Contents

1 About this document ............................................................................. 3

1.1 Using the operating and installation instructions........................... 3

1.2 Exclusion of liability....................................................................... 3

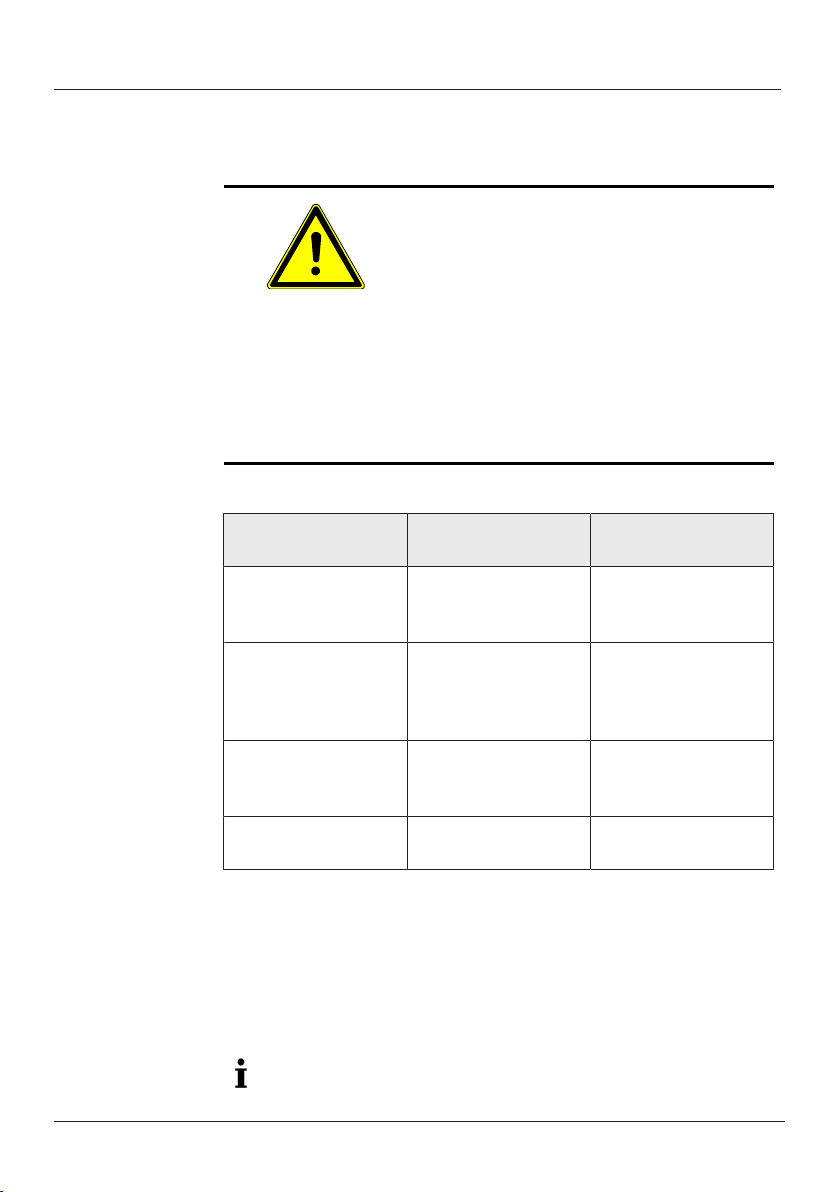

1.3 Symbols and markings.................................................................. 4

2 Safety .................................................................................................... 6

2.1 Personnel and target group .......................................................... 6

2.2 Responsibility of the operator ....................................................... 7

2.3 Working in a safety conscious manner ......................................... 7

2.4 Operating conditions ..................................................................... 8

2.5 Media ............................................................................................ 8

2.6 Use................................................................................................ 9

2.7 Directives and standards ............................................................ 10

2.8 Customer service and repair....................................................... 11

2.9 Disposal ...................................................................................... 11

3 Technical data..................................................................................... 12

3.1 Technical data............................................................................. 12

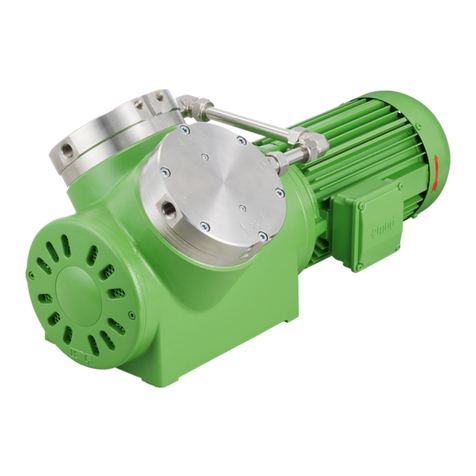

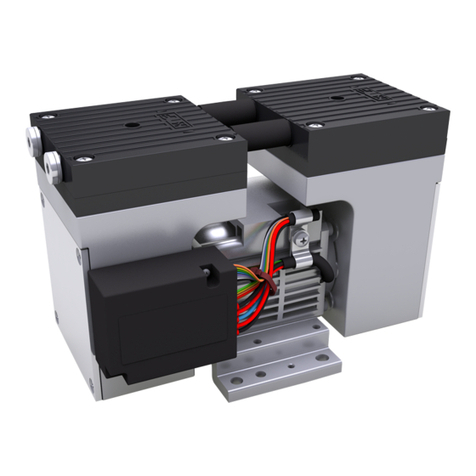

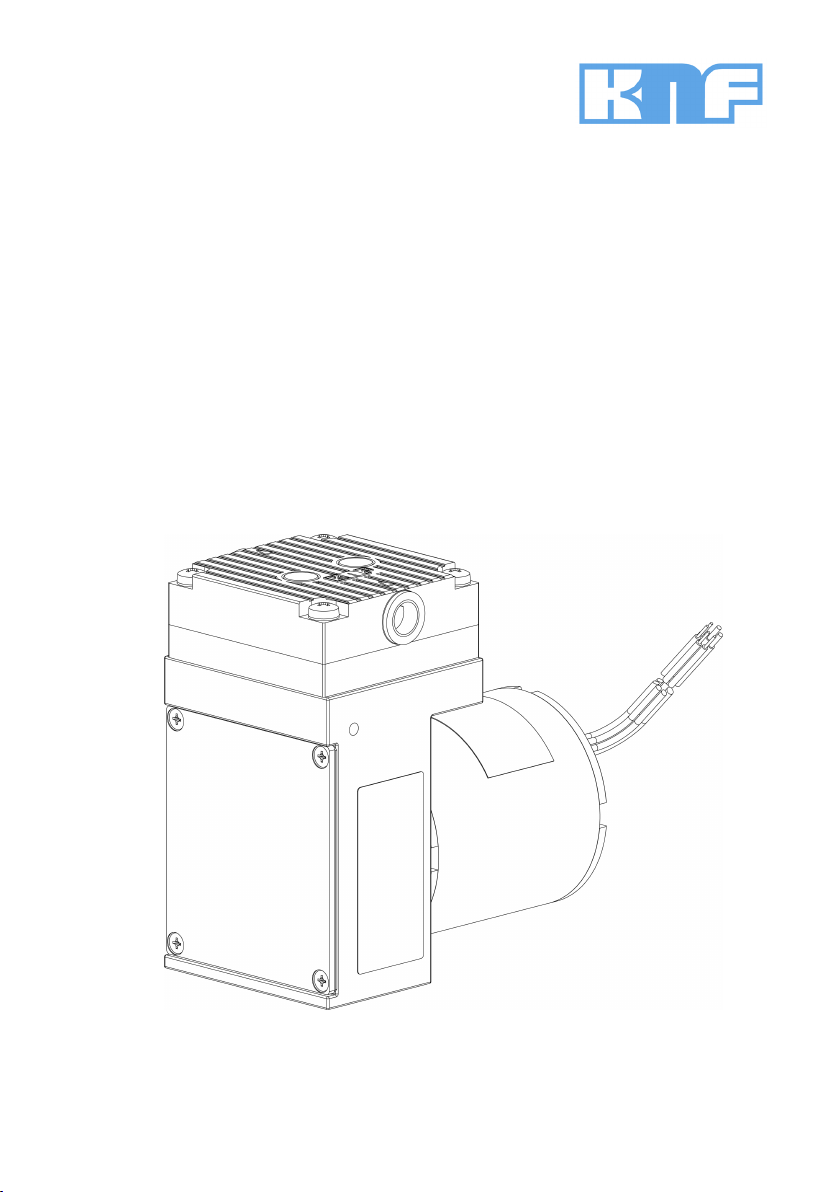

4 Product description ............................................................................. 15

5 Transport............................................................................................. 17

General ....................................................................................... 17

6 Installation and connection.................................................................. 19

6.1 Installing the pump...................................................................... 19

6.2 Electrical connection ................................................................... 22

6.3 Pneumatic connection................................................................. 26

7 Operation ............................................................................................ 28

7.1 General ....................................................................................... 28

7.2 Information on switching the pump on and off ............................ 31

7.3 Control functions DC-B-M ........................................................... 31

8 Servicing ............................................................................................. 33

8.1 Servicing schedule...................................................................... 34

8.2 Cleaning...................................................................................... 34

8.3 Replacing diaphragm and valve plates/sealing rings.................. 36

9 Spare parts and accessories............................................................... 42

9.1 Spare parts ................................................................................. 42

10 Troubleshooting .................................................................................. 43

11 Returns................................................................................................ 47