Kleenmaid KCDW6010S Operating manual

Other Kleenmaid Dishwasher manuals

Kleenmaid

Kleenmaid DW1-N User manual

Kleenmaid

Kleenmaid ST GEORGE DW10W Installation guide

Kleenmaid

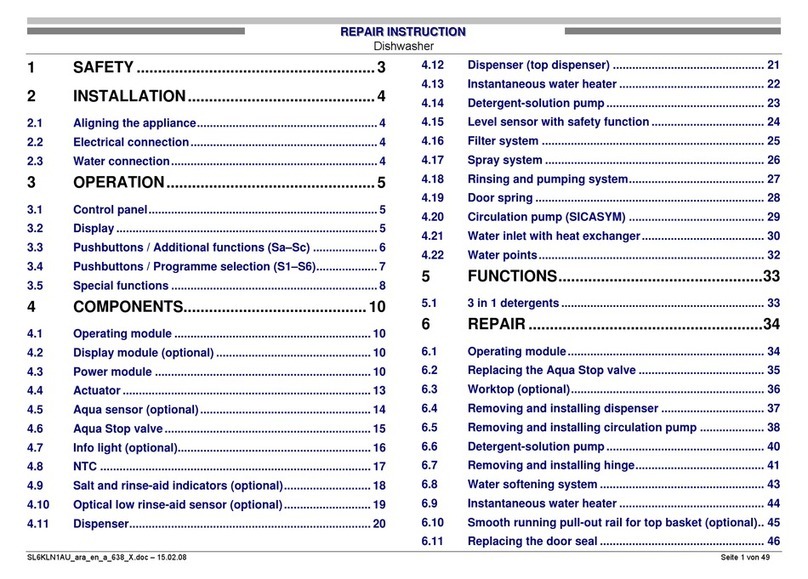

Kleenmaid SL6KLN1AU Setup guide

Kleenmaid

Kleenmaid DW35 X Installation guide

Kleenmaid

Kleenmaid DW7B User manual

Kleenmaid

Kleenmaid DW37 I User manual

Kleenmaid

Kleenmaid DW18I Installation guide

Kleenmaid

Kleenmaid ST GEORGE DW14I User manual

Kleenmaid

Kleenmaid ST GEORGE DW10W Manual

Kleenmaid

Kleenmaid DW6010 User manual

Kleenmaid

Kleenmaid DW27I User manual

Kleenmaid

Kleenmaid DW25 W Installation guide

Kleenmaid

Kleenmaid DW34 X Installation guide

Kleenmaid

Kleenmaid DW36 I Installation guide

Kleenmaid

Kleenmaid DW16I User manual

Kleenmaid

Kleenmaid DW24 X Installation guide

Kleenmaid

Kleenmaid DW6010 Installation guide

Kleenmaid

Kleenmaid DW6020X Installation guide

Kleenmaid

Kleenmaid DW26I User manual

Kleenmaid

Kleenmaid KCDW6012 Installation guide