KMW KIM 108 Series User manual

Operating Manual

Refrigerated display cabinet

Borkum

Commercial refrigerated cabinet

2

defrost running cooling is running fans are running

glass panes outside

oor display

bafe plate inside

decorative panel

load limit line

impact protection

light switch LED (optional)

air intake grille

thermostat controller

button forward back

program keys

display icons

temperature display

substructure

adjustable feet with thread M10

sliding glass lid

temperature display, weighted air inlet and air outlet temperature

3

4

Contents

General 5

Read and keep the operating instructions 5

Explanation of symbols 5

Intended Use 6

Safety 7

Danger of explosion 8

Risk of ignition and explosion 8

Electric shock hazard 8

Safety instruction for the authorized spezialist 9

Risk of health consequences 10

Risk of injury 10

Malfunctions caused by electromagnetic interference 10

Lineup 11

Installation 12

Electric shock warning 12

Electric circuit protection 12

Electric circuit breaker 12

Connect and disconnect the refrigerated island from the power supply 12

Cleaning 13

Do not clean with: 13

Defrosting 13

Defrosting of devices without bus connection 13

Defrosting of devices with bus connection 13

Maintenance 14

Risk of injury 14

Risk of short circuit 14

Decommissioning, transport and storage 15

Productdetails and funcionality 15

Climate class 15

Cooling unit 15

Housing and cooling storage 15

Temperature controller / Refrigeration controller 16

Troubleshooting and service 17

Contact address 17

Technical specications 17

Disposal 18

Dispose of packaging 18

Dispose of the cooling island 18

Energy label Climate Class III (25°C;60%r.F.) 18

Declaration of Conformity 19

Imprint 20

General

Read and keep the operating instruc-

tions

This operating instructions

belong to the Borkum

model series (hereinafter

referred to as “refrigerated

island”). It contains import-

ant information on com-

missioning and handling.

Read the operating instructions carefully,

especially the safety instructions, before

using the refrigerated island. Failure to

follow these operating instructions can

result in serious injury or damage to the

refrigerated island.

The operating instructions are based on

the standards and regulations valid in

the European Union. Also observe coun-

try-specic guidelines and laws abroad.

Keep these operating instructions for

further use. If you pass the refrigerated

island on to third parties, be sure to inclu-

de these operating instructions.

5

Explanation of symbols

The following symbols and signal words

are used in this manual, on the refrigera-

ted island or on the packaging:

This signal symbol/word indicates a ha-

zard with a high level of risk which, if not

avoided, will result in death or serious

injury.

This signal symbol/word indicates a ha-

zard with a medium level of risk which, if

not avoided, will result in death or serious

injury.

This signal symbol/word indicates a

hazard with a low level of risk which, if

not avoided, will result in minor or mo-

derate injury.

This signal word warns of possible dama-

ge of property.

6

This symbol gives you useful

additional information on

installation or operation.

Products marked with this

symbol comply with all

applicable Community

regulations of the Euro-

pean economic area (see chapter

„Declaration of Conformity“).

Warning of ammable

substances

Warning of

electrical voltage

Warning of hot surfa-

ces

Warning of explosive

substances

Entering the area pro-

hibited

Read the manual

Intended use

The refrigerated island is a commercial

refrigeration furniture. It is designed as

sales furniture for packaged food in the

temperature class M1 and MS in the

self-service area. This refrigerated island

is not suitable for use on board ships or

aircraft.

It must be ensured at all times that the

set and reached temperature within the

refrigerated island corresponds to the

respective storage temperature for the

food in question.

7

Safety

The refrigerated island is glazed all

around and is delivered fully assembled

(ready to plug in). Apart from the correct

alignment at the installation site, no nal

assembly by the user is required.

The person responsible on site

(e.g. the store manager in the

case of installation in a super-

market) must ensure that the

operators of the refrigerated

island at the installation site are instruc-

ted in the correct use of the operating

instructions and are familiar with it.

The refrigerated island meets all the

requirements of EU Directive 2011/65EU

(RoHS2) on the avoidance of hazardous

substances in electrical and electronic

equipment and EU Directive 1907/2006

(REACH) on the registration, evaluation

and approval of chemicals. The cooling

system installed in the refrigerated island

works with the refrigerant R290 (propane)

and the insulating foam polystyrene.

• The global warming potential (GWP)

corresponds to the value 3 and the

ozone depletion potential (ODP) to

the value 0.

Technical data and lling

quantities can be found on

the type plate of the refrige-

rated island, as well as on the

product data sheet, which

you can obtain from KMW customer

service.

Only use the cooling island as described

in this user manual. Any other use is con-

sidered improper and can lead to pro-

perty damage or even personal injury.

The refrigerated island is not a child‘s toy.

