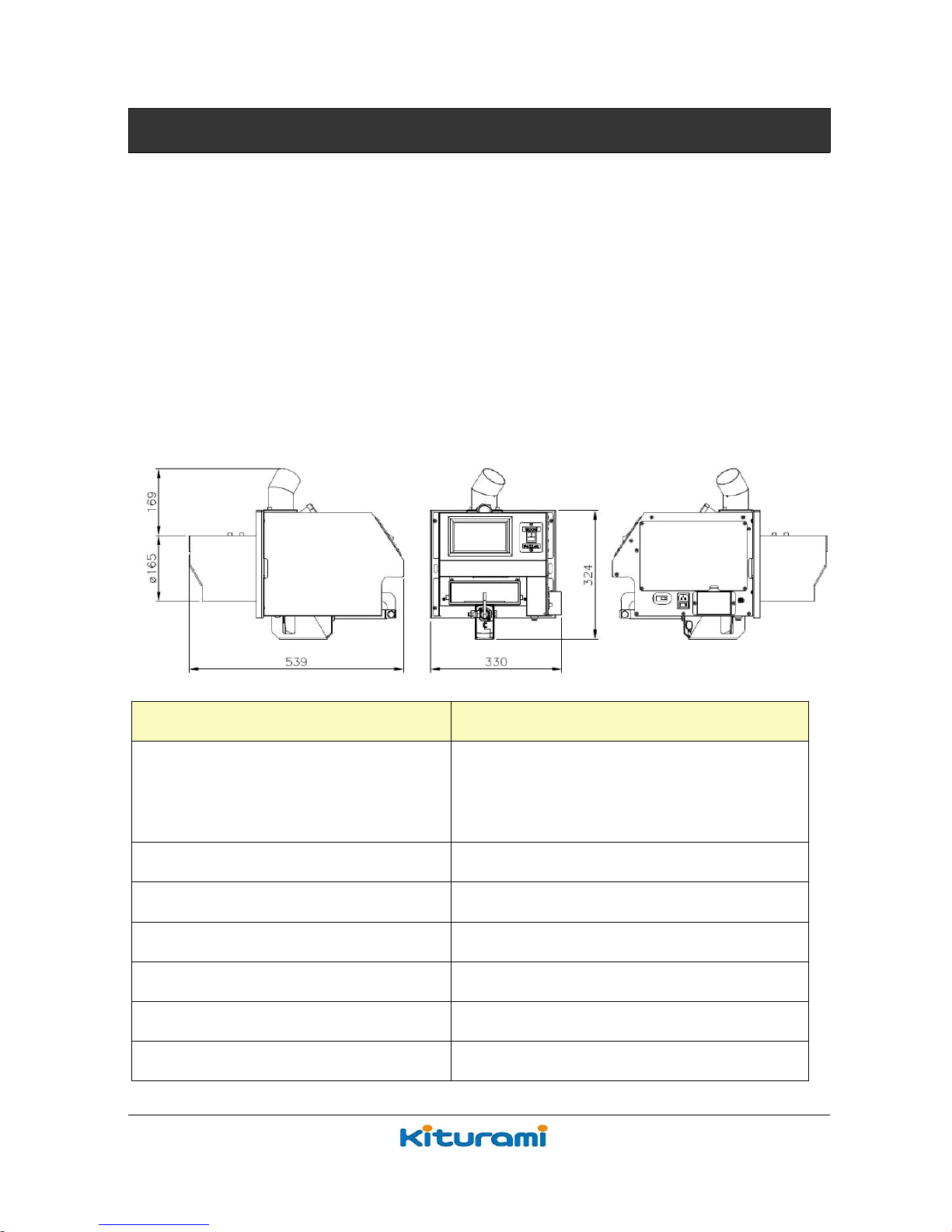

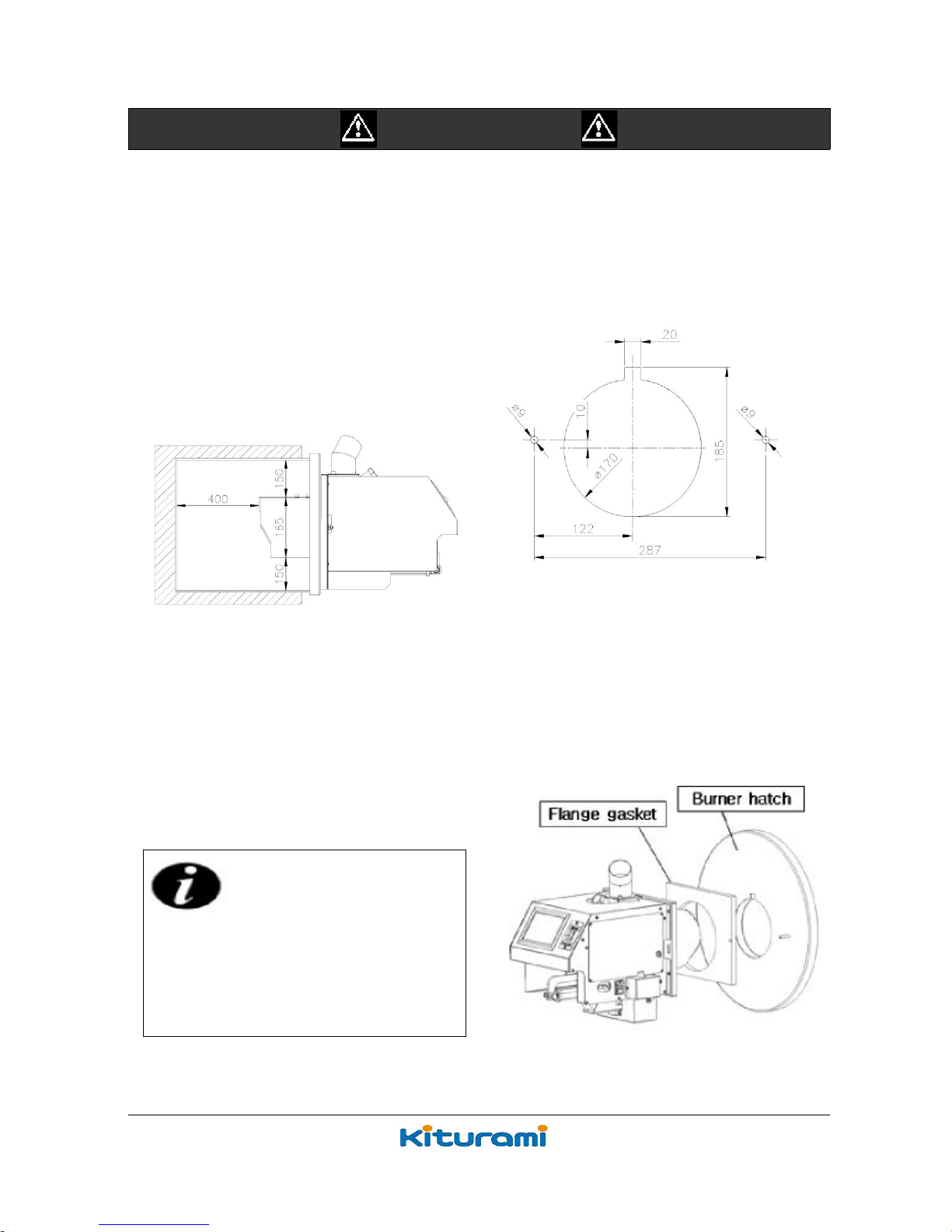

Kiturami KRPB-20A Installation instructions

Popular Burner manuals by other brands

Riello

Riello RLS 160/EV Installation, use and maintenance instructions

Riello

Riello RS 28/M Installation, use and maintenance instructions

True Induction

True Induction TI4B user guide

Riello

Riello RG1RKD Installation, use and maintenance instructions

Weishaupt

Weishaupt WG20 Series manual

Carolina Cooker

Carolina Cooker M116672 owner's guide

AESYS

AESYS TurboFire II Installation, operation and maintenance manual

IKEA

IKEA GRILLSKÄR manual

baltur

baltur TBL 1000 ME Instruction manual for installation, use and maintenance

Riello Burners

Riello Burners P 200 P/G Installation, use and maintenance instructions

WLD-TEC

WLD-TEC powerjet instruction manual

Riello

Riello RDB 3.2 BX 32/50 Installation, use and maintenance instructions