5

10.01.2019 acid-proof extraction arms ERGO-MINI

7. Operational Use

Construction of the device assures reliable function without continuous routine technical su-

pervision. In each of the arm joints is introduced a friction ring to keep the required operatio-

nal position during the work. Tightening the knurled nuts increases the friction moment, whe-

reas, their releasing reduces the friction. Adjustment of the frictional brakes (in subsequent

joints) provide self-supporting properties and position balance of the device during the func-

tion. On the other hand, the brakes should not be tightened to strong, as this would cause

excessive friction / resistance while the operator changes the arm position.

During the work the position of the arm and the suction hood can be changed many times, to

obtain to best arm configuration, according to the User’s current needs.

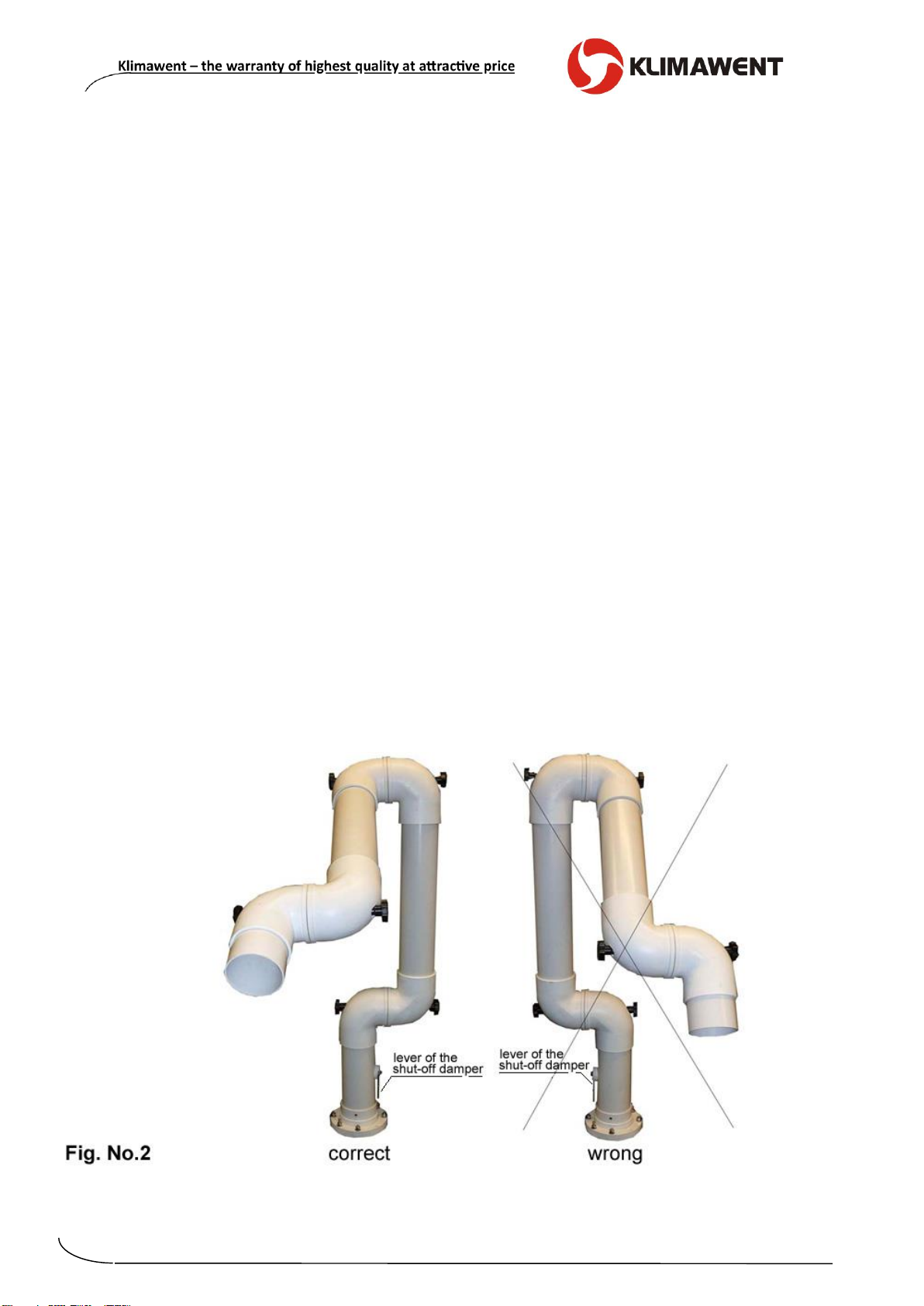

After the work is completed, switch off the extraction fan or, if the device works with a statio-

nary extraction system, close the shut-off damper on the suction hood.

8. Troubleshooting Guide

the extraction arm is falling

incorrectly adjusted joints

increase the tension onto the

friction ring by tightening the

the shut-off damper is closed

in the extraction arm a barrier

remove the barrier object /

object got stack in the extrac-

9. Maintenance

The construction of the device provides longevity and reliable function without the constant

routine technical supervision. During the maintenance check the points of mechanical faste-

ning, the joints and the swivel bearing. Systematically, remove the impurities from the suction

hood / suction pipe.

After one year of operational use, carry out technical revision, replace or repair the faulty ele-

ments, in case when this has been noticed during the technical check.

Servicing is carried out by KLIMAWENT S.A. 81–571 Gdynia, ul. Chwaszczyńska 194 tel. 58

629 64 80.

10. Occupational Health and Safety

ERGO-MINI extraction arms will not cause any hazard under the condition that they are firmly

and correctly installed. Operational use of the arm is easy and safe for the operators. During

the use observe strictly the regulations of the Occupational Health and Safety.

Manufacturer is not responsible for defects / malfunctions resulting from the device application

that is in contradiction with its purpose of use, or when changes have been introduced by user

on one’s own.

11. Transport and Storage

The devices ought to be stored in dry room and in areas of efficient ventilation. During the tran-

sport / reloading protect the device from mechanical damage, scratching, indents, package da-

mage and pay attention that the surface markings do not get detached / obliterated.