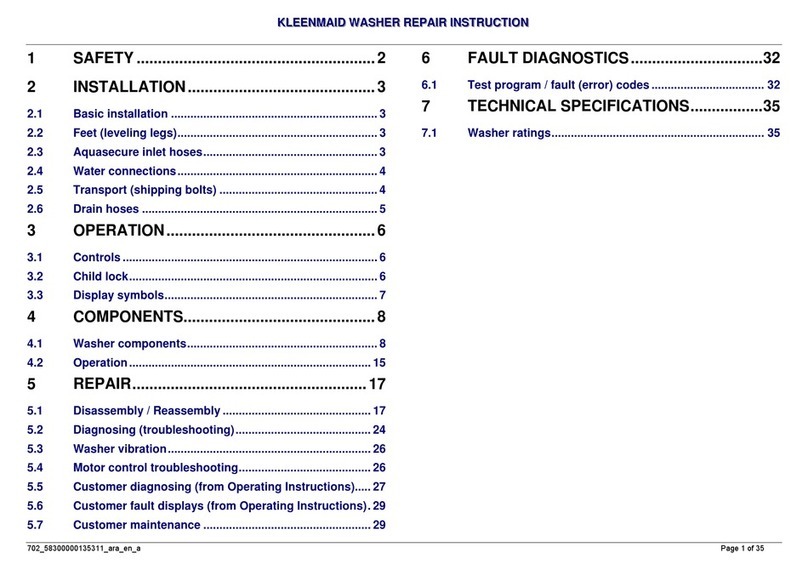

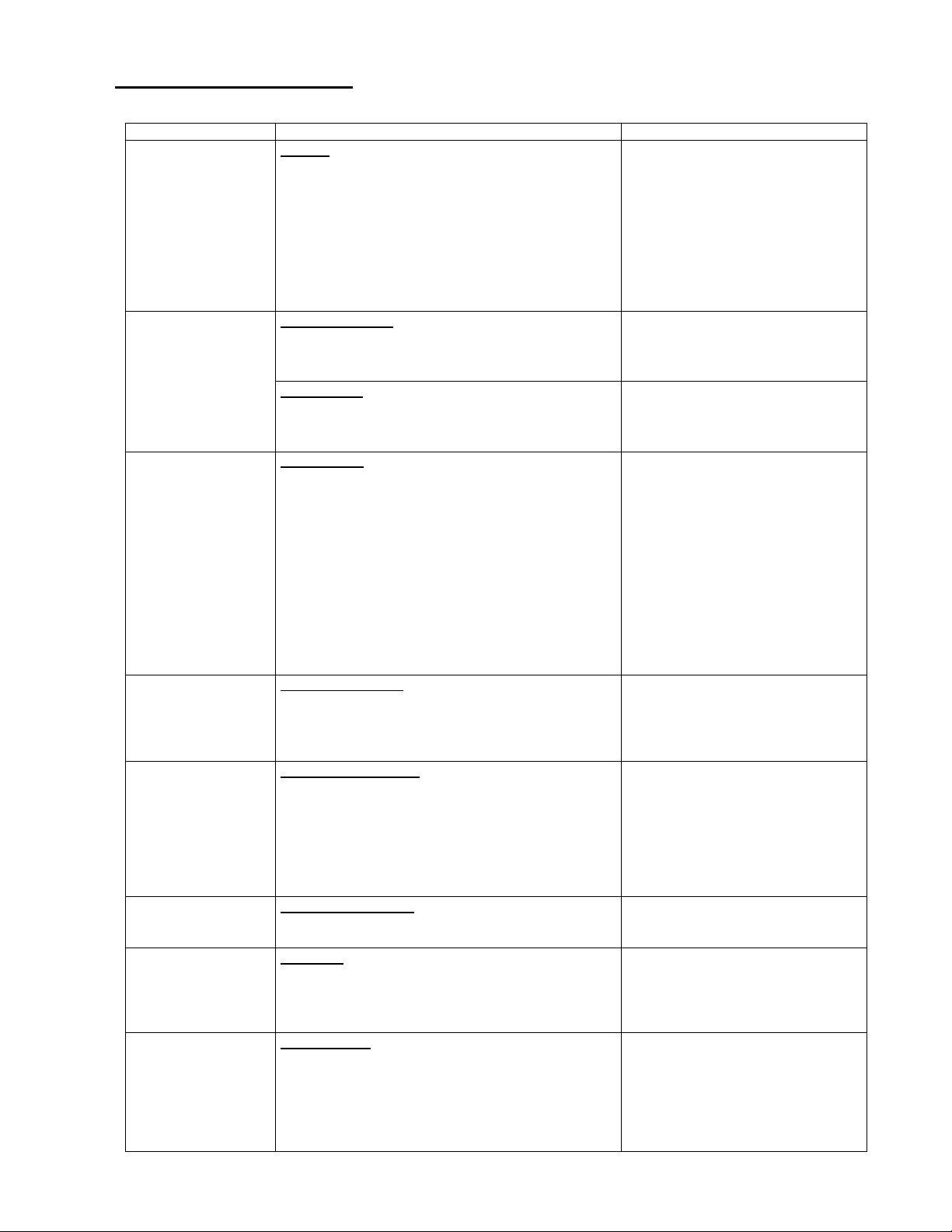

Test program KFL1600

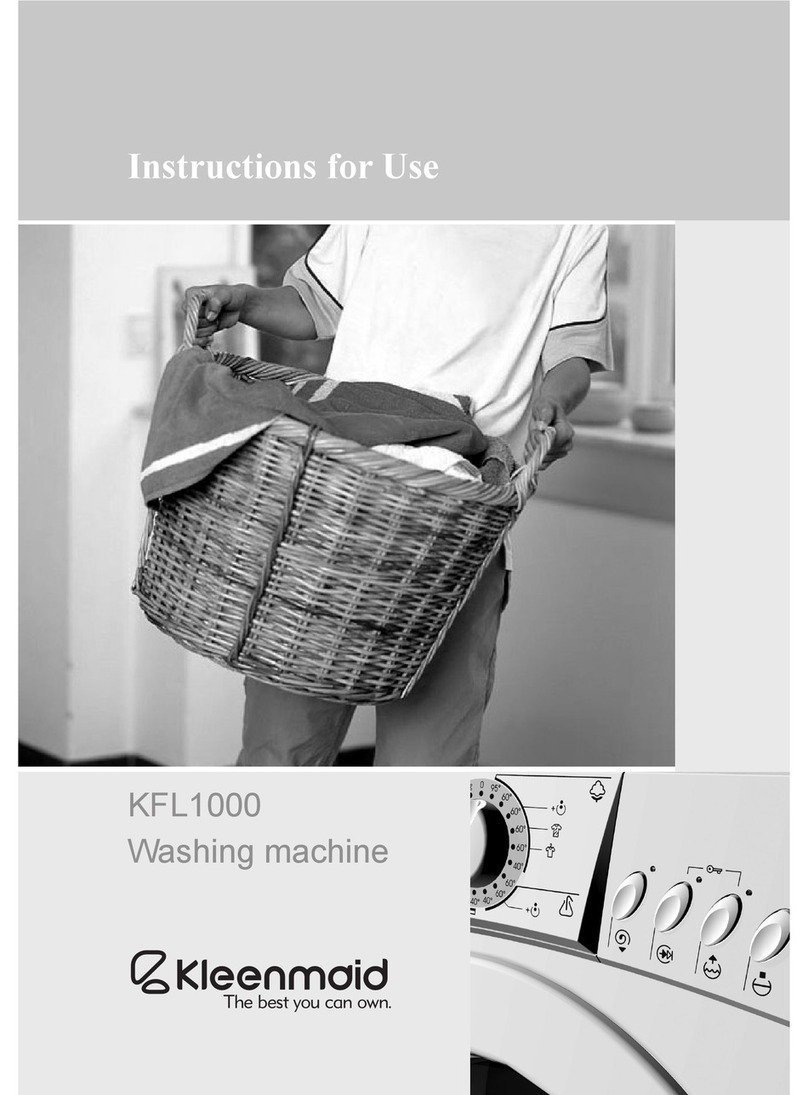

MANUEL ACTION

ACTIVITY INDICATION

Press and hold buttons

START/PAUSE and

EASY IRONING and

turn round the program

knob for 1 step in left

(anti-clock side)

~10”

Self test of micro is executed and test program begins:

- all segments on LCD goes ON for 2 sec.

- after 2’’ on top line write SELF TEST , on bottom line

write max. spin speed for cotton and 99L and all symbols

are ON

- check if is Water clean sensor connect

(read voltage at empty drum)

- check if is pressure sensor (Huba) connect

(read voltage at empty drum)

All step can be 10”.

•If self test O.K, than on top line

write SELF TEST OK (for 2’’)

and all other segments and symbols

switch OFF

•If self test is not O.K., than on top

line write SELF TEST ERROR

(for 2’’) all other segments and

symbols switch OFF, WM stop

Door lock control (text on top line DOOR)

- contact is close at once

•If it is O.K. than on top line write

DOOR OK (for 2’’)

•If it is not O.K. than on top line

write DOOR ERROR, WM stop

~4"

NTC control (text on top line NTC))

check resistance of NTC (can be between 10 to 40°C)

Min. 2 sec.

•If it is O.K. than on top line write

NTC OK (for 2’’)

•If it is not O.K. than on top line

write NTC ERROR

~70”

Water filling (text on top line WATER)

Open the valves Hot Water, Main Wash and Pre Wash.

Water goes in 3 different space in dispenser.

- HW : 5 ’’ (space 2), if it is connected to hot/cold water

- PW : 5’’ (space 1)

- MW : 5’’ (space 2)

- PW + MW : to reach level 1 (space 1,2 and 3)

- pause 2’’

- MW : to level 110 mm H2O

Max. time for all is 70 sec.

•If it is O.K. (reach level on

pressure-switch) than on top line

write WATER OK (for 2’’)

•If it is not O.K. (not reach level on

pressure-switch) than on top line

write WATER ERROR (for 2’’)

•If it is reach level (110 mm H2O ),

than on top line write WATER

FILL OK

•If not reach level (110 mm H2O )

in 70’’, than on top line write

WATER FILL ERROR, WM stop

~12"

Water clean sensor (text on top line WATER SENSOR)

Only check if it is connected (check voltage at water in

drum together 10”)

•If it is connected than on top line

write WATER SENSOR YES (for

2’’)

•If it is not connected than on top

line write WATER SENSOR NO

~77"

Washing and heating (text on top line WASHING)

- Washing: 15’’ON / 5’’OFF / 15’’ON / 5’’OFF

- 3 times repeats washing

- last wash in spin direction

- Heater ON all time of washing

- JET pump ON all time of washing

All together is 75’’. After this time switch OFF heater

and JET pump ; washing goes to spinning.

•If it is O.K. – washing in both

direction, than on top line write

WASHING OK (for 2’’)

•If it is not O.K. than on top line

write WASHING ERROR, WM

stop

Spinning with water (text on top line SPIN)

- 30’’ spin from 50rpm to max.500

- wait to drum stop

Draining (text on top line DRAIN)

- switch pump ON for 40 ‘’

Check if water level fall under level 1

•If it is O.K. than on top line write

DRAIN OK (for 2’’)

•If it is not O.K. than on top line

write DRAIN ERROR, WM stop

~62"

End spinning (text on top line SPIN SPEED)

- pump stay ON

- 10’’ spin from 0 rpm to max. rpm

(if necessary switch ON tape field)

- 50’’ on max. spin speed

- wait to drum stop

- switch OFF all component

•If it is O.K. than on top line write

SPIN SPEED OK (for 2’’)

•If it is not O.K. than on top line

write SPIN SPEED ERROR, WM

stop