© Krick Modelltechnik, Knittlingen, Germany 3

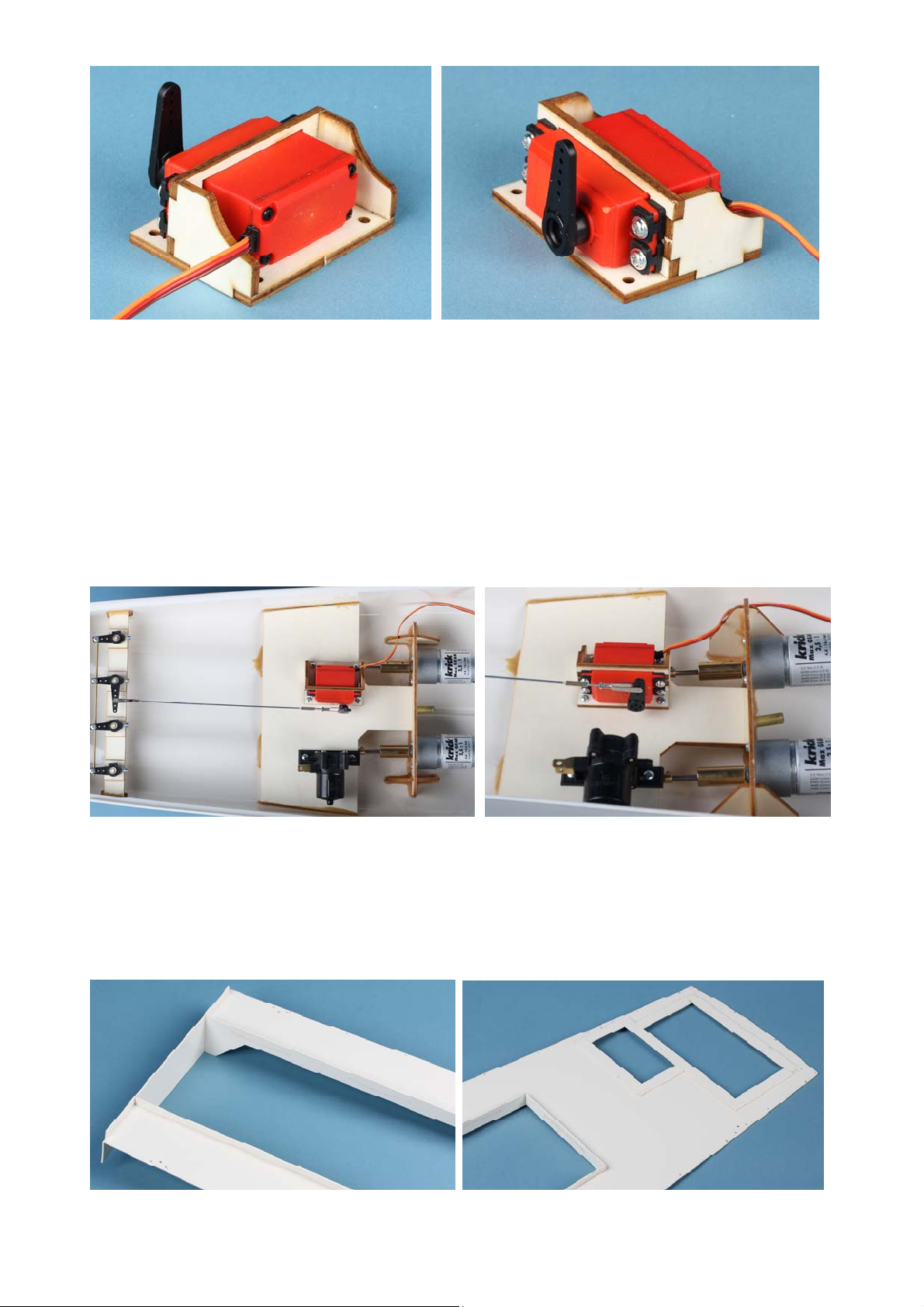

The size and equipment of the romarin fire-fighting boat "Düsseldorf" mounting box is ideally suited for

realising the many possible uses of the original also in the model. The fire monitors, crane, anchor windlass,

radar, headlight, blue light, horn and siren can be designed and installed in a functional way.