The manufacturer assumes no liability for

any injury, loss or damage resulting from

improper or incorrect use. Possible exam-

ples of improper or incorrect use are:

• Use of the refrigerated island for pur-

poses other than those for which it is

intended

• Non-observance of the safety inst-

ructions and warnings, as well as the

assembly, operation, maintenance

and cleaning instructions contained

in this operating manual

• Non-observance of any accident

prevention regulations specic to the

use of the refrigerated island and/or

generally applicable

• Use of accessories and spare parts

that are not intended for the cooling

island

• Changes to the cooling island

• Repair of the refrigerated island by

someone other than the manufactu-

rer or a specialist

• Operation or maintenance of the

refrigerated island by persons who

are unfamiliar with the handling of

the refrigerated island and/or do not

understand the hazards involved.

8

Danger of explosion

There is a risk of explosion if

the refrigerated island is

used or handled improper-

ly.

Do not store any explosive

substances such as aerosol containers

with ammable propellants in the refrige-

rated island.

Risk of ignition and explosion

The refrigerated island is

operating with the refrige-

rant R290 (propane). Ac-

cording to the DIN EN

378-1 standard, this is assig-

ned to the refrigerant group A3 (amma-

ble and explosive). If the refrigeration

island is handled improperly, there is a

risk that an inammable gas-air mixture

will form and be unintentionally ignited.

Never close the ventilation openings.

To speed up the defrosting process

do not use any mechanical devices or

other utilities than those recommended

by the manufacturer.

Never damage the refrigerant circuit.

Do not operate with any electrical

equipment inside the refrigerator that is

not of the type recommended by the

manufacturer.

Electrical shock hazard

Faulty electrical installation

or excessive mains voltage

can lead to electric shock

Safety instructions for the user

• Only connect the refrigerated island if

the main voltage and main frequen-

cy of the socket correspond to the

information on the type plate

• Only connect the refrigerated island

to an easily accessible socket so that

you can quickly disconnect the refri-

gerated island from the mains in the

event of a fault

• Do not operate the cooling island if it

is visibly damaged or if the mains con-

nection cable or mains plug is defect.

• If the mains connection cable of the

refrigerated island is damaged, it

must be replaced by the manufactu-

rer or its customer service or a similarly

qualied person in order to avoid

hazards.

• Do not open the housing, leave re-

pairs to authorized specialists. To do

this, contact KMW customer service.

Liability and guarantee claims are ex-

cluded in case of repairs carried out

independently, improper connection

or incorrect operation.

• Do not touch the power plug of the

refrigerated island with wet hands.

• Never pull the mains plug of the ref-

rigerated island out of the socket by

the mains connection cable, always

hold the mains plug.

• Keep the refrigerated island, the

mains plug and the mains connection

cable away from open ames and

hot surfaces.

• Lay the mains connection cable in

such a way that it does not become

a tripping hazard.

• Do not kink the power cord and do

not lay it over sharp edges.

• Only use the refrigerated island in dry

indoor areas.

• Disconnect the refrigerated island

9

from the power supply by unplugging

the power cord from the outlet when

cleaning the refrigerated island or

when servicing the refrigerated is-

land. During the entire cleaning and

maintenance process, it must be

ensured that the refrigerated island is

disconnected from the power supply.

The operator must be able to check

whether the mains plug is outside the

socket during the entire cleaning or

maintenance process.

• If you discover or suspect malfuncti-

ons or damage to the temperature

controller that endanger safe opera-

tion, take the refrigerated island out

of operation immediately.

• Only allow repair and maintenance

work or adjustments at the tempe-

rature controller only by authorized

specialists. To do this, contact KMW

customer service.

Safety instruction for the authorized spe-

zialist

Only parts that correspond to the original

device data may be used for repairs.

• This refrigerated island contains elec-

trical and mechanical parts that are

essential to protect against sources of

danger.

• Do not operate the refrigerated island

with an external timer or a separate

telecontrol system.

• Incorrect installation of the tempera-

ture controller installed in the refrige-

rated island can lead to an electric

shock. The temperature controller is

installed and adjusted at the factory.

• Do not manipulate or change the

temperature controller and never

open the housing.

• Make sure that the entire system is

switched off when the temperature

controller is mounted, wired or dis-

mantled.

• Please note that main voltage and/

or external voltage may be present

when the control voltage is switched

off.

• Use suitable professional tools for all

work.

• Check all wiring after the temperatu-

re controller installation is complete.

• Observe the information on the ma-

ximum load for all connections (see

chapter „Technical Data“ for the

temperature controller).

• Keep any liquids (e.g. condensed wa-

ter, cleaning agents, etc.) away from

the temperature controller.

10

Risk of health consequences

If the refrigerated island is handled im-

properly or if there is a lack of control,

there is a risk that the food stored in the

refrigerated island will be adversely

affected and possibly spoil.

If the cooling island is unexpectedly di-

sconnected from the power supply, e.g.

in the event of a power failure, the per-

son responsible on site must ensure that

the stored food is checked. Compliance

with the prescribed storage temperature

must be ensured.

Clean up spilled liquids in the goods area

immediately.

Risk of injury

There is a risk of injury if used improperly.

Check at regular intervals whether there

are foreign objects in the goods space

and remove them.

If defrost water leaks out of the refrigera-

ted island, wipe it up immediately; other-

wise there is a signicant risk of people

slipping and injuring themselves.

When cleaning the refrigerated island,

always use suitable protective gloves to

protect against injuries from sharp de-

vice edges.

The market operator undertakes to re-

pair minor damage to the refrigerated

island that does not impair any technical

functions (e.g. dents in the housing cau-

sed by shopping trolleys).

If there is damage to the refrigeration

system or the electrics, the KMW custo-

mer service must be informed immedia-

tely. Otherwise there is a considerable

risk of injury.

In the event of improper handling or use,

there is a risk of damaging the refrigera-

ted island and causing property dama-

ge.

Always ensure that the refrigerated is-

land is level on all sides and stands secu-

rely on all four feet when operating it.

Observe the installation instructions in

these operating instructions.

Never expose the refrigerated island to

direct sunlight and keep the refrigerated

island away from heat sources.

Always note that the refrigerated island

must not heat up above the following

temperatures: +50°C (during operation)

and +70°C (during transport and sto-

rage).

Malfunctions caused by electromagne-

tic interference

Improper installation of the temperature

controller or improper connection to the

Wurm system can result in malfunctions.

Only use shielded data lines for installa-

tion and connection.

When installing the data lines, keep a

large distance to load lines.

Table of contents

Popular Display Case manuals by other brands

Delfield

Delfield F15SC48D Specification sheet

Nuttall

Nuttall Flexeserve Hub 600 Operation manual

Hussmann

Hussmann GSVM 4060D Installation & operation manual

Polar Refrigeration

Polar Refrigeration CP728 instruction manual

Costan

Costan WHALE 2000 G LG300 User instructions

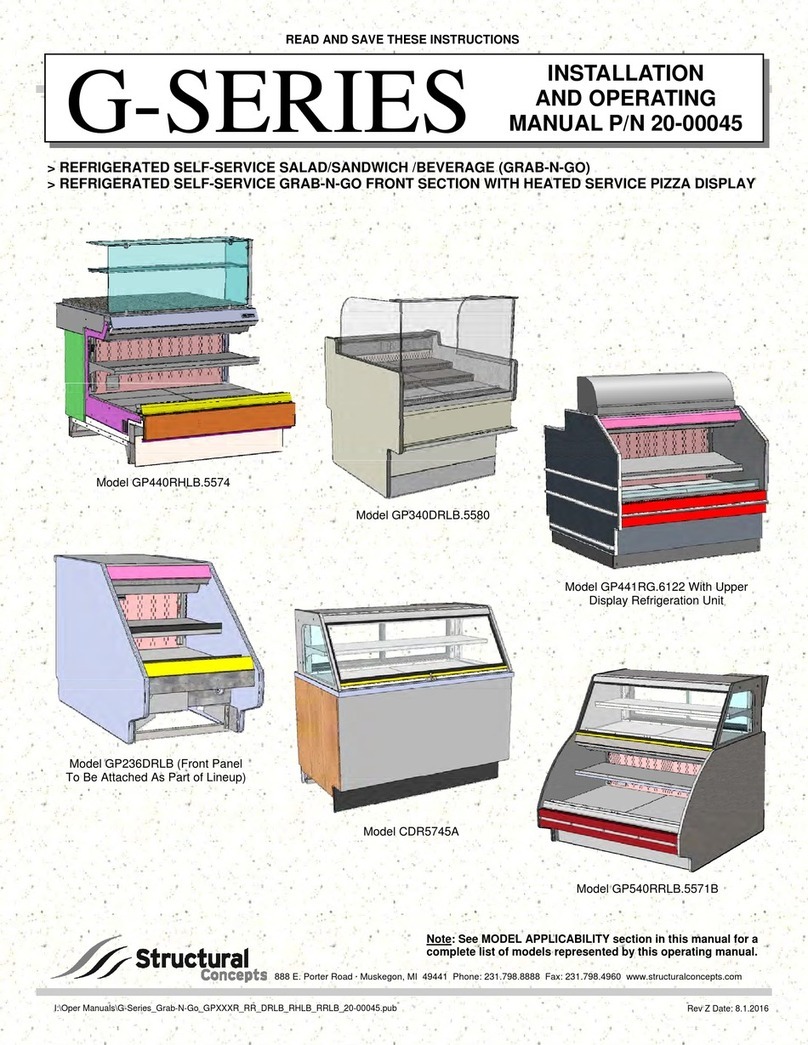

Structural Concepts

Structural Concepts GP441RG.6122 Installation and operating manual