Handling Recirculating Cooler C 900

6 Translation of original Operating Instructions, nglish, KNF 301425-301429 03/14

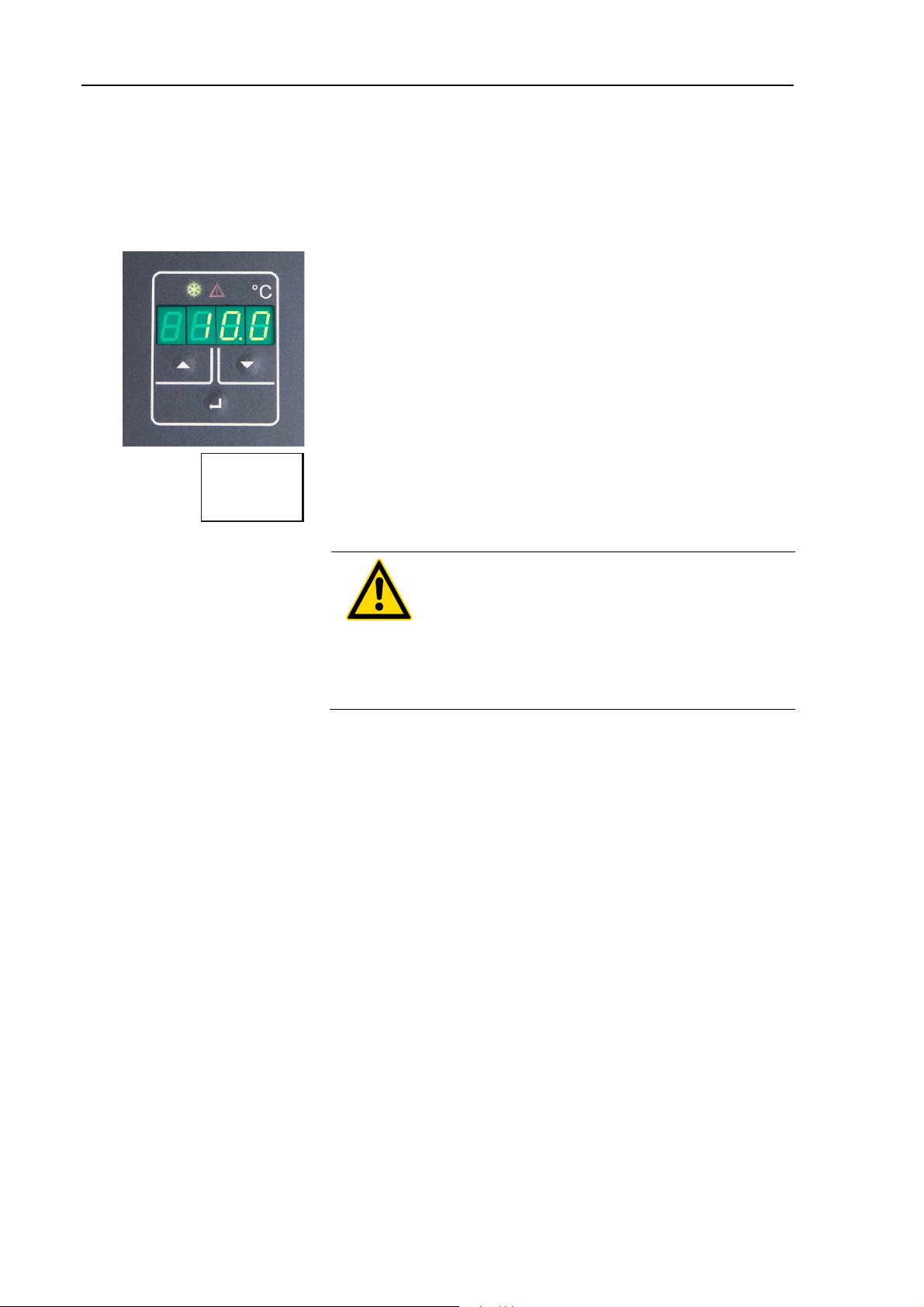

4. Handling

Avoid strikes to the housing, vibrations, damage to the keypad

(keys, display), and heavy contamination.

Make sure the product is regularly checked for proper condition

(depending on the conditions of use).

Regularly check (at least every 2 years) the condition of the

mandatory, warning, prohibition and safety labels.

Make sure that the mains power supply has low impedance to

avoid any negative effects on instruments being operated on

the same mains.

This unit is designed for operation in a controlled electromag-

netic environment. Accordingly, transmitting devices such as

mobile telephones shall not be used in the immediate vicinity.

Other devices with magnetically sensitive components, such as

a monitor, may be influenced by magnetic radiation. We rec-

ommend maintaining a minimum distance of 1 m.

Permissible ambient temperature: max. 40 °C, min. 5 °C.

Permissible relative humidity: 50% (40 °C).

