KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd

Rev A MNL-KP12X-H-TH 2 of 46

TABLE OF CONTENTS

1Introduction ............................................................................................................3

1.1 Contact..................................................................................................................... 3

1.2 Safety....................................................................................................................... 3

2Product Description .................................................................................................5

2.1 Overview.................................................................................................................. 5

2.2 Model Code Key....................................................................................................... 6

2.3 Technical Data.......................................................................................................... 6

2.4 Parts......................................................................................................................... 7

3Installation and Location Selection...........................................................................8

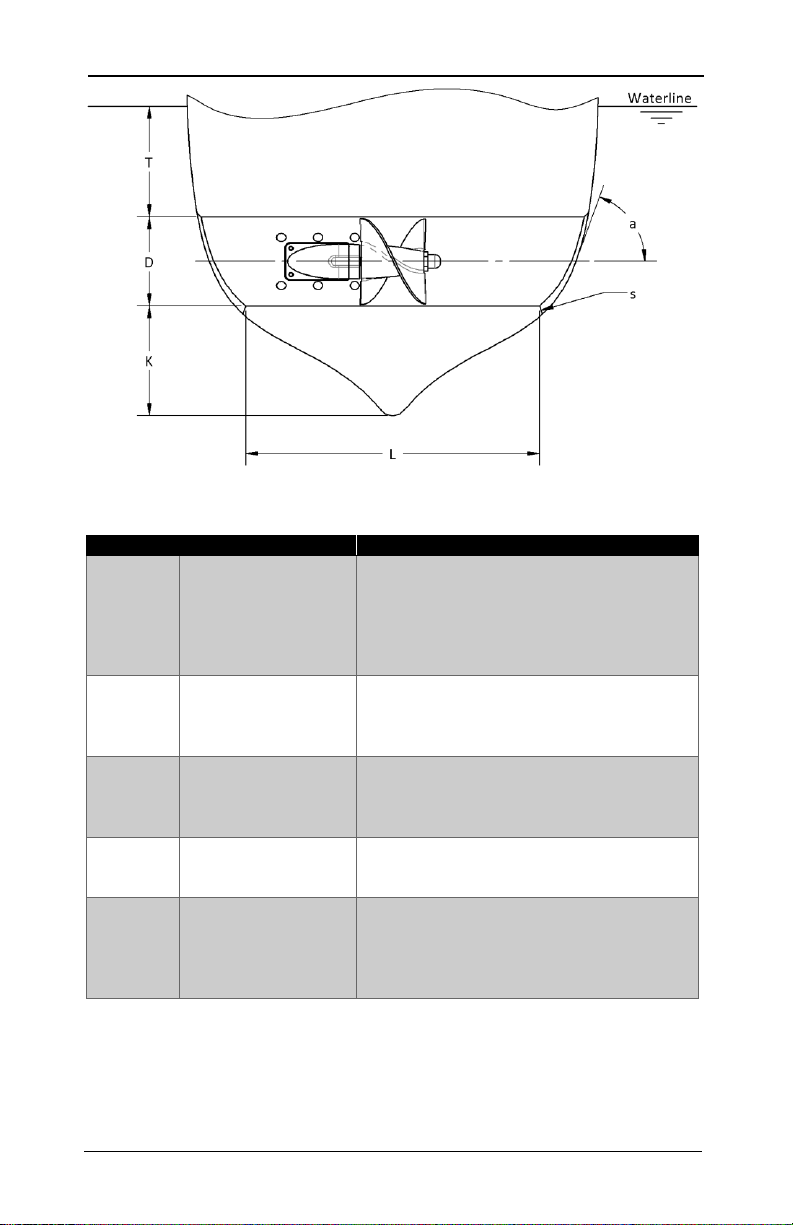

3.1 Tunnel Thruster Location Selection and Installation................................................ 8

3.2 Transom Mounted Thruster Location and Installation........................................... 15

3.3 Lubricating Oil System............................................................................................ 19

4Maintenance and Service....................................................................................... 20

4.1 Preventative Maintenance..................................................................................... 20

4.2 Recommended Spare Parts.................................................................................... 20

4.3 Propeller Installation and Removal........................................................................ 21

4.4 Transom Mount Thruster Tube Removal and Installation...................................... 22

4.5 Setting Coupling Distance ...................................................................................... 24

4.6 Bearing Cap Removal & Oil Drain........................................................................... 24

4.7 Oil Changes ............................................................................................................ 25

4.8 Shaft Seal Replacement ......................................................................................... 26

5Hydraulics.............................................................................................................. 27

5.1 System Requirements ............................................................................................ 27

5.2 Installation ............................................................................................................. 27

6Parts Lists .............................................................................................................. 29

6.1 KP12 Tunnel Thrusters ........................................................................................... 29

6.2 KP14 Tunnel Thrusters ........................................................................................... 31

6.3 KP12 Bolt-On Thrusters.......................................................................................... 33

6.4 Leg Subassembly.................................................................................................... 35

6.5 Shaft Subassembly................................................................................................. 37

6.6 Accessories............................................................................................................. 38

6.7 Parts Lists Notes..................................................................................................... 39

7Technical Drawings................................................................................................ 41

7.1 Tunnel Thrusters.................................................................................................... 41

7.2 Transom-Mounted Hydraulic Thrusters................................................................. 43

8Warranty............................................................................................................... 44