Notes:

1. Mounting hardware is not supplied by Bindicator.

2. When mounting the ORB be sure there is enough clearance to open the front door completely. Removal,

insertion, and wiring of the modular PCB is done through the front of the unit.

DRILLING HOLES IN THE ENCLOSURE

ThestandardberglassORBNEMA4Xratedenclosurehasnoopeningsthroughwhichtoroutecablesorinstall

theconduit.Holelocationiscriticalforproperconduitinstallation.Checkclearancestoensurethatthettings

and wire routing will not interfere with the PCB or enclosure door.

PREPARE THE ENCLOSURE FOR CONDUIT

1. Open door of the ORB.

2. Remove all four (4) mounting screws that attach the ORB to the

enclosure.

3. Remove entire ORB frame, and place in a safe location.

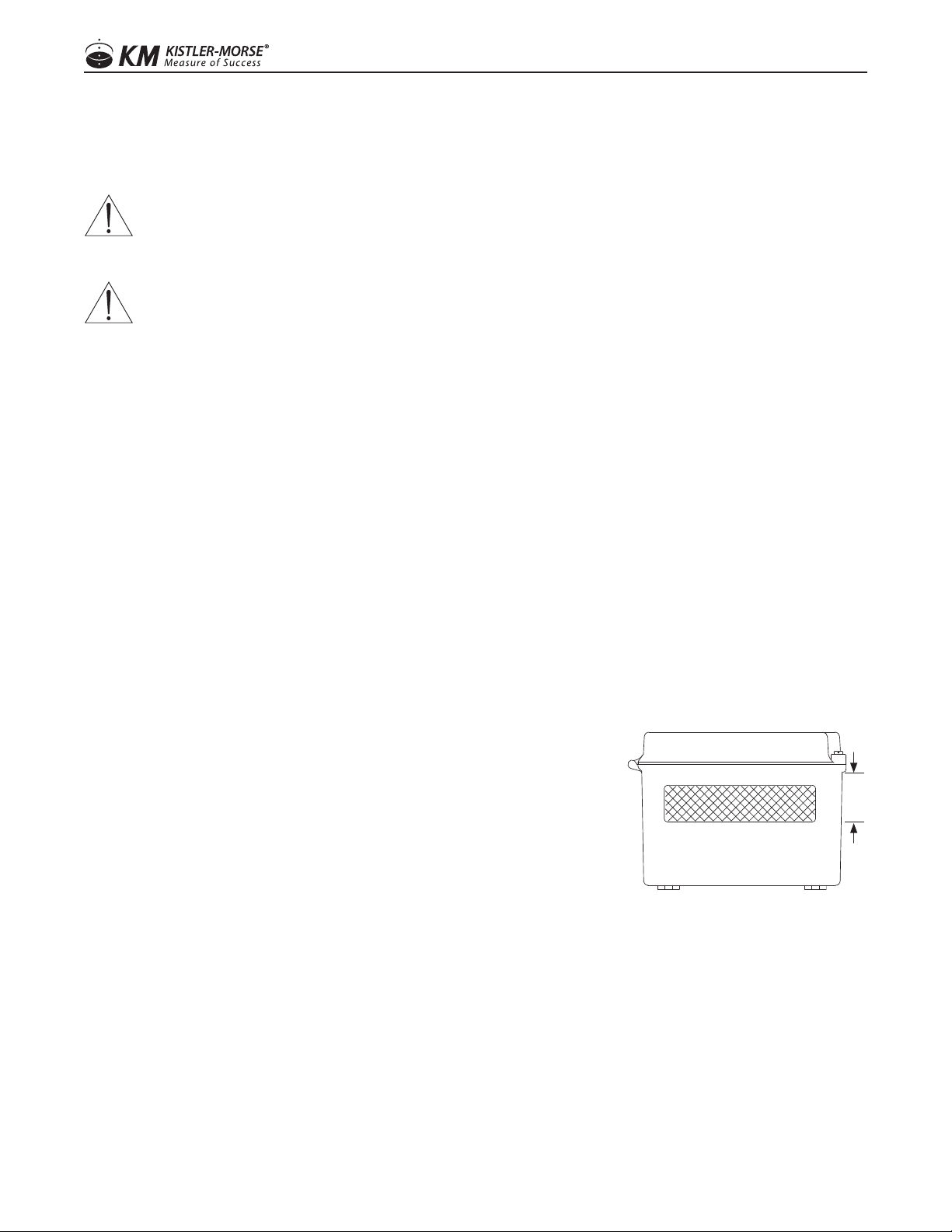

4. Make a hole for the AC cable and the serial and CAT 5 wiring.

Holes should be made in the front 2 inches of the the bottom of the

enclosure (see Figure 1); this allows for appropriate spacing for the

ORB and cables.

5. Clean enclosure of any debris, replace the ORB back into the

enclosure, using all four (4) mounting screws.

6. Determine desired location for mounting the ORB.

TO MOUNT THE ORB

1. Install feet to the ORB enclosure, tightening at the desired angles for mounting location.

2. Hold the enclosure against the wall in the desired location and mark the positions of the mounting holes.

Place the enclosure in a safe location.

3. Drill the mounting holes in the wall.

4. Attachtheenclosuretothewallusinghardwarethatwillsecureitrmlyinplace.

IV. MECHANICAL INSTALLATION

WARNING: TO PREVENT PERSONAL INJURY OR EQUIPMENT DAMAGE ONCE THE ORB HAS

BEEN CONNECTED TO POWER, DISCONNECT POWER BEFORE ADDING OR REMOVING PCBS OR

MOUNTING THE STAND-ALONE ORB AND DEACTIVATE POWER TO THE CONTROLLER.

CAUTION: DO NOT ROUTE SERIAL CABLES IN THE SAME CONDUIT WITH AC POWER CABLES.

ONLY USE SIKAFLEX 1A POLYURETHANE SEALANT OR DOW CORNING RTV 738 OR 739. OTHER

SEALANTS MAY CONTAIN ACETIC ACID WHICH IS HARMFUL TO SENSORS AND ELECTRONICS. DO

NOT DRILL HOLES THROUGH THE TOP AS THIS MAY ALLOW MOISTURE SEEPAGE, WHICH CAN

DAMAGE THE ELECTRONICS AND VOID THE WARRANTY.

Figure 1.

2”

Bottom View

55

97-1167-01 Rev. J

www.kistlermorse.com