The thick-walled ABS fuselage is spacious enough to accommodate large drive batteries, powerful motors

and numerous units for special functions.

The two proven MAX Gear geared motors give the model good speed true to the original. Of course,

brushless direct drives can also be used. Four large rudders guarantee extreme manoeuvrability in forward

and reverse.

The three extinguishing monitors, which are assembled from prefabricated parts, can be swivelled

horizontally and vertically via the remote control. With the recommended electric gear pump you can spray

over a distance of approx. 6 metres.

With the finished sprayed boat crane, the deep-drawn rowing boat can be lifted from the afterdeck, swivelled

outboard and lowered into the water.

In addition to these main functions, it is also possible to carry out numerous other functional parts:

Radar, turn or swivel headlamps, blue light, switch position lamps on and off.

The parts contained in the set of fittings decorate the model perfectly. The special function set contains all

parts required for the special functions shown in the plan, with the exception of the specially offered items,

such as motors, batteries, etc.

Suitable and required tools:

Fretsaw with medium fine and fine blades, fretsaw table, glass paper of various grain sizes, wet sandpaper

fine, sandpaper file, balsa knife, order no. 416002 or 416005, holding clamps, screw clamps, pins, flat nose

pliers, screwdriver, drill, set of drills 1-10mm, set of paint brushes, small hammer, soldering iron with

accessories, side cutter, angle or triangle, one pack of strong rubber rings, approx. 120 x 10 x 1 mm.

Glues:

In the building instructions recommended:

UHU Acrylit or DELUXE Fusion Acrylit or Stabilit Express for wood, ABS, metal

UHU - Hart or Deluxe RC Modeller Power Adhesive for Wood - ABS

DELUXE Roket Rapid - Superglue for ABS - moulded parts.

Similar adhesives can also be used. The processing instructions of the individual adhesive manufacturers

must be observed. The instructions indicate where the individual adhesives are to be used. Allow adhesives

to cure well before starting the next work step.

General information on painting:

We generally recommend the exclusive use of synthetic resin varnish! All ABS parts must be washed with

synthetic resin thinner before painting and then touched as little as possible. All wooden parts, especially

parts that are no longer accessible after assembly, should be thoroughly brushed with pore filler 2-3 times

beforehand. Then slightly sand the adhesive surfaces again.

If you want a perfect and cleanly limited paint finish, you must always paint in sections, i.e. each individual

part that is to have a different colour shade is neatly matched to the model, then painted and then glued to

the model. However, if a part is painted in several colours, the demarcations must be made with special

masking tape, not crepe tape. The tape must be removed when the paint has dried. Do not allow to dry out. If

a lifelike coating is desired, you should use the image of the cardboard for the colouring.

Notes on the building plan and building instructions:

The small letters printed in bold next to the building plan texts are references which refer only to foreign-

language building instructions. Direction indications in the building instructions, e.g. on the right, can be seen

in the direction of travel. In the text, the BOM numbers of the part to be used are enclosed in parentheses.

The abbreviation BS shown in the parts list stands for fitting set, SFS for special function set.

RC system

It is important to find out about the installation options of the planned RC system before construction begins.

If a remote control system other than the one suggested by us is installed, you can follow the installation

scheme. However, small differences in dimensions must be compensated for by yourself.

Make sure that the RC parts such as receivers, servos and speed controllers do not come into contact with

water. It is therefore advisable to arrange these parts high enough in the fuselage. This also applies to the

parts of the special functions.

General information for the construction process:

The numbering of the individual components essentially corresponds to the assembly described in the

instructions. Before starting construction, please read the entire construction manual in conjunction with the