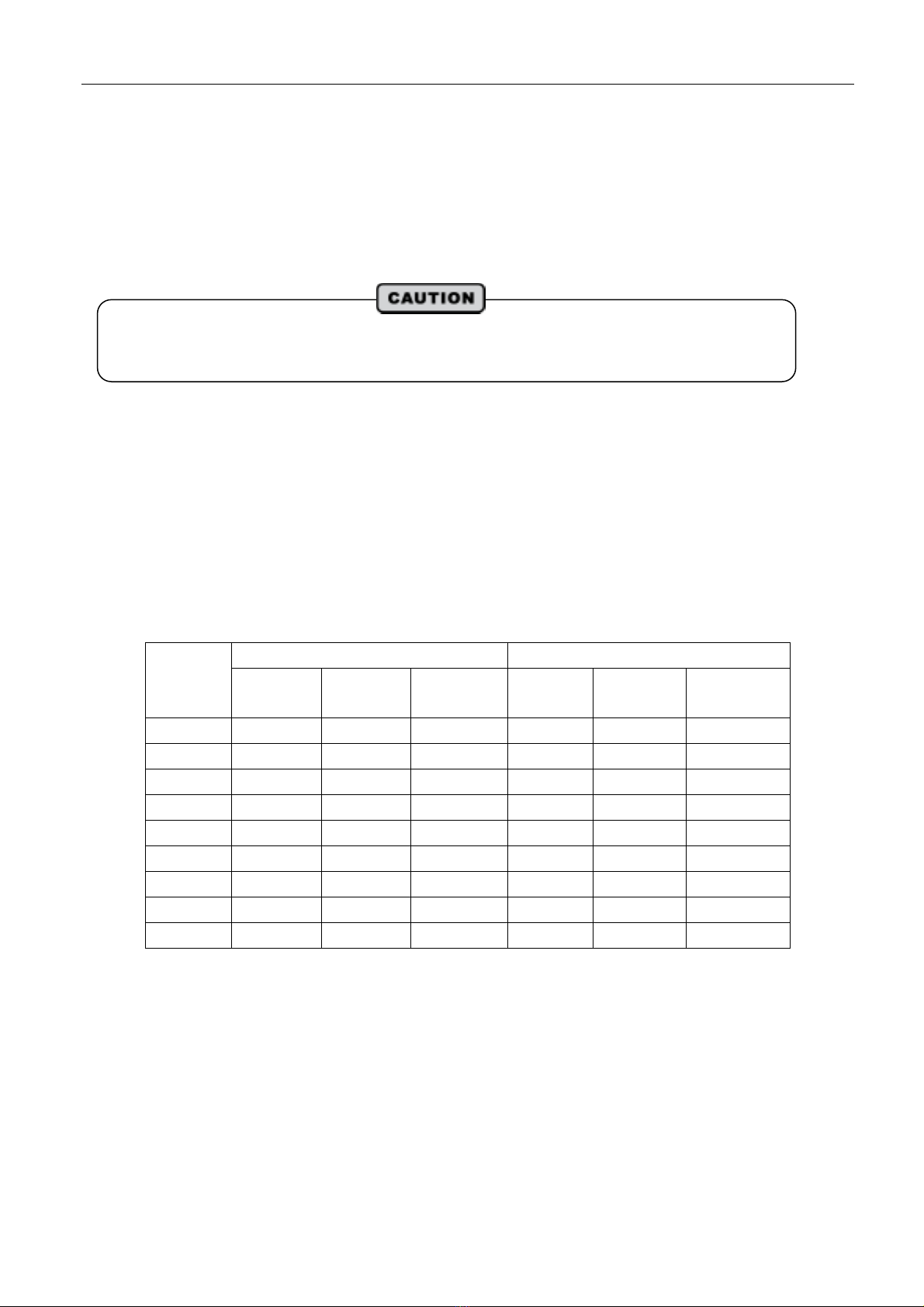

FUEL SWITCH (PETCOCK)

1. Periodically clean the petcock externally with grease remover and water.

2. Check for any leaks or seeping fuel.

3. Replace the petcock if there are any leaks found.

This vehicle has a manually operated fuel valve. There are three positions.

“ RES ” “ OFF “ “ ON “

1.Before and during cleaning, inspect the element for tears. Atorn element must be replaced.

2.Make sure the element is seated properly and no foreign material can pass by it