Do not store the unit in an aggressive atmosphere. Protect the

unit from contamination.

Do not expose the unit to sunlight.

4.1. Appropriate operation

Only qualified personnel are authorized to perform configuration,

installation, maintenance and repairs of the recirculating cooler.

The operator of the cooler must be trained by technical personnel.

4.2. Use

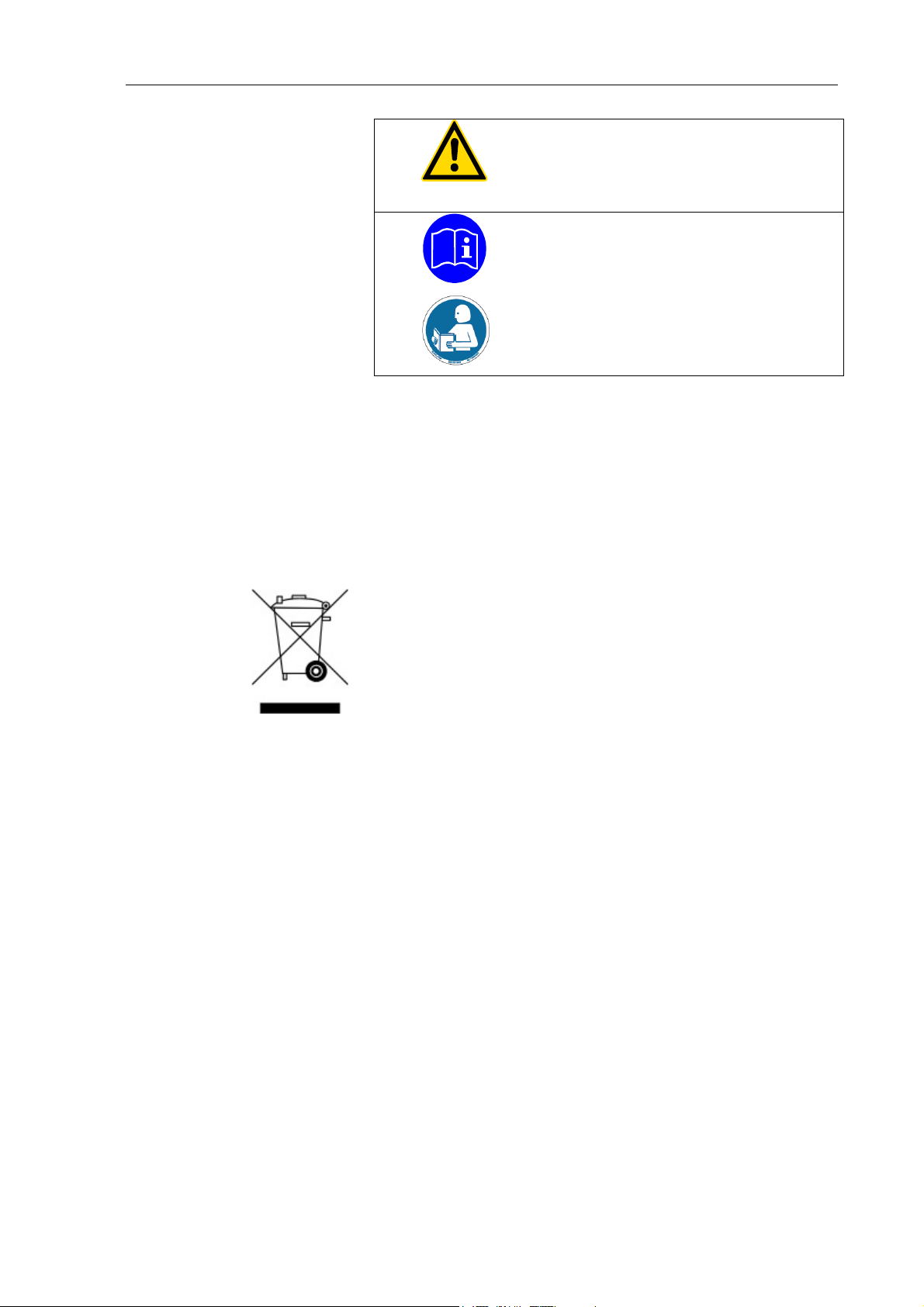

DANGER

Ignition of potentially explosive mixtures

The unit is not for use in a potentially explosive

atmosphere.

Special materials specifications (heat transfer liquids) must be

observed in order to comply with the intended use. Neither corro-

sive nor corrosive-acting heat transfer liquids may be used. Ob-

serve all warnings for the used materials (heat transfer liquids) and

the respective instructions (safety data sheets).

Provide for adequate ventilation at the place of installation (see

Page 14).

When using hazardous materials or materials that could become

hazardous, the operator must affix the enclosed safety labels (1 +

2) to the front of the unit so they are highly visible: