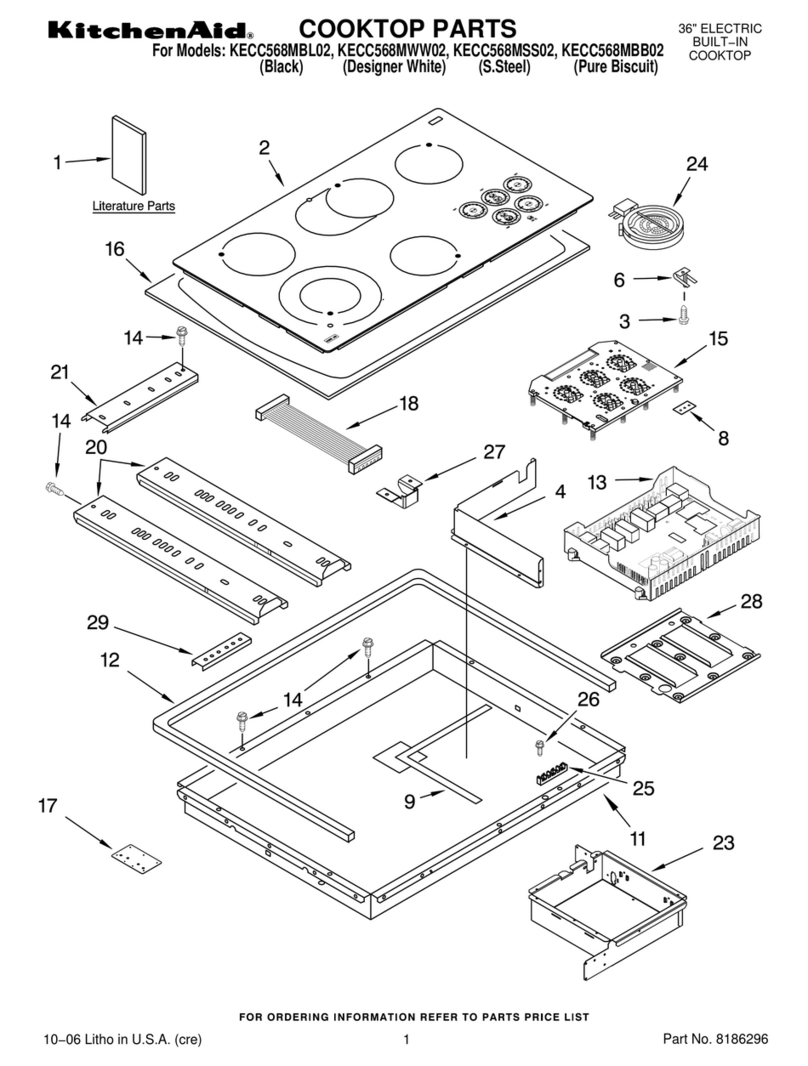

Check air shutter setting. On natural and LP gas there should be

a 3/4” slot in burner at both top and bottom. %

The unit is now ready to plug service cord into receptacle. Make

sure that power supply neutral is connected to the wide blade

slot in receptacle. It is essential that the electrical outlet to

which the plug is connected be properly grounded and polarized.

If this is in doubt, a qualified electrician should be contacted to

check the outlet.

Initial checks are made either with or without cooktop de-

pending upon whether or not the unit was converted for LP gas,

1” OPENING -\

TOP AND

BOTTOM

Test each top burner one at a time by setting knob to “light”

position. This is done by pushing in on knob and turning knob to left or counterclockwise. Repeat at least

four times.

A clicking sound should be heard as soon as the knob is turned to “light” position. If it is not present, turn

burner “off” and make sure that power is being supplied to unit. Check to see that service cord is firmly in

place in receptacle or for a blown fuse or tripped circuit breaker.

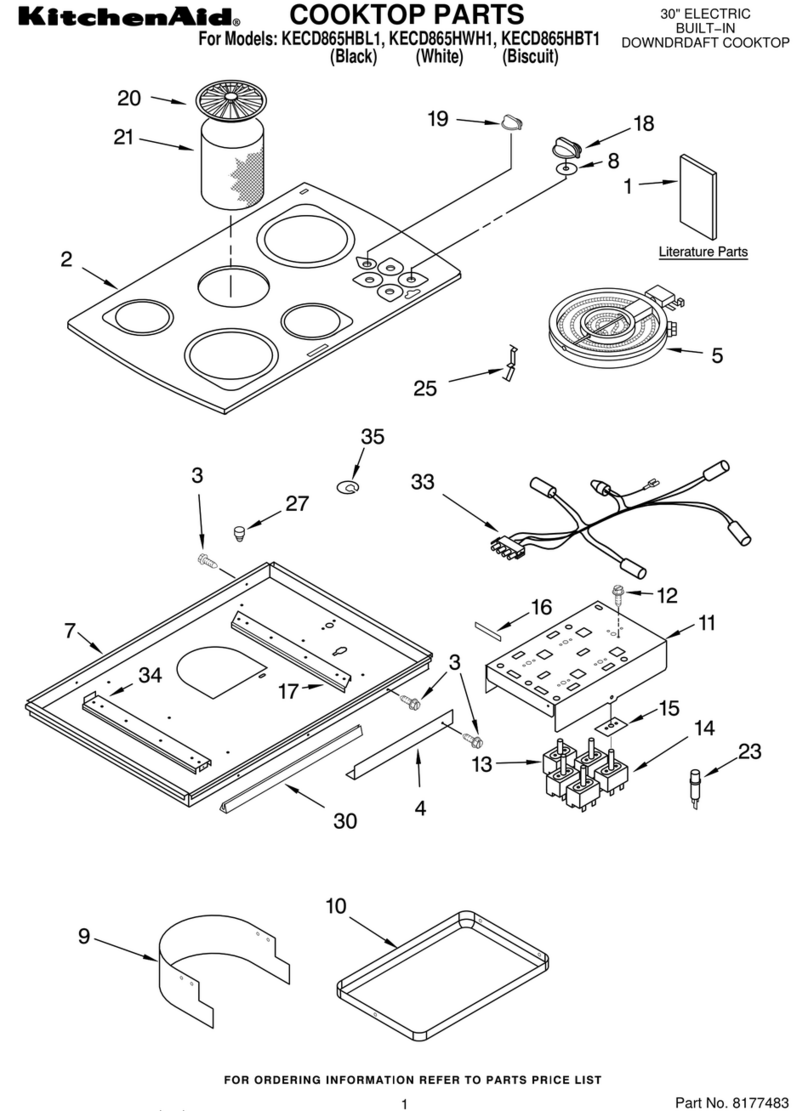

If these are not at fault, remove knobs and handles, four (4) screws from control panel to check connec-

tions at valve switches. Remove left rear drip pan, burner, and remove module cover to check connections

at spark module. Make sure that solid gt-ound connection is made from spark module,

The broiler- burner ignition is checked in the same manner as the top burner, Since it must be done with the

griddle level with the cooktop, ignition is observed through the right hand opening between the griddle and

the cooktop. If ignition does not take place, remove drip pan in right rear burner and reduce air shutter

opening.

After all burners have been individually checked, reattach top, if it has been removed, and put drip pans in

place, Recheck top burner ignition and make initial flame adjustment one burner at a time. If flames lift

from burner, reduce air shutter opening; if flames, are yellow, increase operling, until 3/8” soft blue inner

cone is present. Check ignition on each burner at least four (4) times.

If burner fails to light and ignitor is clicking, turn gas “off”, remove

drip pan and recheck flash tube alignment. A visual check should be

made to make sure that the ignitor is producing a spark. If spark is

not present, recheck connections. Should failure continue after these

checks, reduce air shutter opening. Replace drip pan and check

ignition again. (Try at least 4 times.)

Now proceed to check ignition on both front and back burners at

one time. Sometimes the air shutter opening must be adjusted to get proper ignition when the other burner

is burning. Repeat check four (4) times on each side as before.

LOW FLAME ADJUSTMENT

Top Burners

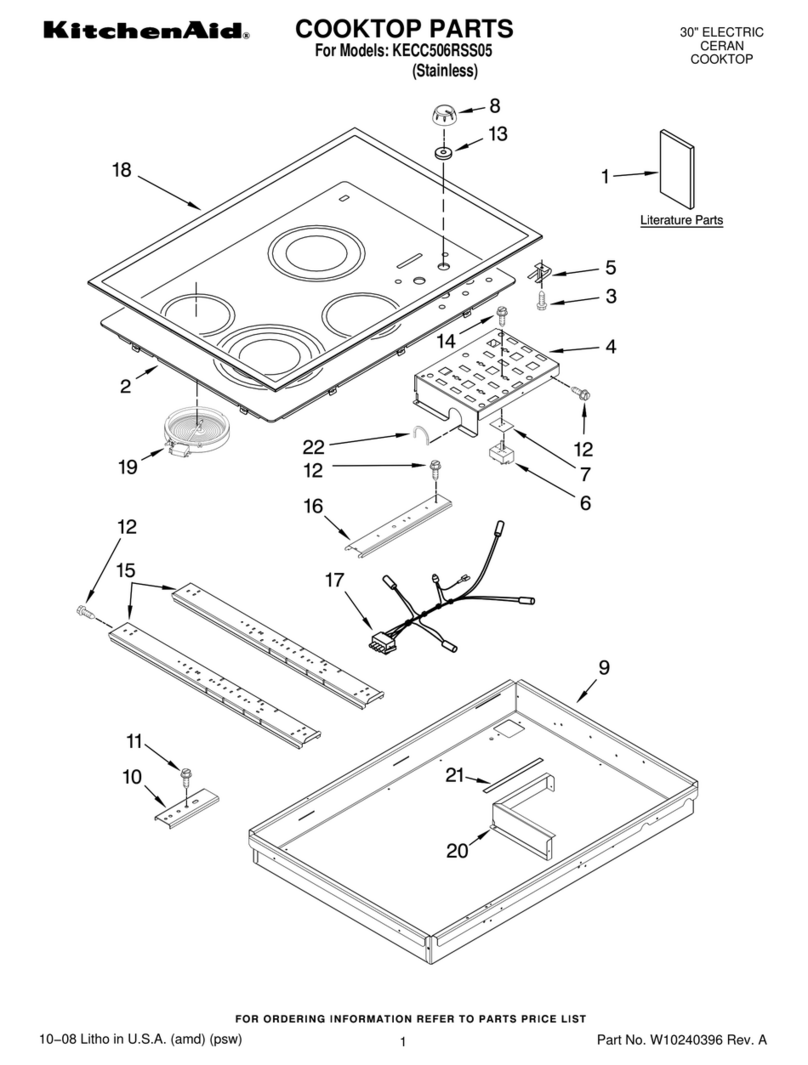

Low flame adjustment IS made by lighting burner, turning knob to “low” and removing knob, Hold base of

valve stem with pliers and insert narrow (3/16”) standard blade screwdriver in adjustment screw slot

(located in center of valve stem). Turn screw until flame is l/8” long, Replace knob.

“Lo” SETTING VALVE AIR SHUTI’J3R

ADJUSTMENT SCREW AIR SHIJTTER SCREW

MANIFOLD

BURNER VALVE 2 NEEDIE